- DL manuals

- Daewoo

- Air Conditioner

- DWA-182RH

- User Manual

Daewoo DWA-182RH User Manual - Sensor(3)

26

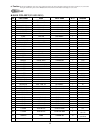

Room temperature Sensor Input

Temperature

(°C)

No. 15

-10

4.06

0 3.60

15 2.76

25 2.20

40

1.48

Voltage (V)

Table 3-1

Sensor(3)

MICOM

15

13

R4

300

C13

0.01

R3

12.7K

Vcc

ROOM:PT-K43C

R3

12.7K

Heat Exchanger

Vcc

2

1

DESCRIPTION

Number 15 of Micom is Terminal of A/D convertor Input.

Room temperature is sensing by change of Thermister Resistance, Micom is put in 5V by ratio between R3

(12.7K

Ω

) and Room sensor.

Relation between temperature and voltage is following Table 3-1.

C13 is Noise filter.

Summary of DWA-182RH

Page 1

Manual de servicio acondicionador de aire tipo ventana modelo:.

Page 2: Contents

Contents 1. Specifications ................................................................................................2 2. Operation .....................................................................................................3 3. Wiring diagram.............................................

Page 3: 1. Specifications

2 1. Specifications item model dwa-182rh power source v/ph/hz ac 208~230v / 1 / 60hz capacity btu/h 18,000 (cooling & heating) kcal/h 4,530 dehumidification l /h 2.4 power input(w) cooling 2,000 heating 1,700 running current(a) cooling 11.0 heating 10.0 type rotary compressor model rca180u001 capaci...

Page 4: Parts of Name and Function

3 1 parts of name and function 2. Operation no part name 1 air filter 2 grill front 3 cabinet 4 blade vertical no part name 5 panel control 6 remote controller 7 blade horizental 8 air vent 6 3 1 2 7 4 8 5.

Page 5: Remote Controller

4 2 remote controller remocon signal transmitter timer/cancel • everytime you push this button, timer is set as follow. (1hr → 2hr → 3hr → 4hr → 5hr → 6hr → 8hr → 10hr → 12hr → 16hr → 20hr → 24hr → cancel). After the unit is timed, if this button is pushed, timer is canceled. Sleep • sleep mode is s...

Page 6: Remote Controller Display

5 3 remote controller display room air-conditioner fan heating cooling room temp temp desired temp timer sensor mode power fan speed auto swing temp./timer display • it displays the temperature and the timer. Mode display • it displays the operating mode. Remocon signal receiver temperature set • it...

Page 7: Replacing Batteries

6 replacing batteries remove the cover from the back of the remote controller. • slide the cover according to the arrow direction insert two battaries. • be sure that the (+) and (–) directions are correct • be sure that both batteries are new re-attach the cover. • slide it back into position • do ...

Page 8: Operation Instruction

7 4 operation instruction function power on push power button cooling mode push the ‘mode’ button until ‘cooling’ lamp lights. Heating mode push the ‘mode’ button until ‘heating’ lamp lights. Fan delay in heating mode change desired room temperature push the ‘temp ▲▼ ’ button. Change ‘fan speed’ pus...

Page 9

8 function fan mode push the ‘mode’ button until ‘fan’ lamp lights. On/off auto swing push the ‘auto swing’ button. Off timer push the ‘timer/cancel’ button when unit is working. (remocon only) operation 1. The fan works only. 2. In this mode, the unit circulate room air. 3. Fan speed can be changed...

Page 10

9 function on timer push the ‘timer/cancel’ button when unit is off. (remocon only) sleep mode push the ‘sleep’ button in ‘cooling’ mode and heating mode. (remocon only) defrost the heat-exchanger of the outside (in heating mode) operation 1. Timer is changed to as follows by pushing “timer/cancel” ...

Page 11: Off-Timer

10 if you set time in off-timer mode, the unit will stop at the set time. If you set time in on-timer mode, the unit will run at the set time. (1) range of setting temperature: 16~32°c (2) setting temperature: operating temperature of compressor if the unit display receive the signal of remote contr...

