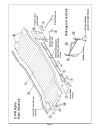

Connoisseur Models GWR HYDRA Diagram G19 Instruction Booklet

PROTOTYPE. The Great Western Railways designation HYDRA, covered a range

of low floored wagons designed to carry road vehicles such as horse drawn

carriages and motor cars and lorries.

They were designed with a gently sloping floor so that a vehicle could be driven

onto the wagon from an end loading dock and then sit within the well of the wagon.

This enabled tall road vehicles to remain within the loading gauge. They were brake

fitted and classified as ‘brown’ vehicles and were intended to be marshalled in

passenger trains.

The Hydra’s to diagram G19 were built in 1908 and ran into BR days. They carried

running numbers 42279-42288.

KIT. This is a very straightforward kit. Some push out rivet detail, a few parts

requiring simple folding and a selection of small detail parts make this an interesting

project.

Wheels are required to complete, 3’7”, Mansell Disc (Slater's Catalogue Number

7124). Available From Slater's Plastikard, Temple Rd, Matlock Bath, Matlock,

Derbyshire, DE4 3PG, Telephone 01629 583993.

Connoisseur Models, 33 Grampian Road, Penfields, Stourbridge,

DY8 4UE, Telephone 01384 371418

GWR HYDRA Diagram G19

Fitted Wagon for Carrying Road Vehicles

- 0 Gauge -