- DL manuals

- Baroness

- Lawn Mower

- LM180C

- Owner's Operating Manual

Baroness LM180C Owner's Operating Manual

Summary of LM180C

Page 1

Super mower owner's operating manual "required reading" read this manual and the owner's manual for the engine before using the machine. Serial no.20001- original instructions ver.1.2.

Page 2

Thank you for purchasing the baroness machine. This manual explains proper handling, adjustment, and inspection of your machine. Prior to use, carefully read this manual to thoroughly understand the contents for safe and correct operation. We hope you will use the machine safely, and take advantage ...

Page 3

Read this manual carefully to ensure that you thoroughly understand how to properly operate and maintain this machine, and to avoid causing injury to yourself or others. The operator is responsible for operating the machine properly and safely. Do not perform maintenance on the machine other than th...

Page 4

Purpose this machine is intended for cutting turf grass at golf courses. Do not use this machine in any way other than its intended purpose, and do not modify the machine. Operating this machine for other purposes and modifying it may be very dangerous and may cause damage to the machine. In additio...

Page 5

Safety............................................................... Page 1-1 safe operating practices................................Page 1-2 disposal........................................................... Page 2-1 waste disposal............................................... Page 2-2 product ...

Page 6

Lm180c contents.

Page 7

Safe operating practices....................... Page 1-2 training...................................................Page 1-2 preparation............................................. Page 1-2 operation................................................ Page 1-3 maintenance and storage......................

Page 8

Failure to adequately follow these safety precautions may cause an accident resulting in injury or death. Danger danger this machine is designed to ensure safe operation and has been tested and inspected thoroughly before shipment from the factory. The machine is equipped with safety devices to prev...

Page 9

Replace all fuel tanks and container caps securely. Check that operator’s presence controls, safety switches and shields are attached and functioning properly. Do not operate unless they are functioning properly. If the brake operation is faulty or the parking brake lever has noticeable play, be sur...

Page 10

Take care when loading or unloading the machine into a trailer or a truck. Load or unload the machine in a flat and safe place. Before loading or unloading, set the parking brake on the truck or trailer, stop the engine, and chock the wheels. When transporting the machine on a truck or a trailer, se...

Page 11

Waste disposal........................................Page 2-2 about the waste disposal.......................Page 2-2 disposal lm180c disposal page 2-1.

Page 12

Waste disposal about the waste disposal make sure that waste generated when servicing or repairing the machine is disposed of in accordance with local regulations. (e.G. Waste oil, antifreeze batteries, rubber products, and wires etc.) lm180c disposal page 2-2 waste disposal.

Page 13

Specifications......................................... Page 3-2 specifications..........................................Page 3-2 sound pressure level.............................. Page 3-2 sound power level.................................. Page 3-2 vibration level.....................................

Page 14

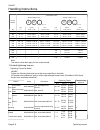

Specifications specifications type lm180c dimensions total length 215 cm total width during operation 208 cm during transport 185 cm total height seat 107 cm steering wheel 102 cm weight 387 kg minimum turning radius 230 cm engine type subaru eh30b type air-cooled 4-cycle vertical ohv-type gasoline ...

Page 15

Vibration level hand-arm vibration this machine was confirmed to transmit a maximum vibration level of 3.63 m/s 2 to hands and arms by measuring identical machines in accordance with the procedure specified in iso 5349-1:2001-5349-2:2001. Whole body vibration this machine was confirmed to transmit a...

Page 16

Noise emission decal the noise emission decal indicates the sound power level determined by measuring identical machines in accordance with the procedure specified in the ec directives. Jiwe3f-001 noise emission decal_001 year of manufacture decal the year of manufacture decal indicates the year whe...

Page 17

Explanation about safety decals and instruction decals 1 2 3 1 qigqnx-009 lm180c-1001z0 sticker, operation warning read the manual. Danger danger flying objects - all persons other than the operator must keep a safe distance from the machine. Danger danger rollover - do not work on slopes of 18 degr...

Page 18

5 check for leakage from hoses and fittings. Shut off fuel valve when engine is not in use. 1 2 3 4 5 7 6 qigqnx-013 stay clear of the hot surface. Check for leakage from hose and fittings. 6. 7. 6 㧳㧮 㧲 㧲 㧺㧸 㧵 㧱 㧼 㧳㧾 㧿 㧿㧲 㧺 㧰㧷 㪪㪧㪘㪩㪢㩷㪧㪣㪬㪞㩷㪚㪦㪭㪜㪩㩷㪤㪬㪪㪫㩷㪙㪜㩷㪠㪥㩷㪧㪣㪘㪚㪜㩷㩷㪮㪟㪜㪥㩷㪩㪜㪝㪬㪜㪣㪠㪥㪞㪅 㪣㪜㩷㪚㪘㪚㪟㪜㩷㪙㪦㪬㪞㪠㪜㩷㪛㪦㪠㪫㩷㪜...

