- DL manuals

- DAELIM

- Scooter

- B-BONE

- Service Manual

DAELIM B-BONE Service Manual

Summary of B-BONE

Page 1

Sm57-0902-01e.

Page 3: How to Use This Manual

How to use this manual this manual explains how to maintain procedure for the sn125 manufactured by daelim motor co., ltd. To ensure safety and optimal operating conditions of the vehicle, carry out regular inspections according to the maintenance schedule(section 2). Sections 1 through 2 provide in...

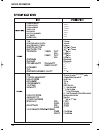

Page 5: 1. Service Information

Service information 1 1-1 1. Service information serial number location · ·· ·· · 1-1 specifications · ·· ·· ·· ·· ·· ·· ·· ·· · 1-2 torque values · ·· ·· ·· ·· ·· ·· ·· ·· · 1-4 standard torque values · ·· ·· · 1-5 symbols/abbreviations · ·· ·· ·· · 1-5 wiring diagram · ·· ·· ·· ·· ·· ·· ·· ·· · 1-...

Page 6

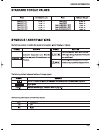

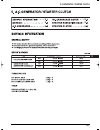

1-2 service information 7.1 1.2 stroke sohc atdc 1,910mm 750mm 1,090mm 1,360mm 755mm 126mm 130kg 277kg 60 2.00 2.25 25 80 90/70 13.8 380 (6.8 ) 1.0 1.05 ※ "( )" marked contents apply to euro 2 only 90mm.

Page 7

1-3 service information ※“( )”marked contents apply to euro2 only item specifications cv type ( vacuum ) / '“ 24.2 mm cvk auto-bystarter # 95 2 ½ 17 mm 1.700±100 rpm automatic transmission 3.000 2.786 ecu (c.D.I) closed type (mf) 12v 10ah cr8eh -9 (ngk) 0.8 - 0.9 mm 15a, 30a (15a) starter motor 12v ...

Page 8

1-4 service information.

Page 9

Service information 1-5.

Page 10

1-6 service information.

Page 11

1-7 service information.

Page 12

1-8 service information.

Page 13

1-9 service information.

Page 14: General Safety

1-10 service information general safety warning 1. Do not run the engine for a long time in closed or not well-ventilated area because the exhaust gas contains toxic substances such as carbon monoxide, hydrocarbon, nitric oxide. 2. The battery fluid(lean sulfuric acid) is extremely toxic. It is dang...

Page 15

1-11 service information 9. Check to see if the rubber part is worn out when removing it and replace it if necessary. Some rubber part is weak to gasoline and kerosene, so pay attention not to soak with gasoline or oils. 10. Recommended grease must be applied to or filled in the specified place. 7. ...

Page 16

1-12 service information 13. Check the smooth rotation of inner or outer race of the ball bearing by rotating it manually. •replace the ball bearing having excessive axial/ longitudinal hanging. •wipe the ball bearing likely to have hanging with cleaning oil.(except double-sided sealed type ball bea...

Page 17

1-13 service information 21. Keep the pneumatic system interior or the engine interior from the infiltration of dust. 22. Install the gasket mounted in the contact surface of each case of the engine while removing gasket material completely. Remove damaged contact surface by wiping with the oil ston...

Page 18: Caution When Wiring

1-14 service information •each cord must be connected depending on its color. When connecting different cord, attach color tube around the connector. Connect the coupler to the connector with same color and same pin number. •identify the two-colored cord by main color first and then striped color . ...

Page 19

1-15 service information •insert the lock of the coupler until the lock is fully secured. •turn off the main switch before connecting/dis- connecting. •release the lock to disconnect the lock of the coupler. •the lock of the coupler has two types according to releasing method(press type and pull typ...

Page 20

1-16 service information •wire band must be secured firmly in the specified location of the frame. In case of aluminium band, secure the wire harness to the coated part. •secure the wire harness firmly using the clamp. •insert the connector until the vinyl cover is fully inserted into the terminal. ...

Page 21

1-17 service information •if necessary, lock the wire harness properly. •when mounting parts, make sure that the wire harness is not pressed by the parts. •in case that the wire harness is contacted with the end or the sharp edge, protect both parts with tube or tape. •the wire must not hang down or...

Page 22

Memo.

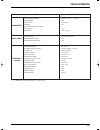

Page 23: 2. Inspections/adjustments

2-1 inspections/adjustments 2 2. Inspections/adjustments 2-1 2-3 2-4 2-4 2-5 2-5 2-6 2-6 2-7 2-7 2-7 2-7 2-8 2-8 2-8 2-9 2-9 2-10 2-10 2-10 2-11 service information ··· maintenance schedule ··· fuel line ········· throttle grip operation ·· air cleaner ······· spark plug ········ valve clearance ···...

Page 24

2-2 inspections/adjustments.

Page 25

2-3 inspections/adjustments.

Page 26

2-4 inspections/adjustments fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel tube fuel tube fuel tube fuel tube fuel tube fu...

Page 27

2-5 inspections/adjustments •hand-tighten the spark plug before using a wrench to tighten to the specified torque. ● remove the spark plug maintenance cover. •the air cleaner element made of dry process paper filter. •do not clean by compressed air blowing. ● check the element, if it is dirty or dam...

Page 28

2-6 inspections/adjustments spark plug maintenance. - floor panel ass'y. Fan cover. Remove the shroud b grommet of the timit hoile cap on the rh. Shroud. Loosen the 4 cylinder head bolts. Feeler gauge feeler gauge feeler gauge feeler gauge feeler gauge feeler gauge feeler gauge feeler gauge feeler g...

Page 29: Carburator Idle Speed

2-7 inspections/adjustments carburator idle speed ●erect the motorcycle on the mainstand. ●remove the rear fender, center cover. ●verify all engine adjustments satisfy specifications. Make adjustment, if necessary. ●heat the engine to make accurate idling inspection and adjustment. ●turn the throttl...

Page 30: Brake Fluid

2-8 inspections/adjustments free play free play free play free play free play free play free play free play free play free play free play free play free play free play free play free play free play free play free play free play free play free play brake fluid ●check the oil level inside the front br...

Page 31

2-9 inspections/adjustments side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side stand side sta...

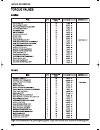

Page 32: Steering Stem

2-10 inspections/adjustments 1.78 2.29 steering stem front wheel 2.00(29 psi) 2.25(32 psi) rear wheel 2.00(29 psi) 2.25(32 psi) item driver only driver and a passenger ㎏/㎠ standard pressure tire pressure gange tire pressure gange tire pressure gange tire pressure gange tire pressure gange tire press...

Page 33: Lubrication Points

2-11 inspections/adjustments lubrication points use general grease unless specified here. Apply oil or grease to the other sliding surfaces not shown here. Control cable lubrication periodically disconnect the upper end of the throttle cable and that of clutch cable, then apply oil after cleaning. C...

Page 34

Memo.

Page 35

3-1 external parts 3 service information ··· 3-1 maintenance procedure ·· 3-2 inner box ········· 3-3 front cover ········ 3-3 front fender ········ 3-4 front under cover ···· 3-4 seat ············ 3-5 rear fender ······· 3-5 rear upper cover ···· 3-5 rear under cover ···· 3-5 seat support pipe ····...

