- DL manuals

- DA

- Air Conditioner

- Data Cool Series

- Installation, Operation And Maintanance Manual

DA Data Cool Series Installation, Operation And Maintanance Manual

Summary of Data Cool Series

Page 1

Data cool installation, operation and maintenance manual 2 and 3 ton air, water and glycol cooled dx and chilled water.

Page 2

2 congratulations on the selection of a data aire precision environmental control system. Proper installation, operation and maintenance of this equipment will ensure years of optimal performance. This manual is intended to assist trained service personnel by providing necessary guidelines for this ...

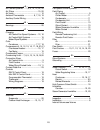

Page 3: Table of Contents

3 table of contents model identification ........................................................................ 5 1.0 installation .......................................................................................... 6 1.1 room considerations .....................................................

Page 4: Table of Contents, Continued

4 table of contents, continued 5.0 charging ..................................................................................................................... 15 5.1 voltage phase check ............................................................................................................ 15...

Page 5: Model Identification

5 model identification.

Page 6: 1.0 Installation

6 1.0 installation there is no intent on the part of data aire, inc. To define local codes or statutes which may supercede common trade practices. The manufacturer assumes no responsibility for their interpretation. Consult local building codes and the national electrical code for special installati...

Page 7

7 note to installing contractor: condensation formation and frequent humidifier flushing (when humidifier is installed) are normal functions of this equipment. Drain connections must be made to ensure proper water removal. Unit will require drain connections for condensate removal and water connecti...

Page 8: 2.0 Piping

8 2.0 piping 2.1 split air cooled unit piping refer to the attached line sizing chart on page 24 for a guideline for sizing refrigerant lines. The ultimate responsibility for line size selection is that of the installing contractor or project engineer. Data aire does not assume this responsibility. ...

Page 9

9 2.1.3 connection sizes, air cooled units model liquid suction dacu 02 1/2" 3/4" note: unit will have a liquid line and dacu 03 1/2" 3/4" suction line dacu 04 1/2" 3/4" dacu 05 1/2" 3/4" field connections at the indoor evaporator and remote condensing unit will not necessarily be the same as the fi...

Page 10

10 2.2 water/glycol cooled unit piping the required field installed condenser water pipe sizes may or may not be the same as the connection sizes at the evaporator or fluid cooler. This will depend on the length of pipe and the calculated pressure drop of peripheral components. Remote water cooled c...

Page 11

11 2.2.3 connection sizes, water/glycol cooled units evaporator water in and out model connections, od dacw/g 02 3/4” dacw/g 03 3/4” 2.2.4 connection sizes, fluid coolers fluid cooler water in and out model connections, od dafc 06 1-5/8" dafc 07 1-5/8" dafc 09 1-5/8" dafc 11 2-1/8" dafc 15 2-1/8" da...

Page 12

12 2.5 humidifier piping the optional humidifier offered on data cool is a steam generator type with a disposable cylinder. The humidifier makeup water should be brought to the humidifier through the field connection opening using 1/4" copper tubing. A compression fitting is provided at the humidifi...

Page 13: 3.0 Electrical Connections

13 3.0 electrical connections before proceeding with the electrical connections, make certain that the volts, hertz and phase correspond to that specified on the unit electrical nameplate. Units damaged from incorrect power input will not be covered under warranty. Use copper conductors only. 3.1 el...

Page 14

14 4.0 installation of remote outdoor heat exchanger 4.1 rigging this section covers outdoor condensing units and fluid coolers. Outdoor heat exchangers should be moved to their (typically rooftop) mounting location using a crane or fork lift. Each fan section has supports with lifting holes at the ...

Page 15: 5.0 Charging

15 4.3 electrical service refer to sections 3.1 to 3.5 for information regarding line voltage and control voltage wiring details. 4.4 air cooled condensing unit - model drcu 4.4.1 fan speed control standard outdoor air cooled condensing units have a fan speed controller on the first fan. On single-f...

