- DL manuals

- Camus Hydronics

- Boiler

- DMC083

- Installation, Operation And Service Manual

Camus Hydronics DMC083 Installation, Operation And Service Manual

6226 Netherhart Road, Mississauga, Ontario, L5T 1B7

99-0212

Rev. 00

INSTALLATION OPERATION

AND SERVICE MANUAL

GAS FIRED WALL HUNG & FLOOR MOUNT RESIDENTIAL

COMMERCIAL STAINLESS STEEL BOILERS

DynaMax HS SERIES

HYDRONIC HEATING

Models; DMH081, 101, 151, 201, 251,

211, 261, 291, 391, 501, 601, 701, 801

HOT WATER SUPPLY

Models; DMW082 ,102, 152, 202, 252,

212, 262, 292, 392, 502, 602, 702, 802

COMBINATION HEATING/HOT WATER SUPPLY

Models; DMC083, 103, 153, 203, 253,

213, 263, 293, 393, 503, 603, 703, 803

H

HLW

WARNING:

If the information in these instructions is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or death

Do not store or use gasoline or other flammable

vapours and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

o

Do not try to light any appliance,

o

Do not touch any electrical switch; do not

use any phone in your building,

o

Immediately call your gas supplier from a

neighbour’s phone. Follow the gas

supplier’s instructions,

o

If you cannot reach your gas supplier, call

the fire department.

Qualified installer, service agency or the

gas supplier must perform installation and

service.

To the Installer: After installation, these instructions

must be given to the end user or left on or near the

appliance.

To the End User: This booklet contains important

information about this appliance. Retain for future

reference.

CAMUS HYDRONICS LTD.

Summary of DMC083

Page 1

6226 netherhart road, mississauga, ontario, l5t 1b7 99-0212 rev. 00 installation operation and service manual gas fired wall hung & floor mount residential commercial stainless steel boilers dynamax hs series hydronic heating models; dmh081, 101, 151, 201, 251, 211, 261, 291, 391, 501, 601, 701, 801...

Page 3

Contents part 1 general information ............................................................................................................... 1 1.1 introduction .............................................................................................................................. 1 1.2 ...

Page 4

4.11 relief valve................................................................................................................................ 18 4.12 dhw tuning valve (combination models only) ....................................................................... 18 part 5 electrical & controls...

Page 5

10.9 domestic hot water with plate heat exchanger ............................................................ 56 10.10 temperature rise at full firing rate .................................................................................. 57 10.11 lead lag setup .......................................

Page 6

1 part 1 general information 1.1 introduction the dynamax hs boiler is a fan assisted boiler based on a push through design which offers several venting options. Heat output is controlled by a one to one air/gas ratio control gas valve which provides seamless modulation. The boiler provides central ...

Page 7

2 1.5.2 end of sequence 1) setpoint temperature is satisfied. 2) power to the gas valve is turned off. 3) combustion air fan ramps to a stop over the factory preprogrammed time period. 4) thermostat is now in standby mode waiting for the next “call for heat”. Warning to minimize the possibility of s...

Page 8

3 1.8 removal of existing appliance when an existing appliance is removed from a common venting system, the common venting system is likely to be too large for proper venting of the appliances remaining connected to it. At the time of removal of an existing appliance, the following steps must be fol...

Page 9

4 • the appliance must be installed so that the ignition system components are protected from water (dripping, spraying, etc.) during appliance operation and service (circulator replacement, control replacement, etc.) • appliances located in a residential garage and in adjacent spaces that open to t...

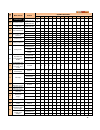

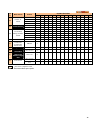

Page 10

5 table 2: dynamax hs wall hung service clearances model service clearance, inches (cm) front top right side left side rear 80 24” (61cm) 3” (8 cm) 4” (10 cm) 4” (10 cm) 0” (0 cm) 100 24” (61cm) 3” (8 cm) 4” (10 cm) 4” (10 cm) 0” (0 cm) 150 24” (61cm) 3” (8 cm) 4” (10 cm) 4” (10 cm) 0” (0 cm) 200 24...

