- DL manuals

- D'Alessandro Termomeccanica

- Wood stove

- CS Small 100

- Use And Maintenance Manual

D'Alessandro Termomeccanica CS Small 100 Use And Maintenance Manual

Summary of CS Small 100

Page 1

C.Da cerreto, 55 - 66010 miglianico (ch) – italy tel. (+39) 0871/950329 fax (+39) 0871/950687 http://www.Caldaiedalessandro.It e-mail: info@caldaiedalessandro.It wood biomass heat generator series cs small models from 20 to 100 use and maintenance guide ver. 1.0 - qcssmallxit0114.

Page 2: Flue

2 flue the flue represents one of the fundamental elements of the heat generator. The correct designing of the fumes evacuation system guarantees the correct and always efficient generator functioning and prevents the potentially dangerous situations for the user. For a correct installation, refer t...

Page 3: Electrical Connections

3 electrical connections the generator is equipped with a main switch not automatic isolator type. It is recommended to protect the power supply line using a differential magne- tothermic switch. Refer to the attached control board manual for electrical connections..

Page 4: Contents

4 contents 1 general information 6 1.1 identification and purpose of the document 6 1.2 technical data plate 6 1.3 ce marking 6 1.4 reference standards 7 1.5 typographic conventions 7 1.6 guarantee and responsability 7 2 safety and residual risks 8 2.1 risks connected to the use of the machine 8 2.2...

Page 5

5 7.4 frequent heat request condition 20 7.5 carburation 20 7.6 comburent air regulation 20 7.7 fuel regulation 21 7.8 switch off 21 8 cleaning 22 8.1 general information 22 9 maintenance 24 9.1 general information 24 10 anomalies, failures and malfunctions, questions and an- swers 25 10.1 table of ...

Page 6

6 1. General information 1.1 identification and purpose of the document this instruction guide drafted by d’alessandro termomeccanica is an integral part of the heat generator. Any reproduction, even partial, is prohibited. The aim of this manual is to provide all the necessary information for a cor...

Page 7

7 1.5 typographic comventions special attention must be paid to the parts of this user guide marked with the symbols listed be- low: important danger mandatory prohibited 1.6 guarantee and liability the guarantee refers to both the mechanical and electrical parts of the generator, in compliance with...

Page 8

8 2. Safety and residual risks 2.1 risks connected to the use of the machine the generator is built in compliance with the main safety requirements laid down in the european directives. The european and national standards concerning the safety of this type of machine have been considered during the ...

Page 9

9 the generator produces low pressure hot water and is suitable for non-pulverised solid fuel combustion with mechanised feeding. Any other use is improper. 2.3 intended use of the generator installing the generator outdoors exposed to weather agents represents a case of improper use. 2.4 improper u...

Page 10

10 3.1 generator operation illustration the generator is a three flue passes type for the production of hot water for residential and indu- strial heating. 3. Functioning, technical features and dimensions 3.2 generator operation description the fuel descends by gravity from the hopper into the uppe...

Page 11

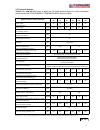

11 tab. 3.3.1 modelli caldaie / models boilers cs small 20 cs small 30 cs small 45 cs small 60 cs small 80 cs small 100 potenza nominale nominal output (kw) 20 30 45 60 80 100 potenza al focolare firebox output (kw) 23,5 34,9 52 71 94 115 pressione max esercizio max operating pressure (bar) 3 pressi...

Page 12

12 pos description 1 control panel 2 knob for opening door 3 front door 4 inspection window 5 safety limit switch 6 fume no-return pressure tube 7 feeding screw tube 8 tubular space between upper and lower screws 9 feeding screw gearmotor 10 transmission protection carter 11 upper screw tube 12 fuel...

Page 13

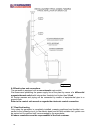

13 3.5 general dimensions tab. 3.5.1 (2) corrisponde allo spazio minimo per l'estrazione della coclea in caso di manutenzione - minimal dimen- sion for extractiong and maintenance cochlea modelli / models cs small 20 cs small 30 cs small 45 cs small 60 cs small 80 cs small 100 dimensioni / dimension...

