- DL manuals

- E-TON

- Scooter

- Sport 150

- Service Manual

E-TON Sport 150 Service Manual

Summary of Sport 150

Page 1

Service manual sf3a 150 sport 150 e-ton power copyright ©2008-2009 eton america, all rights reserved. Www.Get2itparts.Com www.Get2itparts.Com www.Get2itparts.Com.

Page 2: Service Department

E-ton forward this service manual contains the technical data of each component inspection and repair for the e-ton series motorcycle. The manual is shown with illustrations and focused on ᇷservice proceduresᇸ, ᇷoperation key points ᇸ, and ᇷinspection adjustmentᇸ so that provides technician with ser...

Page 3

How to use this manual e-ton this service manual describes basic information of different system parts and system inspection & service for e-ton series motorcycles. In addition, please refer to the manual contents in detailed for the model you serviced in inspection and adjustment. The first chapter...

Page 4

Mechanism illustrations e-ton fuse &c.D.I battery engine stop switch/starter tail light fuel tank cap storage box ignition switch rear brake level side stand frame number gear oil filling bolt gear oil draining bolt engine oil draining bolt front turn signal light front light/ position light high& l...

Page 5

E-ton contents contents general information/trouble diagnosis ...................................1 maintenance information .................................................................2 lubrication system..............................................................................3 fuel system ...

Page 6: E-Ton

E-ton 1. General information/trouble diagnosis 1-1 symbols and marks ....................1-1 general safety............................1-2 service precautions .................1-3 specifications..............................1-9 torque values (engine) .............. 1-10 torque values (frame) ..........

Page 7: E-Ton

1. General information/trouble diagnosis e-ton 1-2 general safety carbon monoxide if you must run your engine, ensure the place is well ventilated. Never run your engine in a closed area. Run your engine in an open area, if you have to run your engine in a closed area, be sure to use an extractor. C...

Page 8: E-Ton

E-ton 1. General information/trouble diagnosis 1-3 service precautions y always use with sanyang genuine parts and recommended oils. Using non-designed parts for sanyang motorcycle may damage the motorcycle. Y special tools are designed for remove and install of components without damaging the parts...

Page 9: E-Ton

1. General information/trouble diagnosis e-ton 1-4 y the length of bolts and screws for assemblies, cover plates or boxes is different from one another, be sure they are correctly installed. In case of confusion, insert the bolt into the hole to compare its length with other bolts, if its length out...

Page 10: E-Ton

E-ton 1. General information/trouble diagnosis 1-5 y lubricate the rotation face with specified lubricant on the lubrication points before assembling. Y check if positions and operation for installed parts is in correct and properly. Y make sure service safety each other when conducting by two perso...

Page 11: E-Ton

1. General information/trouble diagnosis e-ton 1-6 y when separating a connector, it locker has to be unlocked firstly. Then, conduct the service operation. Y do not pull the wires as removing a connector or wires. Hold the connector body. Y make sure if the connector pins are bent, extruded or loos...

Page 12: E-Ton

E-ton 1. General information/trouble diagnosis 1-7 y do not let the wire harness contact with rotating, moving or vibrating components as routing the harness. Y keep wire harnesses far away from the hot parts. Y route wire harness to avoid sharp edges or corners and also avoid the projected ends of ...

Page 13: E-Ton

1. General information/trouble diagnosis e-ton 1-8 y do not let the wire harness been twisted as installation. Y wire harnesses routed along the handlebar should not be pulled too tight or have excessive slack, be rubbed against or interfere with adjacent or surrounding parts in all steering positio...

Page 14: E-Ton

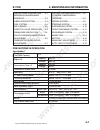

E-ton 1. General information/trouble diagnosis 1-9 specifications maker sanyang model xs125t-13 overall length 1800 mm front telescopic fork overall width 695 mm suspen sion system rear double swing arm overall height 1125 mm front 120/70-12 56j dimension wheel base 1300 mm tire specifi cations rear...

Page 15: E-Ton

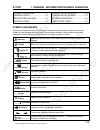

1. General information/trouble diagnosis e-ton 1-10 torque values (engine) item q'ty thread dia (mm) torque value(kg-m) remarks cylinder head holder nuts 4 8 1.8~2.2 cylinder head bolts 2 6 0.8~1.2 cylinder/cylinder head two-ends bolts 4 8 0.7~1.1 tighten to crankcase cylinder head cover bolts 4 6 0...

Page 16: E-Ton

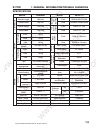

E-ton 1. General information/trouble diagnosis 1-11 torque values (frame) item q'ty thread dia (mm) torque value(kg-m) remarks mounting hex socket bolt for steering handlebar 4 10 4.0~5.0 mounting nut for steering rod 1 25.4 1.0~2.0 cone seat for steering rod 1 25.4 0.2~0.3 front wheel shaft nut 1 1...

Page 17: E-Ton

1. General information/trouble diagnosis e-ton 1-12 troubles diagnosis a. Engine hard to start or can not be started check and adjustment fault condition probable causes loosen carburetor drain bolt to check if there is gasoline inside the carburetor fuel supplied tom carburetor sufficient no fuel i...

Page 18: E-Ton

E-ton 1. General information/trouble diagnosis 1-13 b. Engine run sluggish (speed does not pick up, lack of power) check and adjustment fault condition probable causes try gradual acceleration and check engine speed engine speed can be increased. Engine speed can not be increased. Check ignition tim...

Page 19: E-Ton

1. General information/trouble diagnosis e-ton 1-14 c. Engine runs sluggish (especially in low speed and idling) d. Engine runs sluggish (high speed) check ignition timing (using ignition lamp) ʳ good spark poor no air sucked air sucked good poor abnormal air sucked through carburetor gasket adjust ...

Page 20: E-Ton

E-ton 1. General information/trouble diagnosis 1-15 e. Clutch, driving and driving pulley 1. Clutch ling spring broken 2. Clutch outer stick with clutch balance weights 3. Connection parts in clutch and shaft worn out or burned engine can be started but motorcycle can not be moved. Fault conditions ...

Page 21: E-Ton

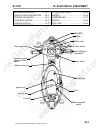

1. General information/trouble diagnosis e-ton 1-16 lubrication points acceleration cable/ front & rear brake lever pivot steering shaft bearing seat lock speedometer gear / front wheel bearing side stand shaft main stand shaft rear wheel bearing copyright ©2008-2009 eton america, all rights reserve...

Page 22: 2-1

E-ton 2. Maintenance information 2-1 precautions in operation .......2-1 periodical maintenance schedule ........................................2-2 lubrication system ....................2-3 fuel system...................................2-4 air cleaner....................................2-5 throttl...

