- DL manuals

- Canon

- Printer

- FAXPHONE L75

- Service Manual

Canon FAXPHONE L75 Service Manual

Summary of FAXPHONE L75

Page 1

Faxphone l75 service manual canon.

Page 2: I. Preface

1 i. Preface this manual is based on the following manuals, and only includes differences between laser class 1060p and faxphone l75 . Hy8-19au-000 laser class 1060p service manual, rev.0 hy8-39ar-000 laser class 1060p catalog, rev.0 hy8-89at-000 laser class 1060p circuit diagram, rev.0 ii. Contents...

Page 3: Chapter 1

2 chapter 1 points of differnece from the originalmachine.

Page 4

3 1. Parts change for details of any change in parts numbers, see the parts catalog. 2. Specification change canges have been made to the electrical circuitry, and the functions of the ncu board have been integrated with those of the scnt board. In this service reference manual, detailed explanation...

Page 5

4 interface specifications (faxphone l75) interface usb only support software windows 98/me/2000/xp winsows 95/nt4.0 (not support) fax-l290 suite usb i/f windows 95 not supported windows 98 conditionally supported* windows nt 4.0 not supported windows 2000 conditionally supported* windows me conditi...

Page 6

7 7. Error codes and recovery methods as for the descriptions of causes of and actions for error codes, only those items to which changes have been made because of the use of different connector numbers are indicated. #001 [tx] paper jam cause: the document jammed in the fax machine. Solutions: remo...

Page 7

8 #003 [tx/rx] copy page transmission time over cause: one page of the document was longer than 39.4 inches (1 meter) or transmission/copying took longer than the regulated time (32 minutes). Solutions: (1) use a copy machine to copy the document onto serveral shorter page, then tranmit/copy. (2) ra...

Page 8

9 ##322 [rx] fixing heater temperature abnormality cause: internal unit defect. Solutions: (1) check the connections between the fixing ass’y and the pcnt board (j102) and between the fixing ass’y and the scnt board (j14). (2) check the connection between the pcnt board (j1) and the power supply uni...

Page 9

10 general errors • the unit does not turn on. (evaluation criteria: look at the actual unit.) (1) check the power cord connection. (2) check the connection between the pcnt board (j1) and power supply unit (j202). (3) check the connection between the scnt board (j8) and power supply unit (j201). (4...

Page 10

11 printing problems • faulty printing (evaluation criteria: test print is faulty.) • the paper is not fed correctly. (evaluation criteria: look at the actual unit.) the main motor does not run. (1) check the connection between the main motor and the pcnt board (j401). (2) check the main motor’s res...

Page 11

12 scanning problems • faulty scanning (evaluation criteria: test print is good, but the copied image is poor.) • the document is not fed. The document feed motor does not run. (evaluation criteria: check it visually.) (1) check the connection between the document feed motor and the pcnt board (j402...

Page 12: Chapter 2

Chapter 2 circuit diagram.

Page 13: II. Product No. List

Ii ii. Product no. List this manual describes the component units of the following products. Product no. H12-2502 faxphone l75 (usa) pcnt board ass’y hg5-2968 hg5-2968 opcnt board ass’y hg5-2970 hg5-2968 scnt board ass’y hg5-2997 hg5-2997 modular board hg5-2998 hg5-2998 ass’y power supply unit hh3-5...

Page 14: Revision 0

Revision 0 copyright © 2001 canon inc. Canon laser class 1060p apr. 2001 printed in japan (imprime au japon) hy8-19au-000 apr. 2001 laser class 1060p h12-2042 120v usa handset kit 3 h12-3701 120v usa.

Page 15

Application this manual has been issued by canon inc. For qualified persons to learn technical theory, installation, mainte- nance, and repair of products. This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does not apply to y...

Page 16: I. Meanings of Marks

I i. Meanings of marks if the following mark is used, follow the directions given. Mark meaning states a precaution to be taken to prevent danger to personnel, damage to the product, or damage to electronic components by discharge of static electricity. For example. States a precaution to be taken t...

Page 17: II. About This Manual

Ii ii. About this manual this manual is divided into four parts, and contains information required for servicing the product. Chapter 1: general description this part explains product specifications and the how to service the unit safely. Chapter 2: technical reference this part explains the technic...

Page 18: III. Revision History

Iii iii. Revision history revision content 0 original.

Page 19: IV. Table of Contents

Iv iv. Table of contents chapter 1: general description page 1-1 1. Features 1-1 1.1 overview 1-2 2. Specifications 1-2 2.1 general specification 1-2 2.2 communication specification 1-3 2.3 scanner specification 1-5 2.4 printer specification 1-7 2.5 copy specifications 1-8 2.6 function 1-10 2.7 inte...

Page 20

V 2-21 7. New function chapter 3: assembly and disassembly 3-1 1. Attention to be paid during assembly/disassembly 3-1 1.1 safety cautions 3-2 1.2 general cautions 3-3 1.3 product-inherent cautions 3-3 1.4 action in the event of abnormality (all clear) 3-4 2. Disassembly/assembly 3-4 2.1 parts layou...

Page 21

Vi 4-7 3. Troubleshooting 4-7 3.1 troubleshooting index 4-9 3.2 errors shown on the display 4-9 3.2.1 user error message 4-12 3.2.2 error codes 4-22 3.3 errors not shown on the display 4-22 3.3.1 general errors 4-23 3.3.2 printing problems 4-31 3.3.3 faults in the printer unit 4-35 3.3.4 scanning pr...

Page 22: Chapter 1

Chapter 1 general description.

Page 23: 1. Features

1-1 laser class 1060p chapter 1: general description 1. Features 1.1 overview this product is a g3 transceiving facsimile based on the itu-t recommendation. The product uses an lbp printer operating on the principle of electro photographic recording. High image quality the product uses a laser beam ...

Page 24: 2. Specifications

1-2 laser class 1060p chapter 1: general description 2. Specifications 2.1 general specification type desktop body colour cool white power source 102 ~ 132v ac, 45 ~ 65 hz, power consumption standby less than 7.5w / less than 500w (when operating) usage environment 50.0°f ~ 90.5°f (10°c ~ 32.5°c), 2...

Page 25

1-3 laser class 1060p chapter 1: general description time required for transmission protocol pre-message post-message post-message protocol *1 protocol *2 protocol *3 mode (between pages) (after pages) t.30 standard approx. 12sec. Approx. 4sec. Approx. 3.5sec. V.34 approx. 9sec. Approx. 1sec. Approx...

