- DL manuals

- Camus Hydronics

- Boiler

- MFH060

- Installation, Operation And Service Manual

Camus Hydronics MFH060 Installation, Operation And Service Manual

99-0073

Rev. 00

INSTALLATION OPERATION

AND SERVICE MANUAL

MODULATING MICOFLAME SERIES

GAS FIRED RESIDENTIAL AND COMMERCIAL COPPER TUBE

BOILERS

FOR HYDRONIC HEATING

Non-Condensing Models; MFH060, 100, 150, 200, 250, 300, 400, 500, 600

Condensing Models; MFH062, 102, 152, 202, 252, 302, 402, 502, 602

HOT WATER SUPPLY

Non-Condensing Models; MFW060, 100, 150, 200, 250, 300, 400, 500, 600

Condensing Models; MFW062, 102, 152, 202, 252, 302, 402, 502, 602

WARNING: If the information in these instructions is not

followed exactly, a fire or explosion may result causing

property damage, personal injury or death

•

Do not store or use gasoline or other flammable

vapours and liquids in the vicinity of this or any other

appliance.

•

WHAT TO DO IF YOU SMELL GAS

o

Do not try to light any appliance,

o

Do not touch any electrical switch; do not use any

phone in your building,

o

Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions,

o

If you cannot reach your gas supplier, call the fire

department.

•

Qualified installer, service agency or the gas supplier

must perform installation and service.

To the installer: After installation, these instructions must be

given to the end user or left on or near the heater.

To the End User: This booklet contains important information

about this heater. Retain for future reference.

CAMUS HYDRONICS LTD.

6226 Netherhart Road, Mississauga, Ontario, L5T 1B7

Summary of MFH060

Page 1

99-0073 rev. 00 installation operation and service manual modulating micoflame series gas fired residential and commercial copper tube boilers for hydronic heating non-condensing models; mfh060, 100, 150, 200, 250, 300, 400, 500, 600 condensing models; mfh062, 102, 152, 202, 252, 302, 402, 502, 602 ...

Page 3

Table of contents 1 general information ............................................................................................................ 1 2 boiler location....................................................................................................................... 2 3 provide ...

Page 4

20.3 service..................................................................................................................................... 50 21 lighting instructions ........................................................................................................ 50 22 troubleshooting...

Page 5

1 1 general information camus hydronics proudly introduces the modulating micoflame series of water heaters / hydronic boilers. The modulating micoflame is a fan assisted appliance based on a push through design which offers several venting options. Heat output is controlled by an adjustable ratio a...

Page 6

2 2 boiler location install this boiler in a clean, dry location with adequate air supply and close to a good vent connection. Do not locate this boiler in an area where it will be subject to freezing. The boiler is suitable for installation on combustible flooring and should be located close to a f...

Page 7

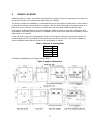

3 table 2: appliance dimensions, (inches) b' dia. Venting e' dia. Model 'w' w a te r c o n n e c tio n g a s c o n n e c tio n o u td o o r s id e w a ll o r c o n d e n s in g s ta n d a rd a ir in le t mfnh060 18 3/4 1 1/2 1/2 3 3 3 3 mfnh100 18 3/4 1 1/2 1/2 3 3 4 3 mfnh150 18 3/4 1 1/2 1/2 3 3 4...

Page 8

4 4 electrical wiring all electrical wiring to the boiler must be electrically bonded to ground in accordance with the requirements of the authority having jurisdiction or, in the absence of such requirements, with the national electrical code, ansi/nfpa 70 or the canadian electrical code part i, cs...

Page 9

5 as the modulating fan ramps up, gas input is adjusted accordingly to match the airflow. When the call for heat ends, the valve is de-energized, and the fan modulates off. Normal operation modulation is controlled from the boiler temperature controller. The modulating fan is equipped with an electr...

Page 10

6 table 4: gas pipe size for distance from natural gas meter or propane second stage regulator distance from natural gas meter or propane second stage regulator 0-100 ft 100-200 ft. 200-300 ft. Input btu/hr nat. L.P. Nat. L.P. Nat. L.P. 60,000 ¾” ½“ ¾” ½“ 1“ ¾” 100,000 ¾” ½“ 1“ ¾” 1“ ¾” 150,000 1“ ¾...

Page 11

7 f) after it has been determined that each appliance remaining connected to the common venting system properly vents when tested as outlined above, return doors, windows, exhaust fans, fireplace dampers and any other gas-burning appliance to their previous condition of use. G) any improper operatio...