Page 36: Maintenance Procedure

3-2 external parts maintenance procedure name of frame covers ●this chart shows arrows connected in the order of disassembling covers. Inner box fr. Cover fr. Fender fr. Wheel fr. Under cover seat rr. Fender rr. Upper cover rr. Under cover seat support pipe center cover under cover truss pipe rr. Wh...

Page 37: Inner Box

3-3 external parts inner box removal / assembly ●loosen the 6 tapping screws securing the front side cover front cover removal/assembly ●loosen the 2 washer screw securing the headlight case. Remove the headlight. ●remove the speedometer cable, headlight cable coupler (left and right) ●loosen the fl...

Page 38: Front Fender

3-4 external parts ●remove the speedometer cable and speedometer. ●loosen the 6 tapping screw securing the front side cover. ●loosen the 3 special screw securing the front cover and remove the front cover. ●install in the reverse order of removal front fender removal/assembly ●loosen the 4 special s...

Page 39: Seat Removal/assembly

3-5 external parts seat removal/assembly ●release the seat lock at the back of seat. ●loosen the 2 flange nuts and remove the seat. ●install in the reverse order of removal. Rear fender removal/assembly ●loosen the 2 special bolts. ●loosen the 2 washer bolts and remove the rear fender. ●remove the t...

Page 40: Rear Under Cover

3-6 external parts handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover upper upper upper upper upper upper upper upper upper upper upper upper upper upper rear under cove...

Page 41: Truss Pipe

Truss pipe removal/assembly ●remove the bar end cap b. ●loosen the flange bolt. ●loosen the 4 cap bolts. ●remove the truss pipe. ●install in the reverse order of removal. Floor side cover removal/assembly ●loosen the 6 special screws lh., rh. In floor side cover and loosen the 4 tapping screws rh., ...

Page 42: Under Cover

3-8 external parts ●remove the inner box. ●remove the floor side cover. ●loosen the tapping screw securing the floor panel and remove the floor panel. ●install in the reverse order of removal. Under cover removal/assembly ●remove the floor side cover. ●loosen the special screw (r/l) and remove ● the...

Page 43: Muffler

●remove the inner box. ●loosen the 2 flange bolts securing the pilot box. ●remove the speedometer cable. ●install in the reverse order of removal. Muffler removal/assembly ●loosen the washer bolt securing the brake hose clamp. ●loosen the 3 hex cap nut securing ex. Pipe comp. ●loosen the 2 flange bo...

Page 44

Memo.

Page 45

4-1 lubrication system 4-1 4-2 4-3 4-3 4-4 4-7 4-8 4-4 4.

Page 46

4-2 lubrication system inclusion of water. Low or no oil pressure close oil valve relief. Clogged oil strainer. Worn and faulty oil pump. Internal oil leaks. Inadequate oil viscosity. Shout of oil quantity. Oil pump drivegear or sprocket it is not right..

Page 47

4-3 lubrication system oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil sight glass oil s...

Page 48

4-4 lubrication system flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flan...

Page 49

4-5 lubrication system oil pump disassembly ●loosen the screw securing the oil pump plate. ●remove the oil pump body and the oil pump plate. ●clean the oil pump body, inner and outer rotors with fresh cleaning oil. Oil pump shaft oil pump shaft oil pump shaft oil pump shaft oil pump shaft oil pump s...

Page 50

4-6 lubrication system inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor inner rotor i...

Page 51

4-7 lubrication system oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil radiator oil ...

Page 52

4-8 lubrication system radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiator radiato...

Page 53

5-1 ems(engine management system) 5 5. Ems(engine management system) 1. Caution when repairing the ems parts 5-2 2. The component parts of the ems 5-3 3.Terminal arrangement of the ecu 5-4 4. Wiring diagram of the ecu 5-4 5. Self-diagnostic function by mil(malfunction indicator lamp) 5-5 - self diag...

Page 54

5-2 ems(engine management system) 1. Caution when repairing the ems parts. ●if the fuse is short-circuited, findout the cause and repair. Replace with the fuse having the specified capacity. ●do not use the electlic wires or others instead of the fuse. ●do not drop or throw the ems parts because the...

Page 55

5-3 ems(engine management system) 2. The component parts of the ems ems consists of intake and fule, ignition and control system. 1) intake system as a system which controls and measures air to be necessary for combustion in engine, the intake system is composed of pressure sensor of intake parts, i...

Page 56: 4. Wiring Diagram of The Ecu

5-4 ems(engine management system) 3. Terminal arrangement of the ecu remarks ecu pin no. 6,7,8,11,13,14,15,16,21,29,32,36,38 were not connected. 4. Wiring diagram of the ecu.

Page 57

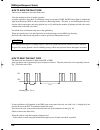

5-5 ems(engine management system) 5. Self-diagnostic function by mil (malfunction indicator lamp) self-diagnostic function the ems is equipped with self-diagnostic function in order to ensure that the engine control system is operation normally. If this function detects a malfunction in the system, ...

Page 58

5-6 ems(engine management system) fail-safe function if the ecu checks something wrong , the vehicle can be driven by its fail safe function. However, if there are something wrong in fuel pump, injector, crank position sensor, the engine operation can be impossible. If there is something wrong in th...

Page 59

5-7 ems(engine management system) how to check the fault code there are two methods of checking the fault codes. 1) use the mil in the speedometer. 2) the diagnostic tool. First) use the mil in the speedometer(refer to how to read the fault codes and fault codes table and diagnostic methods for each...

Page 60

5-8 ems(engine management system) how to show the fault code there are two methods to show the fault codes. First, the methods to show in engine operation in engine operation, when there is something wrong in each part of ems, the mil keeps light on without the light on/off function of mil in order ...

Page 61

5-9 ems(engine management system) fault codes table fault code no. Priority order description mil indication (the number of blinks) - no failure 00 1 injection valve failure(iv) 21 2 idle speed actuator failure (isa) 22 3 electrical fuel pump failure (efp) 23 4 intake manifold absolute pressure sign...

Page 62

5-10 ems(engine management system) how to remove the fault code remove the fault codes in two ways; first) full warm up 1. Starting the engine. - the mil blinks continuously because the ecu memorized the fault code yet. 2. Full warm up the engine (keep idling five minutes) 3. Turn off the ignition k...

Page 63: 6. Ecu

5-11 ems(engine management system) remove ● remove the seat support pipe. ● remove the center cover. ● remove the ecu coupler. ● loosen the 4 flange bolts and remove the ecu. Assembly ● assembly is the reverse order of removal. 6. Ecu (electronic control unit) ●before disassemble, the key is off. ! ...

Page 64: 7. Throttle Body

7. Throttle body ● remove the seat support pipe. ● remove the center cover. ● loosen the screw securing air cleaner connecting tube band. ● remove the throttle body and air cleaner. ● remove the gasoline in fuel tube. ● disconnect fuel tube securing inject cap. ● disconnect injector, mapat, throttle...

Page 65: Disconnect The Throttle Body

Throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body thrott...

Page 66

Checking the insulator ● check the o-ring. ● check the insulator inside. ● check the insulator cap inside. Assembly of the insulator ● assemble is the reverse order of removal. ● assemble the o-ring to insulator. ● install the insulator to the throttle body. ●torque : 1.0 kgf m disassemble the insul...

