- DL manuals

- DAELIM

- Scooter

- S2-125

- Service Manual

DAELIM S2-125 Service Manual

How to use this manual

This manual explains how to maintain procedure for the

S2-125 manufactured by DAELIM MOTOR CO., LTD.

To ensure safety and optimal operating conditions of the

vehicle, carry out regular inspections according to the

maintenance schedule(Section 2).

Sections 1 through 2 provide information on overall

vehicle; section 3, assembly and disassembly procedures

for external components, and section 4 describes

maintenance procedure for the engine, frame and

electrical systems.

To facilitate use of this manual, each page starts with

disassembly and system diagrams, each page starts with

disassembly and system diagrams, service information,

and troubleshooting guide.

Contents of this manual and specifications are subject

to change without prior notice for improvement of

vehicle quality.

No part of this publication may be reproduced without

written permission of DAELIM Motor Co.,Ltd.,

Service Information

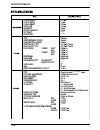

1

2

3

4

6

7

8

9

10

11

14

15

16

17

18

Inspections / Adjustments

External Parts

Lubrication System

5

EMS(Engine Management System)

Fuel System

Engine Removal / Installation

LH, Crank Case Cover

Continuously Variable

Transmission

A.C Generator / Starter Clutch

Cylinder Head / Valves

Cylinder Head / Piston

12

Transmission / Crank Shaft

Crank Case

Rear Wheel / Rear Brake /

Suspension / Rear Swing Arm

Charging System

Ignition System

Starter System

Lights / Switches / Horn

19

Wiring diagram

Contents

Engine

Frame

Electrical

General

13

Front Wheel / Front Fork

/ Steering / Brake

Summary of S2-125

Page 1

How to use this manual this manual explains how to maintain procedure for the s2-125 manufactured by daelim motor co., ltd. To ensure safety and optimal operating conditions of the vehicle, carry out regular inspections according to the maintenance schedule(section 2). Sections 1 through 2 provide i...

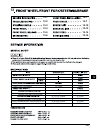

Page 3

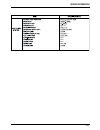

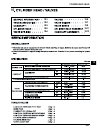

Service information 1 1-1.

Page 4

1-2 service information.

Page 5

Service information 1-3.

Page 6

1-4 service information.

Page 7

1-5 service information.

Page 8

1-6 service information.

Page 9

1-7 service information.

Page 10

1-8 service information.

Page 11

1-9 service information.

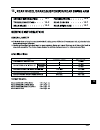

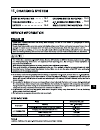

Page 12

1-10 service information 145kg 11.5 2.2 stroke sohc 306.9kg atdc.

Page 13

1-11 service information , 30a led led led.

Page 14

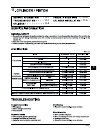

1-12 service information.

Page 15

1-13 service information.

Page 16

1-14 service information.

Page 17

1-15 service information.

Page 18

1-16 service information.

Page 19

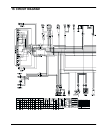

Start-mag. Sw. Cord battery earth cable wire clip acg. Wire to. Fuel tank acg. Cord tube clip tube clip to. Insulator fuel pump to. Carbulator tube clip start motor cable start-magnet sw. Ass’y. Battery + cable start-mag. Sw. Cord battery earth cable wire clip acg. Wire to. Fuel tank acg. Cord tube ...

Page 20

Memo.

Page 21

2-1 inspections/adjustments 2.

Page 22

2-2 inspections/adjustments.

Page 23

2-3 inspections/adjustments.

Page 24

2-4 inspections/adjustments.

Page 25

2-5 inspections/adjustments.

Page 26

2-6 inspections/adjustments.

Page 27

2-7 inspections/adjustments.

Page 28

2-8 inspections/adjustments.

Page 29

2-9 inspections/adjustments.

Page 30

2-10 inspections/adjustments.

Page 31

3-1 external parts 3.

Page 32

3-2 external parts.

Page 33

3-3 external parts.

Page 34

3-4 external parts.

Page 35

3-5 external parts handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover handle cover under under under under under under under under under under under under under under handle cover ha...

Page 36

3-6 external parts front under cover a front under cover a front under cover a front under cover a front under cover a front under cover a front under cover a front under cover a front under cover a front under cover a front under cover a front under cover a front under cover a front under cover a.

Page 37

3-7 external parts.

Page 38

External parts 3-8.

