- DL manuals

- Baroness

- Lawn Mower

- GM2800B

- Owner's Operating Manual

Baroness GM2800B Owner's Operating Manual

Summary of GM2800B

Page 1

Riding quintuple rotary mower owner's operating manual "required reading" read this manual and the owner's manual for the engine before using the machine. Serial no.10001~ original instructions ver.1.0

Page 2

Thank you for purchasing the baroness machine. This manual explains proper handling, adjustment, and inspection of your machine. Prior to use, carefully read this manual to thoroughly understand the contents for safe and correct operation. This machine has been shipped from the factory after compreh...

Page 3

Read this manual carefully to ensure that you thoroughly understand how to properly operate and maintain this machine, and to avoid causing injury to yourself or others. The operator is responsible for operating the machine properly and safely. Do not perform maintenance on the machine other than th...

Page 4

Purpose this machine is intended for cutting grass at golf courses. Do not use this machine in any way other than its intended purpose, and do not modify the machine. Operating this machine for other purposes and modifying it may be very dangerous and may cause damage to the machine. In addition, th...

Page 5

Safety............................................................... Page 1-1 safe operating practices............................................. Page 1-2 disposal........................................................... Page 2-1 waste disposal............................................... Pag...

Page 6

Gm2800b contents.

Page 7

Safe operating practices....................... Page 1-2 training...................................................Page 1-2 preparation............................................. Page 1-2 operation................................................ Page 1-3 maintenance and storage......................

Page 8

Failure to adequately follow these safety precautions may cause an accident resulting in injury or death. Danger danger this machine is designed to ensure safe operation and has been tested and inspected thoroughly before shipment from the factory. The machine is equipped with safety devices to prev...

Page 9

Replace all fuel tanks and container caps securely. Check that operator's presence controls, safety switches and shields are attached and functioning properly. Do not operate unless they are functioning properly. If the brake operation is faulty or the parking brake lever has noticeable play, be sur...

Page 10

Slow down and use caution when making turns and crossing roads and sidewalks. Stop the blades rotating before crossing surfaces other than grass. Disengage drive to attachments when transporting or not in use. When using any attachments, never direct discharge of material toward bystanders nor allow...

Page 11

Make sure that parts such as wires are not touching each other and that their covers have not come off. Use care when checking the blades. Wrap the blades or wear gloves, and use caution when servicing them. Only replace blades. Never straighten or weld them. On multi-bladed machines, take care as r...

Page 12

Gm2800b safety page 1-6 safe operating practices.

Page 13

Waste disposal........................................Page 2-2 about the waste disposal.....................................Page 2-2 disposal gm2800b disposal page 2-1.

Page 14

Waste disposal about the waste disposal make sure that waste generated when servicing or repairing the machine is disposed of in accordance with local regulations. (e.G. Waste oil, antifreeze batteries, rubber products, and wires etc.) gm2800b disposal page 2-2 waste disposal.

Page 15

Specifications......................................... Page 3-2 specifications..........................................Page 3-2 sound pressure level.................................. Page 3-2 sound power level.................................. Page 3-2 vibration level.................................

Page 16

Specifications specifications model gm2800b dimensions total length 370 cm total width during operation 300 cm during transport 230 cm total height roof 230 cm handle 165 cm weight 2,030 kg minimum turning radius 320 cm engine model kubota v2403-m-t type vertical water-cooled 4-cycle diesel engine w...

Page 17

Vibration level hand-arm vibration this machine was confirmed to transmit a maximum vibration level of less than 2.5 m/s 2 to hands and arms by measuring identical machines in accordance with the procedure specified in iso5349-1:2001-5349-2:2001. Whole body vibration this machine was confirmed to tr...

Page 18

Specification decal the specification decal indicates the ce logo, model name, and weight, etc. Kj8jic-001 decal, specifications_001 noise emission decal the noise emission decal indicates the sound power level determined by measuring identical machines in accordance with the procedure specified in ...

Page 19

Positions of the decals (warning and instruction) 1 9 6 2 4 3 8 6 5 4 7 6iul4h-007 positions of the decals (warning and instruction)_001 pr od uc t ove rvie w gm2800b product overview page 3-5 safety and instruction signs.