Page 67

Adjustment of throttle cable ● assemble the throttle cable. ● adjust the free play of throttle grip. Adjustment of idle speed actuator (isa) ● a vehicle is assembled in the state which engine operation is possible. ● loosen the maintenance cover and the adjust- screw is makes possible to adjust. ● t...

Page 68: 8. Injector

5-16 ems(engine management system) remove ● turn off the ignition key. ● disconnect the injector coupler. ! Caution △ ●be sure to check the engine is cooling because a little gasoline remains, it could be still hot. ●be sure to inject the gasoline, after remove the coupler from the ignition coil. It...

Page 69

5-17 ems(engine management system) checking methods by fault codes checking of the injector circuit the fault code is displayed by mil checking circuit coupler terminal is based on wire harness. Checking procedure 1) turn off the ignition key. 2) check to see if the injector coupler has come loose o...

Page 70: Temperature Sensor)

5-18 ems(engine management system) ● located on the left-side of the throttle body. Remove ● disconnect the mapat circuit sensor coupler. ● loosen the 2 mapat circuit sensor screws. Assembly ● assembly is the reverse order of removal. ● disconnect the mapat sensor. ! Caution △ 9. Mapat (mainfold air...

Page 71

5-19 ems(engine management system) check the mapat circuit(intake pressure sensor (imp)+intake temperature sensor(tba))’s circuit fault code number is displayed by mil the fault code of intake pressure sensor the fault code of intake temperature sensor checking circuit coupler terminal is based on t...

Page 72

5-20 ems(engine management system) checking of the intake pressure sensor 1) if voltage value is normal, turn off the ignition key. Connect the mapat(intake pressure sensor + intake temperature sensor) coupler 2) the wire-harness to check the ecu is connected with the ecu with a wire-harness coupler...

Page 73

5-21 ems(engine management system) checking of the intake temperature sensor 1) if voltage value is normal, turn off ignition key. 2) disassemble the mapat coupler and measure the resistance of intake temperature sensor. Resistance of intake pressure sensor : 2000±100[Ω], 25±1 measuring terminal : e...

Page 74

5-22 ems(engine management system) remove ● disconnect the tps coupler. ● loosen 2 tps screws. ● disconnect the tps. ● located on the left side of throttle body. ! Caution △ 10. Tps(throttle position sensor) ● before disassembly, the key is off. Tps tps tps tps tps tps tps tps tps tps tps tps tps tp...

Page 75

5-23 ems(engine management system) checking the tps(throttle position sensor) circuit diagram fault code number is displayed by mil checking circuit the coupler terminal is based on the side of wire-harness checking procedure 1) turn off ignition key . 2) check the tps(throttle position sensor) coup...

Page 76

5-24 ems(engine management system) checking procedure 6) check continuty between the sensor ground terminal of tps and earth. The continuty tps : 0[ ],20±1 measuring terminal : ecu no. 4 (w/r : white/red) ~ earth remarks : measuring unit for resistance : resistance ‘ r ‘ [ ] 7) if not problem, measu...

Page 77

5-25 ems(engine management system) remove ● disconnect the ets coupler. ● situated at the back of the cylinder head. ● remove the rh. Shroud. ! Caution △ 11. Ets(engine temperature sensor) ● before disassembly, the key is off. Assembly ● assembly is the reverse order of removal. ● disconnect the ets...

Page 78

5-26 ems(engine management system) 1)checking the circuit diagram of ets(engine temperature sensor) ●fault code number is displayed by mil checking circuit coupler terminal is based on the side of wire-harness checking procedure 1) turn off the ignition key . 2) check the ets(throttle position senso...

Page 79

5-27 ems(engine management system) 6-1) if the measured value is not normal, replace the ets with the new one, recheck. If the measured value is normal, check the g/l electric wire, w/r electric wire to see if they have been broken or have short-circuited or if the ecu coupler is a bad contact ( no....

Page 80: 12. Isa(Idle Speed Actuator)

5-28 ems(engine management system) remove ● disconnect the isa coupler. ● loosen 2 isa screws. ● located on the throttle body. ● remove the center cover. ! Caution △ 12. Isa(idle speed actuator) ● before disassembly, the key is off. ● remove the isa. Assembly ● assembly is the reverse order of remov...

Page 81

5-29 ems(engine management system) 1)check the isa(idel speed actuator) circuit. ●showing of defects codes by mil checking circuit coupler terminal is based on the side of the wire-harness check procedure 1) turn off ignition key . 2) check the isa(throttle position sensor) coupler is loose, or bad....

Page 82

5-30 ems(engine management system) check procedure 5) if the measured resistance and continuty is abnormal. Replace isa with the new one, and recheck. 6) if resistance and continuty is normal, connect the coupler of isa. 7) turn on ignition key 8) measure isa voltage of wire-harness to check ecu. Me...

Page 83: 13. O2(Oxygen) Sensor

5-31 ems(engine management system) ● remove the o2 sensor on the muffler. ● check the o2 sensor. Remove ● located on the exhaust pipe. ● disconnect the rh. Floor side cover. ● disconnect the o2 sensor coupler. ! Caution △ 13. O2(oxygen) sensor ● before disassembly, the key is off. Assembly ● assembl...

Page 84

5-32 ems(engine management system) 1) checking of oxygen(o 2 ) sensor circuit ●fault code number is displayed by mil ●fault code number is displayed by mil of the oxygen(o 2 )sensor lambda signal. Checking circuit coupler terminal is based on the side of wire-harness. Checking for a fault code by ox...

Page 85

5-33 ems(engine management system) checking for a fault code by oxygen(o 2 )sensor heater if the voltage value is abnormal, check to see if the ecu coupler is loose or if there is bad contact. Check the ‘b/b’’ electric wire, ‘g/w’ electric wire to see if they have been broken or have short- circuite...

Page 86: 14.Checking of Mil

5-34 ems(engine management system) 14.Checking of mil ●fault code number is displayed by mil checking circuit check procedure 1) turn off ignition key. 2) check the ess coupler is loose, or bad. If there is no problem. 3) turn on the ignition key. 4) check the mil on for 3 seconds when turn on the i...

Page 87

5-35 ems(engine management system) ● remove the rh. Shroud. ● remove the cooling fan. ● remove the fly wheel. ● remove the 3 screws securing acg stator. ● remove the 2 screws securing ckp. Remove ● remove the center cover. ● remove the acg coupler. ● remove the ckp coupler. ● ckp is located inside t...

Page 88: Sensor)

5-36 ems(engine management system) measurement pva ● disconnect the acg (l/g) connector. ● connect the (+)cord of pva tester to the green terminal or ground wire. ● connect the (-)cord of pva tester to the blue terminal. ● crank the engine with the starter motor and measure the peak voltage of crank...

Page 89: Check The Circuit of Ckp

5-37 ems(engine management system) check the circuit of ckp ●fault code number is displayed by mil checking circuit check procedure 1) turn on ignition key. 2) check to see if the engine sink on is on or off with diagnosis tool. When start up the engine sink on change “off’ to “on”, it’s okay. Check...

Page 90

5-38 ems(engine management system) 4) check if crank signal a,b wires is breaks or not. Remove the ecu, connect wire harness for inspection to wire harness of vehicle. Check the wiring of crank signal a - measure terminal : no. 30 pin of wire harness for inspection - red wire of coupler of ckp. - me...