Page 39

4-1 lubrication system 4-1 4-2 4-3 4-3 4-4 4-7 4-8 4-9 4-4 4.

Page 40

4-2 lubrication system.

Page 41

4-3 lubrication system.

Page 42

4-4 lubrication system.

Page 43

4-5 service lubrication system.

Page 44

4-6 lubrication system.

Page 45

4-7 lubrication system.

Page 46

4-8 lubrication system.

Page 47

4-9 lubrication system.

Page 48

Memo.

Page 49

5-1 ems(engine management system) 5. Ems(engine management system) 1. Caution when repairing the ems parts 5-2 2. The component parts of the ems 5-3 3.Terminal arrangement of the ecu 5-4 4. Wiring diagram of the ecu 5-4 5. Self-diagnostic function by mil(malfunction indicator lamp) 5-5 - self diagno...

Page 50

5-2 ems(engine management system) 1.Caution when repairing the ems parts. If the fuse is short-circuited, findout the cause and repair. Replace with the fuse having the specified capacity. Do not use the electlic wires or others instead of the fuse. Do not drop or throw the ems parts because these p...

Page 51

5-3 ems(engine management system) 2.The component parts of the ems ems consists of intake and fule, ignition and control system. 1) intake system as a system which controls and measures air to be necessary for combustion in engine, the intake system is composed of pressure sensor of intake parts, in...

Page 52: 4. Wiring Diagram of The Ecu

5-4 ems(engine management system) 3. Terminal arrangement of the ecu remarks ecu pin no. 6,7,8,11,13,14,15,16,21,29,32,36,38 were not connected. 4. Wiring diagram of the ecu.

Page 53

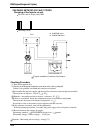

5-5 ems(engine management system) 5. Self-diagnostic function by mil (malfunction indicator lamp) self-diagnostic function the ems is equipped with self-diagnostic function in order to ensure that the engine control system is operation normally. If this function detects a malfunction in the system, ...

Page 54

5-6 ems(engine management system) fail-safe function if the ecu checks something wrong , the vehicle can be driven by its fail safe function. However, if there are something wrong in fuel pump, injector, crank position sensor, the engine operation can be impossible. If there is something wrong in th...

Page 55

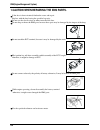

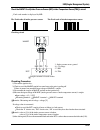

5-7 ems(engine management system) how to check the fault code there are two methods of checking the fault codes. 1) use the mil in the speedometer. 2) the diagnostic tool. First) use the mil in the speedometer(refer to how to read the fault codes and fault codes table and diagnostic methods for each...

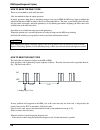

Page 56

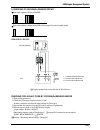

5-8 ems(engine management system) how to show the fault code there are two methods to show the fault codes. First, the methods to show in engine operation in engine operation, when there is something wrong in each part of ems, the mil keeps light on without the light on/off function of mil in order ...

Page 57

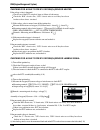

5-9 ems(engine management system) fault codes table no failure injection valve failure(iv) idle speed actuator failure (isa) electrical fuel pump failure (efp) intake manifold absolute pressure signal failure (imp) throttle position signal failure (tps) o2 sensor heater output failure (lsh) lambda s...

Page 58

5-10 ems(engine management system) how to remove the fault code remove the fault codes in two ways; first) full warm up 1. Starting the engine. - the mil blinks continuously because the ecu memorized the fault code yet. 2. Full warm up the engine (keep idling five minutes) 3. Turn off the ignition k...

Page 59: 6.Injector

5-11 ems(engine management system) remove connector connector bolt injector and injector cap. Replace the injector 6.Injector ! Notice before disassemble, the key is off. ! Caution make sure that dust does not enter the throttle body insulator..

Page 60

5-12 ems(engine management system) checking methods by fault codes checking of the injector circuit the fault code is displayed by mil checking circuit coupler terminal is based on wire harness. Checking procedure 1) turn off the ignition key. 2) check to see if the injector coupler has come loose o...

Page 61

5-13 ems(engine management system) 7) if the measured voltage is normal, check the ‘blue/yellow’ electric wire to see if they have been broken or have short-circuited or if the wire-harness coupler and the ecu coupler are a bad contact (ecu terminal no. 40) if there is no problem in the electric wir...

Page 62: Sensor, Temperature Sensor)

7. Mapat(manifold air pressure sensor, temperature sensor) remove mapat connector (push by hand and pull to the front-side) loosen the flange bolt 2ea. Be sure to check the coupler is toward to insulator. ! Caution located on the left- side of the throttle body before disassembly, the key is off. ! ...