Page 26

1-4 laser class 1060p chapter 1: general description scanning range sheet dimensions (w × l) maximum multiple pages: 8.50" × 14.01" (216 mm × 355.9 mm) 1 pages: 8.50" × 39.37" (216 mm × 1000 mm) minimum 5.83" × 4.13" (148 mm × 105 mm) thickness multiple pages: 0.002" ~ 0.005" (0.06 mm ~ 0.13 mm) 40~...

Page 27

1-5 laser class 1060p chapter 1: general description 2.4 printer specification printing method laser beam printer printing cartridge products name canon fx3 cartridge product code h11-6381 (new product code: 1557a) valid period within the guaranteed period indicated on the package of the cartridge. ...

Page 28

1-6 laser class 1060p chapter 1: general description printing range paper dimensions (w × l) letter 8.50" × 11.00" (215.9 mm × 279.4 mm) legal 8.50" × 14.00" (215.9 mm × 355.6 mm) a4 8.27" × 11.69" (210 mm × 297 mm) figure 1-2 printing range item a4 letter legal effective printing width 8.11" ±0.08"...

Page 29

1-7 laser class 1060p chapter 1: general description 2.5 copy specifications color copy none multiple copy 99 copies copy resolution scanning 400 dpi × 300 dpi (direct copy) 200 dpi × 300 dpi (memory copy) printing 600 dpi × 600 dpi copy magnification ratio 100%, 90%, 80%, 70% note • when one copy i...

Page 30

1-8 laser class 1060p chapter 1: general description 2.6 function dialling manual dialling numeric button auto dialing max. 120 digits one-touch:24, coded speed:100 group dial max.123 locations redial numeric button redial function (max. 120 digits) transmission broadcast transmission max. 125 locat...

Page 31

1-9 laser class 1060p chapter 1: general description others closed network none direct mail prevention telephone numbers compared telephone numbers registerd under one-touch and coded speed dial, and a tsi signal number of digits lower 6 digits (number of digits can be changed with service data #3) ...

Page 32

1-10 laser class 1060p chapter 1: general description 2.7 interface spcifications 2.7.1 bi-directional centronics interface a) specifications this parallel interface performs data transmission 8 bits (1 byte) at a time, and conforms to ttl. Interface type ieee p1284-b/bi-directional parallel data tr...

Page 33

1-11 laser class 1060p chapter 1: general description ecp mode ecp stands for extended compatibility port. High-speed data transfer can be accomplished with ecp mode. Data can be transferred faster than in nibble mode because data lines can be used in both direc- tions without changing modes. Option...

Page 34

1-12 laser class 1060p chapter 1: general description jusb1 pc signal name description 1 ← 1 vbus cable power supply (+5v dc) 2 — 2 d– data 3 — 3 d+ data 4 — 4 gnd cable gnd b) usb interface usb is a serial interface which connects up to 127 peripheral devices to a host computer, and transmits data ...

Page 35

1-13 laser class 1060p chapter 1: general description encoding/decoding the data in usb, data transfer lines are ultimately encoded with nrzi (non return to zero invert) method. When the original data bit is 0, sent data bits are inverted; when the original data bit is 1, the value is retained. Howe...

Page 36: 3. Overview

1-14 laser class 1060p chapter 1: general description 3. Overview 3.1 external view figure 1-6 external view (1) support trays multi-purpose tray cover adf (automatic document feeder) document guides operation panel paper delivery selector document support face-up delivery slot front cover face-down...

Page 37

1-15 laser class 1060p chapter 1: general description connecting the laser class 1060p to your pc figure 1-7 external view (2) to connect your fax to a pc, you will need to purchase a printer cable that matches the interface connector on your pc: • a centronics ® -compatible parallel cable (ieee 128...

Page 38

1-16 laser class 1060p chapter 1: general description 3.2 operation panel figure 1-8 operation panel (1) alarm ghi jkl mno abc def tuv wxy pqrs stop hook coded dial pause receive mode redial start/copy resolution set 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 1 0 # 7 8 9 4 5 6 2 3 2...

Page 39

1-17 laser class 1060p chapter 1: general description installing the toner cartridge this section describes how to install the toner cartridge in the fax for the very first time. If you are replacing a used toner cartridge. Before installing the toner cartridge, be sure to read the following: • use ...

Page 40

1-18 laser class 1060p chapter 1: general description this page intentionally left blank.

Page 41: Chapter 2

Chapter 2 technical reference.

Page 42: 1. Component Layout

2-1 laser class 1060p chapter 2: technical reference 1. Component layout 1.1 parts layout the parts layout of this machine consists of the scanning assembly, printing assembly and printer. Figure 2-1 mechanical layout transfer charging roller main motor pressure roller pickup roller separation rolle...

Page 43

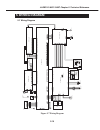

2-2 laser class 1060p chapter 2: technical reference the following six printed circuit boards are located in this machine: • scnt board that controls the entire system • ncu board that interfaces with the telephone line • modular board that connects the telephone line and the ncu board • pcnt board ...

Page 44

2-3 laser class 1060p chapter 2: technical reference figure 2-2 electrical system layout scnt board ncu board modular board power supply unit pcnt board document edge sensor: it detects the document leading/trailing edges. Document sensor: detects whether or not a document is set. Paper edge sensor:...

Page 45: 2. Scanner Mechanism

2-4 laser class 1060p chapter 2: technical reference 2. Scanner mechanism the scanner section scans documents that are to be sent or copied. Figure 2-3 scanner section 7 8 3 4 5 10 2 12 14 9 7 12 6 13 11 1 13 6 9 11.

Page 46

2-5 laser class 1060p chapter 2: technical reference names and functions of parts: 1. Paper guide it is used to hold down the original in horizontal direction to prevent it from moving askew. 2. Document feed motor this motor drives all the rollers in the scanner section. 3. Document sensor (ds) thi...

Page 47

2-6 laser class 1060p chapter 2: technical reference note initializing the upper document feed roller when the separation roller starts to rotate, the position of the upper document feed roller is simultaneously initialized to raise the document stopper. Initialization is carried out when the power ...

