- DL manuals

- E.T. Systems

- Garage Door Opener

- Challenger MKIII

- Installer Manual

E.T. Systems Challenger MKIII Installer Manual

Summary of Challenger MKIII

Page 1

Installer’s manual revised date: march 2004 automatic garage door opener take control of your world.

Page 2: Index

2 1. What’s in the box a list of contents you will receive with this product and technical specifications 2. What’s not in the box a list of optional accessories available for this product. Please contact your e.T supplier for more information. 3. Recommended tools a list of tools recommended for th...

Page 3: What’S In The Box

3 motorhead: · 1 x motorhead - complete · 1 x installer’s manual · 1 x user’s manual in sealed bag: · 4 x m6 x 75mm hexagonal bolts · 4 x 6mm washers · 1 x m8 rawl bolt · 4 x m8 x 40mm coachscrews · 1 x m8 x 90mm hexagonal bolt · 7 x m8 nylock nuts · 4 x m8 x 16mm hexagonal bolts · 2 x m8 x 25mm hex...

Page 4: What’S In The Box

4 technical specifications motor - 220v ac 50hz - 2 amp single-phase - thermal overload protection - intermittent duty cycle drive assembly - worm reduction gearbox - sprocket and chain driven traveling speed: - 8.6 metres/ minute (approx.) operating temperature: - 0°c – 50°c control system: - micro...

Page 5: What’S Not In The Box

5 · 1, 2 or 3 button transmitters (remote controls) · escape lock (to use when no side entrance to garage) · extendable link arm (to use when motor installation above door not possible. Please ask for advice before attempting to fit these) · safety infra-red beams or other safety input device · mult...

Page 6: Recommended Tools

6 recommended tools · electric hammer-action drill · 13mm masonry bit · 5mm wood bit · 10mm spanner/ wrench · 2 x 13mm spanners/ wrenches · 2.5mm blade flat screwdriver · ph01 star screwdriver · hacksaw · hammer · 6ft/ 2m a-frame self-standing stepladder · tape measure · spirit level in the case of ...

Page 7: Before Installing

7 before installing before attempting to install a garage door operator, please be certain you have read and understood the following: 1. Check that the garage door is mechanically sound as per manufacturers specifications. Points to inspect (general to all makes of doors): · mechanisms must be secu...

Page 8: Before Installing

8 4. Inspect the spine (top edge) of the door for weaknesses such as cracks or wood-knots. Ensure that the point that the door mount bracket is attached to, will sufficiently support the weight and load of the door when operated. If there is any question to the above, replace or brace the spine (top...

Page 9: Installing The Hardware

9 installing the hardware before starting your installation, check that you have the correct tools required for your type of installation. Check that your challenger garage door operator kit is complete. Step 1 - assemble the drawbar to the motorhead if you choose to mount the motorhead above the dr...

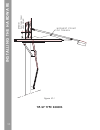

Page 10: Tip-Up Type Doors

10 tip-up type doors installing the hardware figure 10.1 275mm from top of door when closed h i g h e s t p o i n t o f t r a v e l.

Page 11: Installing The Hardware

11 installing the hardware step 2 - mounting the link arm and door mount bracket tip up type door (refer to diagram on page 10) locate and mark the center position of the spine (top edge) of the door. Figure 11.1 . While holding the door mount bracket in place on the centre position, mark the mounti...

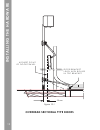

Page 12: Installing The Hardware

12 overhead sectional type doors installing the hardware figure 12.1 h i g h e s t p o i n t o f d o o r t r a v e l d o o r b r a c k e t l e v e l w i t h r o l l e r i n t o p b r a c k e t 5 0 m m.

Page 13: Installing The Hardware

13 installing the hardware overhead sectional type door (refer to diagram on page 12) locate and mark off the centre position on the inside fascia on the spine (top edge) of the top panel of the door, in line with roller in top bracket. Figure 13.1 while holding the door mount bracket in place on th...

Page 14: Installing The Hardware

14 installing the hardware step 3 - determining the mounting position, and mounting of the drawbar front-end tip up type door (refer to diagram on page 10) overhead sectional type door (refer to diagram on page 12) with the door in the closed position swing the link arm up fully vertical, in line wi...