Page 11

6 table 4: dynamax hs floor mount service clearances model service clearance, inches (cm) front top right side left side rear 210 12” (31cm) 24” (61cm) 0” (0cm) 12” (31cm) 14” (36 cm) 260 12” (31cm) 24” (61cm) 0” (0cm) 12” (31cm) 14” (36 cm) 299 12” (31cm) 24” (61cm) 0” (0cm) 12” (31 cm) 14” (36cm) ...

Page 12

7 figure 5: dynamax hs wall hung service clearances figure 6: dynamax hs floor mount service clearances.

Page 13

8 part 2 air inlet and venting it is extremely important to follow these venting instructions carefully. Failure to do so can cause severe personal injury, death or substantial property damage. 2.1 general venting guide the dynamax hs wall hung is a category iv condensing appliance, 97% efficient un...

Page 14

9 table 6: maximum flue temperature for various vent materials vent material maximum flue temperature [ o f] pvc 149 cpvc 194 ppe 230 al29-4c 300+, limited only by rating of seals 316l stainless steel 300+, limited only by rating of seals stack temperature is typically between 15-30 o f above inlet ...

Page 15

10 air inlet point for multiple boiler air inlets must be provided with an exterior opening which has a free area equal to or greater than the total area of all air inlet pipes connected to the common air inlet. This exterior opening for combustion air must connect directly to the outdoors. The tota...

Page 16

11 location of a sidewall air inlet cap 1) total length of piping for air inlet must not exceed the limits stated in table 7. 2) point of termination for the sidewall air inlet cap must be located a minimum of 12 inches (0.30m) away from the flue gas termination, but never above. 3) air piping must ...

Page 17

12 location of a vertical air inlet opening 1) the total length of piping for inlet air must not exceed the limits given in table 7. 2) the air inlet consists of two 90 o elbows installed at the point of termination for the vertical air inlet pipe. A 90 o elbow and a 90 o street elbow may be used to...

Page 18

13 part 3 gas connection verify that the appliance is supplied with the type of gas specified on the rating plate. Consult factory for installations at high altitude. 3.1 gas connection • safe operation of unit requires properly sized gas supply piping. See gas line sizing data. • gas pipe size may ...

Page 19

14 important upon completion of initial installation or following any repair work on the gas system, leak test all gas connections with a soap solution while the main burner is firing. Immediately repair any leak found in the gas train or related components. Do not operate an appliance with a leak i...

Page 20

15 this appliance uses a single cylindrical burner installed horizontally into the cavity located in the center of the heat exchanger. A unique burner is used for each one of the dynamax hs models. Burners may not be interchanged between different btu/hr input models. The burner consists of a round ...

Page 21

16 shelter will help to minimize nuisance problems with electrical connections and will allow easier servicing of the appliance under severe weather conditions. 4.2 warning regarding chilled water systems when an appliance is connected to an air conditioning system where the same water is used for h...

Page 22

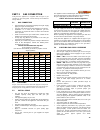

17 condominiums, apartments and motels and typically used in conjunction with tempering valves to achieve temperature control. Table 11: flow and pressure drop at a given temperature rise (hydronic heating) input, btu/hr 30 °f (16.7 °c) 35 °f (19.4 °c) temp rise temp rise usgpm (min. Flow) ∆∆∆∆ p ft...

Page 23

18 4.8 flow proving device (wall mount models and combination models only) figure 20: flow proving device the flow proving device is designed to detect when flow is present. This is done by detecting the amount of current (amperes) that exists in the neutral wire from the pump. When the current beco...

Page 24

19 part 5 electrical & controls it is extremely important that this unit be properly grounded! 5.1 electrical conections table 14: dynamax hs electrical requirements dynamax hs maximum amp draw model voltage requirement full load amps [amperes] maximum over current protection [amperes] 81, 82, 83 12...

Page 25

20 5.3.2 ignition module lockout functions the dynamax hs controller may lockout in either a manual reset condition requiring pushing the reset button to recycle the control for a csd1 requirement or an automatic reset condition. Pushing the “ok” with the control in a hard lockout condition is the o...