Page 48: 3. Paper Supply Section

2-7 laser class 1060p chapter 2: technical reference 3. Paper supply section the paper supply section is designed to separate the recording sheets stacked on the multi-purpose tray one by one for forwarding to the printer unit. Figure 2-4 paper supply section 2 3 5 6 1 4.

Page 49

2-8 laser class 1060p chapter 2: technical reference names and functions of parts: 1. Paper guide this guide can be adjusted to the width of the loadable recording paper sizes. It prevents the recording paper from skewing during recording by accurately aligning the paper width. 2. Main motor this mo...

Page 50

2-9 laser class 1060p chapter 2: technical reference note paper feed jam detection there are one types of paper jam which may occur: a) paper feed stationary jam the paper feed stationary jam occurs if the trailing edge of the recording paper is not detected within 11.7 seconds after the paper edge ...

Page 51: 4. Printer Section

2-10 laser class 1060p chapter 2: technical reference 4. Printer section the laser beam printer engine comprises the following sections. Figure 2-5 printer section paper feed / eject section fixing section toner cartridge toner transfer section laser / scanner section.

Page 52

2-11 laser class 1060p chapter 2: technical reference 4.1 laser/scanner section Æ Æ Æ Æ Æ see page 2-12 this section comprises a laser unit, cylindrical lens, 4-faced polygon mirror, scanner motor, imaging lens, reflection mirror and bd unit. The laser is driven in accordance with the laser drive si...

Page 53

2-12 laser class 1060p chapter 2: technical reference note bd malfunction bd is out of the bd cycle for 2.0 seconds or more during laser drive while the scanner motor is rotating at fixed speed, the printer controller judges this to be a bd malfunction. Scanner motor malfunction if the predetermined...

Page 54

2-13 laser class 1060p chapter 2: technical reference note fixing heater malfunction the printer controller on the pcnt board detects a fixing heater malfunction in the follow- ing instances. A) the thermistor does not detect 150°c or higher 30 sec after temperature control starts. B) the thermistor...

Page 55

2-14 laser class 1060p chapter 2: technical reference paper delivery slot switching the outlets of recording paper are switched over by means of a flapper, which is operated by the delivery selector found at the left bottom of the face-up delivery slot. When the delivery selector is pulled to the fr...

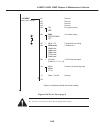

Page 56: 5. Wiring Diagram

2-15 laser class 1060p chapter 2: technical reference 5. Wiring diagram 5.1 wiring diagram figure 2-7 wiring diagram 123 modular board scnt board ncu board pcnt board j5 1 2 j4 1 2 1 7 1234567 7354321 1 7 p o w er supply unit 12 j204 12 cl inl101 3 1 321 123 p s p aper sensor edge 13 1 1 2 3 4 5 6 7...

Page 57: 6. Electric Circuit

2-16 laser class 1060p chapter 2: technical reference 6. Electric circuit 6.1 component block diagram figure 2-8 block diagram c) b) mpu (ic1) reset ic (ic5) system controller(1/2) (ic10) printer controller (ic201) system controller(2/2) (ic10) dram 64m bit (ic4) rom 8m bit (soc1) address bus, a24-s...

Page 58

2-17 laser class 1060p chapter 2: technical reference 6.2 circuit board components a) system control section the system controller is made up of the following components, and controls the entire fax system. A-1) mpu (micro processor unit) (ic1) the main functions of the nec µpd703100agj-33-uen mpu a...

Page 59

2-18 laser class 1060p chapter 2: technical reference b) communication control section modem ic (ic401) a conexant fm336 is used as the modem ic. The modem ic carries out g3 modulation conforming to itu-t standards v.34,v.27ter, v.29, v.17, v.8 and v.21 on transmitted data received from the mpu duri...

Page 60

2-19 laser class 1060p chapter 2: technical reference 6.3 flow of image signals a) g3 transmission (1) with the led as a light source, the image is scanned by the contact sensor, and analogue image data sent to the scnt board. (2) the system controller ic (internal uhq unit) converts analogue image ...

Page 61

2-20 laser class 1060p chapter 2: technical reference b) g3 reception (1) image signals received by l1, l2, pass through the hybrid circuit in the ncu, and are amplified. The modem demodulates these image, and writes them to the dram. (2) the mpu decodes the demodulated image data, checks errors, st...

Page 62: 7. New Function

2-21 laser class 1060p chapter 2: technical reference 7. New function there is no new function in this model..

Page 63

2-22 laser class 1060p chapter 2: technical reference this page intentionally left blank.

Page 64: Chapter 3

Chapter 3 assembly and disassembly.

Page 65

3-1 laser class 1060p chapter 3: assembly and disassembly 1. Attention to be paid during assembly/disassembly 1.1 safety cautions electrical shock in order to prevent any risk of electrical shock, always be sure to check that the power cord and modular jack have been removed. Also, remove all cables...

Page 66

3-2 laser class 1060p chapter 3: assembly and disassembly 1.2 general cautions damage due to electrostatic discharge this machine contains contact sensors and printed circuit boards that use roms, rams, custom chips and other electronic components that are vulnerable to damage by electrostatic disch...

Page 67

3-3 laser class 1060p chapter 3: assembly and disassembly 1.3 product-inherent cautions laser light do not perform any tasks outside the scope of work indicated in the manual. (if exposed to laser light, the retina of the eye can permanently be damaged.) further, the laser scanner unit must not be d...

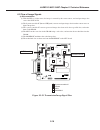

Page 68: 2. Disassembly/assembly

3-4 laser class 1060p chapter 3: assembly and disassembly 2. Disassembly/assembly 2.1 parts layout the parts layout of this machine consists of the scanning assembly, printing assembly and printer. Figure 3-2 mechanical layout transfer charging roller main motor pressure roller pickup roller separat...

Page 69

3-5 laser class 1060p chapter 3: assembly and disassembly the electrical parts are laid out as follows. • scnt board that controls the entire system • ncu board that interfaces with the telephone line • modular board that connects the telephone line and the ncu board • pcnt board that generates high...

Page 70

3-6 laser class 1060p chapter 3: assembly and disassembly figure 3-3 electrical layout scnt board ncu board modular board power supply unit pcnt board document edge sensor: it detects the document leading/trailing edges. Document sensor: detects whether or not a document is set. Paper edge sensor: i...

