- DL manuals

- Baroness

- Tiller

- SP05

- Owner's Operating Manual

Baroness SP05 Owner's Operating Manual

Summary of SP05

Page 1

Read this manual and the owner's manual before using this machine. Bunker rake maintenance machines series owner's operating manual ver.1.0

Page 2: Contents

1 contents introduction .............................................................................................2 introduction .............................................................................................2 safety .....................................................................

Page 3: Introduction

2 introduction introduction read this manual carefully to ensure that you thoroughly understand how to properly operate and maintain this machine, and to avoid causing injury to yourself or others. The operator is responsible for operating the machine properly and safely. Do not perform maintenance ...

Page 4

3 1. Training read the owner's operating manual and other training material carefully. Be familiar with the controls and safety indications and learn how to stop the machine in an emergency. If the operator cannot understand the manual, it is the owner’s responsibility to thoroughly explain the cont...

Page 5

4 3. Precautions during operation do not start the engine in a closed space, there is the danger of carbon monoxide poisoning. Operate the machine during the day or in an area with sufficient lighting. Before starting the engine, set the parking brake. Remember that there is no such thing as a safe ...

Page 6: Safety Warnings

5 charge the battery in a well ventilated area, away from sparks and flames. Unplug the battery charger before connecting it to the battery. Also, wear protective clothing and use insulated tools. Before storing the machine, lower the rake. Using the baroness bunker rake safely the following precaut...

Page 7

6 ● the precautions that are described here are important for safety. Be sure to follow them. ● failure to follow these precautions may cause injury or death, or damage to the machine. * the information described in this manual may differ from the actual machine you have purchased. 1. General precau...

Page 8

7 * failure to follow this precaution may cause an accident or the machine to malfunction due to improper maintenance. 3. Inspection and maintenance before and after operating the machine add oil and refuel when the engine is cool. Do not add oil or refuel when the engine is running or if the engine...

Page 9

8 * failure to follow this precaution may result in the pole connector in the container being exposed if the electrolyte falls below the “lower” level mark. This may cause sparks to be produced when the engine is started and the gas in the container to ignite, resulting in an explosion. Take suffici...

Page 10

9 5. When operating the machine and entering or leaving a field do not operate the machine on public roads. This machine is not authorized for operation as a special motor vehicle. Do not operate it on public roads. * failure to follow this precaution is subject to punishment for violating the traff...

Page 11

10 exercise extreme caution when operating or working on a slope. The balance of the machine worsens on slopes and bumps. Be sure to reduce your speed sufficiently and to operate the machine and work slowly. * failure to follow this precaution may cause the machine to overturn or fall, resulting in ...

Page 12

11 remove debris from the muffler and engine. Check that there is no grass, debris, or fuel around the muffler and engine or on the brakes every day before operating the machine. * failure to follow this precaution may cause the fuel to ignite, resulting in a fire. Be sure to check the electrical co...

Page 13: Part Names

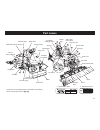

12 part names 2wd-3wd changeover lever cultivator lever blade lever steering wheel front cover headlight (work lamp) front/rear headlight switch rear light blade front wheel rear wheel forward/ reverse pedal brake pedal tilt lever fuel filler hole broom holder rear cover fuel valve serial number pla...

Page 14

13 description of warning labels and operation labels ● attach the warning labels and operation labels in close proximity to the dangerous parts to which they apply, making sure that they are clearly visible. If a label is damaged or peels off, replace it with a new one. : r e a d t h e o w n e r ’ ...

Page 15: Features of Sp05

14 features of sp05 specifications ● as this machine has power steering, less arm fatigue is experienced when operating it. Power steering also enables you to work more efficiently since the machine can travel faster and requires only a small turn radius. ● you can operate the machine stably on slop...

Page 16: Handling Instructions

15 1. Inspections and maintenance before use ● be sure to check the following areas before starting the engine. 1-1 checking and refilling of the engine oil for more details, refer to the owner’s manual for the engine. ● make sure that the engine is level, then check the oil level by fully inserting...

Page 17

16 precautions for the handling of fuel ● fuel is highly flammable. Extinguish all naked flames and cigarettes. ● never fill the fuel tank indoors, while engine is running, or while the engine is still hot. ● in order to prevent a fire, always keep the engine clean and be sure to remove debris, grea...

Page 18

17 1-12 fastening of each part ● bolts and nuts may be loosened after repeated use of the machine. Be sure to inspect and retighten them by the specified torque. ● tighten the following bolts and nuts by the following specified torques. Part code no. Part name quantity appropriate tightening torque ...

Page 19

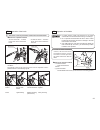

18 2-2 adjustment of the steering wheel position ● the steering wheel position can be adjusted. ● lift the tilt lever to release the steering wheel lock. When the steering wheel is set in a position appropriate for the operation to be performed, pull the lever back down to lock the steering wheel in...

