- DL manuals

- CAB

- Label Maker

- MACH 4.3S/200B

- Operator's Manual

CAB MACH 4.3S/200B Operator's Manual

Summary of MACH 4.3S/200B

Page 1

Made in germany operator's manual mach 4s label printer.

Page 2

2 2 family type mach 4s - mach 4.3s/200b - mach 4.3s/200p - mach 4.3s/200c mach 4s/300b mach 4.3s/300b mach 4s/300p mach 4.3s/300p mach 4s/300c mach 4.3s/300c mach 4s/600b - mach 4s/600p - mach 4s/600c - edition: 01/2018 - part no. 9003058 copyright this documentation as well as translation hereof a...

Page 3

3 1 introduction ............................................................................................................................................ 4 1.1 instructions ..............................................................................................................................

Page 4

4 4 1 introduction 1.1 instructions important information and instructions in this documentation are designated as follows: danger! Draws attention to an exceptionally great, imminent danger to your health or life due to hazardous voltages. ! Danger! Draws attention to a danger with high risk which,...

Page 5

5 1 introduction 1.3 safety instructions • the device is configured for voltages of 100 to 240 v ac. It only has to be plugged into a grounded socket. • only connect the device to other devices which have a protective low voltage. • switch off all affected devices (computer, printer, accessories) be...

Page 6

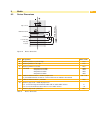

6 6 2 installation 2.1 device overview 1 8 7 6 5 4 3 2 1 cover 2 margin stop 3 roll retainer 4 print module 5 led "power on" 6 control panel 7 touchscreen display 8 label outlet figure 1 overview 9 14 13 12 11 10 9 ribbon unwinder core 10 ribbon rewinder core 11 release button 12 ribbon deflection 1...

Page 7

7 2 installation 2.2 unpacking and setting-up the printer lift the label printer out of the box. Check label printer for damage which may have occurred during transport. Check delivery for completeness. Contents of delivery: • label printer • power cable • usb cable • operator's manual • dvd with la...

Page 8

8 8 3 touchscreen display the user can control the operation of the printer with the control panel, for example: • issuing, interrupting, continuing and canceling print jobs • setting printing parameters, e.G. Heat level of the printhead, print speed, interface configuration, language and time of da...

Page 9

9 with special software or hardware configurations additional symbols appear on the start screen: printing on demand without print job printing on demand within print job direct cut at devices with cutter figure 5 optional symbols on the start screen release printing of a single label within a print...

Page 10

10 10 3.2 navigation in the menu start level selection level parameter/function level figure 7 menu levels to open the menu select on the start screen. Select a theme in the selection level. Several themes have substructures again with selection levels. To return from the current level to the upper ...

Page 11

11 4 loading material 4.1 loading label rolls 4.1.1 adjusting the roll retainer label rolls are supplied with different diameters. The roll retainer can hold label rolls with a core diameter of 38 - 75 mm, or 76 mm with the detachable adapters fitted. 1 2 3 2 4 5 figure 9 adapting the roll retainer ...

Page 12

12 12 4.1.2 loading the label roll 1 5 4 3 2 6 2 figure 10 loading the label roll open the cover and remove the roll retainer (3) with the margin stops (1,5) from the printer. Press the lever (6) and remove the margin stop (5) from the roll retainer (3). Slide the label roll (4) onto the roll retain...

Page 13

13 4.2 loading fanfold media 1 5 4 3 2 6 figure 12 loading fanfold labels stack the labels (2) behind the printer. Ensure that the labels on the strip are facing upwards. Open the cover and unlock and lower the control panel. Feed the media underneath the cover (1) into the printer. Remove the adapt...

Page 14

14 14 4 loading material 4.3 loading labels for peel-off mode ! Attention! Place the printer so that the liner can run down without hindrance. A label jam can cause malfunctions in printing operations. 2 2 1 pressure roller in parking position pressure roller in working position figure 13 activation...

Page 15

15 4 loading material 4.4 selecting and positioning label sensors 4.4.1 gap sensors 3 1a 2a 2b 1b figure 15 selecting the gap sensor the printer has two gap sensors (1, 2) to detect the labels front edge as well as the end of the material, which can be used alternatively. The emitters (1a, 2a) are l...

