- DL manuals

- CAB

- Label Maker

- MACH 4.3S/200B

- Service Manual

CAB MACH 4.3S/200B Service Manual

Summary of MACH 4.3S/200B

Page 1

Made in germany service manual mach 4s label printer.

Page 2

2 2 family type mach 4s - mach 4.3s/200b - mach 4.3s/200p - mach 4.3s/200c mach 4s/300b mach 4.3s/300b mach 4s/300p mach 4.3s/300p mach 4s/300c mach 4.3s/300c mach 4s/600b - mach 4s/600p - mach 4s/600c - edition: 12/2017 - part no. 9003102 copyright this documentation as well as translation hereof a...

Page 3

3 1 introduction ............................................................................................................................................ 4 1.1 instructions ..............................................................................................................................

Page 4

4 4 1.1 instructions important information and the instructions in the documentation are designed as follows: danger! Draws attention to an exceptionally great, imminent danger to your health or life due to hazardous voltages. ! Danger! Draws attention to a danger with high risk which, if not avoide...

Page 5

5 1.1 general safety this service manual is intended for qualified service and maintenance personnel. Further information to the operation of the device can be found the operator's and configuration manuals. The following rules are for your general safety • keep the area during and after maintenance...

Page 6

6 6 1 introduction 1.3 handling electricity the following operations may only be performed by qualified electricians: • any labor performed on electrical component groups. • operations performed on the opened device while it is connected to the power grid. General precautions when commencing mainten...

Page 7

7 2 changing assembly parts 2.1 tools • do not use worn or damaged tools. • only use tools and test devices for their designed purposes. Specialized tools(cab in-house produced): • test devices ribbon holders (cab part no.: 5540932) • assembly assistance coupling (cab part no.: 5541180) • cylindrica...

Page 8

8 8 2 changing assembly parts 2.3 dismounting the cover danger! Risk of death by electrocution. before opening or dismounting the cover disconnect the device from the power grid and wait at least one minute until the device has discharged. 1 1 1 2 3 1 fig. 2 dismounting the cover the printer cover...

Page 9

9 2 changing assembly parts 2.4 changing the print mechanism danger! Risk of death by electrocution. before opening or dismounting the cover disconnect the device from the power grid and wait at least one minute until the device has discharged. 6 1 2 3 4 5 6 3 2 7 8 9 fig. 3 changing the print mec...

Page 10

10 10 2.5 changing the printhead changing a printhead can be completed without fine adjustments to the printer. Changing the printhead is necessary when it is worn or a change of printing resolution is needed. 1 2 3 3 4 1 connector data 2 connector power 3 threaded holes 4 heating element fig. 4 ass...

Page 11

11 2 changing assembly parts 5 6 7 9 8 6 12 13 12 6 16 15 14 14 10 10 11 fig. 5 changing the printhead removing the printhead 1. Open the cover and fold the control panel (7) down. Push the energy regulator (5) and fold the printing module up with the printhead retainer (6). 2. Take the material out...

Page 12

12 12 2 changing assembly parts 2.6 changing the print roller 1 2 3 6 5 4 fig. 6 changing the print roller 1. Open the cover and fold the control panel down. Push the unlocking mechanism and fold the printing module up. 2. Through the openings on both sides, push the pressure points (1) until the pr...

Page 13

13 2 changing assembly parts 2.7 changing the clutch and brake of the ribbon rewinder the clutch (4) is a pre-constructed assembly group, the brake consists of the form disks (5, 7), the friction disk (6) and three springs (9). 2 1 3 4 5 6 7 8 9 11 10 fig. 7 changing the clutch and brake of the ribb...

Page 14

14 14 2 changing assembly parts 2.8 changing the brake of the ribbon unwinder 3 2 1 8 6 5 4 7 5 6 7 10 9 11 11 10 9 12 fig. 8 changing the brake of the ribbon unwinder 1. Fold up the printhead assembly group, undo the three screws (3) and remove the cover (2). 2. Insert the ribbon retainer (1). 3. U...