Page 23: 2-2

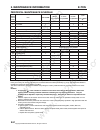

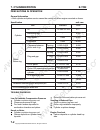

2. Maintenance information e-ton 2-2 periodical maintenance schedule mainte nance code item initial 300km 1 month every1000km 3 month every3000km 6 month every6000km 1 year every12000k m 1 ყ air cleaner i c c r 2 ყ fuel filter i i r 3 ყ oil filter c c c 4 ყ engine oil change r replacement for every ...

Page 24: 2-3

E-ton 2. Maintenance information 2-3 lubrication system engine oil capacity caution remove dipstick to check the oil level. If oil level is below the lower limit mark, add oil to the specified upper limit mark. Oil change shut off the engine and remove dipstick. Remove the oil drain plug on the bott...

Page 25: 2-4

2. Maintenance information e-ton 2-4 gear oil inspection check gear oil if leaking. Park the motorcycle with main stand on flat level place. Turn off engine and remove the gear oil draining plug. Place a measurement cup under the draining hole. Remove the oil drain plug and drain gear oil into a mea...

Page 26: 2-5

E-ton 2. Maintenance information 2-5 air cleaner element remove left side cover. Remove 7 screws from the air cleaner cover. Remove element of air cleaner (2 screws). Check the element if dirt or damaged. Replace it with new one if dirt or damaged. Caution throttle valve operation have a wide open o...

Page 27: 2-6

2. Maintenance information e-ton 2-6 primary adjustment is conducted from button side. Loosen fixing nut, and adjust by turning the adjustment nut. Tighten the fixing nut, and check acceleration operation condition. Crankcase ventilation pull out the plug from draining hose to clean deposits caution...

Page 28: 2-7

E-ton 2. Maintenance information 2-7 check & adjust valve clearance with feeler gauge. Valve clearance (in/ex): 0.06±0.02 mm loosen fixing nut and turn the adjustment nut for adjustment. Caution carburetor idle speed adjustment caution park the motorcycle with main stand and warn up engine. Open the...

Page 29: 2-8

2. Maintenance information e-ton 2-8 ignition system ignition timing caution remove right side cover. Remove ignition timing hole cap located on the cooling fan cap, or remove the cooling fan cap. Check ignition timing with ignition light. Start engine and set engine idle speed in 1700 rpm, and if t...

Page 30: 2-9

E-ton 2. Maintenance information 2-9 cylinder copmression pressure warn up engine and then turnoff the engine. Open the seat. Remove the luggage box. Remove spark plug cap and spark plug. Install compression gauge. Full open the throttle valve, and rotate the engine by means of stepping the kick-sta...

Page 31: 2-10

2. Maintenance information e-ton 2-10 steering system caution lift the front wheel out of ground. Turn handle from right to left and check if turning is smoothly. If handle turning is uneven and bending, or the handle can be operated in vertical direction, then adjust the handle top bearing. Suspens...

Page 32: 2-11

E-ton 2. Maintenance information 2-11 front disc brake system brake system hose make sure the brake hoses for corrosion or leaking oil, and also check brake system for leaking. Brake fluid check brake fluid level in the brake fluid reservoir. If the level is lower than the lower limit, add brake flu...

Page 33: 2-12

2. Maintenance information e-ton 2-12 added brake fluid add brake fluid to upper limit lever. Recommended brake fluid: dot3 or dot4 well run brake fluid. Caution brake lining wear the indent mark on brake lining is the wear limitation. Replace the brake lining if the wear limit mark closed to the ed...

Page 34: 2-13

E-ton 2. Maintenance information 2-13 drum brake system front brake free play: (drum brake) measure free play of rear brake level at the end of the lever. Free play: 10-20 mm adjust the free play by turning the front brake adjustment nut if necessary. Rear brake free play: (drum brake type) measure ...

Page 35: 2-14

2. Maintenance information e-ton 2-14 brake light switch the brake light switch is to lit up brake light as brake applied. Make sure that electrical starter can be operated only under brake applying. Wheel/tire check if both front and rear tire pressure are within specification. Caution appointed ti...

Page 36: 2-15

E-ton 2. Maintenance information 2-15 battery battery removal remove the 2 screws on the floor panel. Remove battery cap. (2 nuts) battery cables removal: 1. At first, remove the negative “-” cable. 2. Then, remove the positive “+” cable. 3. Remove the battery. If there is some rust on battery posts...

Page 37: 3-1

E-ton 3. Lubrication system 3-1 mechanism diagram ....................3-1 operational precautions .......3-2 trouble diagnosis......................3-2 engine oil .......................................3-3 cleaning engine oil strainer... 3-3 oil pump ............................................ 3-4 ...

Page 38: 3-2

3. Lubrication system e-ton 3-2 operational precautions general information this chapter contains maintenance operations for the engine oil pump, engine oil and gear oil. Specifications engine oil quantity disassembly 900 c.C. Replacement 850 c.C. Oil viscosity sae 10w-30 or equivalent gear oil capa...

Page 39: 3-3

E-ton 3. Lubrication system 3-3 engine oil turn off engine, and park the motorcycle in flat ground with main stand. Check oil level with oil dipstick after 3-5 minutes. Do not rotate the dipstick into engine as checking. If oil level is nearly low level, fill out recommended oil to upper level. Oil ...

Page 40: 3-4

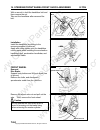

3. Lubrication system e-ton 3-4 oil pump oil pump removal remove the alternator (refer to chapter10). Remove the engine right crankcase cover. Remove the one-way clutch and starting drive gear (1 nut). Make sure that the pump axle can be rotated freely. Remove the oil pump cover (2 bolts), remove th...

Page 41: 3-5

E-ton 3. Lubrication system 3-5 oil pump inspection check the clearance between oil pump body and outer rotor. Limit: below 0.12 mm check clearance between inner and outer rotors. Limit: below 0.12 mm check clearance between rotor side face and pump body. Limit: below 0.2 mm oil pump re-assembly ins...

Page 42: 3-6

3. Lubrication system e-ton 3-6 oil pump installation install the oil pump (2 bolts). Install oil pump driver chain and drive gear. Install oil pump outer cover (2 bolts). Install the starting gear and the alternator. (refer to chapter 10) 2 bolts 2 bolts oil pump driver chain drive gear oil pump ou...

Page 43: 3-7

E-ton 3. Lubrication system 3-7 gear oil oil level inspection park the motorcycle on flat ground with main stand. Turn off engine and remove both engine oil filling bolt and oil draining bolt. Remove gear oil filling hole bolt and place a measurement cup under the draining plug. Remove the oil drain...

Page 44: E-Ton

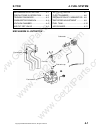

E-ton 4. Fuel system 4-1 mechanism illustration ............. 4-1 precautions in operation ......... 4-2 trouble diagnosis........................ 4-3 carburetor removal .................. 4-4 vacuum chamber ........................... 4-4 air cut-off valve ..........................4-6 auto by-star...