Page 91: 16. Fuel Pump

5-39 ems(engine management system) ● remove the fuel hose. ● remove the fuel pump coupler. ● loosen the 4 fuel pump setting place screws. Remove ● fuel pump is located inside the fuel tank. ● remove the fuel filler cap. ● remove the floor panel. ! Caution △ 16. Fuel pump ● make sure that the key is ...

Page 92: Fuel Pump

5-40 ems(engine management system) connector wiring location function color c d b a fuel unit fuel unit2 pump (+) ground yellow green red black ● the terminal arrangement of the fuel pump (the following color chart is the internal color of the fuel pump) fuel pump.

Page 93

5-41 ems(engine management system) ●check the fuel pump. ●remove the fuel pump. ●measure the resistance between terminals. ●the float position is based on tank bottom plate. ●measure the resistance between y/w (yellow/white) wire and g(ground) wire of fuel unit terminal ※remark : measuring unit of r...

Page 94: 17.How To Use The Scan When

5-42 ems(engine management system) ●the coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. ●turn the lgnition key on. ●press the power button of the diagnostic tool. ●press the enter button in the initial screen. ●press the enter in the vehicle diagnosis scre...

Page 95

5-43 ems(engine management system) ●press the enter button when it is ready ●when the ecu was initialized. Turn off the lgnition key and then turn on the ignition key..

Page 96: 18.How To Use The Scan When

●the coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. ●turn the lgnition key on. ●press the power button of the diagnosis tool. ●press the enter button on the initial screen. ●press the button at the vehicle diagnostic screen. ●press the enter button on the...

Page 97: 19.How To Use The Scan When

Ems(engine management system) 5-45 ●the coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. ●turn the lgnition key. ●start the engine. ●press the power button of the diagnosis tool. ●press the enter button on the initial screen. ●press the enter button on the ...

Page 98: 20.How To Use The Scan When

Ems(engine management system) ●the coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. ●turn the lgnition key. ●start the engine. ●press the power button of the diagnosis tool. ●press the enter button on the initial screen. ●press the enter button on the vehic...

Page 99

Memo.

Page 100

Memo.

Page 101: Service Information

Service information general safety ● gasoline is extremely flammable. Avoid fire in the work place, also paying particular attention to sparks. Furthermore, the evaporated (gasified) gasoline is highly explosive. Work in a well-ventilated areas. ● exhaust gas contains poisonous substance. Do not kee...

Page 102: Troubleshooting

6-2 fuel system troubleshooting the vehicle does not start. ● no gasoline in fuel tank. ● fuel is not coming out of carburetor. ● too much fuel is flowing into cylinder. ● air cleaner is blocked. ● no spark emitted from spark plug. Idle is unstable and engine turns off after starting. ● faulty idle ...

Page 103: Fuel Tank

6-3 fuel system fuel tank removal ● release the seat lock by turning the main switch key to open the seat. ● remove the following parts. - rear fender. - seat support pipe. - center cover. - truss pipe. - battery. - floor panel. ● remove the fuel unit wiry coupler. ● remove the fuel strainer tube. ●...

Page 104

6-4 fuel system ● loosen the throttle cable lock nut and remove the throttle cable from the carburetor. ● remove the fuel tube. ● remove the auto bystarter wiring. ● loosen the screw on the carburetor insulation band. ● remove the carburetor. Removal ● loosen the special pan screw on the carburetor ...

Page 105: Float Chamber / Float /

6-5 fuel system inspection ● check the needlejet for wear and replace if necessary. ● check the vacuum piston for damage and replace if necessary. ● check the diaphragm for damage pin holes, wrinkles and bends and replace if necessary. Float chamber / float / jet disassembly ● loosen the 4 screws se...

Page 106

6-6 fuel system ● remove the main jet, needle jet holder, needle jet, slow jet, screw set, diaphragm comp, compression spring. ● clean the jet and hole of carburetor body with blow the compressed air. Carburetor body top set compression spring float chamber set screw set auto bystarter set needle je...

Page 107

6-7 fuel system assembly ● install the needle jet, needle jet holder, main jet and slow jet. ● tighten the pilot jet until it seat lightly, then turn it out as much as number recorded during removal. ● install the pilot jet rubber. ● install the float valve set, float comp, float pin. ● measure the ...

Page 108: Caburetor Installation

6-8 fuel system caburetor installation ● install the carburetor to the carburetor insulator. ● tighten the carburetor insulator band screw. ● install the fuel tube to the carburetor. ● intall the wiring coupler of the auto bystarter. ● install the throttle cable to the carburetor. ● intall the air c...

Page 109: Pilot Screw Adjustment

6-9 fuel system inspection ● check the carburetor insulator o-ring for wear or damage. ● install in the reverse order of removal. Pilot screw adjustment using the emission analyzer (co,hc) ● open the seat and remove the center cover. ① turn the pilot screw clockwise until it seats lightly, then back...

Page 110: Fuel System

6-10 fuel system pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw pilot screw throttle stop screw...

Page 111: Fuel System

6-11 fuel system ⑥ after the final test of the starting and driving, readjust if necessary. If the engine cannot be adjusted by turning the pilot screw within a ¼ turn, check for other engine problems. ! Caution disassembly ● loosen the 4 screws securing the fuel pump. ● remove the fuel pump. ● chec...

Page 112: Fuel System

6-12 fuel system fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump fuel pump after install the fuel pump, check the blowing quantity of fuel...

Page 113: Engine Removal/installation

7-1 engine removal/installation 7. Engine removal/installation service information ····· 7-1 engine removal/installation · 7-2 service information general safety note •use a jack to remove or install the engine. Support the motorcycle with a jack firmly, taking precautions not to damage the frame, e...

Page 114: Engine Removal/installation

7-2 engine removal/installation engine removal ● drain the engine oil. ● release the seat lock by turning the main switch key to open the seat. ● remove the following parts. - rear under cover. - air cleaner (2-5) - carburetor (6-3) ● disconnect the acg coupler and connector wiring connected to the ...

Page 115: Engine Removal/installation

7-3 engine removal/installation ● loosen the rear cushion under bolt. ● remove the sai tube from the secondary air filter assembly. ● loosen the 10mm u nut from the engine hanger. ● lifting the frame back side and remove the flange bolt securing engine hanger and disassemble the frame and engine. Re...

Page 116

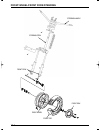

8-0 lh. Crankcase cover/continuously variabletransmission lh. Crank case cover.

Page 117: 8. Lh. Crankcase

8-1 8. Lh. Crankcase /continuously variable transmission service information general safety ● do not allow oil to contact the drive belt or the pulley face. The transmission rate of driving force is reduced with oil contact. ● do not operate starter motor while the lh. Crank case front cover is remo...

Page 118: Lh. Crankcase Cover

Lh. Crankcase cover disassembly ● remove the air cleaner and flange bolt securing b stay. ● remove the flange bolts securing lh. Crankcase. ● remove the lh. Crankcase cover. ● remove the gasket and dowel pin. Installation ● install the new gasket and dowel pin after removing the gasket of the crankc...