Page 19

Inspection before use............................Page 4-2 reel cutter (cutting cylinder) and bed knife (bottom blade)....................... Page 4-2 air cleaner...............................................Page 4-2 tire..........................................................Page 4-3 brake..........

Page 20

Inspection before use be sure to perform an inspection before you start using the machine so that you will be able to take advantage of its optimum performance for a long period of time. Reel cutter (cutting cylinder) and bed knife (bottom blade) inspection of reel cutter (cutting cylinder) and bed ...

Page 21

Follow the steps below to clean the air cleaner. Before installing the element, clean it with white kerosene, immerse it in an admixture of three parts white kerosene to one part engine oil, and then shake/ squeeze it. Before installing the urethane foam, clean it with white kerosene, immerse it in ...

Page 22

The appropriate oil level should be between the two knurl lines on the gauge. 1 bgmiun-001 inspection of engine oil_001 1 oil gauge filling of engine oil for details on handling the engine, please refer to the separate engine handling manual. Caution do not fill too much engine oil. Otherwise, the e...

Page 23

Install the oil gauge. 1 2 gui678-004 change of engine oil_001 1 oil filling port / oil gauge 2 drain plug transmission inspection of transmission oil place the machine so that its frame will be level, and then make sure that the transmission oil level is at the oil level plug at any time. The oil l...

Page 24

Make sure that the transmission oil level is filled up to the tip of the oil level opening. Attach the oil filling port cap and oil level plug. 3 2 1 4sr81t-001 change of transmission oil_001 1 oil filling port 2 oil level plug 3 drain plug fuel inspection of fuel supply observe the fuel gauge locat...

Page 25

Tightening torques standard tightening torques bolts and screws unless otherwise instructed, tighten bolts or nuts by the specified torque using an appropriate tool. Excessive tightening of a screw may cause it to become loose or damaged. The appropriate tightening torque depends on factors such as ...

Page 26

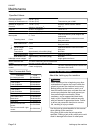

Nominal diameter heat-treated screws strength category: 8.8 strength category: 10.9 8 t 8.8 8 tib3yb-002 11t 10.9 11 tib3yb-003 n-m kgf-cm lb-in n-m kgf-cm lb-in m5 5 - 7 50.99 - 71.38 44.26 - 61.96 7 - 10 71.38 - 101.97 61.96 - 88.51 m6 8 - 11 81.58 - 112.17 70.81 - 97.36 14 - 18 142.76 - 183.55 12...

Page 27

Portion code part name tightening torque thread locking adhesive n-m kgf-cm lb-in mow er bed knife (bottom blade) k0071000092 screw, heat-treated flathead m10-20 29 - 38 295.71 - 387.49 256.68 - 336.34 - front roller k0010100252 bolt, heat-treated m10-25 58 - 76 591.43 - 774.97 513.36 - 672.68 - eng...

Page 28

If the blades still cannot cut well: perform lapping of the reel cutter (cutting cylinder). 1 2 3 4 5 2f8equ-001 adjustment of blade engagement_001 1 lock nut 2 nut a 3 nut b 4 reel cutter (cutting cylinder) 5 bed knife (bottom blade) adjustment of cutting height important the front wheel is provide...

Page 29

Shift the throttle lever to "low", and then warm up the engine for 1 to 2 minutes. Gradually move the throttle lever to "high". Procedure to stop engine depress the brake pedal, and then pull the parking brake lever. Shift the traveling clutch lever and reel rotation lever to the "off" position, and...

Page 30

To lower the left and right mower units, squeeze the clutch lever and slowly move the lifting lever down. 1 2 5zujec-001 left and right mower units_001 1 clutch lever 2 lifting lever to raise the left and right mower units, raise the lifting lever slowly until the hook metal fitting is secured by th...

Page 31

The change lever is a transmission device. It was adapted from a direct change system. To change the speed, park the machine on level ground, and then engage the lever in the desired position. 1 u1v7hf-001 operation of change lever_001 1 change lever traveling clutch lever caution be sure not to eng...

Page 32

To park the machine, pull the parking brake lever completely. To release the parking brake, press the push button while lowering the parking brake lever all the way to its resting position. 3 1 2 n9dmld-001 parking brake lever_001 1 push button 2 parking brake lever 3 adjustment bolt travel of machi...

Page 33

Maintenance precautions...................... Page 5-2 maintenance schedule........................... Page 5-2 specified values..................................... Page 5-4 main consumable parts......................... Page 5-4 jacking up the machine......................... Page 5-4 about the ja...