Page 20

19 ● inspect the area where the machine will be used. ● never operate the engine in a building without proper ventilation. ● inspect whether there is any damage to the engine and make sure that the cover and guard are securely fastened in place. 3. Starting and stopping the engine 3-1 starting the e...

Page 21

20 4-3 operation of the parking brake the parking brake is located to the left of the front cover. ● do not operate the machine while the parking brake is engaged. If the operator presses either the forward or the reverse pedal while the parking brake is engaged, the interlock system sounds a buzzer...

Page 22

21 4-4 operation of the 2wd-3wd changeover lever the 2wd-3wd changeover lever is located to the right of the seat. ● before changing between two- and three-wheel drive, park the machine completely. 2wd 3wd ● use the 2wd setting for blade operation. If you use the 3wd setting, the front wheel will sl...

Page 23

22 5-3 operation of the blade ● for safety reasons, make sure that there are no people or obstacles near the blade before raising or lowering it. ● do not operate the blade while the rake is down. Failure to follow this precaution will result in damage to the rake if the machine is reversed. ● if th...

Page 24

23 5-5 headlight switch the headlights are on when the switch is up and off when it is down. (the front and rear headlights work in tandem.) front/rear headlight switch 5-4 operation of the cultivator ● entering or leaving a bunker via a steep slope or bumpy ground may cause the cultivator to run al...

Page 25

24 part number of points to be greased support point for forward/ reverse pedals 1 support point for brake pedal 1 support point for belt tension lever 1 support point for pump neutral lever 1 rhombic flange unit of front wheel 2 (2wd) 1 (3wd) support point for rear wheel brake lever 2 support point...

Page 26

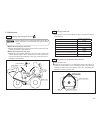

25 ● before adjusting the belt tension, be sure to stop the engine. ● before installing the belt, remove the high nut to loosen the belt tension completely. In doing this, be careful not to get your fingers caught between the belt and the pulley. Belt spring cover spring tension pulley pump pulley e...

Page 27

26 replacement of the engine oil 1st replacement after 8 operating hours 2nd and subsequent replacements every 50 operating hours replacement of the oil filter every 100 operating hours or at the beginning of each season engine oil quantity if only the oil is replaced approx. 1.0 to 1.2 l if the oil...

Page 28

27 ● the hydraulic oil is extremely hot immediately after the machine has been in operation for a long period of time. To avoid burns, wait a short while before removing the drain plug to change the oil. 1. Remove the drain plug from the oil tank in a level area to drain the old hydraulic oil. 2. Re...

Page 29

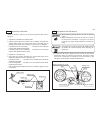

28 6-13 inspection of the battery refer to the instruction manual for the battery. Having cleaned a section around the level lines with a damp cloth, check whether the electrolyte level is between “upper” (maximum level line) and “lower” (minimum level line) limits. If the electrolyte level has fall...

Page 30

29 6-15 maintenance schedule ● perform maintenance earlier than stipulated above if necessary. ● use tools appropriate to the task to be performed. Maintenance items maintenance timing reference engine inspection of oil level before use p.16 and owner’s manual for the engine change of engine oil 1st...

Page 31

30 7. Long-term storage ○ completely remove all mud, grass, and oil from the engine and battery. ○ inspect and replace the engine oil and filter element. ○ refill with oil and apply lubrication/grease to all parts that require lubrication. ○ drain the fuel from the fuel tank. ○ set the air pressure ...

Page 32

31 to magnet switch 1 red red-blue blue black yellow-white yellow-black black-yellow black-white yellow white-red white-black green green-black fuse fuse front light rear light light switch 2 1 3 4 1 2 3 off a b e st ig b bat off on rl rl bw by yb r b y wr wb gb yw g l no no bat r e b ig rl st bw b ...

Page 33

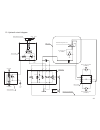

32 rake raise/lower cylinder raise lower 3wd circuit valve module torque generator 2wd-3wd changeover valve in out input shaft output shaft p t pf g 10mpa b1 a1 b a a b r p front wheel motor (2-100bs4s) drain piston pump reverse by pressurization branch metal b2 p3 b1 s1 s2 t 1.0mpa p1 p2 20.6mpa 4....

Page 34

33 2wd-3wd changeover valve valve module motor for right rear wheel front branch metal a b piston pump front wheel motor motor for left rear wheel torque generator input shaft out b3 s2 p2 s1 t b2 a a drain port b b a a a3 a1 b1 g2 b1 a1 p g pf t b b3 b2 a2 g1 b p r b1 p1 in output shaft port name f...

Page 40

Aichi-pref. 442-8530 japan. Fax : ( 053 3) 89- 362 3 head office 1-26, miyuki-cho, toyokawa , tur f c are m ach ine ry te l: (05 33) 8 4-1 390 sp05-um --*% z/10g-00-s .K.