Page 26

21 part 6 control panel 6.1 dynamax hs controller the appliance is provided with an operator interface panel at the front. On a dynamax hs wall hung boiler the dynamax hs controller can be accessed by removing the upper stainless steel jacket and the lower black sheetmetal jacket which are each held...

Page 27

22 parameter description boiler name dynamax hs model state indicates current boiler operation sequence demand indicates origin of call for heat (ch, dhw, lead lag) access status user, installer outdoor outdoor temperature [ o f], if equipped error alert or lockout. Section 5.4 provides additional d...

Page 28

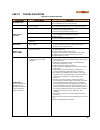

23 central heat programming instructions modulation: boiler inlet, boiler fixed setpoint operation (standalone) description electrical connection(s) programming instructions • boiler operates at a fixed setpoint • modulates on boiler inlet sensor (default) • heat demand is generated when remote oper...

Page 29

24 modulation: boiler inlet, outdoor reset operation (standalone) description electrical connection(s) programming instructions • boiler operates with variable setpoint determind by outdoor reset curve • modulates on inlet sensor (default) • heat demand is generated when remote operator is closed. 1...

Page 30

25 modulation: system sensor, outdoor reset operation (standalone) note: outdoor reset module (pn: 50022037-001) and outdoor sensor (pn: c7089u1006) required description electrical connection(s) programming instructions • boiler operates with variable setpoint determind by outdoor reset curve • modu...

Page 31

26 4-20ma/ 0-10vdc setpoint operation (standalone) consult additional boiler parameters section in manual on page 33 using parameter address 583 and 584. 4-20ma/ 0-10vdc firing rate operation (standalone) description electrical connection(s) programming instructions • boiler operates with variable s...

Page 32

27 domestic hot water programming instructions modulation: fixed setpoint operation (standalone) description electrical connection(s) programming instructions • boiler operates at a fixed dhw setpoint • modulates on boiler inlet sensor (default) • heat demand is generated when remote operator is clo...

Page 33

28 instantaneous dhw with brazed plate heat exchanger (combination models) description electrical connection(s) programming instructions • boiler operates at a fixed dhw setpoint • modulates on boiler inlet sensor (default) • heat demand is generated when remote operator is closed. Dhw sensor/ stat,...

Page 34

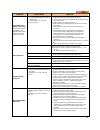

29 lead lag programming instructions master boiler description electrical connection(s) programming instructions • master boiler lead lag setup 1) place both toggle switches in local 2) press and select login 3) select advanced setup 4) select system 5) select system id & access 6) verify mb1 modbus...

Page 35

30 slave boiler description electrical connection(s) programming instructions • slave boiler lead lag setup 1) place both toggle switches in local 2) press and select login 3) select advanced setup 4) select system 5) select system id & access 6) select mb1 modbus address = 2. To be in sequential or...

Page 36

31 outdoor sensor connected to slave boiler 2 (drh only) description electrical connection(s) programming instructions • slave boiler outdoor sensor configuration • when done correctly, the outdoor temperature will be shown on the master boiler slave boiler 1) place both toggle switches in local 2) ...

Page 37

32 base load rate adjustment description electrical connection(s) programming instructions • upon a call for heat the lead boiler will fire to the specified base load rate (80%). If the temperature is not within error threshold (5 o f) of setpoint after interstage delay (2 minutes) a lag boiler will...

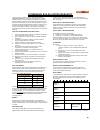

Page 38

33 additional boiler parameter instructions there are some parameters that are not accessible through the advanced setup within the hapi display. Temperature related parameters must be entered in degrees celcius. For example, 50 o f = 10.0 o c. The value “100” is entered into the display. Refer to t...

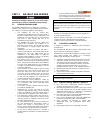

Page 39

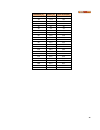

34 fahrenheit [ o f] celcius [ o c] enter into display -20 -28.9 -289 -10 -23.3 -233 0 -17.8 -178 10 -12.2 -122 20 -6.7 -67 30 -1.1 -11 40 4.4 44 50 10.0 100 60 15.6 156 70 21.1 211 80 26.7 267 90 32.2 322 100 37.8 378 110 43.3 433 120 48.9 489 130 54.4 544 140 60.0 600 150 65.6 656 160 71.1 711 170...

