CAC / BDP FOR BYPASS AND FAN POWERED HUMIDIFIERS Owner's Manual

STANDBY GENERATOR

OWNER'S MANUAL

This manual should remain with the unit.

A new standard of reliability

Serial Number

4.2L

48kW

Models

Not intended for use in critical life support applications.

ONLY QUALIFIED ELECTRICIANS OR CONTRACTORS SHOULD ATTEMPT INSTALLATION!

DEADLY EXHAUST FUMES. OUTDOOR INSTALLATION ONLY!

—

CAUTION—

Cover138 Re

v. A 07/08

Par

t No

. 0H0170

Summary of FOR BYPASS AND FAN POWERED HUMIDIFIERS

Page 1

Standby generator owner's manual this manual should remain with the unit. A new standard of reliability serial number 4.2l 48kw models not intended for use in critical life support applications. Only qualified electricians or contractors should attempt installation! Deadly exhaust fumes. Outdoor in...

Page 2

Standby generator sets table of contents section page safety rules ......................................................... 1-1 introduction .....................................................1-3 read this manual thoroughly ...................................1-3 operation and maintenance ...........

Page 3: Warning:

Study these safety rules carefully before install- ing, operating or servicing this equipment. Become familiar with this owner’s manual and with the unit. The generator can operate safely, efficiently and reli- ably only if it is properly installed, operated and maintained. Many accidents are caused...

Page 4

• before performing any maintenance on the gen- erator, disconnect its battery cables to prevent accidental start-up. Disconnect the cable from the battery post indicated by a negative, neg or (–) first. Reconnect that cable last. • never use the generator or any of its parts as a step. Stepping on ...

Page 5: Introduction

1-3 introduction thank you for purchasing this model of the standby generator set product line. Every effort was expended to make sure that the information and instructions in this manual were both accurate and current at the time the manual was written. However, the manufacturer reserves the right ...

Page 6: Identification Record

Identification record data label every generator set has a data label that contains important information pertinent to the generator. The data label, which can be found attached to the gen- erator’s lower connection box, lists the unit’s serial number and its rated voltage, amps, wattage capacity, p...

Page 7: Equipment Description

Equipment description this equipment is a revolving field, alternating cur- rent generator set. It is powered by a gaseous fueled engine operating at 1800 rpm for 4-pole direct drive units, 3600 rpm for 2-pole direct drive units and 2300 - 3000 rpm for quiet drive gear units. See the specifications ...

Page 8: Engine Protective Devices

Engine protective devices the standby generator may be required to operate for long periods of time without an operator on hand to monitor such engine conditions as coolant tempera- ture, oil pressure or rpm. For that reason, the engine has several devices designed to protect it against potentially ...

Page 9: Fuel System

Fuel system fuel requirements the standby generator may be equipped with one of the following fuel systems: • natural gas fuel system • propane vapor (pv) fuel system the manual drawing listing that is affixed to the unit includes the “identification code,” which may be used to identify the type of ...

Page 10: Specifications

Specifications generator type ............................................................................. Synchronous rotor insulation ................................................................... Class h stator insulation .................................................................. Cl...

Page 11

Cold weather kit for cold climates, optional cold weather kit (part number 0f6148) is recommended. The kit includes: battery warmer • 4” junction box with hardware • 6 qt. Pack 5w-30 synthetic oil (engine) • coolant heater kit the optional coolant heater kit (part number 0g6446) is available to be u...

Page 12: 4.2L Ignition Description

6-3 standby generator sets specifications genspec053 rev. A 07/08 3. Disconnect the power wires from the fuel sole- noid located on top of the regulator assembly. 4. Loosen the spring clamp on the small fuel enrich- ment line and remove the hose from the hose barb. 5. Remove the black pipe assembly ...

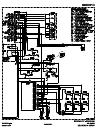

Page 13: Alternator Power Winding

Generator ac lead connections see “voltage codes”. This generator may be rated at any one of three voltages, either single-phase or three-phase. The electrical wires in the unit’s ac con- nection (lower) panel should be installed according to the number of leads and the voltage/phase required for th...

Page 14

Figure 7.4 — stator power winding connections - 3-phase, 346/600v (6 lead) s6 e3 s3 internal connections l-n l-l s4 e2 s2 s5 s1 e1 neutral 3-phase alternators ("delta" configuration) the generator is designed to supply 3-phase electrical loads. Electric power is produced in the alternator power wind...

Page 15: Installation

Installation refer to the separate “installation guide” supplied with the unit. Preparation before start-up the instructions in this section assume that the standby generator has been properly installed, ser- viced, tested, adjusted and otherwise prepared for use by a competent, qualified installati...

Page 16: Start-Up Checklist

• battery charger connection to 120 vac. • communication wires connected between transfer switch and generator (hts only). • unit secured to pad. Start-up checklist before working on the generator, ensure the fol- lowing: • the auto/off/manual switch is in the off position. • the 120vac supply to th...