Page 119: Drive Belt

Drive belt removal ● remove the lh. Crankcase cover. ● loosen the drive face setting flange nut 12mm using the drive face holder and remove the drive face. Tool : drive face holder 8-3 lh.Crank case cover/continuously variable transmission ● loosen the clutch outer setting nut using the universal ho...

Page 120

Drive belt inspection ● check the drive belt for cracks, pry separation and wear, replace as necessary. ● measure the width of the drive belt as shown. Service limit : 20.5mm drive belt installation ● turn the pulley clockwise and spread the face apart while installing the drive belt and install the...

Page 121: Movable Drive Face

● install the drive face to the lh. Crank shaft. ● install the rear axel collar and temporaily install the flange nut. ● tighten the flange nut to the specified torque using the drive face holder. Torque valve : 7.0~8.0kgf · · m torque valve : 5.0~6.0kgf · · m tool : drive face holder universal hold...

Page 122

Movable drive face inspection ● check the rollers for wear or damage. ● measure the o.D. Of each roller. Service limit : 19.5mm ● measure the abnormal wear. Service limit : less than 2.0mm movable drive face installation ● install the weight roller on the movable drive face. ● apply the inside of th...

Page 123

● install the drive belt into the movable drive face. ● install the drive face in to the lh. Crank shaft, and install the rear axcel collar. ● tighten the flange nut into the drive face. ● install the lh. Crankcase cover. ● tighten the nut to the specified torque using the drive face holder. Torque ...

Page 124: Driven Pulley

8-8 lh.Crank case cover/continuously variable transmission driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley driven pulley dri...

Page 125

8-9 lh.Crank case cover/continuously variable transmission ● remove the seal collar from the driven pulley. ● remove the guide pins and guide pin rollers and the movable driven face. ● remove the o-ring from movable driven face. ● remove the oil seal from the movable driven face. ● remove the movabl...

Page 126

8-10 lh.Crank case cover/continuously variable transmission outer ball bearing inner needle bearing movable driven face spring free length vernier caliper clutch outer clutch shoe driven pulley inspection driven face bearing inspection ● check the each parts. ● check the driven face needle bearing(i...

Page 127

8-11 lh.Crank case cover/continuously variable transmission movable driven face guide groove drive face outer bearing snap ring sealed side inner needle bearing outer bearing snap ring specified grease inner rearing inner bearing ● check the following; - movable driven face for damage or excessive w...

Page 128

8-12 lh.Crank case cover/continuously variable transmission oil seal o-ring movable driven face driven face guide pin seal collar lock nut wrench clutch spring compressor guide pin guide roller pin guide roller driven face / movable driven face ● install new oil seal and o-ring on the movable driven...

Page 129

8-13 lh.Crank case cover/continuously variable transmission drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive belt drive bel...

Page 130

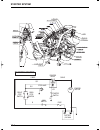

9-0 a.C generator / starter clutch ֢ࢥ@ࡘॕ ॗ͉ێ@ো ࡪχई sai@π˝@ћҸ cooling fan fly wheel starter comp sai lid valve.

Page 131

9 9 9 9 9 9 9 9-1 a.C generator / starter clutch 9 16..

Page 132: Shroud

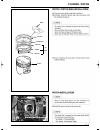

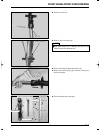

9-2 a.C generator / starter clutch shroud removal ● remove the following parts. - rr. Inner - sai tube - rh. / lh. Pillion step holder - muffler comp a.C generator removal ● loosen the rear cushion under cover. ● loosen the 3 bolts securing rh. Shroud. ● remove the sai. ● remove the shroud. ● loosen...

Page 133

9-3 a.C generator / starter clutch a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler a.C.G coupler...

Page 134: Rh. Crankcase Cover

9-4 a.C generator / starter clutch sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai pipe sai tube sai tube sai tube sai tube sai tube sai tube sai tube sai ...

Page 135

9-5 a.C generator / starter clutch ● remove the rh. Crankcase cover gasket and dowelpin. Starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch sta...

Page 136: Starter Clutch

9-6 a.C generator / starter clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting clutch starting ...

Page 137

9-7 a.C generator / starter clutch thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer thrust washer...

Page 138

9-8 a.C generator / starter clutch starter oneway clutch set starter oneway clutch set starter oneway clutch set starter oneway clutch set starter oneway clutch set starter oneway clutch set starter oneway clutch set starter oneway clutch set starter oneway clutch set starter oneway clutch set start...

Page 139: Memo

Memo.

Page 140

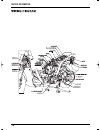

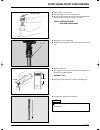

10-0 cylinder head / valves flange nut in valve rocker arm cam shaft horder cam shaft comp inlet valve cylinder head comp cylinder head gasket ex. Valve rocker arm ex. Valve carburetor insulator sai pipe.

Page 141: 10. Cylinder Head / Valves

10-1 10. Cylinder head / valves service information general safety ● the rocker arm and the camshaft can be serviced without removing the engine. However, the engine must be removed from the frame to maintain the cylinder head. ● the oil of camshaft oil is supplied through the cylinder head oil hole...

Page 142: Troubleshooting

Tools valve guide reamer valve guide driver valve spring compressor valve seat cutter seat cutter in 37°(21.5mm) ex 37°(18.5mm) in 45°(22.0mm) ex 45°(22.0mm) in 55°(20.0mm) ex 55°(20.0mm) troubleshooting enging top-end problems useally affect engine performance. These can be diagnosed by a compressi...

Page 143: Camshaft

● turn the crankshaft to the left, and align the “t”mark of the flywheel with the index mark of the rh. Crankcase cover. ● verify that the piston is located at the top dead center. (make all camshaft lobes face downward.) ● if all camshaft lobes face upward, rotate the crankshaft to the left for 1 t...

Page 144

● remove the cam chain from the camshaft. ● remove the camshaft. ● insert the 6mm bolt into the rocker arm shaft, and pulling bolts to remove the rocker arm shaft. ● remove the rocker arm. ● remove the other side rocker arm shaft and rocker arm in the same sequence. Camshaft inspection ● check the r...

Page 145: Cylinder Head

● manually turn the camshaft bearing outer race, and check if it turns smoothly. ● check the bearing for wear or damage. Cylinder head ● remove the following parts. - rear fender - seat support pipe - center cover - truss pipe - floor panel - rh. Lh. Shroud - cylinder head cover - cam shaft - ex. Pi...

Page 146: Valve Springs

● remove the valve spring, valve cotter, retainer, spring and valve. Using the valve spring compressor. Tool : valve spring compressor cylinder head inspection ● remove the carbon deposits from the inside of the combustions chamber. ● check the spark plug assembling hole and the valve seat for crack...

Page 147: Valve Guides

Valve guides inspection ● insert the valve guide reamer from the combustion chamber side and ream the guide to remove any carbon build-up before measuring the guide. Tool : valve guide reamer ● measure and record each valve guide inner diameter. Service limit : 5.030 mm ● measure the guide-to-stem c...

Page 148: Valve Seats

● apply oil to a new o-ring and install it onto a new valve guide. ● drive the new guide in from the camshaft side of the cylinder head while the cylinder head is still heated. Tool : valve guide driver ● when reaming new valve guides, insert the valve guide reamer from the combustion chamber side. ...