Page 63

5-15 ems(engine management system) check the mapat circuit(intake pressure sensor (imp)+intake temperature sensor(tba))’s circuit fault code number is displayed by mil the fault code of intake pressure sensor the fault code of intake temperature sensor checking circuit coupler terminal is based on t...

Page 64

5-16 ems(engine management system) checking of the intake pressure sensor 1) if voltage value is normal, turn off the ignition key. Connect the mapat(intake pressure sensor + intake temperature sensor) coupler 2) the wire-harness to check the ecu is connected with the ecu with a wire-harness coupler...

Page 65

5-17 ems(engine management system) 8.Tps(throttle position sensor) remove lh.Side cover air cleaner tps connector tps screw replace the tps it is located on the right side of throttle body before disassembly, the key is off. ! Caution checking of intake temperature sensor 4) turn on the ignition key...

Page 66

Checking the tps(throttle position sensor) circuit diagram fault code number displayed by mil checking circuit the coupler terminal is based on the side of wire-harness checking procedure 1) turn off ignition key . 2) check the tps(throttle position sensor) coupler is loose, or bad. If there is no d...

Page 67

5-19 ems(engine management system) checking procedure 6) check continuty between the sensor ground terminal of tps and earth. The continuty tps : 0[ ],20±1 measuring terminal : ecu no. 4 (w/r : white/red) ~ earth remarks : measuring unit for resistance : resistance ‘ r ‘ [ ] 7) if not problem, measu...

Page 68

9.Ets(engine temperature sensor) remove rh.Shroud comp connector by hand ets replace the ets install in reverse order of removal situated on the right-hand side of cylinder head before disassembly, the key is off. ! Caution 5-20 ems(engine management system) ets torque:3±0.3[kgf m] ! Caution push pu...

Page 69

5-21 ems(engine management system) 1)checking the circuit diagram of ets(engine temperature sensor) fault code number is displayed by mil checking circuit coupler terminal is based on the side of wire-harness checking procedure 1) turn off the ignition key . 2) check the ets(throttle position sensor...

Page 70

5-22 ems(engine management system) 6-1) if the measured value is not normal, replace the ets with the new one, recheck. If the measured value is normal, check the g/l electric wire, w/r electric wire to see if they have been broken or have short-circuited or if the ecu coupler is a bad contact ( no....

Page 71: 10.Isa(Idle Speed Actuator)

5-23 ems(engine management system) 10.Isa(idle speed actuator) remove seat maintenance cover isa connector it is located upwards on the throttle body before disassembly, the key is off. ! Caution o-ring o-ring o-ring o-ring o-ring o-ring o-ring o-ring o-ring o-ring o-ring o-ring o-ring o-ring isa is...

Page 72

1)check the isa(idel speed actuator) circuit. Showing of defects codes by mil checking circuit coupler terminal is based on the side of the wire-harness check procedure 1) turn off ignition key . 2) check the isa(throttle position sensor) coupler is loose, or bad. If there is no defect, measure the ...

Page 73

5-25 ems(engine management system) check procedure 5) if the measured resistance and continuty is abnormal. Replace isa with the new one, and recheck. 6) if resistance and continuty is normal, connect the coupler of isa. 7) turn on ignition key 8) measure isa voltage of wire-harness to check ecu. Me...

Page 74: 11.O2(Oxygen) Sensor

Remove seat o2 sensor connector muffler o2 sensor located on the exhaust pipe before disassembly, the key is off. ! Caution beware of muffler after driving as it is still hot to be burnt ! Warning 11.O2(oxygen) sensor 5-26 ems(engine management system) o2 sensor o2 sensor o2 sensor o2 sensor o2 sens...

Page 75

5-27 ems(engine management system) 1) checking of oxygen(o 2 ) sensor circuit fault code number is displayed by mil fault code number is displayed by mil of the oxygen(o 2 )sensor lambda signal. Checking circuit coupler terminal is based on the side of wire-harness. Checking for a fault code by oxyg...

Page 76

5-28 ems(engine management system) checking for a fault code by oxygen(o 2 )sensor heater if the voltage value is abnormal, check to see if the ecu coupler is loose or if there is bad contact. Check the ‘b/b’’ electric wire, ‘g/w’ electric wire to see if they have been broken or have short- circuite...