Page 17: Generator Control and

Generator control and operation refer to the appropriate control panel operator’s manual for this unit. Operating unit with manual transfer switch if the generator was installed in conjunction with a transfer switch capable of manual operation only, the following procedure applies. A manually operat...

Page 18: Maintenance Performed By

Maintenance performed by service dealer before working on the generator, ensure the fol- lowing: • the auto/off/manual switch is in the off position. • the 15a fuse has been removed from the con- trol box. • the 120vac supply to the battery charger is switched off. • the negative battery cable has b...

Page 19: Maintenance Owner/

Figure 10.2 - oil dipstick and oil fill cap oil fill cap oil filter oil dipstick battery fluid check battery electrolyte fluid based on the maintenance schedule. Fluid should cover separa- tors in all battery cells. If fluid level is low, add dis- tilled water to cover tops of separators. Do not use...

Page 20

Inspect exhaust system inspect the exhaust system at least once every three months. Check all exhaust system pipes, mufflers, clamps, etc. For condition, tightness, leaks, security, damage. Check fan belt • inspect fan belts every three months. Replace any damaged, deteriorated, worn or otherwise de...

Page 21: Miscellaneous Maintenance

Spark plugs reset the spark plug gap or replace the spark plugs as necessary. 1. Clean the area around the base of the spark plugs to keep dirt and debris out of the engine. Clean by scraping or washing using a wire brush and commercial solvent. Do not blast the spark plugs to clean. 2. Remove the s...

Page 22: Repair Parts

Danger storage batteries give off explosive hydrogen gas. This gas can form an explosive mixture around the battery for several hours after charg- ing. The slightest spark can ignite the gas and cause an explosion. Such an explosion can shat- ter the battery and cause blindness or other injury. Any ...

Page 23: Service Schedule

Service schedule 30 kw - 150 kw standby gas engine driven generator sets the following is a recommended maintenance schedule for standby gas engine driven generator sets from 30kw to 150 kw in size. The established intervals in the schedule are the maximum recommended when the unit is used in an ave...

Page 24

Maintenance level 1 level 2 level 3 level 4 level5 tasks recom- task required task required task task required task mended comp. To be done comp. To be done comp. Required comp. To be done comp. To be done (date- 3 months/ (date- semi- (date- to be done (date- bi- (date- monthly/ initials) break-in ...

Page 25

Maintenance level 1 level 2 level 3 level 4 level5 tasks recom- task required task required task task required task mended comp. To be done comp. To be done comp. Required comp. To be done comp. To be done (date- 3 months/ (date- semi- (date- to be done (date- bi- (date- monthly/ initials) break-in ...

Page 26

Maintenance level 1 level 2 level 3 level 4 level5 tasks recom- task required task required task task required task mended comp. To be done comp. To be done comp. Required comp. To be done comp. To be done (date- 3 months/ (date- semi- (date- to be done (date- bi- (date- monthly/ initials) break-in ...

Page 27: Troubleshooting Guide

Troubleshooting guide problem cause correction engine won’t crank. 1. 15 amp fuse blown. 1. Replace fuse. 2. Loose or corroded or defective 2. Tighten, clean or replace battery cables. Battery cables as necessary. 3. Defective starter contactor. 3. Replace contactor.* 4. Defective starter motor. 4. ...

Page 28

Standby generator sets notes.

Page 29

Standby generator sets notes.

Page 31

1 0g6568 1 rtr 390 45ad1 cpl 0g6562 1 rtr 390 35ad1 cpl 0g6564 1 rtr 390 35kd1 cpl 0g6570 1 rtr 390 45kd1 cpl 2 0g6569 1 str 390 45ad1 cpl 0g6563 1 str 390 35ad1 cpl 0g6566 1 str 390 35kd1 cpl 0g6565 1 str 390 35gd1 cpl 0g6572 1 str 390 45kd1 cpl 0g6571 1 str 390 45gd1 cpl 0g6365 1 str 390 45jd1 cpl...

Page 33

1 0f3137 1 pan cb conn box 2 0f3188 1 stand rh control 3 0f3189 1 stand lh control 4 023484n 1 bushing snap sb-2.5-31 5 0f6366b 1 xfmr dual 120v/16v (for 120/240v & 277/480v units) 0f6366a 1 xfmr dual 104v/16v (for 120/208v units) 6 043180 2 washer flat m4 7 022264 2 washer lock #8-m4 8 0c3990 2 scr...

Page 35

5) ul circuit breaker (qj-2p) a 0f8137 1 cover qj 2p frm cb c 0e7994 - cb 0225a 240v 2p s qj22 d 0f8136 1 cover qj 2p cb dish e 036261 4 rivet pop .125 x .275 ss f 022473 2 washer flat 1/4-m6 zinc g 022097 2 washer lock m6-1/4 h 022127 2 nut hex 1/4-20 steel j 0f8139 1 insul cb 2p qj k 0c2454 9 scre...

