- DL manuals

- Baroness

- Lawn Mower

- LM283

- Owner's Operating Manual

Baroness LM283 Owner's Operating Manual

Summary of LM283

Page 1

3-reel gang rough mowers owner's operating manual reel mower "required reading" read this manual and the owner's manual for the engine before using the machine. Serial no.10001~ original instructions ver.1.0

Page 2

Thank you for purchasing the baroness machine. This manual explains proper handling, adjustment, and inspection of your machine. Prior to use, carefully read this manual to thoroughly understand the contents for safe and correct operation. This machine has been shipped from the factory after compreh...

Page 3

Read this manual carefully to ensure that you thoroughly understand how to properly operate and maintain this machine, and to avoid causing injury to yourself or others. The operator is responsible for operating the machine properly and safely. Do not perform maintenance on the machine other than th...

Page 4

Lm283 introduction.

Page 5

Safety ....................................................................... 1-1 safety management ............................................... 1-2 for safe operation ................................................. 1-2 training ....................................................................

Page 6

Lm283 contents 2.

Page 7

Safety management ....................................... 1-2 for safe operation ......................................... 1-2 training ........................................................... 1-2 before operating the machine ....................... 1-2 when operating the machine ...................

Page 8

This machine met cen standard en 836: 1997 (if the specified label is affixed) for garden equipment-powered lawnmowers at the time of production. Improper use or maintenance may result in injury or death. To prevent an accident, be sure to follow the safety precautions described below and always pay...

Page 9

The safety labels and operation labels should be preserved in their entirety. If they are damaged, become dirty, or peel off, please replace them with new ones. Tighten any nuts, bolts, or screws that become loose to ensure that the machine is always operated under safe conditions. Evaluate the terr...

Page 10

Stop the blades rotating before crossing surfaces other than grass. Use care when approaching blind corners, shrubs, trees, or other objects that may obscure your vision. When using attachments, never direct the discharge at bystanders or allow anyone near the machine while it is operating. Do not c...

Page 11

When filling the tires with air, do not allow the air pressure in the tires to exceed the specified maximum. Check that all nuts, bolts, and screws are properly tightened to ensure that the machine is always operated under safe working conditions. Keep all parts in good working condition and all har...

Page 12

Lm283 safety page 1-6 maintenance and storage.

Page 13

Sound pressure .............................................. 2-2 sound pr essure level lm283 sound pressure level page 2-1.

Page 14

Sound pressure this machine was confirmed to have a continuous a-weighted sound pressure level of 89 db (a) by measuring identical machines (at operator ear-level) in accordance with the procedure specified in directive cen en836:1997. Lm283 sound pressure level page 2-2 sound pressure.

Page 15

Sound power .................................................. 3-2 so und po we r leve l lm283 sound power level page 3-1.

Page 16

Sound power this machine has been confirmed to have a sound power level of 103 dba/lpw by measuring identical machines in accordance with the procedure specified in directive 2000/14/ec. Lm283 sound power level page 3-2 sound power.

Page 17

Hand-arm vibration ........................................ 4-2 whole body vibration .................................... 4-2 vibr atio n leve l lm283 vibration level page 4-1.

Page 18

Hand-arm vibration this machine has been confirmed to transmit a maximum vibration level of less than 3.81 m/s 2 to hands and arms by measuring identical machines in accordance with the procedure specified in iso 5349-1, 2001・5349-2, 2001. Whole body vibration this machine has been confirmed to tran...

Page 19

About the safety labels and operation labels ........... 5-2 safety la bels an d ope ra tion la be ls lm283 safety labels and operation labels page 5-1.

Page 20

About the safety labels and operation labels warning safety labels and operation labels are attached to this machine. Make sure that they are preserved in their entirety. If they are damaged, become dirty, or peel off, replace them with new ones. Part numbers for labels that need to be replaced are ...

Page 21

Waste disposal ............................................... 6-2 about the waste disposal .............................. 6-2 disposal lm283 disposal page 6-1.

Page 22

Waste disposal about the waste disposal make sure that waste generated when servicing or repairing the machine is disposed of in accordance with local regulations. (e.G. Waste oil, antifreeze batteries, rubber products, and wires etc.) lm283 disposal page 6-2 waste disposal.

Page 23

Specifications ................................................. 7-2 names of each section .................................. 7-3 serial number plate ....................................... 7-3 specification decal ......................................... 7-3 positions of the decals (warning and ins...

