- DL manuals

- Camus Hydronics

- Boiler

- MFH060

- Installation, Operation And Service Manual

Camus Hydronics MFH060 Installation, Operation And Service Manual

99-0052

Rev. 7.2

INSTALLATION OPERATION

AND SERVICE MANUAL

MICOFLAME SERIES

GAS FIRED RESIDENTIAL AND COMMERCIAL COPPER TUBE

BOILERS

FOR HYDRONIC HEATING

Non-Condensing Models; MFH060, 100, 150, 200, 250, 300, 400, 500, 600

Condensing Models; MFH062, 102, 152, 202, 252, 302, 402, 502, 602

HOT WATER SUPPLY

Non-Condensing Models; MFW060, 100, 150, 200, 250, 300, 400, 500, 600

Condensing Models; MFW062, 102, 152, 202, 252, 302, 402, 502, 602

WARNING: If the information in these instructions is not

followed exactly, a fire or explosion may result causing

property damage, personal injury or death

•

Do not store or use gasoline or other flammable

vapours and liquids in the vicinity of this or any other

appliance.

•

WHAT TO DO IF YOU SMELL GAS

o

Do not try to light any appliance,

o

Do not touch any electrical switch; do not use any

phone in your building,

o

Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions,

o

If you cannot reach your gas supplier, call the fire

department.

•

Qualified installer, service agency or the gas supplier

must perform installation and service.

To the installer: After installation, these instructions must be

given to the end user or left on or near the heater.

To the End User: This booklet contains important information

about this heater. Retain for future reference.

CAMUS HYDRONICS LTD.

6226 Netherhart Road, Mississauga, Ontario, L5T 1B7

Summary of MFH060

Page 1

99-0052 rev. 7.2 installation operation and service manual micoflame series gas fired residential and commercial copper tube boilers for hydronic heating non-condensing models; mfh060, 100, 150, 200, 250, 300, 400, 500, 600 condensing models; mfh062, 102, 152, 202, 252, 302, 402, 502, 602 hot water ...

Page 2

1 table of contents introduction .......................................................................................................................................... 2 1. General instructions .........................................................................................................

Page 3

2 introduction camus hydronics proudly introduces its micoflame series of water heaters / hydronic boilers. These gas burning appliances are thoughtfully designed for easy operation and maintenance. We are confident that you will come to appreciate the benefits of our product. 1. General instruction...

Page 4

3 2. Boiler location install this boiler in a clean, dry location with adequate air supply and close to a good vent connection. Do not locate this boiler in an area where it will be subject to freezing. The boiler is suitable for installation on combustible flooring and should be located close to a ...

Page 5

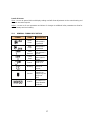

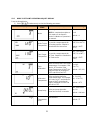

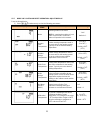

4 table 1 b' dia. Venting* e' dia. Model 'w' w a te r c o n n e c tio n g a s c o n n e c tio n o u td o o r s id e w a ll o r c o n d e n s in g s ta n d a rd a ir in le t mfnh060 18 3/4 1 1/2 1/2 3 3 3 3 mfnh100 18 3/4 1 1/2 1/2 3 3 4 3 mfnh150 18 3/4 1 1/2 1/2 3 3 4 3 mfnh200 18 3/4 1 1/2 1/2 4 4...

Page 6

5 4. Electrical wiring all electrical wiring to the boiler must be electrically bonded to ground in accordance with the requirements of the authority having jurisdiction or, in the absence of such requirements, with the national electrical code, ansi/nfpa 70 or the canadian electrical code part i, c...

Page 7

6 the gas supply line must be of adequate size to prevent undue pressure drop and must never be smaller than the size of the connection on the heater. Sizing based on table 2 is recommended. Before operating the boiler, the complete gas train and all connections must be tested using soap solution. T...

Page 8

7 so they will operate at maximum speed, do not operate a summer exhaust fan. Close fireplace dampers. D) place in operation the appliance being inspected. Follow the lighting instructions. Adjust thermostat so that appliance operates continuously. E) test for spillage at the draft control device re...

Page 9

8 5. Caution: when replacing the burner be careful to fully engage the back of the burner box into the retaining slot in the combustion chamber base. Failure to properly locate the burner will result in erratic flame operation with the possibility of delayed ignition on light off. 6. Restore electri...

Page 10

9 6.1 outdoor venting when fitted with the factory supplied rain shield and ul approved vent cap, the micoflame is self-venting. The following applies to outdoor installations: 1. Use only factory supplied rain shields. 2. Periodically check to ensure that air intake and vent cap are not obstructed....