Page 149

● remove the valve and inspect the valve seat face. ● the valve seat contact should be within the specified width and evenly all around the circumference. If the valve seat width is not within specification, reface the valve seat. ● measure the valve seat width. Standard value : 0.8 -1.0 mm service ...

Page 150

● using a 55 degree cutter, remove the bottom ¼ of the old seat. ● using a 45 degree cutter, cut the seat to the proper width. ● if the contact area is too high on the valve, the seat must be lowered using a 37 degree flat cutter. Refinish the seat to specifications, using a 45 degree finish cutter....

Page 151: In/ex Valve Assembly

● after cutting the valve seat, apply lapping compound to the valve face, and insert the valve with a valve guide reamer. In/ex valve assembly ● install the valve spring and new stem seals. ● lubricate each valve stem with molybdenum disulfide grease and insert the valve into the valve guide. ● chec...

Page 152: Cylinder Head Assembly

● tap the valve stems gently with a soft hammer to firmly seat the cotters. ● apply engine oil to the new o-ring, and assemble it to the carburetor insulator groove. ● tighten the carburetor insulator with mounting bolts. ● install the cam chain tensioner, and assemble pilot. Torque : 1.0 kgf · m ● ...

Page 153: Camshaft Assembly

Camshaft assembly ● apply engine oil to the rocker arm shaft, and assemble the rocker arm to the camshaft holder. ● tighten the rocker arm shaft with 6mm bolts, and align the bolt hole of the camshaft holder with the fitting side of the rocker arm shaft. ● check the camshaft assembly for abnormal co...

Page 154

● apply engine oil to the camshaft, and install it on the cylinder head with the cam thread facing downward. ● assemble the cam chain and cam sprocket after matching the cam sprocket timing mark in parallel with the top of the cylinder head. ● install the dowl pins on the cylinder head. ● install th...

Page 155

● fix the tensioner shaft with a hard clip. ● assemble a new gasket to the tensioner lifter, and install the tensioner lifter on the cylinder. ● tighten the tensioner mounting bolts. Torque value : 1.2 kgf · m ● remove the tensioner shaft clip from the tensioner lifter. Assemble the o-ring and pan s...

Page 156

11-0 cylinder / piston cylinder cylinder gasket piston top ring second ring oil ring.

Page 157: 11. Cylinder / Piston

11-1 11. Cylinder / piston service information general safety ● be careful not to damage the mating surfaces by using a screwdriver when disassembling the cylinder. Do not strike the cylinder too hard during disassembly, even with a rubber or plastic mallet, to prevent the possibility of damage to t...

Page 158: Cylinder

11-2 cylinder / piston cylinder gauge top middle bottom cylinder removal ● remove ex. Pipe. ● remove the cylinder head cover. ● remove the cam shaft. ● remove cylinder head. ● remove the cam chain guide from the cylinder. ● remove cylinder ● remove the gasket and dowel pin. Carefully remove any adhe...

Page 159: Piston / Piston Ring

11-3 cylinder / piston piston ring warpage inspection ● check the cylinder for warpage by placing a straight edge and feeler gauge across the stud holes. Replace the cylinder if the service limit is exceeded. Service limit : 0.02 mm piston / piston ring removal ● remove the piston pin clip using a p...

Page 160

11-4 cylinder / piston.

Page 161

11-5 cylinder / piston top ring second ring mark r top ring second ring side rail side rail oil ring piston 20mm spacer crank shaft connecting rod crank shaft connecting rod crank shaft connecting rod crank shaft connecting rod crank shaft connecting rod crank shaft connecting rod crank shaft connec...

Page 162

11-6 cylinder / piston cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylinder gasket cylin...

Page 163: Memo

Memo.

Page 164

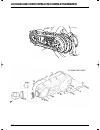

12-0 transmission/crankshaft/crank case.

Page 165

12 12-1 12-2 12-3 12-6 12-7 12-8 12-9 12-10 12-1 transmission/crankshaft/crankcase 12 ( section 4-4) ( section 7) ( section 9) ( section 8) ( section 8) ( section 12) ( section 10 and 11).

Page 166: Troubleshooting

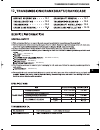

Torque value crank case bolt 1.0kg-m tools -universal bearing puller -bearing remover set -remover assembly -remover shaft -remover head -sliding weight -assembly shaft troubleshooting engine noise ● connecting rod big and small ends loose. ● crank pin bearing loose. Engine started but unable to mov...

Page 167

12-3 transmission/crankshaft/crank case 8-2 3-9 15-8 14-3 8 14-6 transmission cover transmission cover transmission cover transmission cover transmission cover transmission cover transmission cover transmission cover transmission cover transmission cover transmission cover transmission cover transmi...

Page 168

12-4 transmission/crankshaft/crank case final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final shaft final sh...

Page 169

12-5 transmission/crankshaft/crank case ● install the bearing to the case with special tools. Tool : drive handle a outer driver driver pilot needle bearing needle bearing needle bearing needle bearing needle bearing needle bearing needle bearing needle bearing needle bearing needle bearing needle b...

Page 170

12-6 transmission/crankshaft/crank case replace the new oil seal on the transmission cover. Insrall the transmission cover. Flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange bolts flange ...

Page 171

12-7 transmission/crankshaft/crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. Crank case rh. C...

Page 172

Transmission/crankshaft/crank case 12-8 x y dial gauge filler gauge dial gauge oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal oil seal lh. Crank case lh. Cran...

Page 173

12-9 transmission/crankshaft/crank case tool : crank shaft assembler bearing remover set bearing remover set bearing remover set bearing remover set bearing remover set bearing remover set bearing remover set bearing remover set bearing remover set bearing remover set bearing remover set bearing rem...

Page 174

12-10 transmission/crankshaft/crank case ● install the crankcase. ● install the engine on the frame. ( 7-3) dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin do...

Page 175: Memo

Memo.

Page 176

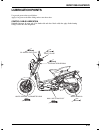

13-0 front wheel/front fork/steering steering handle steering stem front fork front tire front wheel front disk.

Page 177: Service Information

13-1 13. Front wheel/front fork/steering service information general safety ● use special tire levers and rim protectors to remove or assemble tires to protect the rim from being damaged. ● place a jack underneath the engine to support the 2-wheeled vehicle. Specifications torque values steering ste...

Page 178: Troubleshooting

13-2 front wheel/front fork/steering troubleshooting hard steering ● steering top cornice too tight. ● damaged steering stem steel ball. ● faulty steering ball race, cone race. ● insufficient tire pressure. ● tire is worn. Steers to one side or does not track straight ● bent front fork. ● bent front...

Page 179: Steering Handle

13-3 front wheel/front fork/steering steering handle removal ● loosen the bolts securing the front and rear break master cylinder. ● disconnect the throttle cable from the throttle grip. ● remove the handle grip from the handlebar. ● remove the cap on the handle upper holder. ● loosen the hexbolt se...

Page 180: Front Wheel

13-4 front wheel/front fork/steering installation ● align the line of the steering handle to the handle under holder. ● install the handle upper holder using the hexbolt, to the specified torgue. Torque : 3.92 - 4.9 ㎏ f · m ● install in the reverse order of removal. Front wheel removal ● jack the mo...

Page 181

13-5 front wheel/front fork/steering rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation rotation bearing remover head bearing remover head bearing remover head be...