Page 45: 4-2

4. Fuel system e-ton 4-2 precautions in operation general information warning cautions specification item specification main jet 110# slow jet 35# idle speed 1700±100 rpm fuel quantity adjustment screw 2 1/8±3/4 turns level in float chamber 3.0±1 mm jet needle db4e6 add 1 unit 0.5mm washer throttle ...

Page 46: E-Ton

E-ton 4. Fuel system 4-3 trouble diagnosis poor engine start z no fuel in fuel tank z clogged fuel tube z too much fuel in cylinder z no spark from spark plug (malfunction of ignition system) z clogged air cleaner z malfunction of automatic by-starter z malfunction of throttle valve operation stall ...

Page 47: 4. Fuel System

4. Fuel system e-ton 4-4 carburetor removal open the seat. Remove the luggage box. Loosen the adjustment nut and fixing nut of throttle valve cable, and release the cable from carburetor. Remove fuel pipe, vacuum hose. Disconnect auto by-starter connectors. Release the clamp strip of air cleaner. Re...

Page 48: E-Ton

E-ton 4. Fuel system 4-5 remove fuel needle seat, spring, and injector needle. Check if the vacuum piston for wear out, crack or other damage. Check if the diaphragm for damage or crack. Cautions installation install injector needle, spring and fuel needle seat to vacuum piston. Cautions install vac...

Page 49: 4-6

4. Fuel system e-ton 4-6 air cut-off valve removal remove the vacuum hose clamp and then the vacuum hose. Remove the screws (screw x 2) of the air cut-off valve and its cover. Remove the spring and vacuum diaphragm. Check if the vacuum diaphragm for deterioration or crack. Installation install the v...

Page 50: E-Ton

E-ton 4. Fuel system 4-7 auto by-starter inspection turn off engine and waiting for over 10 minutes for cooling. Check resistance across the two terminals of the auto by-starter resistance value: max. 10 ˖ (measured after engine stopped for more than 10 minutes) replace the auto by-starter with a ne...

Page 51: 4-8

4. Fuel system e-ton 4-8 float chamber disassembly remove 4 mounting screws and then the float chamber cover. Remove the float pin and float valve. Checking check float needle valve and valve seat for drop difference damage, wear out, dirty or clogged. Cautions remove main jet, fuel needle jet holde...

Page 52: E-Ton

E-ton 4. Fuel system 4-9 installation install main jet, slow jet and fuel amount adjustment screw. Cautions install the float valve, float, and float pin. Checking fuel level cautions fuel level: 17.5 mm installation of carburetor install carburetor in the reverse order of removal. Following adjustm...

Page 53: 4. Fuel System

4. Fuel system e-ton 4-10 fuel tank fuel unit removal remove the seat. Remove the luggage box assembly (2 bolts and 3 nuts). Disconnect fuel unit connector. Remove fuel unit. Cautions fuel unit inspection. (refer to chapter 16 - electrical equipment). Fuel unit installation install the gauge in the ...

Page 54: E-Ton

E-ton 4. Fuel system 4-11 air cleaner removal open the seat and remove the luggage box . Loosen the clamp strip of air cleaner. Remove evaporative return hose. Remove body cover. Remove the air cleaner body bolts (2 bolts). Remove the air cleaner. Installation install the air cleaner in the reverse ...

Page 55: 5-1

E-ton 5. Removal of engine 5-1 mechanism diagram ...................... 5-1 operational precautions ......... 5-2 engine removal ............................. 5-3 removal of engine suspension bushing ............................................. 5-6 engine suspension frame.......... 5-7 installation...

Page 56: 5-2

5. Removal of engine e-ton 5-2 operational precautions general information engine must be supported by a bracket or adjustable tool in height. The following parts can be serviced with the engine installed on the frame. 1. Carburetor 2. Driving disk, driving belt, clutch, and transporting disk 3. Fin...

Page 57: 5-3

E-ton 5. Removal of engine 5-3 engine removal open the seat. Remove the luggage box assembly (2 bolts and 3nuts ). Remove the body cover (screw3x2). Remove the power connector of auto by- start. Remove the generator connector and pulse generator connector. Remove the starter motor wire on the starte...

Page 58: 5-4

5. Removal of engine e-ton 5-4 remove the fuel pipe, vacuum hose, and throttle valve cable from the carburetor. Loose the strap screw of the air cleaner guide, and remove the air cleaner guide. Remove the exhaust muffler (bolts × 2, nuts × 2). Remove the rear wheel (nut 1). Remove the air cleaner ...

Page 59: 5-5

E-ton 5. Removal of engine 5-5 remove the rear brake cable nut. Remove the rear brake cable. Remove the rear shock absorber lower bolt. Loose the strap screw of engine left guide, and then remove the engine left guide. Remove the engine suspension nuts and bolts (engine side), and then remove the en...

Page 60: 5-6

5. Removal of engine e-ton 5-6 removal of engine suspension bushing if engine suspension frame and the cushion rubber of rear shock absorber bushing damaged. Then, with the bushing remover / presser, 28mm &20mm, to press the bushing out, and replace it with new one. Engine suspension bushing: 28m...

Page 61: 5-7

E-ton 5. Removal of engine 5-7 engine suspension frame removal remove the right side bolt of engine suspension frame. Remove the left side bolt of engine suspension frame. Check if the engine suspension frame bushing and cushion rubber for damage. If so, replace with new ones. Installation tighten t...

Page 62: 5-8

5. Removal of engine e-ton 5-8 installation of engine check if the bushings of engine suspension frame and shock absorber for damaged. If so, replace with new ones. Install the engine according to the reversing order of removal. Caution engine suspension nut: torque value: 4.5~5.5kgf-m rear shock ab...

Page 63: 6-1

E-ton 6. Cylinder head/valve 6-1 mechanism diagram ....................6-1 precautions in operation .......6-2 trouble shooting.......................6-3 camshaft removal .....................6-4 cylinder head removal ............6-6 cylinder head disassembly ....6-7 cylinder head inspection...........

Page 64: 6-2

6. Cylinder head/valve e-ton 6-2 precautions in operation general information this chapter is contained maintenance and service for cylinder head, valve, and camshaft as well as valve rocker arm. Cylinder head service cannot be carried out when engine is in frame. M m : t i n u n o i t a c i f i c e...

Page 65: 6-3

E-ton 6. Cylinder head/valve 6-3 trouble shooting engine performance will be effected by troubles on engine top end. The troubles usually can be determinate or by performing cylinder compression test and judging the abnormal noise generated. Rough idle low compression pressure. Low compression press...

Page 66: 6-4

6. Cylinder head/valve e-ton 6-4 camshaft removal remove the shroud of the engine. Remove the crankcase blow-by system hose from the cylinder head. Remove the cylinder head cover 4 bolts and then remove the cylinder head cover. Loosen the screw of camshaft chain adjuster and remove o-ring. With a fl...