Page 11

10 the following applies to outdoor air installations: 1. Use only factory supplied air intake terminal. 2. Periodically check to ensure that air intake is not obstructed. 3. Refer to local codes for proper installation and location of vent terminals. Vertical vent terminal must be at least 3 feet a...

Page 12

11 conventional venting multiple appliances may be vented into a conventional chimney. The chimney must be lined with al29-4c and a single acting barometric damper must be provided for each appliance. Vent diameters are to be increased by one size over the recommended size a qualified professional u...

Page 13

12 7. Accessories water flow switch (shipped loose) a water flow switch is shipped loose and is to be installed in the outlet piping on all heating boilers and hot water supply boilers. The flow switch is wired in series with the 24vac safety control circuit. A diagnostic light will be indicated on ...

Page 14

13 boiler application (hydronic heating) in case of boiler (hydronic heating boiler) application, the return water (supply water) may be more than 115ºf (46ºc), therefore there is no need for a recirculation loop and the primary heat exchanger and chrm can be piped in parallel. Since the inlet water...

Page 15

14 figure 3 when a boiler is connected to heating coils located in air handling units (where they may be exposed to refrigerated air circulation), the boiler piping system shall be equipped with a flow control valve or other automatic means to prevent gravity circulation of chilled water through the...

Page 16

15 figure 4 if the boiler is installed above radiation level, it must be provided with a low water cutoff device at the time of boiler installation. (available from factory) to eliminate trapped air, install venting devices at high points in the system as well as in the piping on the suction of the ...

Page 17

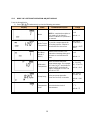

16 12. Micoflame control panel this controller accommodates up to four-stage control with six modes of operation which provides setpoint as well as rest control. It provides the following: 1. Readings of inlet and outlet water temperatures as well as ∆ t temperature rise 2. Six pre-set modes of oper...

Page 18

17 levels of access view – access to general boiler and display settings and will allow adjustments to the central heating and domestic hot water setpoint. Adjust – access to all user parameters and allows for changes to additional boiler parameters to allow for ease of startup and serviceability. 1...

Page 19

18 12.2 mode 1 & 2: setpoint operation: view display mode 1 intended for hydronic heating. The set-point for inlet water control is pre-set to 180 o f and the auto re-set limit is set to 230°f. The inlet set-point can be adjusted, however the limit is fixed. In addition to the auto reset limit the f...

Page 20

19 12.3 mode 1 & 2: setpoint operation: adjust display from the home display; 1) press simultaneously to view the following parameters: display parameter name parameter description parameter range mode operating mode for the boiler. Note: a complete description of each mode can be found in section 8...

Page 21

20 12.4 mode 3: setpoint operation: view display mode 3 is intended for domestic water heating. The set-point for inlet water control is pre- set to 140°f and the auto re-set limit is set to 200°f. The inlet set-point can be adjusted, however the limit is fixed. In addition to the auto reset limit t...

Page 22

21 12.5 mode 3: setpoint operation: adjust display from the home display; 1) press simultaneously to view the following parameters: display parameter name parameter description parameter range mode operating mode for the boiler. Note: a complete description of each mode can be found in section 8.4 m...

Page 23

22 12.6 mode 4 & 5: outdoor reset operation: view display mode 4 is intended for hydronic heating. The set-point for inlet water control is pre-set to 180°f and the auto re-set limit is set to 230°f. The inlet set-point can be adjusted, however the limit is fixed. In addition to the auto reset limit...

Page 24

23 12.7 mode 4 & 5: outdoor reset operation: adjust display from the home display; 1) press simultaneously to view the following parameters: display parameter name parameter description parameter range mode operating mode for the boiler. Note: a complete description of each mode can be found in sect...

Page 25

24 pump delay boiler post pump time after burner has shut off, in seconds. Off, 0:20 to 9:55 min, on default = 1:00 min warm weather shutdown temperature warm weather shutdown temperature using outdoor reset. 35 to 105 o f, off (2 to 41 o c, off) default = 0:20 min temperature units select the desir...

Page 26

25 12.8 mode 6: outdoor reset operation: view display mode 6 is intended for multiple appliance application and all stages are closed at all times. In essence there is no operator at the appliance. A removable jumper is provided in the electrical enclosure across the contacts to be used for connecti...

Page 27

26 12.9 mode 6: outdoor reset operation: adjust display from the home display; 1) press simultaneously to view the following parameters: display parameter name parameter description parameter range mode operating mode for the boiler. Note: a complete description of each mode can be found in section ...

Page 28

27 figure 5 • adjustment procedure. A. Fully open bypass and outlet valves. B. With boiler running, read inlet temperature after 15 minutes. C. If the inlet temperature is less than 115°f (46 o c) slowly close outlet valve until the inlet temperature climbs to 115°f (46 o c) d. If the inlet temperat...