Page 20

Warning and instruction decals 1 䌓䌌䌏䌗 ਸ਼ゞᱛ p u d w 2 d w 4 n w o d 1 3 5 4 2 qigqnx-032 gm2800-0941z0 decal, operation warning read the owner's operating manual. Warning apply the parking brake, stop the engine, remove the ignition key, and then leave the machine. Danger danger flying objects - al...

Page 21

3 qigqnx-010 k4205001600 decal, caution for severe injury danger danger may cut your hand or leg - stop the rotation and engine. Otherwise you may get injured. 4 qigqnx-011 k4205001650 decal, caution for flying object danger danger caution for flying object - when the blades are rotating, keep away ...

Page 22

8 k 4 2 0 9 0 0 0 9 8 0 qigqnx-020 k4209000980 hydraulic oil icon read the owner's operating manual. 9 k 4 2 0 9 0 0 1 0 0 0 qigqnx-021 k4209001000 fuel icon use no. 2 diesel fuel. (low sulfur or ultra-low sulfur diesel fuel only) gm2800b product overview page 3-8 safety and instruction signs.

Page 23

Inspection before use............................Page 4-2 rotary knife............................................ Page 4-2 radiator cover........................................Page 4-2 radiator.................................................. Page 4-3 coolant.........................................

Page 24

Inspection before use be sure to perform an inspection before you start using the machine so that you will be able to take advantage of its optimum performance for a long period of time. Rotary knife inspection of rotary knife danger danger the rotary knife is an edged tool. Handle them carefully, s...

Page 25

1 radiator cover carefully clean the front and back of the radiator cover with water or compressed air. Radiator inspection of radiator for details on handling the engine, please refer to the separate engine operating manual. Make sure that there is no damage to the radiator. Make sure that the radi...

Page 26

1 reserve tank coolant supply for details on handling the engine, please refer to the separate engine operating manual. Warning do not touch the radiator or coolant during engine operation or right after the engine has been turned off. Due to high temperatures, doing so could cause burns. After the ...

Page 27

Warning do not touch the radiator or coolant during engine operation or right after the engine has been turned off. Due to high temperatures, doing so could cause burns. After the radiator has well cooled down, open the radiator cap. Caution change coolant after the engine has well cooled down. Impo...

Page 28

Hydraulic oil supply important do not mix different types of oil. Important use shell tellus s2m46 (or equivalent) as hydraulic oil. If the oil level is low, remove the left tank cover, and then open the tank cap and supply oil. 1 k9yr5z-003 hydraulic oil supply_001 1 tank cap start the engine, rais...

Page 29

1 tank cap start the engine, raise and lower the mower units, and turn the steering wheel left and right. Move forward and reverse repeatedly several times. Raise the mower units and maintain that position on a level surface, and then check to see if the oil level is at the middle of the oil gauge. ...

Page 30

1 reset button 2 vacuum indicator change of air cleaner for details on handling the engine, please refer to the separate engine operating manual. A contaminated air cleaner element may cause malfunction of the engine. To maximize the life of the engine, replace the air cleaner element at the appropr...

Page 31

If the battery fluid level is lower than halfway between the upper level (maximum) line and lower level (minimum) line, add purified water up to the upper level (maximum) line. 1 2 48yhlu-004 supply of battery fluid_001 1 upper level 2 lower level tire inspection of tires check the pneumatic pressur...

Page 32

Position the machine so that the engine will be level, and then insert the oil level gauge all the way to check the oil level. 1 rnr453-001 inspection of engine oil_001 1 oil gauge the appropriate oil level should be between the upper and lower limit lines on the gauge. 2 3 1 rnr453-002 inspection o...

Page 33

Caution be careful with hot oil, which could cause burns if it contacts your skin. Important be sure to use engine oil that is classified as api service grade cf or higher, with an sae viscosity that is appropriate for the operating environment (ambient temperature). Important securely tighten the o...