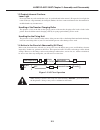

Page 71

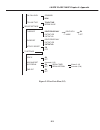

3-7 laser class 1060p chapter 3: assembly and disassembly 2.2 disassembly work-flow the work-flow for the disassembly of the main units is as follows. In order to replace parts, you need to confirm which parts have to be removed. Numbers in parenthese indicate the disassembly number. Figure 3-4 disa...

Page 72

3-8 laser class 1060p chapter 3: assembly and disassembly 2.3 disassembly procedure disassembly 1. Main cover/multi-purpose tray unit 1) while holding the latch a, open the upper cover. Remove the two screws b and the four screws c. 2) remove the connector cover. 3) remove the main cover. 4) remove ...

Page 73

3-9 laser class 1060p chapter 3: assembly and disassembly disassembly 2. Reading ass’y 1) perform disassembly 1. 2) disconnect the cables a and b connected to the scnt board and the relay cable c. 3) remove the three screws d, and remove the grounding wire. 4) remove the pin e. 5) remove the reading...

Page 74

3-10 laser class 1060p chapter 3: assembly and disassembly disassembly 3. Scnt board/ncu board note the scnt board/ncu board may be replaced without removing the reading ass’y. Scnt board 1) perform disassembly 1. 2) disconnect the eight connectors connected to the scnt board. 3) remove the six scre...

Page 75

3-11 laser class 1060p chapter 3: assembly and disassembly ncu board 1) disconnect the four connectors connected to the ncu board. 2) remove the two screws b, and detach the ncu board. Side piate 1) remove the three screws c, and detach the side plate. Figure 3-7 disassembly 3 c a b h i e a g c d d ...

Page 76

3-12 laser class 1060p chapter 3: assembly and disassembly note caution when replacing scnt board follow the procedure given below when replacing the scnt board. A) caution before replacing after replacing the scnt board , you will need to perform an all clear operation. Be sure to print out any dat...

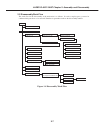

Page 77

3-13 laser class 1060p chapter 3: assembly and disassembly disassembly 4. Modular board/pcnt board/power supply unit and main frame modular board 1) perform disassembly 1 through 3. 2) remove the two screws a, and detach the modular board. Main frame 1) perform disassembly 1 through 3. 2) remove the...

Page 78

3-14 laser class 1060p chapter 3: assembly and disassembly figure 3-8 disassembly 4 pcnt board a a p b c p m l i lever speaker cover modular board n k o front cover cable cover speaker main frame e d j p h f g m fuse (f101) 125v,10a fuse (f102) 125v,5a.

Page 79

3-15 laser class 1060p chapter 3: assembly and disassembly 2.4 reading ass’y disassembly 5. Reading ass’y 1 1) perform disassembly 1 and 2. 2) remove the four screws a, and detach the air duct cover. 3) open the control panel, and remove the stopper b; then, detach the scanner ass’y. 4) remove the f...

Page 80

3-16 laser class 1060p chapter 3: assembly and disassembly disassembly 6. Reading ass’y 2 1) perform disassembly 1, 2, and 5. 2) remove the two screws a, and detach the adf upper. Disassembly 7. One-touch cover 1) while taking care not to bend the claws, remove the one-touch cover. Disassembly 8. Se...

Page 81

3-17 laser class 1060p chapter 3: assembly and disassembly figure 3-10 disassembly 6/7/8/9 white sheet unit b a separation guide ass'y one-touch cover d adf upper c a.

Page 82

3-18 laser class 1060p chapter 3: assembly and disassembly disassembly 10. Contact sensor 1) perform disassembly 5 to detach the scanner ass’y. 2) remove the three screws a. 3) disconnect the contact sensor, and disconnect the cable b. Handing the contact sensor take care not to scratch or soil the ...

Page 83

3-19 laser class 1060p chapter 3: assembly and disassembly figure 3-11 disassembly 10/11/12 contact sensor separation roller a a b a document feed motor c.

Page 84

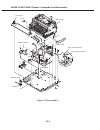

3-20 laser class 1060p chapter 3: assembly and disassembly 2.5 printer ass’y disassembly 13. Scanner unit 1) perform disassembly 1. 2) remove the stopper a. 3) remove the screw b, and detach the actuator unit c. 4) remove the four screws d, and detach the scanner unit. At this time, take care not to...

Page 85

3-21 laser class 1060p chapter 3: assembly and disassembly figure 3-12 disassembly 13/14/15 d scanner unit d paper feed ass'y g g h main motor a c b e f.

Page 86

3-22 laser class 1060p chapter 3: assembly and disassembly disassembly 16. Fixing ass’y 1) perform disassembly 1 through 4. 2) remove the feed roller and the cartridge guide. 3) remove the two screws a, and detach the delievry ass’y. 4) remove the flapper. 5) remove the two screws b, and detach the ...

Page 87

3-23 laser class 1060p chapter 3: assembly and disassembly figure 3-13 disassembly 16/17 1 2 34 5 6 6 5 4 3 2 1 b a feed roller flapper cartridge guide paper guide pressure roller pressure plate delievry ass'y fixing ass'y.

Page 88

3-24 laser class 1060p chapter 3: assembly and disassembly disassembly 18. Transfer roller 1) perform disassembly 1 through 4. 2) using a precision screwdriver or the like, detach the transfer guide. 3) remove the transfer roller. When removing the roller, take care not to touch the sponge portion. ...

Page 89

3-25 laser class 1060p chapter 3: assembly and disassembly disassembly 19. Pickup solenoid 1) perform disassembly 1, 2, and 14. 2) remove the screw a, and detach the pickup solenoid. Disassembly 20. Pickup roller ass’y 1) perform disassembly 1, 2, and 14. 2) remove the gear b and the stopper c; then...

Page 90

3-26 laser class 1060p chapter 3: assembly and disassembly figure 3-15 disassembly 19/20/21/22 guide plate separation pad stopper pickup solenoid a e b c f pickup roller ass'y d feed roller.

Page 91

3-27 laser class 1060p chapter 3: assembly and disassembly e d h pickup roller spring a j f b g c toner sensor sub roller i disassembly 23. Toner sensor 1) perform disassembly 1, 2, 14, and 20. 2) remove the spring. When removing the spring, take care not to lose it. 3) remove the cam a, and pull of...

Page 92

3-28 laser class 1060p chapter 3: assembly and disassembly disassembly 25. Rom replacement with this unit, there should be no need to replace roms, but in the event that rom replacement becomes necessary, follow the procedure described below. A) before starting the work you will have to execute ‘all...

