- DL manuals

- Bunn

- Water Dispenser

- AFPO-3 SL

- Service And Repair Manual

Bunn AFPO-3 SL Service And Repair Manual

AFPO-2

AFPO-2 SL

AFPO-3

AFPO-3 SL

FLA

VOR

INP

UT

1

2

WA

TER

INP

UT

REF

ILL

MA

IN

PO

WE

R

2

1

1

2

3

3

3

FLA

VO

R

OU

TPU

T

FLA

VO

R

OU

TPU

T

WA

TER

OU

TPU

T

FLA

VO

R

OU

TPU

T

WA

TER

OU

TPU

T

WA

TER

OU

TPU

T

FLA

VOR

INP

UT

1

2

WA

TER

INP

UT

FLA

VO

R

OU

TPU

T

FLA

VO

R

OU

TPU

T

WA

TER

OU

TPU

T

WA

TER

OU

TPU

T

REF

ILL

MA

IN

PO

WE

R

2

1

1

2

SERVICE & REPAIR MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

41093.0000A 04/08 ©2008 Bunn-O-Matic Corporation

Summary of AFPO-3 SL

Page 1

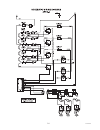

Afpo-2 afpo-2 sl afpo-3 afpo-3 sl fla vor inp ut 1 2 wa ter inp ut ref ill ma in po we r 2 1 1 2 3 3 3 fla vo r ou tpu t fla vo r ou tpu t wa ter ou tpu t fla vo r ou tpu t wa ter ou tpu t wa ter ou tpu t fla vor inp ut 1 2 wa ter inp ut fla vo r ou tpu t fla vo r ou tpu t wa ter ou tpu t wa ter ou ...

Page 2

2 41093 041108 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) compresso...

Page 3

3 user notices all notices on the equipment are written for your protection. All notices are to be kept in good condition. Replace any unreadable or damaged labels. Contents user notices ....................................................................................................................

Page 4

4 cleaning recommended weekly cleaning: this should be done in conjunction with the recommended weekly cleaning of your machine. The hoppers must be empty before starting. 1. Prepare a 1 gallon cleaning solution consisting of 1 gallon of hot water and a sanitizing cleaner which contains 3-5% chlorin...

Page 5

5 1 2 2 1 1 2 3 3 3 mix ratio (water/flavor) time for flavor output (1/2 cup) time for water output (1 cup) 1+1 assume 20 sec. Or obtain time per note below 40 sec. Or 2 times flavor output time 2+1 assume 20 sec. Or obtain time per note below 20 sec. Or equal to flavor output time 3+1 assume 20 sec...

Page 6: Operating Controls

6 fla vor input 1 2 wa ter inp ut refill ma in po we r 2 1 1 2 3 3 3 fla vo r ou tpu t fla vo r ou tpu t wa ter ou tpu t fla vo r ou tpu t wa ter ou tpu t wa ter ou tpu t operating controls a. Main power on/off the main power on/off switch is located on the right of the front panel just above the po...

Page 7

7 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of elect...

Page 8

8 troubleshooting (cont.) problem probable cause 6. Main on/off switch 7. Probe box low/off/high switch- es 8. Circuit board 9. Vacuum switch 10. Vacuum/supply pump 11. Pump (flavor) start switches 1. No water 2. Needle valve 3. Solenoids 1. Motor overheat remedy refer to service - main on/off switc...

Page 9

9 fla vor inp ut 1 2 wa ter inp ut ref ill ma in po we r 2 1 1 2 3 3 3 fla vo r ou tpu t fla vo r ou tpu t wa ter ou tpu t fla vo r ou tpu t wa ter ou tpu t wa ter ou tpu t service this section provides procedures for testing and replacing various major components used in this dispenser should servi...

Page 10

10 j4 j1 j2 j3 service circuit board fig. 2 circuit board p1520 location: the circuit board is located inside the autofill box, mounted on the right side of the solenoid mounting bracket under the switch panel. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the ten ...

Page 11

11 fla vor inp ut 1 2 wa ter inp ut ref ill ma in po we r 2 1 1 2 3 3 3 fla vo r ou tpu t fla vo r ou tpu t wa ter ou tpu t fla vo r ou tpu t wa ter ou tpu t wa ter ou tpu t service location: the fuse holder is located on the lower right front of the autofill box just to the left of the power cord. ...

