- DL manuals

- Cannondale

- Motorcycle

- C440

- Owner's Manual

Cannondale C440 Owner's Manual

P/N 951 - 5002274

Before you operate the vehicle. . . .

•

READ and UNDERSTAND this manual. It contains information important to

your safety.

•

Familiarize yourself with all vehicle controls and their proper operation.

•

Perform the Pre-Ride Inspection found in this manual.

•

Wear appropriate protective gear - approved full faced helmet, eye protection,

gloves, boots, long-sleeve shirt, and pants. Consider specially designed

protective off-road vehicle riding apparel.

• Safety

• Operation

• Maintenance

2002

MOTORCYCLE OWNER’S MANUAL

(E440, C440, X440)

Summary of C440

Page 1

P/n 951 - 5002274 before you operate the vehicle. . . . • read and understand this manual. It contains information important to your safety. • familiarize yourself with all vehicle controls and their proper operation. • perform the pre-ride inspection found in this manual. • wear appropriate protect...

Page 2

© 2002 cannondale corporation - all rights reserved 2 safety alerts.Fm safety alerts • failure to follow the warnings contained in this manual can result in serious injury or death. • keep this manual in a safe place. What is the safety alert symbol ? • pay special attention to all messages preceded...

Page 3

3 printed : 1/9/02 3 general precautions you must always exercise good judgement when assessing your abilities to perform the work described in this manual. • make sure you are familiar with basic safety practices before performing any work on the vehicle. • always work in a well-ventilated area. Ca...

Page 4

© 2002 cannondale corporation - all rights reserved 4 safety alerts.Fm potential hazard improper care when handling fuel. What can happen fuel is highly flammable, spilling it can cause a fire or explosion. How to avoid the hazard be sure the fuel cap is closed securely. Work in a well-ventilated ar...

Page 5

5 printed : 1/9/02 5 contents safety alerts . . . . . . . . . . . . . . . . . 2 contents . . . . . . . . . . . . . . . . . . . . . . 5 important information . . . . . . . . 6 about this manual . . . . . . . . . . . . . . . . . . . . . . . 6 how to use this manual . . . . . . . . . . . . . . . . . . ...

Page 6

© 2001 cannondale corporation - all rights reserved 6 important information.Fm important information a b o u t t h i s m a n u a l the purpose of this manual is to provide the owner with important safety, service, maintenance, and tuning information, and should be thoroughly read before operating or...

Page 7

7 printed : 1/9/02 7 e x p e r i e n c e d r id e r s o n l y • this vehicle is not for beginners. All cannondale motorsports products are designed for use by trained and experienced riders only. All are very high performance, competition sport machines and should only be operated by licensed compet...

Page 8

© 2001 cannondale corporation - all rights reserved 8 important information.Fm a l u m i n u m c h a s s i s c o m p on e n t s the aluminum chassis components of your vehicle have a finite, limited useful life. The length of that life varies depending on the material used in their manufacture, the ...

Page 9

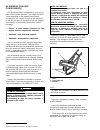

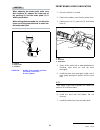

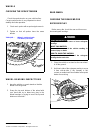

9 printed : 1/9/02 9 if any damage to the swinarm is detected, take corrective action before riding. Contact an authorized cannondale motorsports dealer for servicing. Note : the swingarm is shown removed from the vehicle for clarity. 1. Swingarm (1).

Page 10

© 2002 cannondale corporation - all rights reserved 10 motorcycle vehicle labeling.Fm vehicle labeling read and understand the labels on your vehicle. Examples of the labels can be found in this section. Warning labels contain information which is important to your safety and that of anyone else who...

Page 11

11 printed : 1/9/02 11 label 2 p/n 315-5001262-01 label 3 label 4 label 5 label 6 p/n 315-6000477-01.