Page 67: 6-5

E-ton 6. Cylinder head/valve 6-5 remove the camshaft holder and rocker arm set. Remove the camshaft chain from the camshaft sprocket. Remove the camshaft. Camshaft inspection inspect cam lobe height for damaged. Service limit in: replacement when less than 25.29 mm ex: replacement when less than 25....

Page 68: 6-6

6. Cylinder head/valve e-ton 6-6 measure the valve rocker arm i.D. Service limit: replace when it is above 10.100 mm measure the active o.D. Of the valve rocker arm shaft . Service limit: replace when it is above 9.910 mm calculate the clearance between the rocker arm shaft and the rocker arm. Servi...

Page 69: 6-7

E-ton 6. Cylinder head/valve 6-7 remove the 2 cylinder head mounting bolts from cylinder head left side cover. Remove cylinder head gasket and 2 dowel pins. Remove chain plate. Clean up residues from the matching surfaces of cylinder and cylinder head. Caution cylinder head disassembly use a valve c...

Page 70: 6-8

6. Cylinder head/valve e-ton 6-8 cylinder head inspection check if spark plug and valve holes are crack. Measure cylinder head flat with a straightedge and flat feeler gauge. Service limit: 0.05mm valve spring free length measure the free length of intake and exhaust valve springs. Standard outer : ...

Page 71: 6-9

E-ton 6. Cylinder head/valve 6-9 caution correct it with reamer after replacement. If clearance still exceeds service limit after replaced valve guide, replace valve stem too. Caution valve guide replacement heat up cylinder head to 100~150 ഒ with heated plate or toaster. Caution hold the cylinder h...

Page 72: 6-10

6. Cylinder head/valve e-ton 6-10 valve seat inspection and service clean up all carbon deposits onto intake and exhaust valves. Apply with emery slightly onto valve contact face. Grind valve seat with a rubber hose or other manual grinding tool. Caution remove the valve and check its contact face. ...

Page 73: 6-11

E-ton 6. Cylinder head/valve 6-11 use 60° cutter to cut a quarter lower part out. Remove the cutter and check new valve seat. Use 45° cutter to grind the valve seat to specified width. Caution grind valve seat again if necessary. Coat the valve seat surface with red paint. Install the valve through ...

Page 74: 6-12

6. Cylinder head/valve e-ton 6-12 after the valve seat grinded, coat valve seat surface with emery and then slightly press the grinded surface. Clean up all emery coated onto cylinder and valve after grinded. Cylinder head reassembly lubricate valve stem with engine oil, and then insert the valve in...

Page 75: 6-13

E-ton 6. Cylinder head/valve 6-13 cylinder head installation install the lock pins and new cylinder head gasket onto the cylinder head. Install the camshaft chain plate. Install the cylinder head. Camshaft installation assemble the camshaft holder. Install the exhaust valve rocker arm set onto the c...

Page 76: 6-14

6. Cylinder head/valve e-ton 6-14 install the lock pins. Install the camshaft holder, gasket and nut onto the cylinder head. Tighten the cylinder head nuts. (4 nuts) at first, tighten the 4 nuts on the cylinder top and then tighten the 2 bolts on the left side of cylinder head. Torque value: 1.8~2.2...

Page 77: 7-1

E-ton 7. Cylinder/piston 7-1 mechanism diagram ....................7-1 precautions in operation .......7-2 trouble diagnosis......................7-2 cylinder removal .......................7-3 piston removal............................7-5 piston ring installation..........7-7 piston installation......

Page 78: 7-2

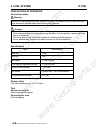

7. Cylinder/piston e-ton 7-2 precautions in operation general information both cylinder and piston service cannot be carried out when engine mounted on frame. M m : t i n u n o i t a c i f i c e p s t i m i l d r a d n a t s m e t i id 57.395~57.415 57.7 bend/wrap age ᧩ 0.050 0 5 0 . 0 5 0 0 . 0 s s...

Page 79: 7-3

E-ton 7. Cylinder/piston 7-3 cylinder removal remove cylinder head. (refer to chapter 6) remove 2 bolts and then take out the cam chain auto-adjuster. Remove cam chain plate. Remove cylinder. Remove cylinder gasket and lock pins clean the residues attached onto the matching surfaces of cylinder and ...

Page 80: 7-4

7. Cylinder/piston e-ton 7-4 cover the holes of crankcase and cam chain with a piece of cleaning cloth. Clean up all residues or foreign materials from the two matching surfaces of cylinder and crankcase. Caution inspection check if the inner diameter of cylinder is worn out or damaged. In the 3 pos...

Page 81: 7-5

E-ton 7. Cylinder/piston 7-5 piston removal plug crankcase opening with a cleaning cloth to prevent from piston pin snap ring or other parts falling into crankcase when disassembling. Hold another snap ring with pliers. Push out the piston pin from the side that not removed the snap ring. Remove pis...

Page 82: 7-6

7. Cylinder/piston e-ton 7-6 measure the outer diameter of piston pin. Service limit: 14.96mm measure the inner diameter of connecting rod small end. Service limit: 15.06mm measure the inner diameter of piston pin hole. Service limit: 15.04mm calculate clearance between piston pin and its hole. Serv...

Page 83: 7-7

E-ton 7. Cylinder/piston 7-7 piston ring installation clean up piston top, ring groove, and piston skirt. Install the piston ring onto piston carefully. Place the openings of piston ring as diagram shown. Caution y do not damage piston and piston rings as installation. Y all marks on the piston ring...

Page 84: 7-8

7. Cylinder/piston e-ton 7-8 piston installation install piston and piston pin, and place the in mark on the piston top side forward to intake valve. Install new piston pin snap ring. Caution cylinder installation clean up all residues and foreign materials on the matching surface of crankcase. Pay ...

Page 85: 8-1

E-ton 8. V-belt driving system/kick starter arm 8-1 mechanism diagram ....................8-1 maintenance description ........8-2 trouble diagnosis......................8-2 left crankcase cover ..............8-3 kick starter arm ........................ 8-3 driving belt.................................

Page 86: 8-2

8. V-belt driving system/kick starter arm e-ton 8-2 maintenance description precautions in operation general information Θʳdriving pulley, clutch, and driven pulley can be serviced on the motorcycle. Θʳdriving belt and driving pulley surface must be free of grease. Specification unit: mm item standa...

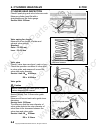

Page 87: 8-3

E-ton 8. V-belt driving system/kick starter arm 8-3 left crankcase cover left crankcase cover removal remove air cleaner. (2 bolts) remove kick starter arm. (1 bolt) loosen vent strap on the front-left side of cover, and then remove the vent. Remove engine left-side cover (8 bolts). Kick starter arm...