Page 14

14 4.1 fuels used crushed solid fuel based on wood can be used, such as: · wooden pellets · crushed almond, walnut and hazel nut shells · exhaust olive residues · crushed olive stones · crushed peach, apricot and other similar stones the nominal power of generators is guaranteed with a biomass fuel ...

Page 15

15 lifting hook supplied by d’alessandro termomeccanica models 20-30-40 models 60-80-100

Page 16

16 6.1 general installation requirements the electrical and thermo-hydraulic installation of the heat generator and any other assistance or maintenance operation must be carried out by personnel registered in the professional register established at the chamber of commerce, in compliance with minist...

Page 17

17 the flue must be sized according to the generator section and firebox power supply by qualified personnel (see uni 13384). For generators connected in parallel, each generator must have its own flue. Due to the various installation places, during normal operation, the flue section and height must...

Page 18

18 fig. 6.5.3 6.6 electric plan and connections the generator is equipped with a non-automatic main switch. We recommend protecting the power supply line of the plant by means of a differential magneto-thermal switch with intervention threshold not higher than 30 ma all foreign masses and piping wil...

Page 19

19 7.1 commissioning checks before the generator commissioning it is essential to check that: the installer has issued regular certification of conformity the water plant is regularly filled with the correct level of liquid inside the open or closed expansion vessel the hopper is filled with suitabl...

Page 20

20 fig. 7.6.2 fig. 7.6.1 usually, the correct combustion is obtained upon reaching of the correct ratio between fuel amount and comburent air amount. In ideal combustion conditions, a clear and lumi- nous flame is generated, easily visible from the porthole. (fig.3.4.1 pos.1 - fig.3.4.2 pos.1) 7.6 c...

Page 21

21 7.7 regulation of the feeding screw fuel a screw potentiometer regulates the amount of fuel (fig 7.4). It is already set on a value corresponding to the power of heat generator model, see tab.7.7 below. Small fuel regulation are allowed through the screw potentiometer using a screwdriver. The fue...

Page 22

22 8.1 general the firebox and the flues must be periodically cleaned from combustion solid residues (ashes). Keeping the flues free from ashes ensures an effective draught and the best geerator efficiency. Table 8.1 lists the cleaning operations to be carried out in the chronological order. 8. Clea...

Page 23

23 tab. 8.1 fuel hopper operation: checking and cleaning of the empty hopper from dust and incrustation due to hu- midity and to the type of the used fuel. Periodicity: 30 / 60 days notes: check the fuel does not contain foreign bodies that could damage the screws. Reference: fig.3.4.1 pos.12 fig. 8...

Page 24

24 9. Maintenance 9.1 general the heat generator must be submitted to regular maintenance to guarantee the efficiency of all the components determining the correct operating of the generator and its main yield. Tab.9.1 summarises the main operations. Attention !! Before performing maintenance operat...

Page 25

25 10. Anomalies, faults and malfunctioning - faq and answers 10.1 anomalies and faults table. Faq and answers sign probable causes solutions insufficient conveying of fuel a) check there is enough fuel inside the hop- per.Pos.12 fig.3.4.1, a) fill the hopper with fuel. B) check there are no objects...

Page 26

26 10.2 table of mulfunctions. Questions and answers problem possible cause solution smoke returns inside the fuel hopper a) make sure that the flue draught is that re- quired in table 3.3.1 a) if not, refer to qualified personnel incorrect combustion a) check the balance between fuel flow rate and ...

Page 27

27 notes.

Page 28: Comply With

28 d'alessandro termomeccanica c.Da cerreto, 55 - 66010 miglianico (ch) declares under his owjn exclusive responsabilità that solid fuel boilers with automatic feeding series cs small models 20-30-45-60-80-100 serial number xxxxx to which this declaration refers to comply with directive 2006/42/ce (...

Page 29

29 d. Copy of partial switching off declaration cs small.