Page 34

If the fuel gauge located in the upper right corner of the operation panel indicates a level close to e (empty), supply fuel (diesel) at your earliest convenience. The fuel tank capacity is approximately 51.0 dm 3 (51.0 l). E f 1 4 f u e l 1 2 3 4 1 2e4emp-001 fuel supply_001 1 fuel gauge air bleedi...

Page 35

Tightening torques standard tightening torques bolts and screws unless otherwise instructed, tighten bolts or nuts by the specified torque using an appropriate tool. Excessive tightening of a screw may cause it to become loose or damaged. The appropriate tightening torque depends on factors such as ...

Page 36

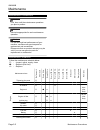

Nominal diameter heat-treated screws strength category: 8.8 strength category: 10.9 8 t 8.8 8 tib3yb-002 11t 10.9 11 tib3yb-003 n-m kgf-cm lb-in n-m kgf-cm lb-in m5 5 - 7 50.99 - 71.38 44.26 - 61.96 7 - 10 71.38 - 101.97 61.96 - 88.51 m6 8 - 11 81.58 - 112.17 70.81 - 97.36 14 - 18 142.76 - 183.55 12...

Page 37

Portion code part name tightening torque thread locking adhesive n-m kgf-cm lb-in re ar whee l wheel k0014120652 bolt, heat-treated m12-65p1.5 67 - 85 683.20 - 866.75 593.02 - 752.34 - front axle k00152200702 bolt, heat-treated m20-70p1.5 370 - 450 3772.89 - 4588.65 3274.87 - 3982.95 - brake ass'y k...

Page 38

Portion code part name tightening torque thread locking adhesive n-m kgf-cm lb-in bumper k0010120302 bolt, heat-treated m12-30 67 - 134 683.20 - 1366.40 593.02 - 1186.03 - cover mounting bracket k0000080202 bolt, m8-25 9 - 14 91.77 - 142.76 61.96 - 123.91 - valve v5267 k0013080902 bolt, 11t, heat-tr...

Page 39

Lift the seat to adjust its height to one of three positions. A s1gskp-005 adjustment of seat_002 a three positions adjustment of cutting height cutting height table the adjustment range for the cutting height is 20.0 - 91.5 mm. 1 2 3 4 yizobu-001 cutting height table_001 1 adjusting plate position ...

Page 40

To decrease cutting height: remove a lower adjusting collar and insert it above. 1 s8skgg-002 adjustment with adjusting collars_002 1 s8skgg-003 adjustment with adjusting collars_003 1 adjusting collar after adjusting the adjusting collars at the three locations, firmly tighten all nuts. 1 s8skgg-00...

Page 41

Lower the mower unit to change the hole positions, and then temporarily secure it with the two bolts. 1 2 1wwy8g-002 adjustment with cutting height adjusting plates_002 1 handle 2 bolt after making adjustments at the three locations, firmly tighten all bolts. 1 3 2 1wwy8g-001 adjustment with cutting...

Page 42

Make sure that the glow plug is generating heat and the thermo-start lamp is turned on. Caution quickly returning the ignition key from the "start" position to the "on" position may result in damage to the machine. After the thermo-start lamp turns off, immediately set the ignition key to the "start...

Page 43

Operation of each section precautions for operating the machine caution drive the machine at such a speed that you can stop it immediately for emergencies. Cautions for when you leave the machine caution if the brake feels soft or ineffective, use the wheel stoppers to secure the machine. Instructio...

Page 44

Led ⑧ lights up when the 2wd/4wd selector switch is in the "4wd" position, and then the machine enters 4wd. 1 2wd/4wd sol 2wd/4wd sol blade rotation sol blade rotation sol tr action assist sol di ff erential-lock sol di ff erential-lock sol di ff erential-lock sol 52bra2-001 relays_001 1 relay box k...

Page 45

The 2wd/4wd selector switch is located in the operation panel. When the switch is set to the "2wd" position, the machine will be in two-wheel drive (front- wheel drive). When it is set to the "4wd" position, the machine will be in four-wheel drive. 1 a b nyxhh2-001 2wd/4wd selector switch_001 1 2wd/...

