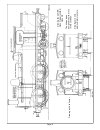

Connoisseur Models LNER Class G5 0-4-4 Tank Manual

Connoisseur Models, 1 Newton Cottages, Nr Weobley,

Herefordshire, HR4 8QX, Telephone 01544 318263

0 Gauge Locomotive Kit

LNER Class G5 0-4-4 Tank

Prototype. This class of 110 locomotives was built from 1894. They were the

standard design of passenger tank until 1907. In later years members of the class

wandered southwards. They worked on outer London suburban services and

East Anglia branch lines. The class lasted until 1958.

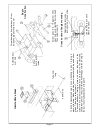

Kit. The body is etched in brass with nickel silver being used for the chassis. The

bogie is sprung and compensated. Slide bars and valve gear are represented

between the frames. Cab interior is detailed and a cast back head is provided.

Alternative components for bunker, buffer beams and other later changes made

to some locomotives are provided. Etched fire irons and a choice of number

plates are included.

This kit has been designed to provide a set of quality components, that will allow

the modeller who has basic kit building skills to build an 0 gauge model of the

prototype, to a standard of detail that is suitable for operating models on most 0

gauge layouts.

Parts Required To Complete

2 Sets 3’1”, 12 Spoke Bogie Wheels (Slater’s Catalogue Number 7837NE)

2 Sets 5’1

1

/

2

”, 16 Spoke Driving Wheels (Slater’s Catalogue Numbers 7861)

Plunger Pickups if desired (Slater’s Catalogue Number 7157)

Handrail Knobs if desired as a replacement for split pins (Slater’s Catalogue

Numbers, Long-7951, Short-7952)

Available From Slater’s Plastikard, Old Road, Darley Dale, Matlock

Derbyshire, DE4 2ER, Telephone 01629 734053.

Mashima 1833 Motor and 40/1 Gear Set.