Page 93: Chapter 4

Chapter 4 maintenance and service.

Page 94: 1. Maintenance List

4-1 laser class 1060p chapter 4: maintenance & service 1. Maintenance list 1.1 consumables level consumable when user toner cartridge (fx3) when “change cartridge” is displayed. Service technician none 1.2 cleaning level consumable when user main unit outer covers when dirty. Separation roller when ...

Page 95

4-2 laser class 1060p chapter 4: maintenance & service level consumable when service technician paper eject face-up when paper jams occur during copying or receiving. Roller flapper when paper jams occur frequently during copying or receiving. Pressure roller when marks appear on back of paper at in...

Page 96: 2. How To Clean Parts

4-3 laser class 1060p chapter 4: maintenance & service 2. How to clean parts 2.1 main unit outer covers lightly wipe the unit’s outer causing with a clean, soft, lint-free cloth moistened with water or diluted dishwashing detergent solution. 2.2 separation roller wipe with a soft, dry clean cloth. 2...

Page 97

4-4 laser class 1060p chapter 4: maintenance & service figure 4-1 cleaning location 1 white sheet separation roller (scanner section) separation guide main unit outer cover scanning glass paper feed guide.

Page 98

4-5 laser class 1060p chapter 4: maintenance & service 2.7 paper pickup roller using lint-free paper dipped in isopropyl alcohol, wipe and dirt off the paper pickup roller. 2.8 transfer charging roller wipe with lint-free paper and remove any toner or paper debris. Do not touch or hold the sponge se...

Page 99

4-6 laser class 1060p chapter 4: maintenance & service figure 4-2 cleaning location 2 transfer charging roller paper pickup roller static charge eliminater high voltage terminal fixing entrance guide paper eject face-up roller pressure roller fixing ass'y flapper document feed roller document eject ...

Page 100: 3. Troubleshooting

4-7 laser class 1060p chapter 4: maintenance & service 3. Troubleshooting 3.1 troubleshooting index use the troubleshooting index below to investigate the cause of a problem and refer to the specified page for countermeasures. Problem • errors shown on the display (evaluation criteria: look at the u...

Page 101

4-8 laser class 1060p chapter 4: maintenance & service • scanning problems (evaluation criteria: test printing is good, but the copied image is poor.) • the document is not fed. Page 4-35 the document feed motor does not run. The document slips against the rollers. The document does not separate. Th...

Page 102

4-9 laser class 1060p chapter 4: maintenance & service 3.2 errors shown on the display 3.2.1 user error message look for the applicable error message and implement the appropriate countermeasures. “busy/no signal” (#018) cause: the receiving fax did not answer within 55 seconds. (t0 time over) solut...

Page 103

4-10 laser class 1060p chapter 4: maintenance & service “check printer” (##322~##324) check the displayed error code and see the measure to eliminate the error. (see page 4-21.) “check subaddr/pswd” (#083/#102) cause: password/subaddress does not match. Solution: contact the other party and confirm ...

Page 104

4-11 laser class 1060p chapter 4: maintenance & service “no rx paper” (#012) cause: the receiving fax machine declares no paper in dis, or its memory is full. Solution: contact the other party, and ask them to put paper in their machine, or to clear their fax machine’s memory. “no tel #” (#022) caus...

Page 105

4-12 laser class 1060p chapter 4: maintenance & service 3.2.2 error codes a) service error code output when service data #1 sssw sw01 bit 0 is set to “1” then service error codes are printed on the activity management reports, reception result reports and error transmission reports when communicatio...

Page 106

4-13 laser class 1060p chapter 4: maintenance & service • ept (echo protect tone) change service data #1 sssw sw03 bit 1. Bit 1:1 transmit an echo protect tone. 0 do not transmit an echo protect tone. • adjust nl equalizer. Set service data #2 menu parameter no.05 to “on”. • reduce the transmission ...

Page 107

4-14 laser class 1060p chapter 4: maintenance & service c) error code list the error codes that have newly been added starting with the product are identified by the notation “new”; those error codes for which remedies unique to the product are offered are identified by the notation “unq (unique).” ...

Page 108

4-15 laser class 1060p chapter 4: maintenance & service no. Tx or rx definition ##220 [ tx/rx ] system error (main program runaway) ##224 [ tx/rx ] abnormal protocol during g3 communication ##229 [ rx ] recording unit locked for 1 minute ##232 [ tx ] encode control unit malfunction ##237 [ rx ] deco...

Page 109

4-16 laser class 1060p chapter 4: maintenance & service no. Tx or rx definition ##757 [tx ] receive dcn after pps-mps transmission during ecm tx ##758 [tx ] exceed protocol retransmission limit or t5 time (60 seconds) after pps-mps transmission during ecm tx ##759 [tx ] exceed retransmit protocol af...

Page 110

4-17 laser class 1060p chapter 4: maintenance & service ##793 [ rx ] time over due to failure to receive valid frame during high speed signal rx upon ecm rx ##794 [ tx ] receive all 0 ppr during ecm tx ##795 [ tx/rx ] trouble in the decoding processing during communication d) new error codes and rec...

Page 111

4-18 laser class 1060p chapter 4: maintenance & service #003 [tx/rx] copy page transmission time over cause: one page of the document was longer than 39.4 inches (1 meter) or transmission/ copying took longer than the regulated time (32 minutes). Solutions: (1) use a copy machine to copy the documen...

Page 112

4-19 laser class 1060p chapter 4: maintenance & service #005 [tx/rx] initial identification time (t0/t1) over cause: tone/pulse parameter set incorrectly. Solutions: set the user data “tel line type” tone/pulse parameter correctly. Cause: the time until connection with the other fax is too long. Sol...

Page 113

4-20 laser class 1060p chapter 4: maintenance & service #080 [tx] other party does not have itu-t recommended subaddress reception cause: the other party’s dis bit 49 is 0. Solutions: contact the other party and confirm whether or not their fax supports subaddress receiving. Try sending again withou...

Page 114

4-21 laser class 1060p chapter 4: maintenance & service ##322 [rx] fixing heater temperature abnormality cause: internal unit defect. Solutions: (1) check the connections between the fixing ass’y and the pcnt board (j206) and between the fixing ass’y and the power supply unit (j102). (2) check the c...