Page 40

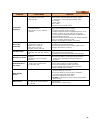

35 boiler setup programming instructions adjust lightoff rate description programming instructions • adjust ignition speed on lightoff • this may need to be adjusted to achieve smooth lightoffs cannot be achieved through combustion settings • all dynamax hs boilers leave the factory with an ignition...

Page 41

36 view burner run time, pump cycles description programming instructions • to view burner run time, pump cycles for maintenance and service purposes 1) place both toggle switches in local 2) press and select login 3) select advanced setup 4) select system config 5) select statistics config.

Page 42

39 part 7 components 7.1 direct spark igniter the direct spark igniter is inserted directly through the combustion chamber front door and held in place by two torx-20 screws. Care must be taken when removing and/or installing the igniter. Always remove the igniter prior to removing the fan assembly ...

Page 43

40 part 8 troubleshooting table 18: troubleshooting table component failure mode analysis incoming power • two wires interchanged • no effect on safety • live and neutral wires are interchanged. Transformer tripped • the 24volts and 120 volts wired are interchanged • transformer immediately burns ou...

Page 44

41 symptom failure mode analysis flame disappears during a run cycle (pressing the manual ok button on the dynamax hs control panel to restart the ignition sequence) • the dynamax hs boiler was running and flame signal suddenly disappeared. • lockout: 106, 107, 108, 109 • alert 149, 150 • verify tha...

Page 45

42 symptom failure mode analysis temperature overshoot • stack temperature has exceeded the limit set on the boiler. • alert 125, 353 • pvc: reduce desired setpoint to less than 140 o f. • measure the resistance of the flue sensor at room temperature, it should be approximately 10k Ω . • pvc: 149 o ...

Page 46

43 manual reset codes* # description 0 none 1-31 internal hardware error 47 flame rod to ground leakage 49 24vac low/high 64 fan speed not proved, ignition failure 67 blocked flue condition 79 heater outlet high limit tripped 82 stack limit tripped (pvc: 149 o f, cpvc: 194 o f, ppe: 230 o f, ss, al2...

Page 47

44 ignition failed displayed on screen hold 109: ignition failed an ignition error occurs when 3 consecutive attempts at lighting the burner have failed. This is a manual reset error where the technician must press ok to clear the error. Check for constant spark for 6 seconds across spark igniter no...

Page 48

45 hold 67: ilk off (flow switch, lwco, gas pressure switch, blocked flue switch) alert 303: abnormal recycle: ilk off during drive to purge alert 304: abnormal recycle: ilk off during measured purge time alert 305: abnormal recycle: ilk off during drive to pre-igntion alert 306, 307: abnormal recyc...

Page 49

46 hold 67: ilk off (flow switch, lwco, gas pressure switch, blocked flue switch) alert 303: abnormal recycle: ilk off during drive to purge alert 304: abnormal recycle: ilk off during measured purge time alert 305: abnormal recycle: ilk off during drive to pre-igntion alert 306, 307: abnormal recyc...

Page 50

47 stack limit exceeded displayed on screen alert 125: modulation was limited due to stack limit alert 353: abnormal recycle: stack limit a flue gas error occurs when the stack temperature has exceeded the maximum limit allowed by the vent material. This is an automatic reset error, when the stack t...

Page 51

48 alert 291: abnormal recycle: flame was not on at end of ignition alert 294: abnormal recycle: flame was lost during run alert 324: abnormal recycle: hardware flame bias alert 377: abnormal recycle: hardware flame bias delta this type of failure indicates a flame rectification signal issue through...

Page 52

49 8.1 setting the correct combustion 1) switch the main power off to the boiler by placing the toggle switch in the ‘off’ position 2) switch the main power on to the boiler and adjust set point so that boiler begins ignition sequence. 3) observe the boiler as it goes through its startup cycle and o...