Page 12

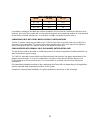

8 figure 2: venting arrangement 7.1 outdoor venting when fitted with the factory supplied rain shield and ul approved vent cap, the micoflame is self-venting. The following applies to outdoor installations: 1. Use only factory supplied rain shields. 2. Periodically check to ensure that air intake an...

Page 13

9 7.2 sidewall venting when fitted with the factory supplied vent terminal, the micoflame can vent up to 50 equivalent feet. Elbows can range from 5 to 9 feet in equivalent length depending on centreline radius. See table 2 for vent sizes. Boilers may be installed with either a horizontal sidewall v...

Page 14

10 7.6 venting for condensing application when supplied with the optional condensing cartridge, the micoflame is 95% efficient (category ii or iv appliance) which requires the use of a special venting system fabricated from al29-4c material. Only venting components listed by a nationally recognized ...

Page 15

11 8 accessories 8.1 water flow switch (shipped loose) a water flow switch is shipped loose and is to be installed in the outlet piping on all heating boilers and hot water supply boilers. The flow switch is wired in series with the 24vac safety control circuit. A diagnostic light will be indicated ...

Page 16

12 9 freeze protection • appliance installations are not recommended outdoors in areas where danger of freezing exists unless precautions are taken. Maintaining a mixture of 50% water and 50% propylene glycol is the preferred method of freeze protection in hydronic systems. This mixture will protect...

Page 17

13 11 piping of boiler to system check all applicable local heating, plumbing and building safety codes before proceeding. Be sure to provide unions and gate valves at inlet and outlet to boiler so that it can be easily isolated for service. This boiler is of a low mass design, which provides for in...

Page 18

14 if the boiler is installed above radiation level, it must be provided with a low water cutoff device at the time of boiler installation. (available from factory) to eliminate trapped air, install venting devices at high points in the system as well as in the piping on the suction of the pump and ...

Page 19

15 14 low water temperature systems in applications where the heating system requires supply water temperatures below 130°f (55 o c), a bypass line must be installed upstream of the boiler pump so that outlet water can be re-circulated to raise the inlet temp to a minimum of 130°f (55 o c). Balancin...

Page 20

16 15 instantaneous water heater an instantaneous water heater is designed to deliver hot water without the use of a storage tank. It is suitable for applications with variable load such as restaurants, condominiums, apartments and motels. (see figure 7) call factory for recommendations. Figure 7: i...

Page 21

17 figure 8: typical condensing system condensate from the micoflame must be treated before being discharged to drain. Ph level of the condensate is to be checked regularly and the neutralizing medium is to be replaced as required. A neutralizing cartridge is available from the factory. The condensi...

Page 22

18 table 6: chrm head loss & flow model us gpm ∆ p - ft. 62 – 152 2.0 0.05 202 – 302 4.0 0.1 402 – 602 10.0 0.4 a neutralizer cartridge is provided and must be installed in the line from the condensate collection pot to the drain. Ph level of the condensate is to be checked regularly and neutralizin...

Page 23

19 figure 10: hydronic heating suggested piping with chrm figure 11: domestic hot water suggested piping with chrm.

Page 24

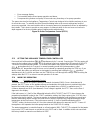

20 17 instrumentation and controls 17.1 safety controls high temperature limit the high temperature limit is located behind the appliance’s access doors. A remote capillary bulb runs to a thermo-well on the outlet side of the inlet/outlet header. The appliance high limit is set at the factory to 210...

Page 25

21 • error message display. • test override feature to test pump operation and alarm. • pump exercising feature runs pump 10 seconds every three days of no pump operation. The menu structure for the appliance temperature control was designed to be intuitive and easy to use for a first time user. To ...

Page 26

22 figure 14: mode 1 piping & electrical layout mode 2: constant temperature control at system sensor this mode is designed for hydronic heating. Once a heat demand is present, the btc 1 modulates the boiler burner to maintain the boiler target at the system sensor. A heat demand is generated when 2...

Page 27

23 mode 3: dedicated domestic hot water operation this mode is designed for domestic hot water. A dhw sensor must be inserted into a temperature immersion well within the dhw tank to function properly. The btc 1 modulates the boiler based on the boiler inlet sensor to maintain a tank temperature at ...

Page 28

24 figure 17: mode 4 piping & electrical layout mode 5: outdoor reset using system sensor this mode is designed for hydronic heating. Once a heat demand is present, the btc 1 turns on the appliance pump and modulates the boiler to maintain the calculated outdoor reset target at the system sensor. Ou...

Page 29

25 mode 6: external target temperature using boiler inlet sensor the external input signal can be provided from a bms, ems or a tekmar tn4 system control. The external input signal creates an internal demand and changes the boiler target according to a linear scale. The btc 1 modulates the boiler to...