Page 37

1 0g5313 1 weldment baseframe 4.2l g3 2 052860 4 nut flanged hex m12-1.75 3 052251 4 dampener vibration 40 blue 4 052257 4 spacer .49 x .62 x 1.87 pwdr/znc 5 052252 4 dampener vibration 6 052259 4 washer flat m12 7 052891 4 screw hhc m12-1.75 x 80 g8.8 8 0536210410 1 assy wire 14.00" 9 042909 1 scre...

Page 39

1 0f3408 1 tray battery 2 0f3411 1 strap battery retainment 3 051768 1 screw hhc m12-1.75 x 25 g8.8 4 022145 1 washer flat 5/16-m8 zinc 5 022195 1 washer lock 1/2 6 022304 1 washer flat 1/2 zinc 7 050331a 1 battery post cover red + 8 050331 1 battery post cover black - 9 038804u 1 cable batt red #1 ...

Page 41

1 0e6586 1 gasket bosch 32 & 40 2 0e0519a 1 adapter carburetor w/pvc conn 3 0c8127 1 element air cleaner 4 049815 4 screw hhc m5-0.8 x 16 g8.8 5 022127 1 nut hex 1/4-20 steel (1) 6 062974 1 stud th 1/4-20 x 4-1/2 g2 znc 7 0g0190 1 plate, air cleaner top 2.4l 8 037561 1 nut wing 1/4-20 nylk (1) apply...

Page 43

1 0g68030st03 1 weldment radiator support c2 2 0f2608a 1 radiator 598 x 568 x 49,cpl lh 3 0e3256 1 v-belt a58 (60in o.C.) ddc s60 4 046526 5 washer lock m10 (1) 5 059981 4 screw hhc m10-1.5 x 30 g10.9 6 0f2776a 1 bracket, signal conditioner (used only with qta product) 7 0f5050a 1 shield radiator c4...

Page 45

1 0g4969 1 engine 4.2l g3 (fwd) 2 047411 4 screw hhc m6-1.0 x 16 c8.8 3 022097 10 washer lock m6-1/4 4 022473 4 washer flat 1/4-m6 zinc 5 0e6585 1 cover iac actuator 6 0g6434 2 shield spark plug boot rh 7 036261 10 rivet pop .125 x .275 ss 8 022145 7 washer flat 5/16-m8 zinc 9 022129 7 washer lock m...

Page 49

1 026915 2 nipple close 3/4 x 1.375 2 075580 1 flange fuel inlet 3 0f6390e 1 regulator assy 4.2l 45kw 0f6390f 1 regulator assy 4.2l 35kw 4 039253 2 screw hhc m8-1.25 x 20 g8.8 5 022145 2 washer flat 5/16-m8 zinc 6 022129 2 washer lock m8-5/16 7 045771 2 nut hex m8-1.25 g8 clear zinc 9 0e8286 1 stree...

Page 51

1 0f9794 2 muffler 7" x 9" x 18-1/2" 2" in/out 2 0g0113 1 exhaust elbow 2"id x 2-1/2"od 3 0g1007 1 bracket muffler 4 0f2830 2 muffler bracket stiffener 5 0f2962 2 muffler strap 6 080762 5 bolt u 3/8-16 x 2.62 7 0g5821 1 pipe exhaust left 2"od 8 0c2454 4 screw thf m6-1 x 16 n wa z/js 9 0g5822 1 pipe ...

Page 53

1 0g0045 (xx) 1 rear wrap c2 cpl 2 0c2454 54 screw thf m6-1 x 16 n wa z/js 3 0f5849 (xx) 2 door c2 4 087233 2 rivet pop .1875 x .450 ss 5 0e3257 4 screw th-frm m6 w/cap shkprf w 6 0f5852 (xx) 2 discharge duct lh & rh side c2 7 0f9833 (xx) 2 front corners c2 8 0f5851 (xx) 1 discharge center duct c2 9...

Page 69

Components included in 0g8458e 1 0f1823b 1 encl hsb control panel 2 0f3078bst06 1 cover control panel r-200b 3 0f2606 1 hinge continuous h-panel 4 036261 7 rivet pop .125 x .275 ss 5 0e7358 4 screw ppph hi-lo #4-24 x 3/8 6 052777 1 washer flat m3 7 0g8455a 1 assy pcb r-200b cntrl 1800 *8 0f1262 ref....

Page 71

1.) c2 units a 0f9832 1 shield conn box c2 0f9832ggs0r 1 shield control stand c2 b 0c2454 4 screw thf m6-1 x 16 n wa z/js 2.) c3 units a 0f9832b 1 shield control stand c3 0f9832kgs0r 1 shield control stand c3 b 0c2454 3 screw thf m6-1 x 16 n wa z/js 3.) c4 units a 0f9832a 1 shield control stand c4 b...

Page 72

Copyright 2008 cac / bdp d 7310 w. Morris st. D indianapolis, in 46231 printed in u.S.A. Edition date: 07/08 manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations. Catalog no: omaspfy048a---01 replaces: new.