Page 53

50 dm 299 – 399 figure 57: dm 299 – 399 gas valve to adjust the high-fire setting 1) press the button 2) select test and press 3) select forced rate and press 4) select set high fire locate the high-fire adjustment screw on the top side of the gas valve. The screw can be identified by a red cylinder...

Page 54

51 part 9 maintenance caution it is important that all gas appliances be serviced by a qualified technician trained by camus hydronics. It is in your own interest and that of safety to ensure that all local codes, and all the “notes” and “warnings” in this manual are complied with. To service or adj...

Page 55

52 12) brush the heat exchanger with a nylon bristle brush. Do not use a metal brush. Re-vacuum the heat exchanger. 13) finish cleaning by wiping down the boiler heating surfaces with a clean, damp cloth. 14) rinse out any additional debris with a low pressure water supply. Start rinsing from the re...

Page 56

53 on an annual basis. An appliance installed in a dust or dirt contaminated environment will require inspection and cleaning on a more frequent schedule. The fan assisted combustion process may force airborne dust and dirt contaminants, contained in the combustion air, into the burner. With sustain...

Page 57

54 9.10 gas valve voltage this appliance uses a transformer to supply a 24 volt signal to the honeywell sola. The voltage on the secondary side should be 24 to 28vac when measured with a voltmeter. A secondary voltage of 21vac or less supplied to 24vac components may cause operational problems. 9.11...

Page 58

55 part 10 installations warning before starting the boiler, smell near the floor and around the boiler for any gas odours or any unusual odour. Remove the stainless steel jacket and smell the interior of the boiler. If there is any sign of a gas leak, do not proceed with startup. Repair all the lea...

Page 59

56 10.7 summary a) typical boiler installations general plumbing rules 1) check all local codes. 2) for serviceability, always install unions. 3) always pipe pressure relief valve to an open drain. 4) locate system air vents at highest points of system. 5) expansion tank must be installed near the b...

Page 60

57 for example in some cases it may be the bath tub and in some cases it may be the clothes washer. 3) allow the dynamax hs to fire up and reach full fire under maximum hot water load demand conditions. 4) observe the outlet water temperature and close the tuning valve gradually as outlet temperatur...

Page 61

58 10.11 lead lag setup the following components are needed for a lead lag setup 1) 10k Ω system sensor turn off all the boilers before beginning the setup process. To setup the dynamax hs lead lag system follow the instructions: system sensor insert the supplied 10k Ω system sensor into the buildin...

Page 62

59 10.12 local/remote switch the local remote switch mounted on the terminal board is designed to generate a call for heat either relying on an external contact closure (remote) or enabling the boiler locally (local). When remote is selected via the spdt switch the remote operator contacts on the te...

Page 63

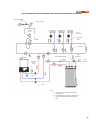

60 part 13 piping diagrams figure 31: single boiler hydronic heating zoned piping arrangement note: 1) size main header to minimize induced flow through zones 2) separate boiler loop as shown is recommended for system piping greater than 50 equivalent feet. Pressure reducing valve pressure gauge bal...

Page 64

61 figure 32: single combination boiler zoned piping arrangement pressure reducing valve pressure gauge ball valve air separator expansion tank zone circulator flow check valve dynamax hs boiler temperature / pressure gauge drain union anti-scald mixing valve note: 1) size main header to minimize in...

Page 65

62 figure 33: single boiler hydronic heating & indirect storage tank zoned piping arrangement pressure reducing valve pressure gauge ball valve air separator expansion tank zone circulator flow check valve dynamax hs boiler temperature / pressure gauge drain union anti-scald mixing valve note: 1) si...

Page 66

63 figure 34: single boiler hydronic heating & direct storage tank zoned piping arrangement cold water in dhw sensor union direct dhw tank anti-scald mixing valve cold water in hot water out.

Page 67

64 figure 35: multiple boiler hydronic heating zoned piping arrangement pressure reducing valve pressure gauge air separator expansion tank ball valve zone circulator flow check valve dynamax hs boiler (master, m1) temperature/ pressure gauge drain union dynamax hs boiler (slave, s2) system sensor n...