Page 46

The mower lock levers (latches) are located in the foot area on the left and right sides and are used when storing the machine with mower units #4 and #5 raised. When storing the machine, hook the mower lock levers (latches) on the arms. 1 xqolpb-001 mower lock lever (latch)_001 1 mower lock lever (...

Page 47

Note: the factory default engine rpm (maximum) is set to 2,600 rpm. 1 a b v2e27i-006 throttle lever_001 1 throttle lever a rabbit icon (high speed) b turtle icon (low speed) diff-lock switch caution do not operate the diff-lock switch unless it is necessary. It may result in the hydraulic system mal...

Page 48

Warning when depressing the brake pedals to make turns with a small radius, obtain a sufficient awareness of the lawn and ground conditions. This may damage the lawn. The brake pedals are located in the left foot area and operate the left and right brakes independently. By depressing the brake pedal...

Page 49

1 brake pedals 2 parking brake lever hood caution do not open the hood in strong winds. Caution be careful not to pinch your fingers when you open or close the hood. Unlock the rubber catch, and then lift up the hood. Hook the hood support rod onto the latch inside the hood. Make sure that the hood ...

Page 50

1 tachometer/hour meter 2 water temperature gauge 3 fuel gauge 4 pilot lamps (charge lamp, thermo-start lamp, oil pressure lamp) tachometer/hour meter the tachometer and hour meter are located in the operation panel. The tachometer indicates the engine rpm. It is connected to a rotation sensor in th...

Page 51

Pilot lamps charge lamp the charge lamp is the left pilot lamp located in the operation panel. It turns on when the ignition key is set to the "on" position before the engine starts. It turns off when the engine starts and the alternator starts operating properly. If this lamp illuminates while you ...

Page 52

Caution do not touch the unload valve except when towing the machine. Caution before restarting the engine, be sure to close the unload valve. Stop the engine. (see "procedure to stop engine" (page 4-20) .) apply the parking brake and chock the wheels. Make sure that the steering wheel is raised com...

Page 53

Shift the mower unit up/down lever to the "down" position to lower the mower units. 1 a b c lwkjk9-001 cutting operation_001 1 mower unit up/down lever a up b neutral c down set the knife rotation switch to the "on" position to rotate the knives of all mower units. 1 a b axscdx-001 cutting operation...

Page 54

Gm2800b handling instructions page 4-32 transporting.

Page 55

Maintenance precautions...................... Page 5-2 maintenance schedule........................... Page 5-2 specified values..................................... Page 5-4 main consumable parts................................... Page 5-4 jacking up the machine......................... Page 5-4 ab...

Page 56

Maintenance precautions caution first, learn well the maintenance operations you plan to perform. Caution use tools appropriate for each maintenance operation. Caution for the safe and best performance of your machine, use baroness genuine parts for replacement and accessories. Please note that our ...

Page 57

Maintenance item bef ore work afte r wo rk eve ry 8 hrs. Every 5 0 hrs. Every 100 h rs. Every 200 h rs. Every 250 h rs. Every 400 h rs. Every 500 h rs. Every ye ar every 2 years every 4 years remar ks mai n b ody tightening the parts ○ interlock system ○ emergency switch ○ electrical wiring ○ knife ...

Page 58

Specified values fuel tank capacity 51.0 dm 3 (51.0 l) hydraulic tank capacity 44.0 dm 3 (44.0 l) shell tellus s2v46 or equivalent quantity of engine oil 9.7 dm 3 (9.7 l) coolant volume 12.0 dm 3 (12.0 l) including reserve tank (1.0 l) front tires 150 kpa (1.5 kgf/cm 2 ) 29 × 14.00 - 15 rear tires 1...

Page 59

Jack-up points 1 front right frame 2 front left frame 3 center of pivot 4 below rear wheel motors front right frame rwyt62-008 jack-up points_002 front left frame rwyt62-009 jack-up points_003 center of pivot rwyt62-010 jack-up points_004 1. 2. 3. Below rear wheel motors two locations rwyt62-032 jac...