Page 115

4-22 laser class 1060p chapter 4: maintenance & service 3.3 errors not shown on the display 3.3.1 general errors • the unit does not turn on. (evaluation criteria: look at the actual unit.) (1) check the power cord connection. (2) check the connection between the pcnt board (j101) and power supply u...

Page 116

4-23 laser class 1060p chapter 4: maintenance & service 3.3.2 printing problems • faulty printing (evaluation criteria: test print is faulty.) • the paper is not fed correctly. (evaluation criteria: look at the actual unit.) the main motor does not run. (1) check the connection between the main moto...

Page 117

4-24 laser class 1060p chapter 4: maintenance & service • the printing operation is abnormal. The unit indicates there is a paper jam when there is no paper jam. (1) check the connection from the paper edge sensor to the power supply unit (j205). (2) check whether the paper edge sensor and actuator ...

Page 118

4-25 laser class 1060p chapter 4: maintenance & service • poor printing quality (evaluation criteria: check the test print image’s faults.) before checking for the cause of print defects, check whether the user uses canon-recommended paper and stores it correctly. If the problem is solved by using t...

Page 119

4-26 laser class 1060p chapter 4: maintenance & service • light solutions: (1) remove the toner cartridge and shake it lightly five or six times. (2) verify that user data “printer setting” “economy prt” is not “on”. (3) replace the toner cartridge. (4) open the front cover during printing, and remo...

Page 120

4-27 laser class 1060p chapter 4: maintenance & service • dots solutions: (1) clean the static charge eliminator in the toner transfer section. (2) check the static charge eliminator contact. (3) clean the transfer charging roller. (4) replace the transfer charging roller. • marks on back of papers ...

Page 121

4-28 laser class 1060p chapter 4: maintenance & service • blank spots solutions: (1) clean the transfer charging roller. (2) replace the transfer charging roller. (3) replace the toner cartridge. (4) check for foreign matter button the transfer charging roller gear and the drive gear. (5) clean the ...

Page 122

4-29 laser class 1060p chapter 4: maintenance & service • poor fixing solutions: (1) if the marks are at intervals of approx. 75mm (2.95"), clean the fixing ass’y; if they are at intervals of approx. 63mm (2.48"), clean the pressure roller. (2) replace the fixing ass’y. (3) replace the pressure roll...

Page 123

4-30 laser class 1060p chapter 4: maintenance & service note checking the fixing nip width improperly set fixing nip may cause a fixing ass’y problem. The fixing ass’y is not designed to allow adjustment of the nip. Check the fixing ass’y nip by using the following procedure. (1) either take along o...

Page 124

4-31 laser class 1060p chapter 4: maintenance & service 3.3.3 faults in the printer unit you can check the lbp status using the machine’s test mode. An lbp status is indicated by means of a 16-bit signal that represents the condition of the inside of the printer generated by the cpu mounted on the s...

Page 125

4-32 laser class 1060p chapter 4: maintenance & service b) lbp status check the lbp status is indicated in 4-digit hexadecimal notation (instead of 16-digit binary notation). Bit 16 is a parity bit (odd). Note parity bid (odd) the parity bit is one of the 16 bits transmitted from the pcnt board to t...

Page 126

4-33 laser class 1060p chapter 4: maintenance & service c) lbp status explanation lbp status is an 16-bit binary number as described in the previous page. An example of status data is given below. Figure 4-9 table description 1 2 3 4 5 6 7 8 bit meaning 1 0 unused unused unused scanner motor failure...

Page 127

4-34 laser class 1060p chapter 4: maintenance & service status 16 (sarvice call status) bit meaning 1 0 1 unused 2 unused 3 unused 4 scanner motor failure failure normal 5 nbd signal error failure normal 6 fixing unit failure failure normal 7 unused 8 unused 9 unused 10 unused 11 unused 12 unused 13...

Page 128

4-35 laser class 1060p chapter 4: maintenance & service 3.3.4 scanning problems • faulty scanning (evaluation criteria: test print is good, but the copied image is poor.) • the document is not fed. The document feed motor does not run. (evaluation criteria: check it visually.) (1) check the connecti...

Page 129

4-36 laser class 1060p chapter 4: maintenance & service • the scanning image is abnormal. (evaluation criteria: check the copy image’s faults.) nothing is printed. (1) check the connection between the contact sensor and scnt board (j2). (2) replace the contact sensor unit. (3) replace the scnt board...

Page 130

4-37 laser class 1060p chapter 4: maintenance & service 3.4 processing communication problems 3.4.1 initial identification of problems since the facsimile must transmit picture information, a transmitter, a receiver and telephone lines are re- quired for this purpose. Transmissions may cause problem...

Page 131

4-38 laser class 1060p chapter 4: maintenance & service 3.4.2 procedures for processing communication problems if the problem proves to be communication trouble, deal with it according to the following procedures. (1) study the conditions at the time of trouble as closely as possible. Record or keep...

Page 132

4-39 laser class 1060p chapter 4: maintenance & service • procedures for processing communication problems with canon facsimile. The process for carrying out communications at three points as shown in the figure. Figure 4-12 flowchart for processing communication troubles with canon facsimile • proc...

Page 133

4-40 laser class 1060p chapter 4: maintenance & service figure 4-13 flowchart for processing communication troubles with other manufacturer’s facsimile fax:a trouble fax:b fax:c fax:d start is the group the same? (g1/g2/g3) unable to receive is there the similar trouble case? Process according to th...

Page 134: 4. Service Switches

4-41 laser class 1060p chapter 4: maintenance & service 4. Service switches 4.1 hardware switches none.

Page 135

4-42 laser class 1060p chapter 4: maintenance & service 4.2 service data settings service data can be checked and changed with items on display menus. The default values of the sssw/ parameters available in this fax machine are shown in this chapter, 4.2.3 service data settings in this manual. The s...

Page 136

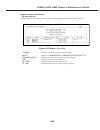

4-43 laser class 1060p chapter 4: maintenance & service 4.2.2 service data registration/setting method service data can be registered and set by the following operations: figure 4-14 service data setting method user settings standby (time and receive mode display) 10:06 fax only #1 sssw #3 numeric p...