Page 88: 8-4

8. V-belt driving system/kick starter arm e-ton 8-4 driving belt removal remove left crankcase cover. Hold the driving pulley with a universal fixture, and then remove the nut and driving pulley. Hold driving pulley with universal fixture, and remove nut and clutch outer. Caution push the driving be...

Page 89: 8-5

E-ton 8. V-belt driving system/kick starter arm 8-5 installation pull out the driving pulley and then insert the driving belt into the driving pulley. Caution install the clutch set with driving belt onto the driving shaft. Install the sliding pulley on the other end of belt. Install clutch outer. I...

Page 90: 8-6

8. V-belt driving system/kick starter arm e-ton 8-6 sliding pulley removal remove left crankcase cover. Hold driving pulley with universal fixture, and then remove driving pulley nut. Remove driving pulley. Remove the driving belt from the pulley. Remove sliding pulley set and driving pulley hub fro...

Page 91: 8-7

E-ton 8. V-belt driving system/kick starter arm 8-7 inspection the operation of sliding pulley is means of the weight roller to pressing on it with centrifuge force. And then the speed is changed by the title plate rotation. Thus, if weight rollers are wear out or damage, the centrifuge force will b...

Page 92: 8-8

8. V-belt driving system/kick starter arm e-ton 8-8 apply with grease 4~5 g to inside of driving shaft hole, and install driving pulley hub. Caution install siding pulley assembly onto crankshaft. Driving pulley install press driving belt into pulley groove, and then press down the up & down sides o...

Page 93: 8-9

E-ton 8. V-belt driving system/kick starter arm 8-9 clutch/driven pulley disassembly remove driving belt and clutch/driven pulley. Install clutch spring compressor onto the pulley assembly, and operate the compressor to let nut be installed more easily. Caution hold the clutch spring compressor onto...

Page 94: 8-10

8. V-belt driving system/kick starter arm e-ton 8-10 clutch lining measure each clutch lining thickness. Replace it if exceeds service limit. Service limit: 1.5mm driven pulley spring measure the length of driven pulley spring. Replace it if exceeds service limit. Service limit: 163.7mm driven pulle...

Page 95: 8-11

E-ton 8. V-belt driving system/kick starter arm 8-11 clutch block replacement remove snap and washer, and the remove clutch block and spring from driving plate. Check if spring is damage or insufficient elasticity. Check if shock absorption rubber is damage or deformation. Replace it if necessary. A...

Page 96: 8-12

8. V-belt driving system/kick starter arm e-ton 8-12 install snap ring and mounting plate onto setting pin. Replacement of driven pulley bearing remove inner bearing. Caution remove snap ring and then push bearing forward to other side of inner bearing. Place new bearing onto proper position and its...

Page 97: 8-13

E-ton 8. V-belt driving system/kick starter arm 8-13 installation of clutch/driven pulley install new oil seal and o-ring onto sliding pulley. Apply with specified grease to lubricate the inside of sliding pulley. Install sliding pulley onto driven pulley. Install guide pin and guide pin roller. Ins...

Page 98: 9-1

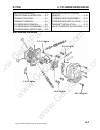

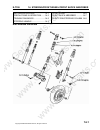

E-ton 9. Final driving mechanism 9-1 mechanism diagram ....................9-1 operational precautions .......9-2 trouble diagnosis......................9-2 disassembly of final driving mechanism......................................9-3 inspection of final driving mechanism ............................

Page 99: 9-2

9. Final driving mechanism e-ton 9-2 operational precautions specification application gear oil: 4-stroke lubricant recommended gear oil:85w-140 oil quantity: 100 c.C. (90 c.C. When replacing) tools special service tools inner type bearing puller outer type bearing puller gear box oil seal installer...

Page 100: 9-3

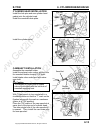

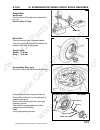

E-ton 9. Final driving mechanism 9-3 disassembly of final driving mechanism remove the rear wheel. (refer to chapter 15) remove the clutch. Drain gear oil out from gear box. Remove gear box cover bolts (7bolts) and then remove the cover and the final driving shaft. Remove gasket and setting pin. Rem...

Page 101: 9-4

9. Final driving mechanism e-ton 9-4 check bearings on gear box and cover. Rotate each bearing’s inner ring with fingers. Check if bearings can be turned in smooth and silent, and also check if bearing outer ring is mounted on gear box & cover tightly. If bearing rotation is uneven, noising, or loos...

Page 102: 9-5

E-ton 9. Final driving mechanism 9-5 press out the driving shaft from the gear box. Remove oil seal from the gear box. Remove the driving shaft bearing from the gear box cover with the inner type bearing puller. Caution specified tool: inner type bearing puller. If the driving shaft is pulled out wi...

Page 103: 9-6

9. Final driving mechanism e-ton 9-6 re-assembly of final driving mechanism install final driving shaft and final driving gear, countershaft, and countershaft gear. Install the setting pins(2 pins) and new gasket. Apply with grease onto the oil seal lip of final driving shaft. Install the gear box c...

Page 104: 10-1

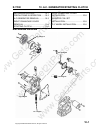

E-ton 10. A.C. Generator/starting clutch 10-1 mechanism diagram ....................10-1 precautions in operation .......10-2 a.C.Generator removal ...........10-3 right crankcase cover removal .......................................... 10-4 starting clutch .......................... 10-5 right cran...

Page 105: 10-2

10. A.C. Generator/starting clutch e-ton 10-2 precautions in operation general information refer to chapter 5: engine removal and installation refer to chapter 1: the troubleshooting and inspection of a.C. Generator refer to chapter 16: the service procedures and precaution items of starter motor sp...

Page 106: 10-3

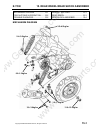

E-ton 10. A.C. Generator/starting clutch 10-3 a.C. Generator removal drain out the engine oil. Remove the rear center cover. (2 screws) remove the right side cover. (3 screws) remove the exhaust muffler. (2 bolts, 2 nuts) remove the fan shroud. (4 bolts) remove the fan. (4 bolts) hold the flywheel w...

Page 107: 10-4

10. A.C. Generator/starting clutch e-ton 10-4 remove the flywheel with the flywheel puller. Special service tools: flywheel puller shaft protector caution remove the connectors of the a.C. Generator and pulse generator. Remove the 6 bolts for the pulse generator, the a.C. Generator coil and cable gu...

Page 108: 10-5

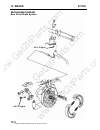

E-ton 10. A.C. Generator/starting clutch 10-5 starting clutch starting clutch removal hold the starting driven gear with the universal fixture. Remove the 22mm anti-loosen lock nut and gasket. Special service tools: anti-loosen lock nut socket universal fixture. Caution remove the starting driven ge...

Page 109: 10-6

10. A.C. Generator/starting clutch e-ton 10-6 check the starting driven gear for wear or damage. Measure the id of the starting driven gear. Service limit: id: 32.06 mm or less check the starting reduction gear and shaft for wear or damage. Measure the id of the starting reduction gear. Service limi...