Page 12

12 fla vor inp ut 1 2 wa ter inp ut ref ill ma in po we r 2 1 1 2 3 3 3 fla vo r ou tpu t fla vo r ou tpu t wa ter ou tpu t fla vo r ou tpu t wa ter ou tpu t wa ter ou tpu t p1522 fig. 7 main on/off switch terminals blk from fuse holder blk to solenoid (water) switch #2 afpo-2 & 3 main on/off switch...

Page 13

13 bu nn probe boxes: 1. Disconnect the signal cable from the probe boxes. 2. Remove probe box from cds hopper. 3. Place the switch on the probe box in the “high” position. 4. Check the resistance across the box cable pins, see fig. 10. 5. With the probe box switch in the “low” position check the re...

Page 14

14 1 2 2 1 1 2 3 3 3 service (cont.) pump (flavor) on/off switches location: the pump (flavor) start switches are located on the switch mounting plate inside the autofill box on the right side. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the wires from the switch...

Page 15

15 1 2 2 1 1 2 3 3 3 service (cont.) refill switches fig. 14 refill switches location: the refill switches are located on the upper right front of the autofill box. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect the two white/red, brown/black or red/black wires fro...

Page 16

16 1 2 2 1 1 2 3 3 3 service (cont.) solenoids fig. 16 solenoids location: the solenoids are located inside the autofill box. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the white/violet, violet or blue wire and the white wire from the solenoid. 3. Connect the di...

Page 17

17 1 2 2 1 1 2 3 3 3 service (cont.) solenoid (water) on/off switches fig.18 solenoid (water) on/off switches p1521 location: the solenoid (water) on/off switches are located on the switch mounting plate inside the autofill box on the right side. Test procedure: 1. Disconnect the dispenser from the ...

Page 18

18 1 2 2 1 1 2 3 3 3 service (cont.) test/operate on/off switch fig. 20 test/operate switch location the test/operate switch is located inside the autofill box on the right side. Test procedures: 1. Disconnect the dispenser from the power source. 2. Remove the black wire from the top center switch t...

Page 19

19 1 2 2 1 1 2 3 3 3 service (cont.) vacuum/supply pump assembly fig. 22 vacuum/supply pump assembly p1521 location: the vacuum/supply pumps are located inside the autofill box. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the white wire from the pump lead and the...

Page 20

20 service (cont.) vacuum/supply pump tube installation fig. 24 tubing start position p1542 rollers pump head tubing key entry port exit port fig. 25 tubing loaded rotor rotor shaft p1541 2. Separate the two halves of the pump and carefully remove the tubing from within. 3. Hold the new pump head as...

Page 21

21 vacuum switches fig. 26 vacuum switches location: the vacuum switches are located inside autofill box, mounted on the left side of the solenoid mounting bracket just below the needle valves. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect flavor input lines. 3. Di...

Page 22

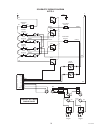

22 piping diagram (afpo-2) the only difference between the afpo-2/3 and afpo-2/3 sl is the sl models have a water output line and a flavor output line for each product. This allows the water and flavor to be mixed in the hoppers. Refer to the illustration below when connecting the lines. 41093 04040...

Page 23

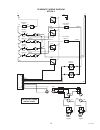

23 grn sol #1 sol #2 pump #1 pump #2 10 amp main on/off switch refill on/off switch #1 refill on/off switch #2 j4-1 2 3 4 5 6 7 8 9 j4-10 c i r c u i t b o a r d l1 n blk blk blk b l k b l k b l k solenoid switch #2 pump sw itch #2 pump sw itch #1 t e s t / o p e r a t e s w i t c h brn/blk brn/blk ...

Page 24

24 41093 040408.

Page 25

25 grn sol #1 sol #2 pump #1 pump #2 10 amp main on/off switch refill on/off switch #1 refill on/off switch #2 j4-1 2 3 4 5 6 7 8 9 j4-10 c i r c u i t b o a r d l1 l2 blk blk blk b l k b l k b l k solenoid switch #2 pump sw itch #2 pump sw itch #1 t e s t / o p e r a t e s w i t c h brn/blk brn/blk...