Page 60

Greasing points grease nipples are installed in the following locations. Add grease every 50 hours of operation. 1 #2 #3 #4 #1 #5 2 3 4 6 7 8 2 4 5 8bq62b-023 greasing points_001 portion no. Of greasing points 1 rear roller 10 2 mower arm fulcrum 5 3 lift arm fulcrum 5 4 lift arm cylinder fulcrum 12...

Page 61

Mower units #2 and #3 8bq62b-026 greasing points_004 lift arm fulcrum there is one greasing point on the arm connected to each mower unit. Lower the mower units before greasing the lift arm fulcrums. Mower units #1 and #4 8bq62b-027 greasing points_005 mower units #2 and #3 8bq62b-028 greasing point...

Page 62

Pivot middle between the rear wheels 8bq62b-032 greasing points_010 rear left wheel 8bq62b-033 greasing points_011 rear right wheel 8bq62b-034 greasing points_012 5. Neutral position area there are two locations. 8bq62b-035 greasing points_013 traveling pedal shaft fulcrum there are two locations. 8...

Page 63

Danger danger if the rotary knife becomes worn or damaged, a crack or tear between the sail and flat part will result. Since a piece of the rotary knife may break and fly off while it is rotating, be extremely careful. Caution when touching edged tools, wear gloves, since they could cut your hands. ...

Page 64

1 cotter pin 2 hardened roundhead pin follow the steps below to remove the rotary knife. Use the square pipe from the included tools to secure the rotary knife so that it does not turn. Remove the two bolts, spring washers and washers used to install the rotary knife. Remove the knife guide. Remove ...

Page 65

1 mower unit remove the cotter pin and hardened roundhead pin inserted at a, and then insert them at b. 1 2 a b to41g1-003 mower units #2/#3_005 1 cotter pin 2 hardened roundhead pin follow the steps below to remove the rotary knife. Use the square pipe from the included tools to secure the rotary k...

Page 66

Remove the rotary knife. 1 6 2 3 4 5 to41g1-007 mower units #4/#5_003 1 square pipe 2 rotary knife 3 bolt 4 spring washer 5 washer 6 knife guide install the rotary knife. For installing the rotary knife, reverse the removing procedure. Sharpening of rotary knife danger danger the rotary knife is an ...

Page 67

Follow the steps below to sharpen the rotary knife. Remove the rotary knife from the machine. (see .) important sharpen only the top surface of the edge, and be sure to maintain the original angle. By equally grinding the left and right ends of the rotary knife, it can be sharpened without becoming ...

Page 68

If the balancer equipment is not available, insert a screwdriver into the hole at the center of the rotary knife, and then balance the left and right ends so that the rotary knife is level. A 1 2 vzoenp-001 balancing of rotary knife_002 1 rotary knife 2 screwdriver a level maintenance (main body) re...

Page 69

For installing the rear tires, reverse the removing procedure. Adjustment of belt tension caution be sure to stop the engine before adjusting the belts. If the belt becomes slack due to frequent use, it may jump or slip. In addition, if it is overtightened, it may wear prematurely. If necessary, adj...

Page 70

1 adjustment bolt (on brake disc side) 2 lever a open (neutral) reduce the clearance by loosening the lock nut, then tightening the adjustment nut. Tighten the adjustment nut until the friction material contacts the friction surface of the disc. 1 2 3 4 nfzln9-003 adjustment of brake_003 1 brake dis...

Page 71

If the machine moves forward or backward while the traveling pedals are released, they are not set to the neutral position. Follow the steps below to make adjustments. Stop the engine. Place the jacks beneath the jack-up points, and then lift the machine off the ground. Use stable jack stands, and r...

Page 72

Change of fuse fuse box the fuse box includes spare fuses and tools. 1 pkm25s-004 fuse box_001 1 fuse box the machine uses a mini fuse for automobiles. Replace an old fuse with a new fuse of the specified capacity. A b c d e g f h i j k l m n o pkm25s-003 fuse box_002 a 5 a timer b 5 a thermo-start ...

Page 75

Head office 1-26, miyuki-cho, tyokawa, aichi-pref. 442-8530 japan. Tel : (0533) 84 - 1390 fax : (0533) 89 - 3623 gm2800b-um--gbz/12a-00-s.K.