Page 110: 10-7

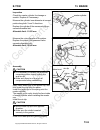

E-ton 10. A.C. Generator/starting clutch 10-7 installation install the components in the reverse procedures of removal. Caution torque value: 1.0~1.4kgf-m starting clutch installation install reduction gear shaft and reduction gear. Install starting clutch. Install the starting driven gear onto the ...

Page 111: 10-8

10. A.C. Generator/starting clutch e-ton 10-8 right crankcase cover installation install setting pin and new gasket on the crankcase. Replace the right crankshaft oil seal of the crankcase and apply some oil onto the oil seal lip. Install right crankcase cover onto the right crankcase. (8 bolts) tor...

Page 112: 10-9

E-ton 10. A.C. Generator/starting clutch 10-9 install the cooling fan. (4 bolts) torque value: 0.8~1.2kgf-m install the cooling fan shroud. (4 bolts) install the exhaust muffler. (2 bolts, 2 nuts) install the right side cover. (3 screws) install the rear center cover. (2 screws) add some engine oil ...

Page 113: 11-1

E-ton 11. Crankcase/crankshaft 11-1 mechanism diagram .............. 11-1 operational precautions ... 11-2 trouble diagnosis ................ 11-2 disassembly of crankcase 11-3 crankshaft inspection ....... 11-5 assembly of crankcase ..... 11-6 mechanism diagram 0.8~1.2 kgf-m 0.8~1.2 kgf-m 3.5~4.5 k...

Page 114: 11-2

11. Crankcase/crankshaft e-ton 11-2 operational precautions general information z this section contains descriptions concerning disassembly of the crankcase so that the crankshaft can be serviced. Z complete following operations before disassembling crankcase. Engine chapter 5 cylinder head chapter ...

Page 115: 11-3

E-ton 11. Crankcase/crankshaft 11-3 disassembly of crankcase remove the 2 bolts from the right crankcase. Remove the cam chain tensioner (hex socket bolt) from the left side of crankcase. Place the left side of crankcase upward, and then install the crankcase remover/set onto the crankcase. Drive th...

Page 116: 11-4

11. Crankcase/crankshaft e-ton 11-4 remove the crankshaft from the right crankcase. Caution remove gasket and dowel pins (2). Scrape gasket residues off the crankcase contact surface. Caution remove oil seal from the left crankcase. Z do not damage contact surface of the crankcase. Z soap the gasket...

Page 117: 11-5

E-ton 11. Crankcase/crankshaft 11-5 crankshaft inspection measure left and right clearance of connecting rod big end. Service limit: replace when it is more than 0.55 mm measure the radical clearance of the big end at the vertical directions. Service limit : 0.05 mm place the crankshaft onto a v-blo...

Page 118: 11-6

11. Crankcase/crankshaft e-ton 11-6 assembly of crankcase install cam chain into the chain hole of the left crankcase, and then split out the cam chain. Caution install crankshaft into the left crankcase and then install two dowel pins and new crankcase gasket. Install the right crankcase and tighte...

Page 119: 11-7

E-ton 11. Crankcase/crankshaft 11-7 apply with some grease onto the oil seal lip and then install it onto the left crankcase. Press-fit the oil seal to specified position with the oil seal installer (19.8 x30 x5). Special service tools: the oil seal installer (19.8 x30 x5) copyright ©2008-2009 eton ...

Page 120: E-Ton

E-ton mechanism diagram 12. Body cover 12-1 maintenance mechanism diagram information........12-2 ....................12-1 handle cover ...............................12-3 front cover..................................12-4 front inner box........................... 12-4 body cover.......................

Page 121: 12-2

12. Body cover e-ton 12-2 maintenance information body covers disassemble sequence: y be careful not to damage various covers in disassembly or re-assembly operation. Y never injure hooks molded on the body covers in disassembly or re-assembly operation. Y align the buckles on the guards with slot o...

Page 122: 12-3

E-ton 12. Body cover 12-3 handle cover removal: remove 4 lower mounting screw of the front handle cover. Remove the mounting screws (2 screws) between the front handle cover and the rear handle cover. Remove the front handle cover. Removed the meter connector. Installation: install according to the ...

Page 123: 12-4

12. Body cover e-ton 12-4 front cover removal remove the 6 mounting screws of front cover from the front inner box side. Remove the 2 mounting screws of front cover emblem from the front cover. . Remove the headlight wire connector. Remove the turn left/right light wire connector. Remove the front c...

Page 124: 12-5

E-ton 12. Body cover 12-5 body cover removal remove the rear carrier. (4 bolts) remove the 4 bolts of the luggage box. Remove the luggage box and the seat. Remove the mounting bolts of the body cover. Remove the mounting screws of the body cover. Remove the mounting screws of the body cover. Remove ...

Page 125: 12-6

12. Body cover e-ton 12-6 front center cover removal remove the front center little cover. Remove the screws of the front center cover. Remove the rear luggage box and the seat. Remove the front center cover mounting screws. Remove the front center cover. Installation install the cover according to ...

Page 126: 12-7

E-ton 12. Body cover 12-7 remove the 4 bolts on both left & right sides. Remove the floor panel. Installation install the floor panel according to the reverse procedure of removal. Under cover removal remove the front wheel. Remove the 4 screws on the floor panel. Remove the 4 screws on the front in...

Page 127: 12-8

12. Body cover e-ton 12-8 rear fender removal remove 4 the rear carrier mounting bolts and remove the rear carrier. Remove the 4 bolts from the luggage box and remove the luggage box and the double seat. Remove the left & right body cover. Remove the 3 bolts on the rear fender then remove the fender...

Page 128: 13-1

E-ton 13. Brake 13-1 mechanism diagram-front disc brake system ...................... 13-1 mechanism diagram-rear drum brake system .................... 13-2 maintenance information........ 13-3 trouble diagnosis ...................... 13-4 hydraulic brake system inspection.............................

Page 129: 13-2

13. Brake e-ton 13-2 mechanism diagram rear drum brake system 0.8~1.2 kgf-m 0.8~1.2 kgf-m copyright ©2008-2009 eton america, all rights reserved. Www.Get2itparts.Com www.Get2itparts.Com www.Get2itparts.Com.

Page 130: 13-3

E-ton 13. Brake 13-3 maintenance information precautions in operation caution the brake caliper can be removed without removing the hydraulic system. After the hydraulic system is removed, or the brake system is felt to be too soft, bleed the hydraulic system. While refilling brake fluid, care shoul...

Page 131: 13-4

13. Brake e-ton 13-4 trouble diognosis disc brake soft brake lever z air inside the hydraulic system z hydraulic system leaking z worn master piston z worn brake pad z poor brake caliper z worn brake lining/disc z low brake fluid z blocked brake pipe z warp/bent brake disc z bent brake lever hard op...