Page 137

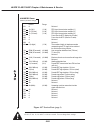

4-44 laser class 1060p chapter 4: maintenance & service 4.2.3 service data settings figure 4-15 service data (page 1) the switches marked “–” are not used. Do not change their settings. #1 sssw bit service data error management memory clear list output setting echo solution setting communication tro...

Page 138

4-45 laser class 1060p chapter 4: maintenance & service figure 4-16 service data (page 2) no. 01 to 04, 11 to 20 are not used. Do not change their settings. #2 menu 01: 02: 03: 04: 05: 06: 07: 08: 09: 10: 11 : 20: on off dial serviceman off 10 (0~15) not used not used not used not used nl equalizer ...

Page 139

4-46 laser class 1060p chapter 4: maintenance & service #3 numeric param. 01: 02: 03: 04: 05: 06: 07: 08: 09: 10: 11: 12: 13: 14: 15: 16: 17: 18: 19: 20: 21: 22: 23: 24: 25: 26: 27: 28: 29: 30: 0 10 (10%) 15 (15 lines) 12 (12 times) 4 4 0 0 6 (6 digits) 5500 (55 seconds) 3500 (35 seconds) 0 1310 (13...

Page 140

4-47 laser class 1060p chapter 4: maintenance & service figure 4-18 service data (page 4) #4 ncu (ncu settings) the values of these items are all set to match a specific nation’s communications standards by the #5 type setting. #6 genesis (uhq function settings) tampering with this setting may cause...

Page 141

4-48 laser class 1060p chapter 4: maintenance & service figure 4-19 service data (page 5) #7 printer (printer function settings) 1. Sssw sw01 sw02 sw03 sw04 sw05 sw06 sw07~20: sw20 maximum drop-out range not used not used leading edge margin trailing edge margin not used 01: 14 02: 0 03: 0 04: 2 05:...

Page 142

4-49 laser class 1060p chapter 4: maintenance & service figure 4-20 service data (page 6) for details on test mode, see 5.1 service test functions on page 4-56. #8 clear #9 rom tel user sw service sw ncu service data report counter all usa-xx-xx dialling data initialization user data and service dat...

Page 143

4-50 laser class 1060p chapter 4: maintenance & service 4.2.4 explanation of service data a) sssw (service soft switch settings) the items registered and set by each of these switches comprise 8-bit switches. The figure below shows which numbers are assigned to which bits. Each bit has a value of ei...

Page 144

4-51 laser class 1060p chapter 4: maintenance & service 4.2.5 new sssws/parameters added to this model #1 sssw (service soft switch setting) sw01 (service soft switch 01: error management) bit function 1 0 0 service error code output not output 1 error dump list output not output 2 enter password at...

Page 145

4-52 laser class 1060p chapter 4: maintenance & service sw18 (service soft switch 18: communication trouble solutions settings (2)) bit function 1 0 0 (new) detection of carrier disconnection detect do not detect between the dcs signal and the tcf signal 1 (new) waiting time for carrier 600 ms 300 m...

Page 146

4-53 laser class 1060p chapter 4: maintenance & service #1 sssw (service soft switch setting) sw28 (service soft switch 28: v.8/v.34 protocol settings) bit function 1 0 0 (new) caller v.8 protocol no yes 1 (new) called party v.8 protocol no yes 2 (new) caller v.8 protocol late start no yes 3 (new) c...

Page 147

4-54 laser class 1060p chapter 4: maintenance & service #2 menu bit function selecting range default setting 08 v.34 max. Baud rate 2400 ~ 3429 3429 (3429 baud) 09 v.34 max. Transmission speed 24 ~ 33.6 33.6 (33600 bps) [no. 08] select the maximum baud rate for v.34 transmission: 3429, 3200, 3000, 2...

Page 148

4-55 laser class 1060p chapter 4: maintenance & service sssw default setting type usa type usa #1 sssw #3 numeric sw01 00000000 param sw02 00000000 02: 10 sw03 00000000 03: 15 sw04 10000000 04: 12 sw05 00000000 05: 4 sw06 10010000 06: 4 sw07 00000000 09: 6 sw08 00000000 10: 5500 sw09 00000000 11: 35...

Page 149: 5. Test Functions

4-56 laser class 1060p chapter 4: maintenance & service 5. Test functions 5.1 service test functions the fax functions for testing individual operations, such as below. See page 4-46 for details of entering the test mode. To leave the test mode, press the data registration button, and then # button....

Page 150

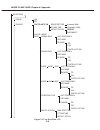

4-57 laser class 1060p chapter 4: maintenance & service 5.1.2 test mode flowchart figure 4-23 test mode [1] d-ram [2] cs [4] modem ncu [7] data set [6] faculty test test mode [3] print [5] aging test [1] relay [2] freq [3] not used [4] g3 tx [5] dtmf tx test [6] tone rx [1] white [2] black [3] strip...

Page 151

4-58 laser class 1060p chapter 4: maintenance & service 5.1.3 d-ram tests pressing the 1 button from the test mode menu selects the d-ram tests. D-ram test 1 writes data to the entire d-ram region and reads it out to check that operations are correct. D-ram test 2 just reads data at high speed. Figu...

Page 152

4-59 laser class 1060p chapter 4: maintenance & service 5.1.4 print the print test menu is selected by pressing the 3 key from the test mode menu. In this test, various print patterns are output from the printer. As service print patterns, press numeric button 2 from the print test menu to select “3...

Page 153

4-60 laser class 1060p chapter 4: maintenance & service 5.1.5 modem and ncu tests these tests test modem and ncu transmission and reception. The modem tests check whether signals are sent correctly from the modem by comparing the sound of the signals from the speaker with the sounds from a normal mo...

Page 154

4-61 laser class 1060p chapter 4: maintenance & service b) g3 signal transmission test the g3 signal transmission test menu is selected by pressing numeric button 4 from the modem ncu test menu. The g3 signals below are sent from the modem using the modular jack and the speaker. The frequency can be...

Page 155

4-62 laser class 1060p chapter 4: maintenance & service c) cng and dtmf signal reception test the cng and dtmf signal reception test is selected by pressing the 6 button from the modem ncu test menu. This test checks whether the cng signals and dtmf signals received from the modular jack are detecte...

Page 156

4-63 laser class 1060p chapter 4: maintenance & service 5.1.6 faculty tests the faculty tests are selected by pressing numeric button 6 from the test mode menu. These tests check the following faculties of this fax. Test type overview sensor tests test whether the sensors are operating correctly. Op...