Page 15: Installing The Hardware

15 step 4 - determining mounting position of motorhead unit tip up type door (refer to diagram on page 10) overhead sectional type door (refer to diagram on page 12) with the door in the closed position, fasten front-end moulding into wall bracket using the m8 x 90mm hexagonal bolt and a m8 nylock n...

Page 16: Installing The Hardware

16 figure 16.1 mount the hanging straps to the fixed structure or rafters with 2 of the m8 x 40mm coachscrews provided. Do not exceed one hanging angle length from fixed structure or rafters. In the case of double volume roof clearance, manufacture or extend stable support structure down. Mount powe...

Page 17: Wiring & Schematics

17 wiring & schematics external receiver figure 17.1 beams figure 17.2 to (+) of receiver (+) (c) to (-) and/ or com of receiver 200ma max. (bt) from n/o or neg. Out of receiver to (+) of beams (+) (c) to (-) and/ or com of beams 200ma max. (bm) from n/o of beams.

Page 18: Wiring & Schematics

18 wiring & schematics wall console figure 18.1 programming figure 18.2 (+) red (c) black/ blue (l) green (bt) white receiver (b) (l) programming prg l.E.D. Prg jumper pcb button.

Page 19: Wiring & Schematic

19 wiring & schematic s auto-close figure 19.1 load pot figure 19.2 load pot auto-close jumper prg jumper.

Page 20: Programming & Commissioning

20 programming & commissioning programming a remote transmitter into the onboard receiver (fig 18.2) the receiver can learn one code for the garage door control button and one code for the light control button. 1. Code the transmitter with a unique code as per make and model of transmitter (refer to...

Page 21: Programming & Commissioning

21 3. Press and release the button on the pcb or use the transmitter which has been pre-programmed in programming the transmitter into the onboard receiver (fig 18.2). The door will start closing. 4. When the door reaches the closed position, use the pcb button or the tx to stop the door. 5. Slide t...

Page 22: Programming & Commissioning

22 programming the load profile 1. Momentarily short the two pins ‘prg’ with the jumper supplied. The unit will close the door and find the closed limit where the unit will stop. The unit will beep once at this point. 2. The unit will then automatically start opening the door until the open limit is...

Page 23: Maintenance

23 maintenance the challenger has been designed as a low maintenance operator there- fore almost no maintenance is required. However, please bear the following points in mind: in order to ensure maximum life of the challenger, it is recommended that the drawbar and chain be cleaned and lightly oiled...

Page 24: Troubleshooting

24 troubleshooting unit is dead unit beeps once when triggered and will only open on second trigger unit does not respond to remote transmitter in all cases of testing, remove all wires from the (+), (c), (l), (bt) and (bm) terminals first. If unit operates correctly after completing this, begin re-...

Page 25: Troubleshooting

25 no range from transmitter door opens randomly on its own unit responds to open/ close trigger by chirping and flashing light, but won’t open or close unit beeps 3 times and then closes on its own crosstalk between external receiver and onboard receiver incorrect frequency transmitter another tran...

Page 26: Troubleshooting

26 when aut jumper replaced for auto-close operation, unit beeps 3 times and auto-opens unit will not close motor and limits configu- ration in reverse swop motor reverse and forward wiring and swop limit switch wiring as per page 9. Beams input triggered remove obstacle from door travel check beam ...

Page 27: Troubleshooting

27 door stops and reverses while openinng or stops and remains stopped while closing. This happens when door senses an obstruction. Door closes then re-opens immediately door jams in closed position motor and limits configura- tion in reverse swop motor reverse and forward wiring and swop limit swit...

Page 28: Troubleshooting

28 link arm flips over on top of door when unit starts to close (tip-up type doors) link arm twists and bends out of shape when closing door door opens too far unit hanging angle is incorrect put rubber stoppers on the door to stop against the lintel and prevent the door from over-opening re-hang un...

Page 29: Warranty

29 warranty one-year manufacturer’s warranty · all goods manufactured by g & c electronics cc t/a e.T. Systems carry a 12 month factory warranty from date of invoice. · all goods are warranted to be free from faulty components and manufac- ture. · the following items are expressly excluded from the ...

Page 30: Notes

30 notes specifications are subject to change without notice. Www.Et.Co.Za notes serial number date of purchase.