Page 182: Speedometer Gear

13-6 front wheel/front fork/steering speedometer gear inspection ● remove the speedometer gear from the speedometer gear box. ● apply grease to the speedometer gear unit and install. Assembly ● apply grease to left side dust seal rim. ● install the left side dust seal. ● install the brake disk. ● in...

Page 183: Front Fork

Front wheel installation ● insert the front wheel between the front forks. ● insert the disk, taking precautions not to damage the pad, and assemble the wheel. ● align the slots of the speedometer gear with the tangs of the rh. Fork slider. ● insert the front axle into the speedometer gear box and t...

Page 184

13-8 front wheel/front fork/steering disassembly ● remove the fork pipe bolt. ● wrap the bottom case with a piece of cloth, and remove the socket bolt. ● when removing the front fork, loosen the flange bolt lightly. ● loosen the 4 setting bolts securing the rh./lh. Front fork, remove the rh./lh. Fro...

Page 185

13-9 front wheel/front fork/steering ● remove the oil seal stop ring. ● remove the dust seal. ● remove the fork pipe from the bottom case. ● remove the cution spring, pipe seat and oil lock piece from the fork pipe. ● check and inspect the each parts. Dust seal dust seal dust seal dust seal dust sea...

Page 186

13-10 front wheel/front fork/steering front fork assembly ● wash parts with clean oil prior to assembling. ● assemble the rebound spring and the fork piston to the fork tube. ● assemble the fork pipe to the bottom case. ● wrap the bottom case with a piece of cloth, and fix it to the vise. ● apply sc...

Page 187

● install the dust seal. ● fill a prescribed amount of automatic transmission fluid(atf) into the fork tube. Capacity : 90cc ● slowly press the fork tube 2-3 times to discharge air. ● assemble the springs to the fork pipe. 13-11 front wheel/front fork/steering ● install the oil seal stopper ring. ● ...

Page 188: Steering Stem

Steering stem removal ● remove the following parts. - handle cover - rear handle cover - front cover - handle bar - front wheel ● remove the steering stem lock nut with steering stem lock nut socket. ● remove the steering top nut with steering stem socket. 13-12 front wheel/front fork/steering assem...

Page 189

Installation ● install the steering head dust seal washer and dust seal onto the steering stem. ● press in the steering bottom cone race using the steering stem driver. ● install the under ball ass’y into the steering stem. Tool : steering stem driver ● insert the steering stem into the head pipe. ●...

Page 190

14-0 rear wheel/suspension/rear swing arm.

Page 191: Service Information

14-1 14. Rear wheel / suspension / rear swing arm service information ● use the specified tire lever and rim protector to remove or assemble tires to protect the rim from being damage. Specifications torque values : rear cushion upper bolt 3.5~4.5㎏f·m rear cushion under bolt 3.5~4.5㎏f·m rear cushion...

Page 192: Troubleshooting

Troubleshooting wobble or vibration in motorcycle ● bent wheel tire ● faulty tire ● axle not tightened properly ● insufficient air in tire ● wheel out of balance soft suspension ● weak springs ● rear damper improperly adjusted, oil leakage hard suspension ● rear damper improperly adjusted ● bent sho...

Page 193: Rear Wheel

14-3 rear wheel/suspension/rear swing arm rear wheel removal ● support the motorcycle on the main stand. ● remove the muffler. ● remove the rear brake caliper assembly with brake hose from the rear swing arm. ● loosen the rear axle nut. ● remove the rear swing arm. ● remove the rear wheel inside col...

Page 194

14-4 rear wheel/suspension/rear swing arm dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge dial gauge rear wheel rear ...

Page 195: Rear Cushion

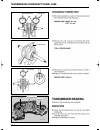

14-5 rear wheel/suspension/rear swing arm rear cushion removal ● remove the upper bolt. ● remove the lower bolt. ● remove the rear cushion. Disassembly ● install the compressor attachment as shown in the figure. ● install the cushion on the cushion compressor, and compress the spring. Tool : rear ch...

Page 196: Rear Swing Arm

14-6 rear wheel/suspension/rear swing arm rear swing arm removal ● remove the ex. Muffler. ● remove the rear brake caliper. ● loosen the rear axle u-nut. ● remove the rear swing arm. ● install the rear cushion. ● tighten the top and bottom of the cushion with bolts. Torque valve : upper side : 3.5~4...

Page 197

14-7 rear wheel/suspension/rear swing arm disassembly ● disassemble the rear wheel outside collar from the rear swing arm. ● disassemble the oil seal (28 x 42 x 7) and radial ball bearing (6302uu). Outside collar outside collar outside collar outside collar outside collar outside collar outside coll...

Page 198: Memo

Memo.

Page 199: Memo

Memo.

Page 200

15-0 brake system.

Page 201: 15. Brake System

15-1 brake system 15. Brake system service information general safety ● do not allow foreign material to enter the system when replenishing brake fluid. ● to prevent chemical changes, do not mix different types of brake fluid. ● do not use the old brake fluid again. ● brake fluid can cause damage to...

Page 202: Troubleshooting

15-2 brake system troubleshooting brake lever / pedal soft or spongy ● air bubbles in the hydraulic system. ● leaking hydraulic system. ● contaminated brake pad / disk . ● worn caliper piston seal. ● worn master cylinder piston seal. ● worn brake pad. ● contaminated caliper. ● caliper not sliding pr...

Page 203: Brake Fluid

15-3 brake system front brake air bleeding ● fill the reservoir with dot 3 or 4 brake fluid up to the upper level. ● remover the fluid maintenance lid. ● remove the oil cup cap, diaphragm plate, and diaphragm from the master cylinder. ● connect the bleeder hose to the bleeder valve. Loosen the bleed...

Page 204

15-4 brake system when the brake bleeder is not available > ● fill the brake fluid up to the upper limit line. ● connect the transparent bleeder hose to the bleeder valve and place the other end of the hose in a container. ① squeeze the brake lever, then open the bleeder valve 1/2 turn, and close th...

Page 205: Front Brake Pad

15-5 brake system rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake lever rr. Brake ...

Page 206: Front Brake Caliper

15-6 brake system front brake caliper removal ● drain the brake fluid. ● loosen the oil bolt securing the brake hose. ● loosen the 2 bolts securing the caliper. Rr. Caliper rr. Caliper rr. Caliper rr. Caliper rr. Caliper rr. Caliper rr. Caliper rr. Caliper rr. Caliper rr. Caliper rr. Caliper rr. Cal...

Page 207

15-7 brake system inspection ● check the caliper cylinder bore for scoring, scratches, or other damage. ● measure the caliper cylinder i.D. Service limit : cylinder i.D.A : 34.01mm cylinder i.D.B : 25.46mm ● check the caliper piston outer diameter part for scratches or other damage. ● measure the pi...

Page 208: Rear Brake Caliper

15-8 brake system lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper body lh caliper...

Page 209

15-9 brake system dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal piston piston piston piston piston piston piston piston piston...

Page 210

15-10 brake system dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug dust plug lock plate lock plate lock plate lock plate lock plate lock p...

Page 211: Master Cylinder

15-11 brake system master cylinder set master cylinder set master cylinder set master cylinder set master cylinder set master cylinder set master cylinder set master cylinder set master cylinder set master cylinder set master cylinder set master cylinder set master cylinder set master cylinder set m...