Page 132: 13-5

E-ton 13. Brake 13-5 hydraulic brake system inspection inspection visual inspect for brake fluid leaking or damage. Check if brake hose connection loosened with wrench and turn the handlebar from right to left motion or press down the shock absorber to check if there is something is interfered with ...

Page 133: 13-6

13. Brake e-ton 13-6 remove the master cylinder cap and diaphragm. Add good quality brake fluid and it has to add same brand brake fluid into the master cylinder. Clean dirty brake disc. Caution brake fluid replacement/ air-bleed connect drain hose to drain valve. Open the drain valve on the caliper...

Page 134: 13-7

E-ton 13. Brake 13-7 brake caliper removal place a container under the brake caliper, and loosen the brake hose bolt and finally remove the brake hoses. Caution remove two caliper bolts and the caliper. Make sure the brake lining condition. Replace the lining if the brake lining wear limitation groo...

Page 135: 13-8

13. Brake e-ton 13-8 brake disc inspection visually check the brake disc for wear or break. Measure the thickness of the disc at several places. Replace the disc if it has exceeded the service limit. Allowable limit: 2.0 mm remove the brake disc from wheel. Check the disc for deformation and bend. A...

Page 136: 13-9

E-ton 13. Brake 13-9 inspection check the master cylinder for damage or scratch. Replace it if necessary. Measure the cylinder inner diameter at several points along both x and y directions. Replace the cylinder if the measured values exceed allowable limit. Allowable limit: 11.055 mm measure the ou...

Page 137: 13-10

13. Brake e-ton 13-10 installation place the master cylinder onto handlebar, and install the split ring and bolts. The “up” mark on the split ring should face upward. Align the split ring on the master cylinder seat with the alignment point on the handlebar. Tighten the upper bolt of the seat to spe...

Page 138: 13-11

E-ton 13. Brake 13-11 drum brake-drum brake drum removal use a vacuum cleaner and other suitable tools to clean the brake parts to minimize the hazard caused by the dust. Caution remove wheel. Remove brake drum from wheel hub. Inspection check the brake drum for wear and damage, replace wheel hub if...

Page 139: 13-12

13. Brake e-ton 13-12 removal caution remove brake shoes from the brake panel by pulling out the brake linings with two hands. Installation apply a thin coat of grease to the brake cam and the anchor pin. Hook the brake spring onto the brake cam. Pull out the brake linings and install them onto the ...

Page 140: 14-1

E-ton 14. Steering/front wheel/front shock absorber 14-1 mechanism diagram ....................14-1 precautions in operation .......14-2 trouble diagnosis......................14-2 steering handle.......................... 14-3 front wheel ................................. 14-4 front shock absorber ...

Page 141: 14-2

14. Steering/front wheel/front shock absorber e-ton 14-2 precautions in operation general information before remove front wheel, use a jack to lift the body until front wheel free of ground, and take care not to rotate body in reverse. Be careful not to allow oil or grease get on brake drum or linin...

Page 142: 14-3

E-ton 14. Steering/front wheel/front shock absorber 14-3 steering handle removal remove handle front & rear covers and the front cover (refer to chapter 12). Disc brake remove the 2 bolts of the brake master cylinder, and then take out the master cylinder and the split ring. Caution remove accelerat...

Page 143: 14-4

14. Steering/front wheel/front shock absorber e-ton 14-4 with a wrench to hold the handlebar bolt and then remove the nut. Take out the handlebar after removed the bolt. Installation install the handlebar according to the reverse procedure of removal. Apply with some grease onto the handlebar moving...

Page 144: 14-5

E-ton 14. Steering/front wheel/front shock absorber 14-5 inspection wheel axle set the axle in v-blocks and measure the run-out. Service limit: 0.2 mm. Wheel rim place the wheel onto a rotated bracket. Turn the wheel with hand and measure its wobble value with a dial gauge. Service limit: radial : 2...

Page 145: 14-6

14. Steering/front wheel/front shock absorber e-ton 14-6 bearing inspection turn the inner race of bearing with fingers. The bearing should be turn smoothly. Also check if the outer collar is tightly connected to the wheel hub. If the bearing does not turn smoothly, or if they are too loose in the r...

Page 146: 14-7

E-ton 14. Steering/front wheel/front shock absorber 14-7 installation align the flange part on the speedometer gear with the slot of wheel hub, and then install the brake disc (drum brake) or speedometer gear box. Place the front wheel between the front shock absorbers. Disc brake align the flange p...

Page 147: 14-8

14. Steering/front wheel/front shock absorber e-ton 14-8 remove the top connection bolt of the right shock absorber. (bolt x 4) remove the shock absorber from the front fork. Installation install the shock absorbers according to the reverse procedure of removal. Align the shock absorber top-edge wit...

Page 148: 14-9

E-ton 14. Steering/front wheel/front shock absorber 14-9 with a plastic hammer to tap the steering column slightly, and then remove the top ball bearing seat. Remove the lower-end cone bearing seat on the frame with a punch. Caution installation install a new top-cone bearing seat onto the top of st...

Page 149: 15-1

E-ton 15. Rear wheel/rear shock absorber 15-1 mechanism diagram.................... 15-1 precautions in operation....... 15-2 trouble diagnosis ..................... 15-2 exhaust muffler......................... 15-3 rear wheel.................................... 15-3 rear shock absorber ..............

Page 150: 15-2

15. Rear wheel/rear shock absorber e-ton 15-2 precautions in operation general information as for the wheel removal, service, and installation procedures, please refer to the service manual of high speed tire. Specification unit: mm items standard limit radial - 2.0 wheel wobbling axial - 2.0 thickn...

Page 151: 15-3

E-ton 15. Rear wheel/rear shock absorber 15-3 exhaust muffler removal remove the front-end nut of the exhaust muffler. (nuts x 2) remove the bolts. (bolts x 2) remove the exhaust muffler. Installation install the exhaust muffler according to the reverse procedure of removal. Caution torque value: ex...

Page 152: 15-4

15. Rear wheel/rear shock absorber e-ton 15-4 rear shock absorber removal remove the left & right covers. (screws x 8) remove the luggage box. (bolts x 4, nuts x 2, screw x 1) remove the rear carrier. (bolts x 3) remove the body cover (bolts x2) remove the air cleaner bolts (bolts x2) remove the low...

Page 153: 16-1

E-ton 16. Electrical equipment 16-1 mechanism diagram ....................16-1 precautions in operation .......16-2 trouble diagnosis ......................16-4 charging system.........................16-5 ignition system ............................16-11 starting system ..........................16...

Page 154: 16-2

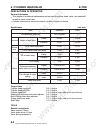

16. Electrical equipment e-ton 16-2 precautions in operation charging system z when remove the battery, the disconnection sequence of cable terminals shall be strictly observed. (first disconnect the negative cable terminal, next, the positive cable terminal.) z mf (maintenance free) battery does no...