Page 12: Sleep Mode

11 (1) when you are going to sleep, select sleep button in remocon and the unit controls the room to the desired temperature. (the unit will not operate after 4 hour) (2) for changing the temperature. • mode (cooling) • the unit will not operate after 4 hour. • mode (heating) • the unit will not ope...

Page 13: Auto Swing

12 auto swing (1) when you push this button, in remocon the left/right flap move to the position of keeping the room temperature comiortable. (2) the air discharge direction procedure is below. Auto swing fixed de-ice operation self-diagnostic function the control will contain diagnostic test to ver...

Page 14: 3. Wiring Diagram

13 3. Wiring diagram.

Page 15: 4. Refrigerant Cycle

14 4. Refrigerant cycle evaporator blower fan motor reversing valve accumulator propeller fan condenser refrigerant flow(cooling) refrigerant flow(heating) capillary tube m compressor.

Page 16: 5. Control Block Diagram

15 5. Control block diagram relay 3, 4 auto swing motor 4-way fan motor compressor 88 led front pcb fan mode lamp heating mode lamp remocon signal receiver cooling mode lamp room temp lamp desired temp lamp timer lamp operating mode remote controller fan speed timer selection auto swing temp setting...

Page 17: 6. Circuit Diagram

16 6. Circuit diagram.

Page 18

6.

Page 19: Part List

17 no part name spec part code q’ty remark 1 ic micom tmp47p443n – 1 u1 2 ic drive td62004ap 13gt62004a 1 u3 3 ic drive td62783ap 13gt62783a 1 u2 4 ic regulator kia7812p 1ka7812ap- 1 u4 5 ic regulator kia7805p 1ka7805ap- 1 u5 6 ic reset kia7042p 1ka7042p-- 1 u6 7 fuse clip afc-520 3107000600 2 fuse ...

Page 20

18 no part name spec part code q’ty remark 1 led display 88 3103003700 1 disp 2 c-cera 103z 50vdc cxch1h103m 1 c1 3 receive module pic-26043th2 1pc26043th 1 remo 4 led dlso-5031d ddls05031d 3 5 led dlg-5031d ddlg5031d- 3 6 switch tact jtp1212 3109300900 6 7 diode 1n4148 dzn4148a-- 6 d1-6 8 wafer sma...

Page 21: 7. Trouble Shooting Guide

19 7. Trouble shooting guide trouble situation analysis cause remedy fan motor and compressor do not run compressor does not run 1. Power failure 2. Power is supplied, but the equipment does not run 1. Not operating at all 2. Compressor 3. Frequent start and stop 1) power plug 2) circuit breaker 1) ...

Page 22

20 trouble situation analysis cause remedy the compressor runs but the motor doesn’t run both fan motor and compressor are running but cooling or heating is bad vibration & noise water leakage into room electric shock (leakage of current) not cooling at all not heating at all insufficient cooling or...

Page 23: Self-Diagnostic Function

21 1) error code e1 or e2 1 check the connector of room air thermistor. (or connecting wire) 2 check soldering of connecting on control p.C.B. (error of soldering or short) 3 check the resistance of room air thermistor. “press the temperature keys (up & down), error code is displayed.” self-diagnost...

Page 24: Only Compressor Do Not Run

22 - check the following at cooling mode check the voltage between “power ” and “rl1 ” of main p.C.B 3 1 check the compressor wiring check the relay(rl1) check the wiring of outdoor unit check the compressor (check the winding resistance) check the compressor capacitor check the connecting wire betw...

Page 25: Pcb Driving Description

Pcb driving description.

Page 26: Power Supply(1)

24 power supply(1) description dc power supply in circuit needs +12v and +5v. +12v is used for compressor driving relay, fan motor driving relay, buzzer driving, swing motor driving relay and led display. Ac voltage of secondary power transformer is rectified by 4 diode, and it is filtering by main ...

Page 27: Oscillation(2)

25 oscillation(2) 1 2 8 mhz micom v dd -10% v ss +10% fig 2-1 description oscillatory frequency drive micom, it is made up 8mhz resonator oscillatory freqency. Ocillatory wave is as following fig 2-1..