Page 24

Specifications model lm283 dimensions total length mower roller type 265 cm mower wheel type 276 cm total width during operation 203 cm during transport 203 cm total height 133 cm weight 1,080 kg minimum turning radius 277 cm engine model kubota d1105-t type water-cooled 4-cycle diesel engine total ...

Page 25

Names of each section 1 12 13 14 15 16 17 18 19 20 2 3 4 5 6 7 8 9 b a 10 11 quwxcl-004 names of each section_001 1 headlight 2 brake pedal 3 throttle lever 4 seat 5 box 6 hood 7 muffler 8 fuel tank 9 parking brake lever 10 mower unit #3 11 mower unit #2 12 angle meter 13 reel rotation lever 14 reel...

Page 26

Positions of the decals (warning and instruction) 5 7 4 1 2,3 2,3 6 6iul4h-003 positions of the decals (warning and instruction)_001 warning and instruction decals 1 20 1 3 4 5 2 qigqnx-019 lm283--0967z0 decal, lever operation warning read the owner's operating manual. Warning apply the parking brak...

Page 27

2 qigqnx-010 k4205001600 decal, caution for severe injury danger danger may cut your hand or leg - stop the cutter rotation and engine. Otherwise you may be injured. 3 qigqnx-011 k4205001650 decal, caution for flying object danger danger caution for flying object - when the blades are rotating, keep...

Page 28

Lm283 product overview page 7-6 warning and instruction decals.

Page 29

Inspection before use ................................... 8-2 inspection of reel cutter (cutting cylinder) ........... 8-2 inspection of radiator cover .......................... 8-2 inspection of radiator .................................... 8-2 inspection of coolant ..................................

Page 30

Inspection before use be sure to perform inspection before you start operating the machine so that you will be able to take advantage of its optimum performance for a long period of time. Inspection of reel cutter (cutting cylinder) the reel cutter (cutting cylinder) may become dull due to frequent ...

Page 31

Cleaning of radiator for details on handling the engine, please refer to the separate engine operating manual. Important an unclean radiator may cause overheating or damage to the engine. It may also cause malfunction of the hydraulic system. Important do not use solid objects, such as a spatula or ...

Page 32

Relationship between concentration of long-life coolant (llc) and freezing temperature freezing temperature llc concentration (volume %) down to -10°c (14°f) 20% down to -15 °c (5°f) 30% down to -20 °c (-4°f) 35% down to -25 °c (-13°f) 40% if the coolant level in the reserve tank is lower than the "...

Page 33

Make sure that the oil cooler is not contaminated. 2 1 37k9g1-001 inspection of oil cooler_001 1 radiator 2 oil cooler cleaning of oil cooler for details on handling the engine, please refer to the separate engine operating manual. Caution an unclean oil cooler may cause overheating or damage to the...

Page 34

Raise the mower units and maintain that position on a level surface, then check to see if the oil level is at the middle of the oil gauge. If necessary, supply oil. Check underneath the machine for oil leakage. Change of hydraulic oil warning when you change the hydraulic oil, be sure to drain it in...

Page 35

1 air cleaner element 2 clip 3 air cleaner cap 4 air cleaner body cleaning of air cleaner for details on handling the engine, please refer to the separate engine operating manual. A contaminated air cleaner element may cause malfunction of the engine. To maximize the life of the engine, clean the ai...

Page 36

If the battery fluid level is lower than half way between the upper level (maximum) line and lower level (minimum) line, add purified water up to the upper level (maximum) line. 2 1 48yhlu-002 supply of battery fluid_001 1 upper level 2 lower level inspection of tires check the pneumatic pressure of...

Page 37

Position the machine so that the engine will be level, then insert the oil gauge all the way to check the oil level. 1 2oowuz-003 inspection of engine oil_001 1 oil gauge the appropriate oil level should be between the upper and lower limit lines on the gauge. 2 3 1 rnr453-004 inspection of engine o...

Page 38

Change the engine oil more frequently, if the engine oil is contaminated, and especially if you use the machine in dusty areas or operate the engine at high loads or in high temperatures. Move the machine onto a level surface, stop the engine, remove the drain plug while the engine oil is warm, then...

Page 39

Tightening torques standard tightening torques bolts and screws unless otherwise instructed, tighten bolts or nuts by the specified torque using an appropriate tool. Excessive tightening of a screw may cause it to become loose or damaged. The appropriate tightening torque depends on factors such as ...