Page 12

© 2002 cannondale corporation - all rights reserved 12 motorcycle machine identification.Fm machine identification note : your vehicle may differ from those shown in the illustrations in this manual. Record your vehicle’s identification numbers in the spaces provided. Keep another record of the numb...

Page 13

13 printed : 1/9/02 13 parts & controls this section describes the parts and control functions found on your vehicle. Not all the items found in this section may be installed on your vehicle. If you have any questions about the parts, control functions, or components installed on your vehicle, consu...

Page 14

© 2001 cannondale corporation - all rights reserved 14 motorcycle parts and controls.Fm l i gh t in g s w i t c h the lighting switch is used to activate the headlight and taillight together. It is located on the ride computer mounting bracket in front of the handlebar. The taillight should turn on ...

Page 15

15 printed : 1/9/02 15 h e a d l i g h t the headlight is located at the front of the vehicle and is activated with the headlight/ taillight switch. The highlight can be switch to hi or lo intensity with the headlight switch. Be sure the headlight is fastened securely with the mounting straps and op...

Page 16

© 2001 cannondale corporation - all rights reserved 16 motorcycle parts and controls.Fm f u s e s the fuses for your vehicle are located inside fuse holders under the seat. Unless directed otherwise in a procedure, you should always remove the fuses before working on the vehicle. Fuse replacement is...

Page 17

17 printed : 1/9/02 17 m u l t i - f u n c t i o n r i d e c o m p u t e r the multi-function ride computer is located between the handlebars. Consult the manufacturer’s instruction manual included with this manual for the unit features and operating instructions. Never remove your hands from the ha...

Page 18

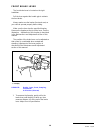

© 2001 cannondale corporation - all rights reserved 18 motorcycle parts and controls.Fm t h r o t t l e gr i p s e rv ic e : throttle lever freeplay 1/8 - 5/16 in (3 - 8 m m ) the throttle lever is located on the right handlebar and controls acceleration and deceleration of the engine. Before every ...

Page 19

19 printed : 1/9/02 19 f r o n t b r a k e l e v e r the front brake lever is located on the right handlebar. Pull the lever against the handle grip to activate the front brake. Always make sure the brakes (front and rear) on your vehicle operate properly before riding. Make sure the lever has the s...

Page 20

© 2001 cannondale corporation - all rights reserved 20 motorcycle parts and controls.Fm f o ot p e g s the right and left footpegs on your vehicle should be fastened securely and free of any collected mud or dirt. The footpegs should move freely (up and down on the pivot) and not bind - springing ba...

Page 21

21 printed : 1/9/02 21 s i d e s t a n d o r k i c k s t a n d the side stand or kickstand (on equipped vehicles) can be used to support the vehicle on firm level ground when not in use (with engine off). It is only designed to support the weight of the vehicle; so do not apply extra weight when usi...

Page 22

© 2001 cannondale corporation - all rights reserved 22 motorcycle parts and controls.Fm h a n d gu a r d s the handguards are located on the right and left sides of the handlebar directly in front of the handle grips. These guards are designed to only offer limited hand protection. Make sure you rea...

Page 23

23 printed : 1/9/02 23 f u e l c a p remove the fuel cap to fuel the motorcycle. You should fill the vehicle with the specified gasoline before each ride. See the fluids section of this manual. To open: turn the cap counter-clockwise. To close: reinstall the fuel cap and turn it clockwise until it i...

Page 24

© 2002 cannondale corporation - all rights reserved 24 motorcycle fluids.Fm fluids f u e l use only clean, fresh unleaded gasoline with a minimum anti-knock index of 92 or higher. Fill the tank with the specified fuel before every ride. We recommend that the inline fuel filter is replaced every 5 ho...

Page 25

25 printed : 1/9/02 25 b r a k e f l u id check the brake fluid in both the front and rear systems before every ride. Use only clean dot #4 brake fluid from a sealed container. Do not mix brake fluid types or brands. Have the brake fluid in both systems replaced every year. Caution avoid spilling br...