Page 28: Sensor(3)

26 room temperature sensor input temperature (°c) no. 15 -10 4.06 0 3.60 15 2.76 25 2.20 40 1.48 voltage (v) table 3-1 sensor(3) micom 15 13 r4 300 c13 0.01 r3 12.7k vcc room:pt-k43c r3 12.7k heat exchanger vcc 2 1 description number 15 of micom is terminal of a/d convertor input. Room temperature i...

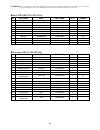

Page 29: Remote Controller(4)

27 description signal from remote controller put in only control data signal at micom terminal of number 5, which is gotten field of carrier (38khz) from receive module. Signal wave repeat third as following fig 5-1. But in secondary wave custom code is reversed face. Remote controller(4) leader cod...

Page 30: Micom Power Supply(5)

28 description micom power is supplied 5v at number 28 using vdd, number 6 using analog reference of a/d converter. C9, c10 is ripple filter. Micom power supply(5) micom 28 14 6 c10 100 µ f/16v c9 104 vcc 5v.

Page 31: Reset(6)

29 reset(6) +c11 1 µ f/50 r1 5.6k 5v 5v reset ic micom 3 7042 3 1 2 4.2v h l t t power on vcc (+5v) delay time for power on reset description voltage less than about 4.2v put in micom terminal of number 6 and then micom reset. Reset ic detect power on and voltage greater than 4.2v, and then send res...

Page 32: (1) Ic3 (Micom)

30 (1) ic3 (micom) (2) u2 (td62783ap) xout 1 28 vdd xin 2 27 hold (ke0) test reset 3 26 r92 (sck) display out r70 4 25 r91 (so) fan speed(hi) display out r71 (pulse) 5 24 r90 (si) remocon signal display out r72/varef 6 23 r83 (t1) display out r40 (ain0) 7 22 r82 (int1/zin) display in, key out comp r...

Page 33

31 (3) u2(td62004ap) darlington arrays (4) u7 (7805ct): voltage regulator (5vdc) (5) u6 (7812act): voltage regulator (12vdc) in1 1 16 out 1 in2 2 15 out 2 in3 3 14 out 3 in4 4 13 out 4 in5 5 12 out 5 in6 6 11 out 6 in7 7 10 out 7 gnd 8 9 common free wheeling diodes com 10.5k 7.2k 3k (top view) (equi...

Page 34: 9. Disassembly Instructions

32 9. Disassembly instructions 1 before service of 1. Stop the unit, remove the power cord from the receptacles. Any part. 2. Move the unit to the safe location for the suitable work. 2 ass’y fan motor 1. Remove front grille - fan motor - remove filter pre. - propeller fan - remove screw(2 point) in...

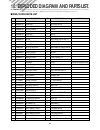

Page 35

33 10. Exploded diagram and parts list. ■ dwa-182rh parts list no. Code components q’ty specification remark 1 3100066241 ass’y pan base 1 dwa-181ch liquid-inj 2 3106003110 comp bolt 3 m8 x l46.5 (od 10) 3 3100002900 ass’y seal cap drain 1 ass’y 4 3106600910 scroll lower 1 eps h/p 5 3106700400 cam 1...

Page 36

34 no. Code components q’ty specification remark 40 3100070811 as pipe cond in 1 assy(c1220t) 41 3100070911 as pipe cond out 1 assy(c1220t) 42 3105400310 reversing valve 1 chv-0201 sub part of 12 43 3100074630 as pipe discharge 1 dwa-182rh jaka h/p (hi-eer) sub part of 12 44 3100074530 as pipe sucti...

Page 37

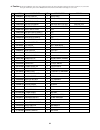

35 ■ dwa-182rh.

Page 38

5.

Page 39

S/m no.: dwa182rh01 daewoo electronics corp. 686, ahyeon-dong mapo-gu seoul, korea c.P.O. Box 8003 seoul, korea telex: dwelec k28177-8 cable: “daewooelec” fax: 02) 590-6291 tel: 02) 360-7114/590-6151~5 http://www.Dwe.Co.Kr printed date: jan.2004.