Page 40

Nominal diameter heat-treated screws strength category: 8.8 strength category: 10.9 8 t 8.8 8 tib3yb-002 11t 10.9 11 tib3yb-003 n-m kgf-cm lb-in n-m kgf-cm lb-in m5 5 - 7 50.99 - 71.38 44.26 - 61.96 7 - 10 71.38 - 101.97 61.96 - 88.51 m6 8 - 11 81.58 - 112.17 70.81 - 97.36 14 - 18 142.76 - 183.55 12...

Page 41

Portion code part name tightening torque thread locking adhesive n-m kgf-cm lb-in engine k00171002 52 bolt, heat-treated, small, 10-25 p1.25 45 – 57 458.87 – 581.23 398.30 – 504.51 - since it may be difficult to tighten bolts and nuts in the upper front left area of the engine, the strength category...

Page 42

1 reel rotation/stop switching lever a rotate b stop adjust the engagement between the reel cutter (cutting cylinder) and the bed knife (bottom blade) so that newspaper (two pieces) will be cut by the edge of both blades when the blades in their entirety come slightly into contact with each other vi...

Page 43

1 reel cutter (cutting cylinder) 2 front roller 3 cutting height gauge 4 bed knife (bottom blade) 5 cutting height adjustment nut a 6 cutting height adjustment nut b 7 rear roller a cutting height front wheel type adjust the cutting height to fit your cutting work. You can adjust the front wheels in...

Page 44

Adjustment of lift arm spring important adjust the spring if the front wheels slip on an ascending slope. Raise the mower units. Loosen lock nut a, then tighten lock nut b to adjust the spring. Perform the same procedure for both left and right. Make an adjustment so that the lift arm spring will be...

Page 45

Shift the throttle lever halfway from the "low" to "high"position. 1 2 3 4 v2e27i-001 procedure to start engine_002 1 parking brake lever 2 throttle lever 3 reel rotation lever 4 brake pedal important the thermo-start lamp turns off at the specified time. However, the lamp turning off does not relat...

Page 46

In the event the operator leaves the seat with the parking brake applied and the engine running, the safety device will be activated and will stop the engine under any of the following conditions: the traveling pedal is not set to neutral. (the operator has depressed the traveling pedal.) the reel r...

Page 47

1 reel up/down lever a lower b raise stop valve caution when you move the machine, or if you stop the engine with the mower units raised, be sure to set the stop valve to the "stop" position. The stop valve is located underneath the right side of the driver's seat. This valve prevents the raised mow...

Page 48

1 anti-reverse reel rotation stopper a for mowing b for backlapping reel rotation/stop switching lever caution before operating the reel rotation/stop switching lever, be sure to shift the reel rotation lever to the "stop" position. The reel rotation/stop switching lever is located on the reel motor...

Page 49

1 rubber catch 2 hood 3 hood support rod 4 latch to close the hood, release the hood support rod from the latch, then lower the hood slowly. Lock the rubber catch securely. 1 2 i5jb7e-002 hood_002 1 rubber catch 2 hood underseat cover caution be careful not to pinch your fingers when you open or clo...

Page 50

The hour meter indicates total operation time of the engine. Every six minutes of engine operation will increase the number on the first digit (black number on a white background) by one. Every one hour of engine operation will increase the number on the next digit (white number on a black backgroun...

Page 51

Thermo-start lamp the thermo-start lamp is the middle pilot lamp located in the lower right of the operation panel. When the ignition key is set to the "glow" position, it illuminates as the glow plug generates heat. Illumination of the thermo-start lamp is controlled by the glow lamp timer, and the...

Page 52

Open the unload valve located on the frame under the seat. 1 2 gay3t1-001 towing the machine_001 1 unload valve 2 center cover (rear) open the unload valve located on the rear frame. 1 gay3t1-002 towing the machine_002 1 unload valve important before towing, be sure to open the unload valves in two ...

Page 53

Before starting the engine, check the following points. An operator is sitting on the seat. The parking brake lever is pulled. The reel rotation lever is shifted to the "stop" position. The anti-reverse reel rotation stopper is set to the "for mowing" position. The reel rotation/stop switching lever...

Page 54

Lm283 handling instructions page 8-26 cutting work.

Page 55

Maintenance schedule ................................... 9-2 maintenance precautions .............................. 9-3 specified values for maintenance ................. 9-3 main consumable parts ................................. 9-4 jacking up the machine ................................. 9-4 abou...

Page 56

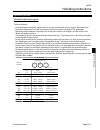

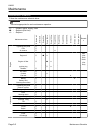

Maintenance schedule follow the maintenance schedule below. Caution use tools appropriate for each maintenance operation. ○・・・ inspect, adjust, supply, clean ●・・・ replace (first time) △・・・ replace maintenance item before w ork after w ork every 8hrs . Eve ry 50 hr s. Every 10 0hrs. Every 20 0hrs. Ev...