Page 26

© 2002 cannondale corporation - all rights reserved 26 motorcycle fluids.Fm 4. Pour dot#4 brake fluid from a sealed container until the fluid level rises to the top of the site window and no higher. If you fill above the window the fluid will overflow when the diaphragm and cover are re-installed. 5...

Page 27

27 printed : 1/9/02 27 e n g i n e o i l see the model specification section in this manual for the recommended engine oil type and capacity. Check the engine oil level before every ride. Clean the engine oil filters (screen type) or replace with new ones (paper element type) in accordance with main...

Page 28

© 2002 cannondale corporation - all rights reserved 28 motorcycle fluids.Fm funnel. If you see that the level is too high, drain some out using the left spar drain bolt until the oil level is visible through the window. Changing engine oil and cleaning the filters your vehicle has two engine oil fil...

Page 29

29 printed : 1/9/02 29 3. Remove the left spar drain bolt and drain the contents into an oil pan. Note : position a clean shop towel behind a folded piece of thin cardboard to channel or direct the flow of oil from the spar drain bolts into your oil pan. 4. When the spar flow is reduced, have an ass...

Page 30

© 2002 cannondale corporation - all rights reserved 30 motorcycle fluids.Fm 7. Remove the engine oil crankcase drain bolt and sealing washer and allow the oil to drain into your oil pan. 8. Apply some anti-seize compound to the threads of the drain bolt. Install the sealing washer onto the bolt so t...

Page 31

31 printed : 1/9/02 31 10. Clean the filter housing and cover with a clean shop towel to remove any accumulated sediment/debris. When you are cleaning, avoid displacing the contaminants into the areas noted in the photo. Also, be sure to clean the cover (o-ring) mating surfaces. Do not use any type ...

Page 32

© 2002 cannondale corporation - all rights reserved 32 motorcycle fluids.Fm 16. Remove the inlet fitting and inlet filter (screen) from the crankcase hole. Protect your eyes. Wear safety glasses when working with compressed air. 17. Clean the filter using compressed air. Inspect the inlet fitting, o...

Page 33

33 printed : 1/9/02 33 note : make sure you use a clean funnel. Pour slowly allowing the oil to flow throughout the spar. 21. Reinstall cap and run engine for 1 minute at idle speed to circulate the new oil. 22. Inspect the oil level through the inspection window. Adjust level as required. 1. Engine...

Page 34

© 2002 cannondale corporation - all rights reserved 34 motorcycle fluids.Fm tr a n s m i s s i on o i l see the model specification section in this manual for the recommended transmission oil and capacity. Check the transmission oil level before every ride. Change the transmission oil and clean the ...

Page 35

35 printed : 1/9/02 35 changing the transmission oil note : the transmission drain bolt is located on the right side of the engine. 1. Position the vehicle on a level surface. 2. Remove the transmission drain bolt and allow the oil to drain into your oil pan. Lean the vehicle slightly to the right t...

Page 36

© 2002 cannondale corporation - all rights reserved 36 motorcycle fluids.Fm note : the sealing washer is reusable however a damaged washer may result in a leak. Caution insert the filter into the bolt before installing. This method helps assure that the other end of the filter will locate into the b...

Page 37

37 printed : 1/9/02 37 c o o l a n t use a high quality ethylene glycol based anti- freeze containing corrosion inhibitors specifically formulated for use in aluminum engines. Use a 1:1 mixture of coolant and distilled water. Check the coolant level before every ride. Have the coolant in your vehicl...

Page 38

© 2002 cannondale corporation - all rights reserved 38 motorcycle fluids.Fm 2. When all pressure has escaped, press down on the cap and keep turning it until it can be removed. 3. The coolant level should be at the bottom of the filler neck. 4. Reinstall the radiator cap. 5. Check the entire cooling...