Page 30

26 mode 7: external target temperature using system temperature sensor the external input signal can be provided from a bms, ems or a tekmar tn4 system control. The external input signal creates an internal demand and changes the boiler target according to a linear scale. The control modulates the b...

Page 31

27 mode 8: external direct drive operation this mode is designed only for hydronic heating operation. This mode allows for an external control to operate the boiler through an analog direct drive input signal provided by a boiler sequencing control, such as, the s12 sequencer. When operating in this...

Page 32

28 18 micoflame control panel figure 22: btc 1 display panel figure 23: btc key functions table 8: btc key functions key key description item the abbreviated name of the selected item will be displayed in the item field of the display. To view the next item, press the item button. Increase a paramet...

Page 33

29 18.1 general symbol description symbol symbol name symbol description boiler pump shown when boiler pump is in operation dhw pump shown when dhw pump is in operation heat demand shown when heat demand is present flame proof shown when flame signal is proven burner shown when burner is on warning ...

Page 34

30 18.2 mode 1 & 2: setpoint operation: view display from the home display; 1) press [item] to view the following parameters: display parameter name parameter description parameter range boiler target temperature to provide a target setpoint for the heating system. Setpoint is controlled to the inle...

Page 35

31 18.3 mode 1 & 2: setpoint operation: adjust display from the home display; 1) press simultaneously to view the following parameters: display parameter name parameter description parameter range mode operating mode for the boiler. Note: a complete description of each mode can be found in section 8...

Page 36

32 18.4 mode 3: dedicated domestic hot water operation: view display from the home display; 1) press [item] to view the following parameters: display parameter name parameter description parameter range boiler target temperature to provide a target setpoint for the heating system. Setpoint is contro...

Page 37

33 18.5 mode 3: dedicated domestic hot water operation: adjust display from the home display; 1) press simultaneously to view the following parameters: display parameter name parameter description parameter range mode operating mode for the boiler. Note: a complete description of each mode can be fo...

Page 38

34 18.6 mode 4 & 5: outdoor reset operation: view display from the home display; 1) press [item] to view the following parameters: display parameter name parameter description parameter range outdoor temperature real-time outdoor temperature -60 to 190 o f (-51 to 88 o c) boiler target temperature t...

Page 39

35 18.7 mode 4 & 5: outdoor reset operation: adjust display from the home display; 1) press simultaneously to view the following parameters: display parameter name parameter description parameter range mode operating mode for the boiler. Note: a complete description of each mode can be found in sect...

Page 40

36 display parameter name parameter description parameter range warm weather shutdown temperature warm weather shutdown temperature using outdoor reset. 35 to 105 o f, off (2 to 41 o c, off) default = 0:20 min temperature units select the desired unit of measurement o f, o c default = o f 18.8 mode ...

Page 41

37 display parameter name parameter description parameter range modulation real-time modulating output percentage 0 to 100% total run time since installation monitors the amount of operational time since the micoflame was installed. The first two digits are the number of thousands of hours and the t...

Page 42

38 18.10 mode 8: external drive opeation: view display from the home display; 1) press [item] to view the following parameters: display parameter name parameter description parameter range boiler outlet temperature real-time outlet temperature to boiler 14 to 266 o f (-10 to 130 o c) boiler inlet te...

Page 43

39 18.11 mode 8: external drive opeation: adjust display from the home display; 1) press simultaneously to view the following parameters: display parameter name parameter description parameter range mode operating mode for the boiler. Note: a complete description of each mode can be found in section...

Page 44

40 error message description inlet sensor short circuit the boiler will continue operation. Test the inlet sensor and related wiring. The error message will clear once the error condition is corrected and a button is pressed. Inlet sensor open the boiler will continue operation test the inlet sensor...

Page 45

41 error message description dhw sensor open the control will not operate the burner. Test the dhw sensor and related wiring. The error message will clear once the error condition is corrected and a button is pressed. Flame proof error flame was not proved within 120 seconds of demand 1 19 pilot and...

Page 46

42 figure 24: micoflame 60 – 300 burner assembly figure 25: micoflame 400 – 600 burner assembly if burner characteristics do not match the above, check for proper air box pressure. Also look for accumulation of lint and other foreign material at fan air inlets. Typical air box settings are as follow...

Page 47

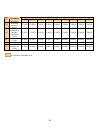

43 table 9: air box settings model air box “ w.C. (with burner firing) flue switch recycle point “ w.C 060 0.20 0.15 100 0.25 0.20 150 0.30 0.25 200 0.35 0.30 250 0.38 0.33 300 0.40 0.35 400 0.80 0.70 500 0.90 0.80 600 1.00 0.90 depending on field conditions air box pressures will have to be adjuste...