Page 29

28 figure 6 16. Condensing heat recovery module the micoflame could be provided in condensing mode for a variety of application including domestic hot water and hydronic space heating. The chrm is intended to extract total (sensible and latent) heat from the flue gases downstream of the primary heat...

Page 30

29.

Page 31

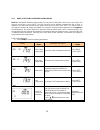

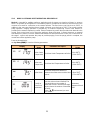

30 17. Pilot and main burner flames to maintain safe operation and the greatest efficiency of the boiler, check the main burner and pilot burner every six months for proper flame characteristics. 17.1. Main burner the main burner, figure 7 should display the following characteristics; • acceptable c...

Page 32

31 depending on field conditions air box pressures will have to be adjusted accordingly. Always set the appliance for a co 2 level in the range of 7.5% to 8.0 % for non-condensing appliances and 8.5% to 9.0% for condensing appliances. For propane fired appliances the setting will be approximately 1....

Page 33

32 17.3 pilot burner turn the pilot firing valve to off position and allow the appliance to try for ignition. Observe the spark making sure that it is strong and continuous. If the spark is not acceptable the igniter will have to be adjusted. This can be readily accomplished after removing the main ...

Page 34

33 18. Operation and service operation: before operating the boiler, the entire system must be filled with water, purged of air and checked for leaks. Do not use stop leak or other boiler compounds. The gas piping must also be leak tested. Any safety devices including low water cutoff, flow switch a...

Page 35

34 service: disconnect main power and turn off gas supply before servicing unit. To remove and clean the burner, follow the detailed procedure in section 17 of this manual after the first season of operation inspect the heat exchanger and venting. Follow the detailed instructions in section 6 of thi...

Page 36

35 20. Trouble shooting guide symptom solution 1. Power light is not lit when switch is flipped to “on” • check wiring to switch. • check circuit breaker. • check fuse. 2. Water flow light remains off. • verify that pump is running. • check wiring to flow switch. 3. Pilot sparks but does not light •...

Page 37

36 21. Typical gas train figure 9 22. Electrical diagrams each micoflame boiler will be provided with its own wiring diagram to guarantee that any options ordered with the unit are properly detailed. The following diagram 99-5060 is provided as a typical sample only..

Page 38

37.

Page 39

38 tekmar btc-4pa electrical connections tekmar btc-4pa terminal # label description 1 cd unused 2 htd call for heat signal 3 pr d proof demand to signal pilot is active 4 com common terminal for outdoor, system and/or dhw sensors 5 outdr 10kΩ outdoor sensor 6 sys/d 10kΩ system or dhw sensor 7 boil ...

Page 40

39 23. Exploded view.

Page 41

40

Page 42

41 24. Micoflame replacement parts list item # part description micoflame i model size 60 100 150 200 250 300 400 500 600 1 combustion chamber base panel 14-4075 14-4055 14-4005-02 14-4005-03 2 combustion chamber common end panel-right 14-4051 14-4001 3 combustion chamber common end panel-left 14-40...

Page 43

42 item # part description micoflame i model size 60 100 150 200 250 300 400 500 600 18 combustion chamber right support 14-4053 14-4003 19 combustion chamber left support 14-4054 14-4004 20 flue collector top 14-4057-03 14-4057-04 14-4057-05 14-4057-06 14-4007-02 14-4007-03 *21 combustion chamber b...

Page 44

43 item # part description micoflame i model size 60 100 150 200 250 300 400 500 600 34 blower assembly 55-0005 55-0008 55-0007 35 inlet/outlet header 13-0110 13-0004a 36 return header 13-0111 13-0003a 37 header bar 14-4156 15-4157 38 refractory set 60-150-rfrs 200-rfrs 250-rfrs 300-rfrs 400-rfrs 50...

Page 45

44 item # part description micoflame i model size 60 100 150 200 250 300 400 500 600 *55 ignition module continuous s8610m3017 ignition module single try s8600h2010 56 tekmar controller (stg) btc4pa 57 air switch is3010106-5769a is20105-5762a 58 transformer hct-01j28807 59 fan manager st82d1004 60 w...

Page 46

45 warranty general camus hydronics limited (“camus”), extends the following limited warranty to the owner of this appliance, provided that the product has been installed and operated in accordance with the installation manual provided with the equipment. Camus will furnish a replacement for, or at ...

Page 47

46.

Page 48

Camus hydronics is a manufacturer of replacement parts for most copper finned the camus certified! Seal assures you that reliability, efficiency & serviceability are built water heaters and heating boilers as well as a into every single unit! For more information supplier of specialty hvac products....