Page 77

5-29 ems(engine management system) 12.Checking of mil(malfunction indicator lamp)circuit fault code number is displayed by mil checking circuit check procedure 1) turn off ignition key. 2) check the ess coupler is loose, or bad. If there is no problem. 3) turn on the ignition key. 4) check the mil o...

Page 78

5-30 ems(engine management system) remove body cover connector (a display portion is pulled behind) flange bolt 4 ea replace the ecu install in the reverse order of removal. Replace the ecu located inside the lh. Side cover ! Caution be sure to assemble the ecu ground wire. (the color is green) ! Ca...

Page 79: 14.Ignition Coil

5-31 ems(engine management system) remove seat body cover ignition coil -connector -spark plug cap -ignition coil bolt 2ea -ignition coil locate on the rh.Body cover be sure to check the engine is cooling. Because a little gasoline remains, it is still hot. ! Caution be sure to assemble the ig coil ...

Page 80

Ems(engine management system) 5-32 remove connector - cps connector(blue, light green) - acg connector(yellow) rh.Shroud cooling fan flywheel stator cps screw replace the cps eng rh.Crankcase cover before disassembly, the key is off. ! Caution install in the reverse order of removal. 15.Crank positi...

Page 81: 16.Fuel Pump

5-33 ems(engine management system) remove fuel pump nut 4ea replace the fuel pump injector cap do not push the fuel pump base under the fuel tank when the fuel tank is stored. Always replace the packing when the fuel pump is removed. Before disconnecting the fuel hose, release the fuel pressure by l...

Page 82: 16.Fuel Pump

Ems(engine management system) 5-34 the terminal arrangement of the fuel pump (the following color chart is the internal color of the fuel pump) 16.Fuel pump.

Page 83

5-35 ems(engine management system) remove the fuel level gauge (19-10) measure the resistance between terminals. The float position is based on the tank bottom plate after assemble. Measure the resistance between y/w (yellow/white) wire and g(ground) wire of fuel unit terminal remark : measuring uni...

Page 84: 17.Throttle Body

5-36 ems(engine management system) 17.Throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body throttle body isa isa isa isa isa isa isa isa isa isa isa isa isa ...

Page 85: Disconnect The Throttle Body

5-37 ems(engine management system) disconnect: - luggage box - tps,isa,mapat coupler - throttle cable do not disconnect both the throttle adjust screw and adjusting nut disconnect the throttle body checking the throttle body disassemble the throttle body ! Caution - disconnect the insulator and the ...

Page 86: Disassemble The Insulator

5-38 ems(engine management system) disconnect: - injector cap bolt - injector and injector cap at the same time from the insulator - injector and injector cap. Disassemble the insulator checking the insulator check: - o-ring - insulator - injector assembly of the insulator assemble is the reverse or...

Page 87: Throttle Body

5-39 ems(engine management system) assembly of the throttle body assembly is the reverse order of removal. Assemble the o-ring to the throttle body. Installation of insulator and throttle body installation of insulator and throttle body in the reverse order of removal check the o-ring when the insul...

Page 88: Supplement

5-40 ems(engine management system) adjustment of throttle adjust screw a vehicle is assembled in the state which engine operation is possible. Loosen the maintenance cover and the adjust-screw is makes possible to adjust. The coupler to check the malfunction of vehicle is connected to the coupler of...

Page 89: 18.How To Use The Scan When

5-41 the coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. Turn the lgnition key on. Press the power button of the diagnostic tool. Press the enter button in the initial screen. Press the enter in the vehicle diagnosis screen. Press the enter button on the r...

Page 90

Press the enter button when it is ready when the ecu was initialized. Turn off the lgnition key and then turn on the ignition key. Ems(engine management system) 5-42.

Page 91: 19.How To Use The Scan When

The coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. Turn the lgnition key on. Press the power button of the diagnosis tool. Press the enter button on the initial screen. Press the button at the vehicle diagnostic screen. Press the enter button on the curre...

Page 92: 20.How To Use The Scan When

Ems(engine management system) the coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. Turn the lgnition key. Start the engine. Press the power button of the diagnosis tool. Press the enter button on the initial screen. Press the enter button on the vehicle dia...

Page 93: 21.How To Use The Scan When

Ems(engine management system) the coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. Turn the lgnition key. Start the engine. Press the power button of the diagnosis tool. Press the enter button on the initial screen. Press the enter button on the vehicle dia...

Page 94

Memo.

Page 95

6-1 fuel system / engine 6 4 6 6 6 6.