Page 39

39 printed : 1/9/02 39 h y d r a u l i c c l u t c h o i l see the model specification section in this manual for the recommended hydraulic clutch oil. Check the hydraulic clutch oil level every 10 hours. Bleed the system if the level feels weak or spongy. Caution never substitute brake fluid for sa...

Page 40

© 2002 cannondale corporation - all rights reserved 40 motorcycle fluids.Fm 4. Loosen the bolt and slowly compress the syringe until only oil, (no air bubbles) is discharged at the bore of the master cylinder. Make sure the oil does not overflow out of the master cylinder. 1. Bore 1.

Page 41

41 printed : 1/9/02 41 pre-ride inspection perform a pre-ride inspection of your motorcycle before every ride. Potential hazard failure to inspect the vehicle before operating. What can happen increases the possibility of equipment failure resulting in an accident. How to avoid the hazard always ins...

Page 42

© 2001 cannondale corporation - all rights reserved 42 motorcycle operation.Fm operation c o l d s t a r t i n g 1. Position the vehicle on level ground and shift the transmission into neutral. 2. Pull-in the clutch lever. 3. Press and hold the engine start button for 1 second then wait 5 seconds. 4...

Page 43

43 printed : 1/9/02 43 s h i f t i n g g e a r s caution when shifting gears, press the shift lever firmly to make sure the gear engagement is complete. Careless shifting can result in incomplete gear engagement and can cause the transmission to jump out of gear. This can severely damage the engine....

Page 44

© 2001 cannondale corporation - all rights reserved 44 motorcycle operation.Fm b r e a k - i n the break-in period is critical to the long term life and reliability of the engine. The break-in period for the engine is 1 hour. When operating during this period be sure to observe the following caution...

Page 45

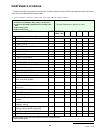

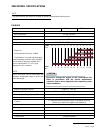

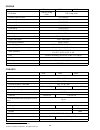

45 printed : 1/9/02 45 maintenance schedule perform the vehicle inspections found in the pre-ride inspection section of this manual before every ride and at each of the scheduled maintenance periods. C: clean, r: replace, l: lubricate, i: inspect, verify, clean, adjust, lubricate, replace if necessa...

Page 46

© 2001 cannondale corporation - all rights reserved 46 motorcycle maintenance schedule.Fm •• wheels/tires (pressure, condition, wear, spoke tightness, wheel bearing play) i i i i • swingarm (inspect, re-pack bearings) 1,2 i c: clean, r: replace, l: lubricate, i: inspect, verify, clean, adjust, lubri...

Page 47

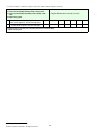

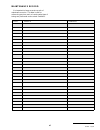

47 printed : 1/9/02 47 m a in t e n a n c e r e c o r d it is important to keep accurate records of maintenance service. This data is vital for referencing previous work or knowing what type of tuning was performed under certain conditions. Date service remarks.

Page 48

© 2001 cannondale corporation - all rights reserved 48 motorcycle maintenance and adjustment.Fm maintenance & adjustment periodic inspection, adjustment, and lubrication of your vehicle help to keep it safe and reliable to operate. The maintenance schedule provided in this manual is intended as a ge...

Page 49

49 printed : 1/9/02 49 4. Examine the receivers (slots) on the bottom of the seat pan. Make sure they are in good condition. If damage is found, replace the seat with a new one. Seat installation 1. To install the seat, align the retaining tabs on the fuel tank with the receivers on the underside of...

Page 50

© 2001 cannondale corporation - all rights reserved 50 motorcycle maintenance and adjustment.Fm f u e l throttle freeplay adjustment 1. To adjust the freeplay at the grip, slide boot back to expose lock ring and adjuster. Loosen the lock ring and turn the adjuster until the specified freeplay is rea...

Page 51

51 printed : 1/9/02 51 6. Remove remove the left (below top) and right (below bottom) radiator shrouds. 7. Press in the tabs on the fuel tank fittings and remove the inlet and outlet hoses from the tank. Caution later, when re-installing the tank, remember to inspect and coat the o-rings with clean ...