Page 157

4-64 laser class 1060p chapter 4: maintenance & service figure 4-27 sensor tests tn on xx crg on ds of des of dcvs on ds: document sensor des: document edge sensor on/of: document/no document dcvs: front cover sensor pressing the 2 key. Pressing the 3 key. Pressing the 4 key. Pressing the 5 key. Pre...

Page 158

4-65 laser class 1060p chapter 4: maintenance & service b) operation panel tests the operation panel test is selected by pressing numeric button 7 from the faculty test menu. This test checks that the display, led lamps, and buttons on the control panel are operating correctly. B-1) display test pre...

Page 159

4-66 laser class 1060p chapter 4: maintenance & service figure 4-28 operation panel 6-7:panel hhhhhhhhhhhhhhhh led test 1 2 3 4 5 6 7 8 9 ✽ 0 # r d p $ & o e press start button. Press start button. Press start button. Press start button. H pattern displayed all lcd dots displayed all led lamps light...

Page 160

4-67 laser class 1060p chapter 4: maintenance & service c) line signal reception test the line detect test menu is selected by pressing numeric button 9 from the faculty test menu. This test checks the operation of the ncu signal sensor and frequency counter. In menu 1, the ci, status can be detecte...

Page 161: 6. Service Report

4-68 laser class 1060p chapter 4: maintenance & service 6. Service report 6.1 report output function 6.1.1 user report output functions the fax can output user reports manually, and some reports can be output automatically using the to user data settings. A) manual output of reports report type oper...

Page 162

4-69 laser class 1060p chapter 4: maintenance & service c) reports output automatically memory clear list the fax automatically outputs a memory clear list when the power is turned on after a power cut. Figure 4-29 memory clear list tx/rx no : indicates four digits of the transaction number mode : i...

Page 163

4-70 laser class 1060p chapter 4: maintenance & service 6.1.2 service report output functions the fax outputs current service data settings, and past communications history reports. A) list of service reports the fax outputs the service reports shown below. Report type operations system data & dump ...

Page 164

4-71 laser class 1060p chapter 4: maintenance & service figure 4-31 system data list (page 5) note “start date” records the date when the fax performs its first operation, after shipment from the factory..

Page 165

4-72 laser class 1060p chapter 4: maintenance & service a-2) system dump list figure 4-32 system dump list (1/2).

Page 166

4-73 laser class 1060p chapter 4: maintenance & service clear date : date on which data was initialized using service data #8 clear, all rx/tx : total number of pages received/transmitted doc/mem : total nu mber of pages directly/memory transmitted a4/b4/a3/a5 : total number of pages transmitted and...

Page 167

4-74 laser class 1060p chapter 4: maintenance & service figure 4-33 system dump list (2/2).

Page 168

4-75 laser class 1060p chapter 4: maintenance & service ##nnn : service error code start time : communication start date and time (on 24 hour clock) other party : telephone number sent from other party maker code : maker code [1000 1000] indicates a canon fax lower nibble upper nibble machine code :...

Page 169

4-76 laser class 1060p chapter 4: maintenance & service a-3) service activity report (sending/receiving) figure 4-34 service error tx report.

Page 170

4-77 laser class 1060p chapter 4: maintenance & service tx/rx no : indicates four digits of the transaction number connection tel : number sent from the other party or number dialled (other party) (lower 20 digits) subaddress : subaddress number sent from the other party connection id : id sent from...

Page 171

4-78 laser class 1060p chapter 4: maintenance & service figure 4-35 service error activity report (receiving).

Page 172

4-79 laser class 1060p chapter 4: maintenance & service tx/rx no : indicates four digits of the transaction number connection tel : number sent from the other party or number dialled (other party) (lower 20 digits) subaddress : subaddress number sent from the other party connection id : id sent from...

Page 173: Chapter 5

Chapter 5 appendix.

Page 174

5-1 laser class 1060p chapter 5: appendix 1. Installing the laser class 1060p this machine has been designed for user installation. Therefore, this manual contains only an outline description of the procedures. For details of the installation, see the user’s guide. 1.1 setting up • choosing a locati...

Page 175: 2. User Data Flow

5-2 laser class 1060p chapter 5: appendix 2. User data flow figure 5-1 user data flow (1/5) telephone number optional setting name 1-touch spd dial coded speed dial group dial press the data registration button telephone number optional setting name telephone number name tel registration user settin...

Page 176

5-3 laser class 1060p chapter 5: appendix figure 5-2 user data flow (2/5) standard high rx call level tel line type repo rt settings tx report rx report activity report ecm tx mid pause set auto redial on off touch tone rotary pulse print error only output yes output no print error only output yes o...

Page 177

5-4 laser class 1060p chapter 5: appendix figure 5-3 user data flow (3/5) on off ecm rx rx settings rx mode fax/tel auto sw ring start time f/t ring time default action 8 seconds (0-30) 15 seconds (10-60) receive disconnect fax only mode normal ring double ring short short long unit telephone # unit...

Page 178

5-5 laser class 1060p chapter 5: appendix figure 5-4 user data flow (4/5) printer setting on off incoming ring ring count 2 times (1-99) on off man/auto switch f/t ring time 15 seconds (1-99) vertical only remote rx remote rx id 25 on off on off on off horiz & vertical paper size a4 ltr lgl custom r...

Page 179

5-6 laser class 1060p chapter 5: appendix figure 5-5 user data flow (5/5) system settings on rx restriction off dd/mm yyyy yyyy mm/dd mm/dd/yyyy data setup set file change data delete file polling box english french spanish display language tx start speed 33600 bps 14400 bps 9600 bps 4800 bps 2400 b...

Page 180: 3. Option

5-7 laser class 1060p chapter 5: appendix 3. Option 3.1 handset kit figure 5-6 control and functions (1).

Page 181

5-8 laser class 1060p chapter 5: appendix figure 5-7 control and functions (2).

Page 182

5-9 laser class 1060p chapter 5: appendix figure 5-8 maintaining your handset.

Page 183: Revision 0

S e r v ic e m a n u a l r e v is io n 0 c a n o n in c . Printed in japan (imprime au japon) 0401ab canon inc. Revision 0 copyright © 2001 canon inc. Canon laser class 1060p apr. 2001 printed in japan (imprime au japon) hy8-19au-000 apr. 2001 laser class 1060p h12-2042 120v usa.