- DL manuals

- E-Tech

- Boiler

- 15

- Installation, Operating And Maintenance Instructions

E-Tech 15 Installation, Operating And Maintenance Instructions

Summary of 15

Page 1

09/09/2004 - 66402800 excellence in hot water installation, operating and maintenance instructions e-tech 09 - 15 single phase e-tech 22 - 28 - 36 tri phase.

Page 2

- 1 - warnings 2 who should read these instructions 2 symbols 2 recommendations 2 applicable standards 2 importants notes 2 manual handling instructions 2 removing the boiler from the packaging 2 introduction 3 description of the specifications 3 lining 3 heating body 3 heating elements 3 equipment ...

Page 3

- 2 - who should read these instructions these instructions should be read by: - the specifying engineer - the installer - the user - the service engineer symbols recommendations • these instructions are an integral part of the equipment to which they refer and the user must be provided with a copy....

Page 4

- 3 - description of the specifications this wall hung electric boiler is available in 5 models : • models 09 and 15 are supplied with 230 volt single phase • models 22, 28 and 36 are only supplied with 400 v triphase + n the maximum power can be adjusted for all models by acting on the terminals br...

Page 5

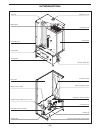

- 4 - introduction top cover rear panel water pressure switch expansion vessel connection supplementary heating return (not used) heating return automatic air vent expansion vessel valve of expansion vessel heating out manual reset high limit pressure gauge expansion vessel connection circulating pu...

Page 6

- 5 - user data all user controls are situated on the front panel of the boiler, there are no user controls inside the boiler casing. The following instructions assume that the boiler has been commissioned, and that the system is filled with water and has been fully vented. Setting up • before switc...

Page 7

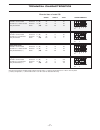

- 6 - technical characteristics 45 45 45 45 45 weight empty (kg) 332 332 332 332 332 depth (mm) 442 442 442 442 442 width (mm) 763 763 763 763 763 height (mm) 3/4” 3/4” 3/4” 3/4” 3/4” heating connection 125 85 45 20 10 hydraulic presure drop (mbar) 85 85 85 85 85 max. Working temperature (°c) 0.8 0....

Page 8

- 7 - technical characteristics electrical data of model 09 stage 1 stage 2 total power terminals single phase 8.4 kw (*) terminals 1 and 2 shunted terminal 3 l1 (a) 24 12 36 terminals 3, 4, 5 and 6 shunted terminal 1 n (a) 24 12 36 relay k3 activated power (kw) 5.6 2.8 8.4 single phase 7 kw termina...

Page 9

Electrical data of model 15 stage 1 stage 2 total power terminals - 8 - technical characteristics single phase 14.4 kw (*) terminals 1 and 2 shunted terminal 3 l1 (a) 41.6 20.8 62.4 terminals 3, 4, 5 and 6 shunted terminal 1 n (a) 41.6 20.8 62.4 relay k3 activated power (kw) 9.6 4.8 14.4 single phas...

Page 10

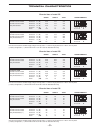

Electrical data of model 28 stage 1 stage 2 total power terminals tri phase 28.8 kw (*) terminals 3 and 4 shunted terminal 2 l1 (a) 20.8 20.8 41.6 terminals 5 and 6 shunted terminal 3 l2 (a) 20.8 20.8 41.6 relay k4 activated terminal 5 l3 (a) 20.8 20.8 41.6 terminal 1 n (a) 0 0 0 power (kw) 14.4 14....

Page 11

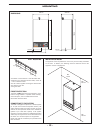

- 10 - mounting min. 25 mm min. 400 mm min. 200 mm 763 mm 763 mm 442 mm 332 mm 178 mm 379 mm 90 mm 101,6 mm 101,6 mm 48,4 mm 53,2 mm 53,2 mm 48,4 mm • the boiler must be fixed to a non flammable wall. • observing the clearances shown below, drill 2 off 14mm x 100mm holes. • fit the 2 bolts supplied ...