Page 52

© 2001 cannondale corporation - all rights reserved 52 motorcycle maintenance and adjustment.Fm 8. Remove the fuel tank mounting bolts. 9. Lift the tank out from the frame and position the tank on a level surface away from the work area. Caution don’t allow the weight of the tank to rest on the fitt...

Page 53

53 printed : 1/9/02 53 frame using the mounting bolts as this will cause damage to the fuel tank or other vehicle systems. 3. Install the tank mounting bolts and tighten them to the specified torque. To r q u e : fuel tank m ounting bolts 5.0 lbf•ft (6.8 n• m) 4. Reinstall the outlet (left side) and...

Page 54: Fuel

© 2001 cannondale corporation - all rights reserved 54 motorcycle maintenance and adjustment.Fm 5. Tighten the hose clamps securely. 6. Inspect the quick connect fitting o-rings. Replace them with new ones if you find and swelling, tears, rips or other damage. Coat o-rings with o-ring lubricant or c...

Page 55

55 printed : 1/9/02 55 b r a k e s testing the brakes for safe vehicle operation it is critical to have the brake system performing at its best. Regular inspection of the brake components and brake fluid level should become a habit prior to riding the vehicle. 1. Squeeze the front brake lever and te...

Page 56

© 2001 cannondale corporation - all rights reserved 56 motorcycle maintenance and adjustment.Fm 4. To adjust the lever position, loosen the clamp bolts and rotate the brake lever to the desired position. To r q u e : front brake m aster cylinder m ounting bolts 5.0 lbf•ft (6.8 n •m ) rear brake peda...

Page 57

57 printed : 1/9/02 57 caution when adjusting the brake pedal, make sure that clearance (a) between the lower end of the pushrod (1) and the brake pedal (2) is within specification. When raising the brake pedal, do not allow the lower end of the pushrod thread to enter into the brake pedal joint. S ...

Page 58

© 2001 cannondale corporation - all rights reserved 58 motorcycle maintenance and adjustment.Fm front brake pads inspection worn brake pads can damage the brake disc, adversely affecting brake performance and possibly causing an accident. Never ride the vehicle with worn or damaged brake pads. Each ...

Page 59

59 printed : 1/9/02 59 c l u t c h adjusting the clutch lever position caution the adjusting screw can be turned within certain limits. Do not use excessive force when turning the screw. 1. To adjust the lever position, turn the adjusting screw clockwise to reduce the distance between the lever and ...

Page 60

© 2001 cannondale corporation - all rights reserved 60 motorcycle maintenance and adjustment.Fm d r i v e drive chain see the model specifications section of this manual for the chain type and service limits (specifications). Significant forces act on the chain during operation. If its not clean and...

Page 61

61 printed : 1/9/02 61 2. Carefully clean the chain with a mild detergent and water solution. Rinse with clean water while gently scrubbing the chain with a light nylon brush. Repeat as needed. 3. Wipe dry with a clean shop towel. 4. Slowly rotate the wheel and apply the specified lubricant on the s...

Page 62

© 2001 cannondale corporation - all rights reserved 62 motorcycle maintenance and adjustment.Fm 4. Loosen the rear wheel axle nut (2) and the adjuster bolt locknuts (3). 5. Increase or decrease slack by using the adjuster bolts. Caution the alignment marks on the adjuster blocks and the marks on the...

Page 63

63 printed : 1/9/02 63 to r q u e : w heels, rear axle, nut 72.0 lbf•ft (98.0 n• m) 8. Install a new cotter pin and properly bend the tabs around the axle nut. 9. Tighten the drive chain adjuster locknuts securely. 10. Measure the drive chain freeplay again. Correct if necessary. 11. Take the vehicl...