Page 68

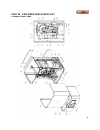

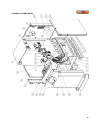

65 part 14 exploded view & parts list dynamax hs wall hung.

Page 69

66 dynamax hs floor mount.

Page 70

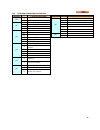

67 ref # name of part part id dynamax hs models all 80 100 150 200 210 250 260 299 399 500 600 700 800 1 heat exchanger 4 + 1 wall x x 5 + 2 wall x 8 + 4 wall x x 8 + 4 floor x x 10 + 6 floor x 15 + 8 floor x 18 + 10 floor x 21 +11 floor x x 24 + 12 floor x 2 burner 221.042.001-a x x 221.039.001-a x...

Page 71

68 ref # name of part part id dynamax hs models all 80 100 150 200 210 250 260 299 399 500 600 700 800 14 hydronic heating/ combination pump 59896343 (ups15-58frc) x x x x x 52722512 (ups26-99fc) x x pl30 x pl36 x x e12 x 182212-667 (e22) x x dhw pump e7b x x e9b x x x x x e12b x x e33b x 127091.1.1...

Page 72

69 ref # name of part part id dynamax hs models all 80 100 150 200 210 250 260 299 399 500 600 700 800 34 plastic bezel bezel hs x x x x x 35 bracket for neutralizer box 14-5419 x x x x x 36 air inlet/ vent adapter fsa-hex03 x x x x x x x x x 37 plate heat exchanger (combination models only) lb31-20...

Page 73

70 ref # name of part part id dynamax hs models all 80 100 150 200 210 250 260 299 399 500 600 700 800 57 top cover assembly 14-5521 x x x x x x x x 58 dashboard dashboard hs x x x x x x x x 59 bracket for neutralizer box 14-5525 x x x x x x x x 60 rubber bushing 33-0101 x x x x x x x 62 condensate ...

Page 74

71 ref # name of part part id dynamax hs models all 80 100 150 200 210 250 260 299 399 500 600 700 800 83 flue sensor ntc- sensor-003 x 84 outdoor sensor ntc- sensor-004 x 85 dhw sensor (clip on) ntc- sensor-001 x 86 gas valve elbow 45900400-132/b x x x x x x x 45900400-144/b x x 87 gas valve wire h...

Page 75

72 ref # name of part part id dynamax hs models all 80 100 150 200 210 250 260 299 399 500 600 700 800 103 rubber air sleeve 1056-22 x x x x x x x x x 1056-33 x 1056-44 x x 1056-55 x 104 burner gasket gm10-25-074-09 x x x x x x x x x x gm10-35-078-03 x x x 105 fan gasket/ mixing chamber gasket 33-00...

Page 76

73 part 15 electrical diagrams 15.1 dm 80- 299 internal wiring diagram.

Page 77

74 15.2 dm 399 – 800 internal wiring diagram.

Page 78

75.

Page 79

76 15.2 field wiring all wires being placed into the terminal block should be horizontal for at least an inch to ensure sufficient electrical conductivity. 15.2.1 system sensor the temperature of the primary return can be controlled by installing a system sensor. The system sensor must be used in al...

Page 80

77 15.5 detailed connector description connector pin # connector description j1 2 flame sensor 3 igniter ground j2 1 blower tach signal 2 blower vdc power 3 blower pwm signal 4 blower ground signal j3 a1 modbus + b1 modbus - c1 +vdc display a2 lead lag, modbus + b2 lead lag, modbus - c2 -vdc display...

Page 81

78 condensing boiler limited warranty camus hydronics limited (“camus”) extends the following limited warranty to the owner of this appliance, provided that the product has been installed and operated in accordance with the installation manual provided with the equipment. Camus will furnish a replac...

Page 82

Camus hydronics is a manufacturer of replacement parts for most copper finned the camus certified! Seal assures you that reliability, efficiency & serviceability are built water heaters and heating boilers as well as a into every single unit! For more information supplier of specialty hvac products....