Page 96

6-2 fuel system / engine.

Page 97

6-3 fuel system / engine.

Page 98

Memo.

Page 99

7-1 engine removal/installation 7 7 7-1 7-2.

Page 100

7-2 engine removal/installation.

Page 101

7-3 engine removal/installation.

Page 102

8-0 lh.Crankcase cover/continuously variable transmission.

Page 103

8-1 lh.Crankcase cover/continuously variable transmission 8 8 8 8 8 8 8 8.

Page 104

8-2 lh.Crankcase cover/continuously variable transmission.

Page 105

8-3 lh.Crankcase cover/continuously variable transmission.

Page 106

8-4 lh.Crankcase cover/continuously variable transmission.

Page 107

8-5 lh.Crankcase cover/continuously variable transmission.

Page 108

8-6 lh.Crankcase cover/continuously variable transmission.

Page 109

8-7 lh.Crankcase cover/continuously variable transmission.

Page 110

8-8 lh.Crankcase cover/continuously variable transmission.

Page 111

8-9 lh.Crankcase cover/continuously variable transmission.

Page 112

8-10 lh.Crankcase cover/continuously variable transmission.

Page 113

8-11 lh.Crankcase cover/continuously variable transmission.

Page 114

8-12 lh.Crankcase cover/continuously variable transmission.

Page 115

8-13 lh.Crankcase cover/continuously variable transmission.

Page 116

9-0 a.C generator / starter clutch.

Page 117

9 9 9 9 9 9 9 9-1 a.C generator / starter clutch 9.

Page 118

9-2 a.C generator / starter clutch.

Page 119

9-3 a.C generator / starter clutch.

Page 120

9-4 a.C generator / starter clutch.

Page 121

9-5 a.C generator / starter clutch.

Page 122

9-6 a.C generator / starter clutch.

Page 123

9-7 a.C generator / starter clutch.

Page 124

9-8 a.C generator / starter clutch.

Page 125

Memo.

Page 126

Injector assy engine temp.Sensor 10-0 cylinder head / valve.

Page 127

10 10-1 10-2 10-3 10-5 10-6 10-6 10-7 10-8 10-11 10-13 10-1 cylinder head / valve 10

Page 128

10-2 cylinder head / valve.

Page 129

10-3 cylinder head / valve.

Page 130

10-4 cylinder head / valve.

Page 131

10-5 cylinder head / valve.

Page 132

10-6 cylinder head / valve.

Page 133

10-7 cylinder head / valve.

Page 134

10-8 cylinder head / valve.

Page 135

10-9 cylinder head / valve.

Page 136

10-10 cylinder head / valve.

Page 137

10-11 cylinder head / valve.

Page 138

10-12 cylinder head / valve.

Page 139

10-13 cylinder head / valve.

Page 140

10-14 cylinder head / valve.

Page 141

Throttle body 10-15 cylinder head / valve.

Page 142

Cylinder/piston 11-0

Page 143

11-1 11 11 11-1 11-1 11-2 11-3 11-5.

Page 144

11-2 cylinder/piston.

Page 145

11-3 cylinder/piston.

Page 146

11-4 cylinder/piston.

Page 147

11-5 cylinder/piston.

Page 148

11-6 cylinder/piston.

Page 149

Memo.

Page 150

12-0 transmission/crankshaft/crankcase.

Page 151

12 12-1 12-2 12-3 12-6 12-7 12-8 12-9 12-10 12-1 transmission/crankshaft/crankcase 12.

Page 152

12-2 transmission/crankshaft/crankcase.

Page 153

12-3 transmission/crankshaft/crankcase.

Page 154

12-4 transmission/crankshaft/crankcase.

Page 155

12-5 transmission/crankshaft/crankcase.

Page 156

12-6 transmission/crankshaft/crankcase.

Page 157

12-7 transmission/crankshaft/crankcase.

Page 158

12-8 transmission/crankshaft/crankcase.

Page 159

12-9 transmission/crankshaft/crankcase.

Page 160

12-10 transmission/crankshaft/crankcase.

Page 161

Memo.

Page 162

13-0 front wheel/front fork/steering/brake.

Page 163

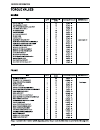

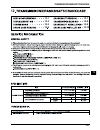

Front front front combi brake caliper piston o.D 24.914~24.935mm 25~25.039mm 25.27mm 25.07mm 25.278~25.328mm 25.44~25.41mm 25.27mm 25.42mm 33.914~33.935mm 34~34.039mm 33.87mm 34.01mm front combi brake caliper cylinder i.D rear rear 13 13-1 13-2 13-3 13-4 13-5 13-6 13-7 13-7 13-10 13-12 13-14 13-19 1...