Page 64

© 2001 cannondale corporation - all rights reserved 64 motorcycle maintenance and adjustment.Fm master link clip the open end of the masterlink clip must face the opposite direction of the chain rotation. Swingarm buffer inspect the swingarm buffer before every ride. Wear may be distributed unevenly...

Page 65

65 printed : 1/9/02 65 1. To replace the buffer, place the vehicle on a suitable stand. 2. Remove the bolts and the old buffer. Make sure you clean the buffer mounting screws with contact cleaner and apply loctite #242 agent before installing the new buffer. 3. Install the new buffer and tighten scr...

Page 66

© 2001 cannondale corporation - all rights reserved 66 motorcycle maintenance and adjustment.Fm sprocket inspection note : replace both the sprockets and drive chain as a set inspect the sprockets for cracks, chipped or broken teeth, excessive wear, and/or any other damage. Check the countershaft sp...

Page 67

67 printed : 1/9/02 67 mc1000 engine control module (unit) - (ecm or ecu) the ecm is located on the battery box within the subframe. . The ecm (also known as ecu) is the brain of the fuel injection system. This brain calculates fuel delivery and ignition timing based on information gathered from veh...

Page 68

© 2001 cannondale corporation - all rights reserved 68 motorcycle maintenance and adjustment.Fm e l e c t r ic a l fuse replacement 1. To replace a fuse, remove the seat. See seat removal in this manual. 2. Use a thin blade screwdriver to lift up on the latch. In the top photo, the connectors have b...

Page 69

69 printed : 1/9/02 69 3. Pull the bottom of the fuse socket towards the front of the vehicle. Caution do not pull on the wires. 4. Remove the fuse and install the specified replacement fuse. See the model specification section of this manual for the fuse rating. Battery the efi (electronic fuel inj...

Page 70

© 2001 cannondale corporation - all rights reserved 70 motorcycle maintenance and adjustment.Fm always use the specified spark plug with the proper gap. Torque the plug as specified. An overly-tight or cross-threaded spark plug will damage the threads in the spark plug hole. 1. Remove the seat. Prot...

Page 71

71 printed : 1/9/02 71 7. Lift out the coil. 8. Use a 5/8” spark plug socket and an extension to loosen and remove the spark plug. In the photo below, we used a 3/8” drive with a 6” long 5/8” spark plug socket on a 2 1/2” extension. 9. Lift out the spark plug and cover the cylinder head hole with a ...

Page 72

© 2001 cannondale corporation - all rights reserved 72 motorcycle maintenance and adjustment.Fm of specification, adjust it. If the spark plug utilizes multiple ground electrodes, measure each gap. 11. Set the specified gap. 12. Lightly coat the plug threads with a suitable anti-seize compound; this...

Page 73

73 printed : 1/9/02 73 20. Reconnect the coil harness connector. Slide it onto the coil making sure it latches. Install a zip tie over the latch. See photo below. 21. Reinstall removed components. Headlight bulb replacement consult the model specifications section of this manual for the replacement ...

Page 74

© 2001 cannondale corporation - all rights reserved 74 motorcycle maintenance and adjustment.Fm note : you may elect to examine the overall headlight mounting at this point. The entire headlight can be positioned slightly higher or slightly lower on the two fork legs. The position of the straps on t...

Page 75

75 printed : 1/9/02 75 a i r cleaning the air filter caution be very careful not to allow any dirt or foreign matter into the airbox when you have the filter removed. Severe engine damage will result if foreign matter or dirt enter the combustion chamber via the airbox. Use only high quality foam ai...

Page 76

© 2001 cannondale corporation - all rights reserved 76 motorcycle maintenance and adjustment.Fm 4. Place a clean shop towel over the airbox opening. 5. Separate the foam element from the screen. 6. Clean both with non-flammable (high-flash point) and rinse both with warm water. Squeeze the foam to r...

Page 77

77 printed : 1/9/02 77 e x h a u s t the exhaust system on your motorcycle has the two main roles of transferring combustion gases away from the rider and reducing engine noise levels. You should not attempt to remove or modify the exhaust system in any way. Visually inspect the exhuast system befor...