Page 34

Maintenance precautions caution first, learn well the maintenance operations you plan to perform. Caution use tools appropriate for each maintenance operation. Caution for the safe and best performance of your machine, use baroness genuine parts for replacement and accessories. Please note that our ...

Page 35

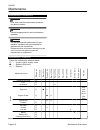

Maintenance item bef ore work afte r wo rk eve ry 8 hrs. Every 5 0 hrs. Every 100 h rs. Every 200 h rs. Every 250 h rs. Every 400 h rs. Every 500 h rs. Every ye ar every 2 years every 4 years remar ks mai n b ody tightening the parts ○ interlock system ○ emergency switch ○ electrical wiring ○ knife ...

Page 36

Specified values fuel tank capacity 6.0 dm 3 (6.0 l) quantity of transmission oil 2.0 dm 3 (2.0 l) transmission gear oil #90 quantity of engine oil 1.2 dm 3 (1.2 l) summer: sae30, winter: sae20 front tire 200 kpa(2.0 kgf/㎝ 2 ) 4.00 - 5 rear tire 80 kpa(0.8 kgf/㎝ 2 ) 18 x 8.50 - 8 diff-lock wire crea...

Page 37

Jack-up portion 2 1 4 5 6 3 rwyt62-011 jack-up portion_001 jack-up portion 1 front axle, center 2 front axle, right 3 front axle, left 4 transmission case, lower 5 transmission axle case, left 6 transmission axle case, right front axle, center rwyt62-012 jack-up portion_002 1. Front axle, right rwyt...

Page 38

Transmission axle case, right rwyt62-017 jack-up portion_007 greasing about the lubrication the moving parts of this machine need to be lubricated as a lack of grease on such parts could cause them to seize or be damaged. Grease the moving parts according to the maintenance schedule. Greasing points...

Page 39

Reel housing there is one point each on the left and the right of each unit. 8bq62b-058 greasing point_004 mower frame there is one point each on the left and the right mower units. 8bq62b-059 greasing point_005 mower lifting arm there is one point each on the left and the right mower units. 8bq62b-...

Page 40

Rear mower oscillating metal part 8bq62b-065 greasing point_011 rear roller there is one point each on the left and the right of each unit. 8bq62b-066 greasing point_012 mower tension 8bq62b-067 greasing point_013 8bq62b-068 greasing point_014 9. 10. 11. Maintenance (mower) lapping of reel cutter (c...

Page 41

1 newspaper 2 lapping powder 3 gel compound 4 brush 5 27 socket wrench note: mixing ratio for abrasive in volume is one part lapping powder to three or four parts oil. Caution before cutting newspaper as a test, be sure to stop the engine and wear gloves to protect your hands. Pay attention not to l...

Page 42

Rear tires follow the steps below to remove the rear tires: loosen the bolts. Upekw4-001 rear tires_001 place the tire jack beneath the jack-up point of the rear wheel transmission area securely, then raise it until the tire lifts off the ground. (see .) remove the bolts. Remove the tire from the wh...

Page 43

1 adjustment bolt 2 rod 3 traveling clutch lever 4 rod-tension metal fitting 5 collar reel rotation lever loosen the adjustment bolt, then change the length of the rod. Adjust the clearance between the rod- tension metal fitting and the collar to be 5mm, when the traveling clutch lever is engaged. T...

Page 44

1 adjusting nut a 2 adjusting nut b 3 rod rear mower tension loosen adjusting nut a. Tighten adjusting nut b, then change the length of the rod. Lower the rear mower unit on a level surface, then adjust the clearance of the spring to 1mm. Tighten adjusting nut a and make sure that the rod is fixed s...

Page 45

Make sure that the brake is applied properly when you pull the parking brake lever, and that there is no brake dragging when you release the parking brake lever. 1 4 4 5 2 3 3 ulabms-002 adjustment of parking brake_001 1 parking brake lever 2 brake wire 3 nut 4 wire adjustment metal fitting 5 brake ...

Page 46

Adjustment of diff-lock wire if the diff-lock seems ineffective when you depress the diff-lock pedal, adjust the diff-lock wire. Make sure that the diff-lock pedal has completely returned to its resting position. Loosen the nut on the transmission side. Loosen the wire adjustment bracket upward to i...

Page 47

1 nut 2 wire adjustment bracket 3 wire (to hook the mower) 4 right mower unit 5 hook metal fitting 6 bottom of the hook wire to hook the rear mower loosen the nuts and move the wire adjustment metal fitting toward the center of the machine to increase the wire tension. Lower the rear mower unit, the...

Page 48

Lm180c maintenance page 5-16 long-term storage.

Page 51

Head office 1-26, miyuki-cho, toyokawa, aichi-pref. 442-8530 japan. Tel : (0533) 84 - 1390 fax : (0533) 89 - 3623 lm180c--um--gbz/13d-00-s.K c.