Page 12

- 11 - installation panel removal and access to hydraulic connections 1. Undo screws 2. Tilt panel towards you and lift clear remove the top cover 3. Loosen screws of the control panel 4. Turn up the control panel 5. Block the control panel with the screw disassembling a b c 1 2 2 3 4 5.

Page 13

- 12 - installation 39 38 37 36 35 34 3 3 32 31 29 28 2 7 26 25 24 23 22 21 19 18 17 16 15 14 1 3 12 11 9 8 7 6 5 4 3 2 1 39 38 37 36 35 34 3 3 32 31 29 28 2 7 26 25 24 23 22 21 19 18 17 16 15 14 1 3 12 11 9 8 7 6 5 4 3 2 1 39 38 37 36 35 34 3 3 32 31 29 28 2 7 26 25 24 23 22 21 19 18 17 16 15 14 1 ...

Page 14

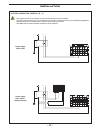

- 13 - installation • this appliance must be permanently connected to fixed wiring and must be earthed. • the wiring must be carried out by a competent person and be in accordance with the current iee wiring regulations. • isolation device must be provided with a minimum contact clearance of 3mm. • ...

Page 15

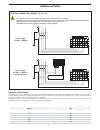

- 14 - installation • this appliance must be permanently connected to fixed wiring and must be earthed. • the wiring must be carried out by a competent person and be in accordance with the current iee wiring regulations. • isolation device must be provided with a minimum contact clearance of 3mm. • ...

Page 16: Wiring Dia

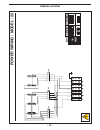

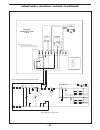

- 15 - installation wiring dia grams / models : 09 - 15 - 22 l1 1 2 br br br bk n 3 4 b b or bb b bk bb 7 t p b b 8 b 9 b 5 6 b bk or g b r 3 amp mcb c 2 1 r c 1 2 or 10 11 12 13 y y t or or or r r gg gp k pk b b w b w g b 14 15 16 m 2.1. 2.2. 2.1. 2.2. 17 18 t w r ab c d e hj j l i k1 k3 k2 f g b b...

Page 17: Wiring Dia

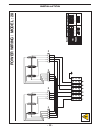

- 16 - installation wiring dia grams / model : 2 8 l1 1 2 br br br bk n 3 4 b b or bb b bk bb 7 t p b b 8 b 9 b 5 6 b bk or g b r 3 amp mcb c 2 1 r c 1 2 or 10 11 12 13 y y t or or or r r gg gp k p k p k b b w b w g b 14 15 16 m 2.1. 2.2. 2.1. 2.2. 17 18 t w r ab c d e hj j l i k1 k3 b w 19 20 w pk ...

Page 18: Wiring Dia

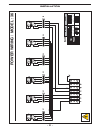

- 17 - installation wiring dia grams / model : 3 6 l1 1 2 br br br bk n 3 4 b b or bb b bk bb 7 t p b b 8 b 9 b 5 6 b bk or g b r 3 amp mcb c 2 1 r c 1 2 or 10 11 12 13 y y t or or or r r gg gp k p k p k b b w b w g b 14 15 16 m 2.1. 2.2. 2.1. 2.2. 17 18 t w r ab c d e hj j l i k1 k3 b w 19 20 w pk ...

Page 19: Wer

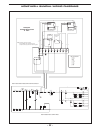

- 18 - installation po wer wiring / models : 09-15 k1 k2 k3 3 x b 3 x b 2 x or 2 x bk r r r bk b b b b b b bk or or r r bk b b b b b b bk or or r 8.4 kw type 9 mono phase 7 kw 5.6 kw 4.2 kw 1 n 23 l 456 1 n 23 l 456 1 n 23 l 456 1 n 23 l 456 17 18 17 18 17 18 17 18 17 18 17 18 17 18 17 18 17 18 17 1...