Page 78

© 2001 cannondale corporation - all rights reserved 78 motorcycle maintenance and adjustment.Fm s u s p e n s i o n suspension: internal settings and external adjusters the suspension components (front fork and rear shock) on your cannondale vehicle are fully adjustable. The adjustment is gained thr...

Page 79

79 printed : 1/9/02 79 note : the initial suspension impression (or “feel”) could be harsh or stiff, this will change after about 1 hour of use. Therefore, do not change the initial suspension settings until after the vehicle has been ridden for 1 hour. Suspension servicing potential hazard worn or ...

Page 80

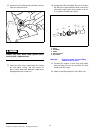

© 2001 cannondale corporation - all rights reserved 80 motorcycle maintenance and adjustment.Fm front suspension (6) (2) (5) (7) (1) (3) (4) 1. Fork 2. Protector 3. Rebound damping adjuster 4. Air bleed screw 5. Wear ring 6. Seal (wipers) 7. Compression damping adjuster.

Page 81

81 printed : 1/9/02 81 front suspension inspection 1. Make sure the fork leg protectors are clean (not packed with mud or dirt) fastened securely and undamaged. 2. Make sure the fork seals are in good condition and clean. Replace leaking fork seals before you ride the vehicle. Replacement involves f...

Page 82

© 2001 cannondale corporation - all rights reserved 82 motorcycle maintenance and adjustment.Fm caution observe the torque specification found in the torque table in this manual. The forks can be severely damaged if you over tighten them in the clamps. 6. Inspect bolts and nuts for tightness. 7. App...

Page 83

83 printed : 1/9/02 83 front ride height & static sag the ride height and static sag specifications for your vehicle can be found in the model specification section of this manual. Make sure the vehicle ride height and static sag dimensions are as specified before performing compression or rebound a...

Page 84

© 2001 cannondale corporation - all rights reserved 84 motorcycle maintenance and adjustment.Fm fork rebound damping adjustment caution adjust both forks to the same setting. Rebound damping affects how quickly the fork “rebounds” or returns to the fully extended position after compression. A reboun...

Page 85

85 printed : 1/9/02 85 cleaning the forks clean the forks after every ride. Caution pressure or steam washing will severely damage the fork legs on your vehicle - resist the temptation! The forks, although quite sturdy, have delicate internal components that must stay clean and free of contaminants....

Page 86

© 2001 cannondale corporation - all rights reserved 86 motorcycle maintenance and adjustment.Fm rear suspension note : component shown removed for clarity (1) (2) (3) (4) (8) (7) (6) (5) (10) (9) 1. Body 2. Reservoir 3. Nitrogen gas hazard warning 4. Compression damping adjuster 5. Spring 6. Spring ...

Page 87

87 printed : 1/9/02 87 rear ride height & static sag the ride height and static sag specifications for your vehicle can be found in the model specification section of this manual. Make sure the vehicle ride height and static sag dimensions are as specified before performing compression or rebound ad...

Page 88

© 2001 cannondale corporation - all rights reserved 88 motorcycle maintenance and adjustment.Fm adjusting the rear spring preload the following rear shock spring service specifications can be found in the model specifications section in this manual: (free length, installed length (minimum preload), ...

Page 89

89 printed : 1/9/02 89 rear shock rebound damping adjustment rebound damping affects how quickly the shock “rebounds” or returns to the fully extended position after compression. A rebound damping adjuster is located at the bottom of the shock. The adjuster has 42 positions. Each position can be ide...

Page 90

© 2001 cannondale corporation - all rights reserved 90 motorcycle maintenance and adjustment.Fm w h e e l s checking the spoke tension check the spoke tension on your vehicle often. Correct spoke tension is very important to wheel stability and safe operation. 1. Check each spoke with a spoke nipple...