Page 16

16 start the evaporator fan and compressor. Check the liquid line sight glass to get a feel for the approximate charge. Bubbles in the sight glass are not unusual at this point and can be caused by flashing from liquid line pressure drop, low sub-cooling or low charge. It is likely that more refrige...

Page 17

17 5.3 water/glycol cooled split systems 5.3.1. Water/glycol cooled split systems charging all water/glycol data cool units are split systems requiring field charge. After the refrigerant piping and water line piping is properly completed, connect the refrigerant drum to the low side and charge with...

Page 18: 6.0 Controls

18 5.4 refrigerant handling the use of recovery/recycling units is required by u.S. Environmental protection agency (epa) regulations. Technicians who service and dispose of air conditioning and refrigeration equipment must recover the refrigerant instead of venting to atmosphere. Except for extreme...

Page 19

19 6.2 programmable digital thermostat a cooling only digital thermostat designed to provide accurate control, displays room temperature and cooling on mode. The buttons on the front of the thermostat allow complete control of the equipment. Cooling - select the temperature by pressing the “up” or “...

Page 20

20 the wiring diagram in the evaporator will indicate field interface terminals to the secondary heat exchanger. The internal wiring of the heat exchanger is found on a separate diagram which can be found on the inside cover of the heat exchanger electrical box. Both diagram types are also placed in...

Page 21

21 7.6 refrigerant filter drier factory installed refrigerant filter driers do not normally require maintenance. When replacing compressors or other repairs that open the refrigeration system to atmosphere, it is advisable to replace the filter drier. The equivalent type and size should be used..

Page 22: 8.0 Warranty Policy

22 8.0 warranty policy data aire inc. Warrants your data aire environmental control unit to be free from defects in material and workmanship under normal use and service for a period of (18) eighteen months from date of shipment. Our obligation under this warranty shall be limited to repairing or re...

Page 23: 10.0 Contact Data Aire

23 10.0 contact data aire address: data aire inc. 230 w. Blueridge ave. Orange, ca 92865 phone: 714-921-6000 800-347-aire (2473) toll free fax: 714-921-6010 main 714-921-6011 engineering 714-921-6022 part sales e-mail: tech_support@dataaire.Com technical support engineering@dataaire.Com engineering ...

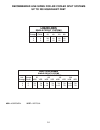

Page 24: Liquid Lines

24 recommended line sizing for air cooled split systems up to 200 equivalent feet liquid lines single circuit systems unit tons per equivalent feet tonnage circuit 50 100 150 200 2 2 3/8 1/2 1/2 1/2 3 3 1/2 1/2 1/2 1/2 suction lines single circuit systems equivalent feet unit tons per 50 100 150 200...

Page 25

25 data aire, inc. Monthly maintenance inspection checklist model no.__________________ serial no. ____________________ prepared by: _______________ date: ___ / ___/ 201__ air filters ___ check for restricted air flow blower section ___ blower wheel free of debris moves freely ___ check motor mounts...

Page 26

26 data aire, inc. Quarterly maintenance inspection checklist model no. _______________________ serial no. ___________________________ prepared by: _____________________ date: ___ / ___/ 201__ air filters ____ check for restricted air flow ____ wipe filter rack section clean blower section ____ blow...

Page 27

27.

Page 28

28 - f - fan speed control systems .................... 15 field piping air cooled ........................................... 9 chilled water ...................................... 11 condensate ........................................ 11 condensing unit ................................. 11 fluid c...

Page 29

29 - l - liquid lines ..................................... 8, 9, 24 leak testing ........................................... 12 locating evaporator ........................................... 6 secondary heat exchanger ............... 14 low pressure cutout switch.................... 18 - m - maint...

Page 30

Notes: _______________________________________________________________________________________ ____________________________________________________________________________________________ ____________________________________________________________________________________________ ___________________...

Page 32

230 w. Blueridge avenue orange, ca 92865 800-347-2473 www.Dataaire.Com e-mail: sales@dataaire.Com a member of the cs group of companies © 2011 data aire, inc. Data aire, inc. Reserves the right to make design changes for the purpose of product improvement or to withdraw any design without notice. Da...