Page 155: 16-3

E-ton 16. Electrical equipment 16-3 specification charging system n o i t a c i f i c e p s s m e t i capacity/type 12v6ah(closed type maintenance-free battery) charging rate std:0.6a/5~10hrs, emergency charging: 6a/0.5hrs full charged 13.1v(at 20ഒ) battery voltage under charged below 12.3 v (at 20 ...

Page 156: 16-4

16. Electrical equipment e-ton 16-4 trouble diagnosis charging system no power supply z dead battery z disconnect battery cable z fuse burned out z faulty ignition switch low voltage z weak battery z loose battery connection z charging system failure z voltage-current regulator failure intermittent ...

Page 157: 16-5

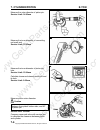

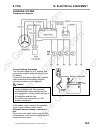

E-ton 16. Electrical equipment 16-5 charging system charging wire diagram current leakage inspection turn the main switch to off position, and remove the negative cable terminal (-) from the battery. Connect an ammeter between the negative cable terminal and the battery negative terminal (as shown o...

Page 158: 16-6

16. Electrical equipment e-ton 16-6 battery removal remove the battery cover. Caution remove the battery cover. Disconnect the negative (-) cable from the battery first, then the positive (+) cable. Remove the battery. Install the battery in reverse order of removal. Caution z to prevent form circui...

Page 159: 16-7

E-ton 16. Electrical equipment 16-7 voltage check with a digital voltage meter or multi-meter to measure battery voltage. Voltage: fully charged: 13.0 – 13.2v (at 20 ഒ) undercharged: below 12.3 v (at 20 ഒ) charging connect the charger positive (+) to the battery positive (+) terminal. Connect the ch...

Page 160: 16-8

16. Electrical equipment e-ton 16-8 charging voltage/current inspection caution after the engine is warmed up, replace original battery with a fully charged battery. Connect a digital voltmeter to the battery terminals. Connect an ammeter between both ends of the main fuse. Caution caution connect a...

Page 161: 16-9

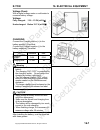

E-ton 16. Electrical equipment 16-9 voltage regulator inspection remove the front cover. (screws x 4 x 2). Remove the front cover mounting screw(screws x 1)and remove the headlight wiring connector. Disconnect the 4p connector on the diode, and check the continuity between main wire terminals accord...

Page 162: 16-10

16. Electrical equipment e-ton 16-10 alternator charging coil caution check remove the 3p connector of the alternator. Measure the resistance between the white wire on the alternator and frame ground with a multi-meter. Standard: 0.6 f0.1˖ (20ഒ) replace the alternator charging coil if the measured v...

Page 163: 16-11

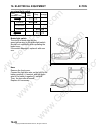

E-ton 16. Electrical equipment 16-11 ignition system ignition system circuit cdi unit removal remove the right body cover, then the c.D.I. Unit can be removed from the frame. Check disconnect the connector from the cdi unit. Make the following inspection at each terminal of the harness side connecto...

Page 164: 16-12

16. Electrical equipment e-ton 16-12 ignition coil removal remove the luggage box, center cover. Remove spark plug cap. Remove the primary coil wire of ignition coil. Remove the fix bolts for the ignition coil, and remove the ignition coil. Install the ignition coil in reverse order of removal. Caut...

Page 165: 16-13

E-ton 16. Electrical equipment 16-13 secondary coil attached the spark plug cap, measure the resistance between plug cap side and green terminal. Standard value: 7-12 k ˖ (20ഒ) remove the spark plug cap, measure the resistance between plug cap side and green terminal. Standard value: 3-5 k ˖ (20ഒ) s...

Page 166: 16-14

16. Electrical equipment e-ton 16-14 starting system starter magnetic switch inspection turn main switch to "on", and operate the brake lever. Then press starting button to check if there a click sound. It is normal if there is a click sound. Remove the luggage box. Disconnect the battery negative (...

Page 167: 16-15

E-ton 16. Electrical equipment 16-15 starting motor removal remove the right side cover. (screws x3) firstly, remove the battery negative (-) terminal, and then remove the positive (+) terminal. Remove the luggage box. Remove the starting motor power wire. Remove the starting motor mounting bolts an...

Page 168: 16-16

16. Electrical equipment e-ton 16-16 caution installation install the meter in reverse order of removal. Do not wipe the meter or headlight with organic solvent such as gasoline to prevent from damage these components. High/low beam indicator turn left signal light fuel gauge odometer speedometer tu...

Page 169: 16-17

E-ton 16. Electrical equipment 16-17 light/bulbs headlight bulb replacement rear the screw of the front cover. Rear the front cover. Disconnect the headlight wire connector, and then remove the rubber boot. Press down the bulb spring locker and then remove the locker with turning it left motion. Rem...

Page 170: 16-18

16. Electrical equipment e-ton 16-18 front turn signal lamp bulb replacement remove the front handle cover. ( screw x 4) remove the wire connector of the turn signal light. Pull out the bulb and replace it with new one. (12v 10w) installation install the bulb in reverse order of removal. Pull out th...

Page 171: 16-19

E-ton 16. Electrical equipment 16-19 bulbs replacement of tail light/brake light/rear turn signal light. Remove the rear carrier (bolts x4). Remove the rear luggage box (bolts x4). Remove the left/right body cover. Remove the luggage box bracket and fuel tank. Bolts x2 bolts x2 right body cover left...

Page 172: 16-20

16. Electrical equipment e-ton 16-20 replace the bolts of the tail light. Replace the bulbs of the tail light, brake light (12v 5w/21w and the turn signal light (12v/10w). Installation install the bulb in reverse order of removal. Switch main switch check remove front cover. Disconnect main switch l...

Page 173: 16-21

E-ton 16. Electrical equipment 16-21 handle switch remove the right handle switch. Disconnect the connector of the handle switch. Check the continuity of follow pins listed below columns. Engine stop switch color location black black /red off on starting switch color location yellow/red green free h...

Page 174: 16-22

16. Electrical equipment e-ton 16-22 urn signal light switch color location sky blue gray orange from r push off n from l brake light switch the circuit of black wire and the green/yellow wire on the brake light switch should be in continuity when operating the brake lever. If the switch damaged, re...

Page 175: 16-23

E-ton 16. Electrical equipment 16-23 fuel unit open the seat. Remove the luggage box . (bolts x4). Disconnect the fuel unit wire connector. Caution the resistance values are listed below when the float arm in “f” and “e” positions. Float arm position resistance value e(empty) 97.5~107.5 f(full) 4~10...

Page 176

E-ton power tech co., ltd. 2009.01.14 copyright ©2008-2009 eton america, all rights reserved. Www.Get2itparts.Com www.Get2itparts.Com www.Get2itparts.Com.