Page 20: Wer

- 19 - installation po wer wiring / model : 2 2 21.6 kw type 22 tri phase 14.4 kw 1 n 2 l1 3 l2 45 l3 6 1 n 2 l1 3 l2 45 l3 6 17 18 17 18 17 18 17 18 3 x b 3 x or 2 x bk 1 x bk 2 x r 1 x r k1 or r bk b or r bk b k2 or r bk b or r bk b k3 or r bk b or r bk b.

Page 21: Wer

- 20 - installation po wer wiring / model : 2 8 28.8 kw type 28 tri phase 21.6 kw 1 n 2 l1 3 l2 45 l3 6 1 n 2 l1 3 l2 45 l3 6 19 20 19 20 19 20 19 20 4 x b 4 x or 3 x bk 1 x bk 3 x r 1 x r k1 or r bk b or r bk b k2 or r bk b or r bk b k4 or r bk b or r bk b k3 or r bk b or r bk b.

Page 22: Wer

- 21 - installation po wer wiring / model : 3 6 6 x b 6 x or 5 x bk 1 x bk 5 x r 1 x r k1 or r bk b or r bk b k2 or r bk b or r bk b k3 or r bk b or r bk b k4 or r bk b or r bk b k5 or r bk b or r bk b k6 or r bk b or r bk b 36 kw type 36 tri phase 30 kw 1 n 2 l1 3 l2 45 l3 6 1 n 2 l1 3 l2 45 l3 6 1...

Page 23

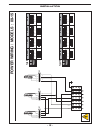

- 22 - honeywell sundial wiring diagrams note: illustrated model = 36 kw tri phase note: all bold numbers indicate a din rail terminal connection cylinder stat htg hw n l 1 4 3 2 5 6 t6306b room stat 2 1 3 v4043h htg zone valve motor 7 8 9 10 v4043h dhw zone valve motor honeywell sundial wiring cent...

Page 24

- 23 - honeywell sundial wiring diagrams note: illustrated model = 36 kw tri phase note: all bold numbers indicate a din rail terminal connection cylinder stat htg hw on n l 1 4 3 2 5 6 t6306b room stat 2 1 3 7 8 9 10 honeywell sundial wiring centre `y ` plan note: earth wires not shown for clarity ...

Page 25

- 24 - commissioning - water 1. The system must be thoroughly cleansed prior to connection of the boiler. The system water should be treated to prevent general corrosion and deposition of scale or sludge in the boiler, please refer to bs7593. If installing the boiler onto an existing system, acv rec...

Page 26

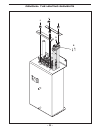

- 25 - removal the heating elements 2 1 3.

Page 27

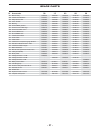

N° casing 09 15 22 28 36 a01 side panel 21471421 21471421 21471421 21471421 21471421 a02 front panel 21473421 21473421 21473421 21473421 21473421 a03 top cover 21475421 21475421 21475421 21475421 21475421 a04 rear panel 21474421 21474421 21474421 21474421 21474421 a05 control panel abs 497b1025 497b...

Page 28

- 27 - spare parts n° accessories 09 15 22 28 36 b01 base for relay 54428195 54428195 54428195 54428195 54428195 b02 control circuit “siemens” 54766015 54766015 54766015 54766015 54766015 b03 relay siemens 3tg 54452082 54452082 54452082 54452082 54452082 b04 timer “crouset” 54428192 54428192 5442819...

Page 29

- 28 - spare parts b01 b02 b03 b04 b05 b06 b07 b08 b09 b10 b11 b12 b13 b14 b16 b17 b18 b19 b21 b22 b23 b24 b15 b20 b25 b26 b27 b28 b29 - - - b30 - - -.

Page 30

- 29 -.

Page 32

International acv international n.V kerkplein, 39 b-1601 ruisbroek - belgium tel.: +32 2 334 82 20 fax: +32 2 378 16 49 e-mail: international.Info@acv-world.Com belgium acv belgium nv/sa kerkplein, 39 b-1601 ruisbroek-belgium tel.: +32 2 334 82 40 fax: +32 2 334 82 59 e-mail: belgium.Info@acv-world....