Page 15

15 2 changing assembly parts 2.9 changing the drive of the cutter 2 3 8 5 6 4 7 3 2 1 9 10 11 12 10 9 fig. 9 changing the drive of the cutter 1. Fold down the control panel (1), release the cutter (4) from the brackets (3) and fold this up too. 2. Unhook the springs (3). 3. Disconnect the plug (7). ...

Page 16

16 16 2 changing assembly parts 2.10 changing the blade of the cutter unit 2 3 7 4 5 6 2 1 8 9 10 12 11 fig. 10 changing the blade of the cutter unit ! Danger! Danger of lacerations! do not touch the blade without protective measures. 1. Fold down the control panel (1). 2. Release the cutter unit ...

Page 17

17 2 changing assembly parts 2.11 changing the circuit board danger! Danger of electrocution. before opening the pinter cover disconnect the device from the power source and wait at least one minute until the device has discharged the remaining residual energy. 2 1 2 3 2 4 9 5 6 2 8 7 1 circuit bo...

Page 18

18 18 2 changing assembly parts 2.12 changing the power supply warning! Risk of death by electrocution! before opening the cover plate remove the device from the power supply and wait at least one minute until the residual energy has dissipated. 1 2 2 2 3 fig. 12 changing the power supply 1. Remov...

Page 19

19 3 adjustments 3.1 measuring the winding force the measurement of the un- and re-winding torque of the ribbon is determined by the tensile force on the test material that is connected to the ribbon retainer. The physical connection between the torque and tensile force is as follows. F= m / r f: fo...

Page 20

20 20 3 adjustments 3.1.2 measuring the breaking force of the unwinder 1 2 a b c 3 1 2 3 1 2 3 fig. 14 measuring the breaking force of the unwinder target value measurement torque m force f break of the unwinder ribbon c 3,9 - 4,5 ncm 1,3 - 1,5 n 1. Insert the test device (3) onto a ribbon retainer ...

Page 21

21 3.2 setting the winding force 8 7 6 5 1 2 3 4 fig. 15 setting the winding force the settings of the winding force of the break (5) of the unwinder and the clutch (6) of the rewinder is done in the same way. 1. Insert the ribbon retainer (4) onto the winders. 2. Fold the printhead assembly group u...

Page 22

22 22 3 adjustments 3.3 adjusting the print mechanism changing the settings of the printing mechanic over and above a format change is only necessary when something other than the printhead is exchanged or if the printhead assembly group has been demounted or altered. The following identifiers point...

Page 23

23 3 adjustments screw for adjusting the camber (3) - by turning the screw clockwise the printhead will be changed minimally in the center causing pressure in the middle of the printhead. If all else fails to decrease creases in the ribbon the printhead can be altered by turning the screw clockwise....

Page 24

24 24 4 troubleshooting and error treatment 4.1 failure of device functions function error possible solutions no material transport check electronic connection between the cpu circuit board and the motor check the drive mechanism exchange the cpu circuit board exchange the motor no printed image at ...

Page 25

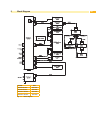

25 5 block diagram printer nr.1 mach 4s/300... 5977444 mach 4s/600... 5977380 mach 4.3s/200... 5977382 mach 4.3s/300... 5977383 fig. 17 block diagram.

Page 26

26 26 6 layout diagram pcb cpu 1 l6 12 r 130 l57 c185 r 323 b6 22 c3 91 r37 p6 r 131 r33 r 159 2 r 304 v19 1 g b + c1 3 k r 61 r220 v1 1 g x1 v m r 305 top21 n r22 c14 r 268 l2 7 1 v1 r 64 l12 ac c16 v 18 9 c205 c208 10 r 270 c 341 l b3 a1 c73 c 255 20 c 211 4 r169 5 c192 c 256 l43 l15 c214 1 r70 1 ...

Page 27

27 7 index a adjustable elements .........................22 adjusting the print mechanism ......... 22 b block diagram ...................................25 c changing the brake of the ribbon unwinder ...................... 14 changing the clutch and brake of the ribbon rewinder ......................