Page 48

44 19.2 pilot burner turn the pilot firing valve to off position and allow the appliance to try for ignition. Observe the spark making sure that it is strong and continuous. If the spark is not acceptable the igniter will have to be adjusted. This can be readily accomplished after removing the main ...

Page 49

45 for your safety follow the lighting and operating instructions below and on the boiler. To turn on main burner, slowly open firing valve after pilot is established. Set primary system controller to desired temperature. To turn off boiler close main manual gas valve, close pilot manual valve and t...

Page 50

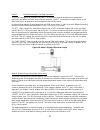

46 mf 60 – 150 to adjust the high fire setting set the target temperature to 190 o f using the btc 1 controller. Figure 27: venturi & gas valve assembly once the appliance is at maximum fan speed locate the input adjustment screw on the side of the venturi. Using a flat head screwdriver turn the scr...

Page 51

47 mf 200 – 300 figure 28: mf 200 – 300 gas valve to adjust the high fire setting set the target temperature to 190 o f using the btc 1 controller. Once the appliance is at maximum fan speed locate the high-fire adjustment screw on the top side of the gas valve. The screw can be identified by a red ...

Page 52

48 mf 400 – 600 figure 29: mf 400 – 600 gas valve to adjust the high fire setting set the target temperature to 190 o f using the btc 1 controller. Once the appliance is at maximum fan speed locate the input adjustment screw on the top side of the gas valve. Using a flat head screwdriver turn the sc...

Page 53

49 blocked flue switch the normally-closed blocked flue switch has been preset at the factory according to table 9. In cases where the heater loses the flame signal as it approaches high-fire adjustment to the blocked flue switch may be necessary. The following description is for the benefit of the ...

Page 54

50 20.3 service disconnect main power and turn off gas supply before servicing unit. To remove and clean the burner, follow the detailed procedure in section 16 of this manual after the first season of operation inspect the heat exchanger and venting. Follow the detailed instructions in section 6 of...

Page 55

51 22 troubleshooting guide symptom solution 1. Power light is not lit when switch is flipped to “on” • check wiring to switch. • check circuit breaker. • check fuse. 2. Water flow light remains off. • verify that pump is running. • check wiring to flow switch. 3. Pilot sparks but does not light • v...

Page 56

52 23 typical gas train figure 30: micoflame modulation 60 – 300 gas train figure 31: micoflame modulation 400 – 600 gas train.

Page 57

53 24 electrical diagrams each micoflame boiler will be provided with its own wiring diagram to guarantee that any options ordered with the unit are properly detailed. The following diagrams 99-5085-c, 99-5086-c and 99-5086-s are provided as a typical sample only..

Page 58

54 24.1 mf 60 - 300 internal wiring connection diagram.

Page 59

55 24.2 mf 400 - 600 internal wiring connection diagram.

Page 60

56 24.3 mf 60 – 1000 internal wiring ladder diagram.

Page 61

57 25 exploded view.

Page 62

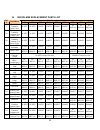

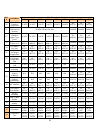

58 26 micoflame replacement parts list micoflame series model ref # part name 60 100 150 200 250 300 400 500 600 1 combustion chamber base panel 14-4075 14-4075 14-4075 14-4075 14-4055 14-4055 14- 4005-01 14- 4005-01 14- 4005-03 2a combustion chamber common end panel, left 14-4050 14-4050 14-4050 14...

Page 63

59 micoflame series model ref # part name 60 100 150 200 250 300 400 500 600 20 combustion chamber rear panel 14-4072 14-4072 14-4072 14-4072 14-4052 14-4052 14- 4002-01 14- 4002-01 14- 4002-01 21 flue collector end bracket 14-4058 2 req'd per unit 14-4008 14-4008 14-4008 22 combustion chamber upper...

Page 64

60 micoflame series model ref # part name 60 100 150 200 250 300 400 500 600 39 micoflame modulating harness-1 burner 77-0018 77-0018 77-0018 77-0018 77-0018 77-0018 77-0018 77-0018 77-0018 40 mico modulating harness- panel main (110v) 77-0019 77-0019 77-0019 77-0019 77-0019 77-0019 77-0019 77-0019 ...

Page 65

61 warranty general camus hydronics limited (“camus”), extends the following limited warranty to the owner of this appliance, provided that the product has been installed and operated in accordance with the installation manual provided with the equipment. Camus will furnish a replacement for, or at ...

Page 66

Camus hydronics is a manufacturer of replacement parts for most copper finned the camus certified! Seal assures you that reliability, efficiency & serviceability are built water heaters and heating boilers as well as a into every single unit! For more information supplier of specialty hvac products....