Page 57

Maintenance item b efo re w or k af ter work every 8hrs. Eve ry 50 hrs. Every 1 00h rs. Every 2 00h rs. Every 2 50h rs. Every 4 00h rs. Every 5 00h rs. Every year every 2 years every 4 years remark s ma in bod y hydraulic oil ○ ● △ 100hrs (first time) hydraulic oil filter ● △ 100hrs (first time) hyd...

Page 58

Front tires 120 kpa (1.2 kgf/㎝ 2 ) 23 x 10.50 - 12 4p rear tires 150 kpa (1.5 kgf/㎝ 2 ) 23 x 8.50 - 12 4p cutter adjustment spring 1 mm clearance of spring main consumable parts part name code fan belt pf1g345-9701-0 oil element pf16271-3209-2 air cleaner element pft0270-1632-0 fuel filter element p...

Page 59

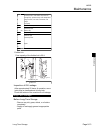

Front left frame rwyt62-020 jack-up points_003 rear right pivot rwyt62-021 jack-up points_004 rear left pivot rwyt62-022 jack-up points_005 rear center frame rwyt62-023 jack-up points_006 2. 3. 4. 5. Lubrication about the lubrication the moving parts of this machine need to be lubricated as a lack o...

Page 60

Portion no. Of greasing points 1 front roller 6 2 rear roller 6 3 reel housing 3 4 mower arm fulcrum 3 5 lift arm fulcrum 3 6 idle lever fulcrum 1 7 pivot 3 8 piston pump 2 9 traveling pedal fulcrum 1 10 traveling pedal shaft fulcrum 1 11 brake lever shaft 2 front roller there is one greasing point ...

Page 61

Mower #2 and #3 8bq62b-075 greasing points_007 idle lever fulcrum 8bq62b-046 greasing points_008 pivot use jack stands to support the machine and apply grease. Middle between the rear wheels 8bq62b-047 greasing points_009 6. 7. Rear right wheel 8bq62b-076 greasing points_010 rear left wheel 8bq62b-0...

Page 62

Traveling pedal shaft fulcrum 8bq62b-053 greasing points_014 brake lever shaft there is one greasing point each in the left and right brake areas. 8bq62b-054 greasing points_015 maintenance (mower) lapping of reel cutter (cutting cylinder) lapping is work similar to sharpening a cooking knife. If th...

Page 63

Insert two or three strips of newspaper into the space between the reel cutter (cutting cylinder) and the bed knife (bottom blade) at an angle of 90 degrees, then rotate the reel cutter (cutting cylinder) from up to down manually to check the sharpness. Check the sharpness at entire range (three or ...

Page 64

Finally, apply the abrasive on the entire range of the reel cutter (cutting cylinder) and perform final lapping. Stop the rotation of the reel cutter (cutting cylinder), stop the engine, and then wash off the abrasive using a washer etc. While checking the blade for sharpness, adjust blade engagemen...

Page 65

If the belt is too slack, loosen bolts a and b (that affix the alternator), then move the alternator to adjust the tension. 2 5 3 4 1 10 mm(0.39 in) sdie3r-002 fan belt_001 1 fan belt 2 blade 3 alternator 4 bolt a 5 bolt b adjustment of parking brake danger danger if the brake wire is cut, the machi...

Page 66

If the front tires rotate in reverse, loosen the lock nuts, then turn the front wheel rod to extend it. 1 2 3 4 5 5 hsn2jo-001 adjusting the neutral position of the piston pump_001 1 rear wheel rod 2 front wheel pump 3 rear wheel pump 4 front wheel rod 5 lock nut find the position where the front wh...

Page 67

A 5a proximity sensor, reel rotation stop solenoid b charge lamp, hydraulic lamp, water temperature gauge, buzzer, hour meter, tachometer, fuel gauge c fuel pump d thermo-start lamp e glow lamp timer f starter relay g engine stop solenoid h alternator (ig) i glow lamp timer j spare k l m n tool fusi...

Page 68

Lm283 maintenance page 9-14 long-term storage.

Page 71

Tel : (0533)84-1390 fax : (0533)89-3623 head office 1-26, miyuki-cho, toyokawa, aichi-pref. 442-8530 japan. Lm283---um--gbz/11h-00-s.K lm283---um--twz/11h-00-s.K.