Page 212

15-12 brake system piston piston piston piston piston piston piston piston piston piston piston piston piston piston piston piston piston piston piston piston piston piston secondary cup secondary cup secondary cup secondary cup secondary cup secondary cup secondary cup secondary cup secondary cup s...

Page 213: Brake Disk

15-13 brake system brake hose oil bolt brake hose oil bolt brake hose oil bolt brake hose oil bolt brake hose oil bolt brake hose oil bolt brake hose oil bolt brake hose oil bolt brake hose oil bolt brake hose oil bolt brake hose oil bolt brake hose oil bolt brake hose oil bolt brake hose oil bolt b...

Page 214

16-0 charging system 15a.

Page 215: 16. Charging System

16-1 16. Charging system service information ·do not place flammable materials near battery when charging. This can be a fire hazard as hydrogen gas is created during charging battery. ·do not allow battery acid to come into contact with clothes, skin or eyes. Battery acid contact can cause burns or...

Page 216: Troubleshooting

16-2 charging system troubleshooting no power (key turned on) low power (engine running) ● dead battery. ● battery undercharged. -low fluid level. ● battery is failing. -low specific gravity. ● charging system failure. -charging system failure. ● disconnected battery cable. Intermittent power ● main...

Page 217: Battery

16-3 charging system battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover battery cover...

Page 218: Charging System Inspection

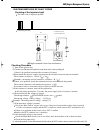

16-4 charging system ampere meter battery terminal earth cable main fuse terminal main fuse charging system inspection leak test ● trun off the ignition switch, and disconnect the ground (-) cable from the battery. ● connect an ampere meter between negative (-) terminal and ground cable. ● with the ...

Page 219: A.C Generator Inspection

16-5 charging system ● this test can be made without removing the stator from the engine. Disconnect the wellow wire from the auto bystarter. ! Note △ ac generator coupler ac generator coupler ac generator coupler ac generator coupler ac generator coupler ac generator coupler ac generator coupler ac...

Page 220

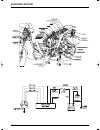

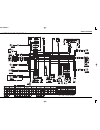

+ _ ac. Generator b/y pulse generator battery (12v 10ah) unit side stand switch ignition coil spark plug g r main sw fuse (15a) g g b/w p b g/b b/y g b/y headlight relay ignition sysytem 17-0 ignition system.

Page 221: 17. Ignition System

17-1 17. Ignition system service information general safety ● follow the steps described in the troubleshooting flow chart when servicing the ignition system. ● the cdi unit may be damage if dropped. Also, if the connector is disconnected when current is flowing, the excessive voltage may damage the...

Page 222: Troubleshooting

Troubleshooting no spark at plug. 17-2 ignition system unusual condition probable cause (check in numerical order) 1. The multitester impedance is too low. 2. Cranking speed is too slow. - battery is undercharged (or operating force of the kick starter is weak). 3. The sample timing of the tester an...

Page 223: Cdi Unit Inspection (Euro2)

17-3 ignition system cdi unit inspection (euro2) cdi ignition circuit inspection ● release the seat lock with the main key. ● remove the rear under cover. ● disconnect the coupler from the cdi unit, and check the ignition system circuits from the wiring coupler side. Inspection items ● if there are ...

Page 224: Ignition Coil Inspection

17-4 ignition system ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil ignition coil...

Page 225: Ignition Timing Inspection

17-5 ignition system ignition timing inspection ● warm up the engine. Side stand ignition cut- off switch inspection ● remove the coupler of the side stand switch linked to the wire. ● check for continuity between the terminal as shown below; ● as the system uses the cdi unit, the ignition timing ne...

Page 226

18-0 starter system m cable cable starter relay starter motor battery (12v 10ah fuse y/r starter switch rear stop switch g/y stop lamp g/y front stop switch b main switch g starter system.

Page 227: 18. Starter System

18-1 18. Starter system service information general safety ·always turn the ignition switch off before servicing the starter motor. The moter could suddenly start, causing serious injury. ● the starter motor can be maintained without removing the engine from the vehicle. ● a weak battery may be unab...

Page 228: Troubleshooting

Troubleshooting starter motor will not turn. ● check for a blown main fuse before servicing. ● check that the stop light is correctly adjusted. ● check that the side stand is positioned in the condition under which the engine can be started. With the ignition switch “on”and squeeze the brake lever, ...

Page 229: Starter Motor

18-3 starter system starter motor removal ● remove the starter motor cable from the starter magnetic switch. ● loosen the 2 flange bolts securing the engine case, remove the battery earth cable and starter motor. ● install in the reverse order of removal. Disassembly ● remove the starter motor cable...

Page 230

● remove the brush spring, and then remove the brush. ● measure the brush length. Replace the brush if it is worn beyond the service limit. Service limit : 5 mm tool : vernier caliper ● check the commutator for : -damage or abnormal wear. → replace with a new one. -discoloration of the commutator ba...

Page 231

18-5 starter system brush holder set brush holder set brush holder set brush holder set brush holder set brush holder set brush holder set brush holder set brush holder set brush holder set brush holder set brush holder set brush holder set brush holder set brush holder set brush holder set brush ho...

Page 232: Starter Magnetic Switch

Starter magnetic switch removal ● remove the center cover and battery cover. ● remove the battery (+) cable from the starter magnetic switch terminal. ● remove the starter motor cable from the starter magnetic switch terminal. ● disconnect the yellow / red connector and green / yellow connector from...

Page 233

18-7 starter system operation check ● disconnect the magnetic switch wire connector. ● apply battery voltage between terminals, when the yellow / red wire is connected to the positive (+) battery terminal and the green / yellow wire to the negative (-) battery terminal. ● if there is continuity betw...

Page 234: Memo

Memo.

Page 235: 19. Lights/switches/horn

19-1 19. Lights/switches/horn troubleshooting light not turned on when the main switch is on ● faulty light bulb ● faulty switch ● faulty or disconnected wiring ● fuse cut ● battery discharged dim headlight ● battery discharged ● wiring and switch resistance high headlight hi-low bean cannot be char...

Page 236: Headlight Bulb

19-2 lights/switches/horn head light head light head light head light head light head light head light head light head light head light head light head light head light head light head light head light head light head light head light head light head light head light washer screw washer screw washer...

Page 237: Rear Tail Light

19-3 lights/switches/horn tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb tail & stop bulb ta...

Page 238: Main Switch

19-4 lights/switches/horn main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switch main switc...

Page 239: Horn

19-5 lights/switches/horn front stop switch front stop switch front stop switch front stop switch front stop switch front stop switch front stop switch front stop switch front stop switch front stop switch front stop switch front stop switch front stop switch front stop switch front stop switch fron...

Page 240: Fuel Gauge

19-6 lights/switches/horn fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank fuel tank unit set cap unit set cap unit set cap unit set cap un...

Page 241: Memo

Memo.

Page 242: Memo

Memo.

Page 243

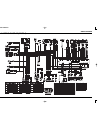

20-1. Wiring diagram (euro-2) wiring diagram.

Page 244

20-2. Wiring diagram (euro-3) wiring diagram.

Page 245

Service manual 2009. 02 printed 2009. 02 publication c co op py y p pr ro oh hiib biit t.

Page 246

Sm57-0902-01e.