Page 16

16 16 4 loading material 4.5 loading transfer ribbon i note! Do not insert transfer ribbon for direct thermal printing! ! Attention! Risk of contamination! When inserting the transfer ribbon ensure that the coated side faces the labels, otherwise the printhead will be dirtied. 2 1 3 figure 17 removi...

Page 17

17 4 loading material 8 7 10 9 11 figure 19 loading transfer ribbon remove and adjust the ribbon rewinder core (8) in the same manner. Slide an empty cardboard roll (9) onto the core (8) against the lever. Press the rectangular end of the core against the spring of the tensioning wheel (10) and slid...

Page 18

18 18 5 printing operation ! Attention! Printhead damage caused by improper handling! Do not touch the bottom side of the printhead with fingers or sharp objects. Ensure that the labels are clean. Ensure that the label surfaces are smooth. Rough labels act like emery paper and reduce the service lif...

Page 19

19 6 cleaning 6.1 cleaning information danger! Risk of death via electrocution! Disconnect the printer from the power supply before performing any maintenance tasks. The label printer requires very little maintenance. It is important to clean the thermal printhead regularly. This guarantees a consis...

Page 20

20 20 6 cleaning 6.5 cleaning the cutter i note! When cutting through the label material remains of adhesive may accumulate on the blades. If operating in backfeed mode, such remains of adhesive may be deposited on the drive roller as well. Clean the drive roller and the cutter blades often. 1 1 2 5...

Page 21

21 7 fault correction 7.1 error display the appearance of an error will be shown on the display: figure 22 error display the error treatment is dependent on the error type 7.2 on page 21. The display offers the following possibilities to continue after an error occurred: repeat the print job will be...

Page 22

22 22 7 fault correction error message cause remedy no label size the size of the label is not defined in the programming. Check programming. Out of paper out of label roll load labels. Error in the paper feed check paper feed. Out of ribbon out of transfer ribbon insert new transfer ribbon. Transfe...

Page 23

23 7 fault correction 7.3 problem solution problem cause remedy transfer ribbon creases transfer ribbon deflection not adjusted adjust the transfer ribbon deflection. 4.6 on page 17 transfer ribbon too wide use a transfer ribbon slightly wider than the width of label. Print image has smears or voids...

Page 24

24 24 8 media 8.1 media dimensions labels endless material feed direction figure 23 label / endless material dimensions dim. Designation dim. In mm b label width 6 - 116 h label height in peel-off mode 5 - 2000 20 - 200 - tear-off length > 30 - cut length > 12 a label distance > 2 c width of liner o...

Page 25

25 8.2 device dimensions feed direction gap sensors reflective sensor printhead peel-off edge cut edge tear bar figure 24 device dimensions dim. Designation dim. In mm ip distance printhead - peel-off edge 13,2 ic distance printhead - cut edge 17,5 it distance printhead - tear bar 24,0 k print width...

Page 26

26 26 8.3 reflex mark dimensions labels with reflex marks endless material with reflex marks feed direction virtual label front edge reflex mark figure 25 reflex mark dimensions dim. Designation dim. In mm a label distance > 2 l width of reflex mark > 5 m height of reflex mark 3 - 10 x distance mark...

Page 27

27 8.4 cut-out mark dimensions labels with cut-out marks endless material with cut-out marks feed direction for marginal cut-out marks minimum liner thickness 0,06 mm figure 26 cut-out mark dimensions dim. Designation dim. In mm a label distance > 2 n width of cut-out mark > 5 p height of cut-out ma...

Page 28

28 28 9 licenses 9.1 reference to the eu declaration of conformity the printers of the mach 4s series comply with the relevant fundamental regulations of the eu rules for safety and health: • directive 2014/35/eu relating to electrical equipment designed for use within certain voltage limits • direc...

Page 29

29 10 index a adapter dismounting ................................ 11 mounting ..................................... 11 c cleaning cutter .......................................... 20 label sensors ............................. 19 printhead .................................... 19 print roller .........

Page 30

30 30 this page was left blank intentionally..