Page 91

91 printed : 1/9/02 91 ti r e s the following tire service specifications for your vehicle can be found in the model specifications section in this manual: (front tire size, rear tire size, front/rear cold tire pressure). Be sure to observe the specifications and service limits for your vehicle. Che...

Page 92

© 2001 cannondale corporation - all rights reserved 92 motorcycle maintenance and adjustment.Fm to r q u e : r im lock nut 9.0 lbf-ft (12.2 n• m) note : if the tire or inner tube needs to be replaced or remounted, contact an authorized cannondale dealer for servicing. 1. Vale stem 2. Locknut 3. Riml...

Page 93

93 printed : 1/9/02 93 s t e e r i n g adjusting the handlebar position the handlebar position can be adjusted rearward from the factory-set position by removing the lower handlebar clamps and rotating them 180°. 1. Place the vehicle on a stand and cover the gas tank with a clean rag. 2. Remove the ...

Page 94

© 2001 cannondale corporation - all rights reserved 94 motorcycle maintenance and adjustment.Fm 6. After installing the handlebar, sit on the vehicle, apply the front brake, and push down on the front end a few times to check if the handlebar moves. 7. Also, turn the handlebar from lock-to-lock to c...

Page 95

95 printed : 1/9/02 95 c l e a n i n g regular cleaning helps to maintain appearance and contributes to overall performance of the vehicle by keeping it free of damaging dirt, soils, and grime. • when cleaning, avoid harsh detergents and chemical solvents. Use mild solutions of ordinary dish soaps a...

Page 96

© 2001 cannondale corporation - all rights reserved 96 motorcycle maintenance and adjustment.Fm 2. Remove any debris with a clean rag. Use contact cleaner to displace any hidden water residue. 3. Reinstall the generator cover making sure that the cover gasket is properly installed onto the cover and...

Page 97

97 printed : 1/9/02 97 s t o r a g e when the vehicle will not be operated for an extended period of time (e.G., winter months, 45 days or more), it is necessary to perform certain procedures to guard against deterioration and to make sure it is in perfect running condition when the riding season be...

Page 98

© 2001 cannondale corporation - all rights reserved 98 motorcycle maintenance and adjustment.Fm to r q u e t a b l e item lbf•ft n•m kgf•m side panel mounting bolts 5.0 6.8 0.69 rear fender mounting bolt 5.0 6.8 0.69 engine oil spar drain bolts (left/ right) 15.0 20.3 2.07 engine oil drain bolt (cra...

Page 99

99 printed : 1/9/02 99 2002 model specifications note : the specifications are subject to change for product improvement without notice. E n g i n e x440 c440 e440 engine 4 - stroke single bore and stroke 95 mm x 61 mm compression ratio 12.5: 1 displacement 432 cc engine management system mc 1000, e...

Page 100

© 2001 cannondale corporation - all rights reserved 100 2002 motorcycle model specifications.Fm final drive 520 non o-ring chain 520 o-ring chain primary reduction ratio 3.071 (86/28) gear ratio 1 2,000 (30/15) gear ratio 2 1.588 (27/17) gear ratio 3 1.316 (25/19) gear ratio 4 1.095 (23/21) gear rat...

Page 101

101 printed : 1/9/02 101 air filter wet foam type front brake 240mm disc, nissin dual piston caliper rear brake 220mm disc, nissin dual piston caliper brake fluid dot 4 (sealed container) brake pad thickness (min) 0.04 in (1.0 mm) brake disc thickness (min) 0.14 in (3.5 mm) clutch oil (hydraulic) sa...

Page 102

© 2001 cannondale corporation - all rights reserved 102 2002 motorcycle model specifications.Fm compression damping (std) 18 18 23 rebound damping (std) 14 15 15 ride height 3.7 - 4.0 in (95 - 100 mm) static sag 1.0 - 1.2 in (25 - 30 mm) s u s p e n s i o n x440 c440 e440