Page 164

13-2 front wheel/front fork/steering/brake.

Page 165

13-3 front wheel/front fork/steering/brake.

Page 166

13-4 front wheel/front fork/steering/brake.

Page 167

13-5 front wheel/front fork/steering/brake.

Page 168

13-6 front wheel/front fork/steering/brake.

Page 169

13-7 front wheel/front fork/steering/brake.

Page 170

13-8 front wheel/front fork/steering/brake.

Page 171

13-9 front wheel/front fork/steering/brake.

Page 172

13-10 front wheel/front fork/steering/brake.

Page 173

13-11 front wheel/front fork/steering/brake.

Page 174: Brake Caliper

13-12 front wheel/front fork/steering/brake brake caliper removal first drain the baeke fluid from the h¥draulic brake system. Remove the brake fluid tube bolt. Remove the two bolts attaching the brake caliper. Remove the brake caliper. Remove the piston from the brake caliper. If necessary, use com...

Page 175: Inspection

13-13 front wheel/front fork/steering/brake inspection check the piston for scratches or wear.. Measure the piston o.D. With a micrometer gauge. Top service limit : 26.91mm under service limit:33.87mm assembly clean all removed parts. Apply silicon grease to the psiton and oil seal. Lubricate the br...

Page 176

13-14 front wheel/front fork/steering/brake.

Page 177

13-15 front wheel/front fork/steering/brake.

Page 178

13-16 front wheel/front fork/steering/brake.

Page 179

13-17 front wheel/front fork/steering/brake.

Page 180

13-18 front wheel/front fork/steering/brake.

Page 181

13-19 front wheel/front fork/steering/brake.

Page 182

13-20 front wheel/front fork/steering/brake.

Page 183

Memo.

Page 184

Rear wheel/brake/suspension/rear swing arm 14-0

Page 185

14-1 14 14 14-1 14-2 14-3 14-5 14-7 14-7.

Page 186

14-2 rear wheel/brake/suspension/rear swing arm.

Page 187

14-3 rear wheel/brake/suspension/rear swing arm.

Page 188

14-4 rear wheel/brake/suspension/rear swing arm.

Page 189

14-5 rear wheel/brake/suspension/rear swing arm.

Page 190

14-6 rear wheel/brake/suspension/rear swing arm.

Page 191

14-7 rear wheel/brake/suspension/rear swing arm.

Page 192

14-8 rear wheel/brake/suspension/rear swing arm.

Page 193

Memo.

Page 194

30a 15-0 charging system.

Page 195

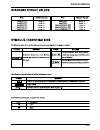

15 15-1 15-2 15-2 15-3 15-4 15-5 15-1 15.

Page 196

13.5~15.5v 13.5v 15-2 charging system.

Page 197

15-3 charging system.

Page 198

15-4 charging system.

Page 199

15-5 charging system.

Page 200

Memo.

Page 201

0.73±0.08Ω(23℃±5℃) 80~150 (15kΩ) 16 16-1 16-3 16-4 16-5 16-6 16-6 16-1 16.

Page 202

16-2 ignition system.

Page 203

Pulser pulser 16-3 ignition system.

Page 204

The secondary coil resistance might not measure cause by the high voltage diode inside the ignition coil. ( ) 16-4 ignition system.

Page 205

Green and black/white green and black/white 16-5 ignition system.

Page 206

Re d 3 0 17-0 starter system.

Page 207

17 17-1 17-4 17-7 17-2 17-3 17-1 17.

Page 208

17-2 starter system.

Page 209

17-3 starter system.

Page 210

17-4 starter system.

Page 211

17-5 starter system.

Page 212

17-6 starter system.

Page 213

17-7 starter system.

Page 214

Memo.

Page 215

18 18-1 18-1 18-4 18-2 18-2 18-3 18-3 18-4 18-4 18-1 18.

Page 216

Color bat 1 2 p gray bat 2 18-2 lights/switch/horn.

Page 217

3 18-3 lights/switch/horn.

Page 218

18-4 lights/switch/horn.

Page 219

Memo.

Page 220

Memo.

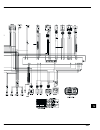

Page 221: 19. Circuit Diagram

19. Circuit diagram.

Page 222

19-1 19.