Summary of IDROLAVA

Page 1

Rev a february 2004 idrolava parts & operations manual.

Page 2: Table of Contents

Table of contents important safety instructions ..................................................... 1 vacuum and accessories........................................................... 4 operation ................................................................................... 5 daily maintenanc...

Page 3: Warning

Important safety instructions when using an electrical appliance, basic precaution must always be followed, including the following: read all instructions before using this machine. This machine is for commercial use. Warning danger: the machine should never be immersed in water or a pressure jet of...

Page 4: Save These Instructions

Save these instructions warning: rotating fan blades inside the cover. Before opening cover, switch off machine.Wait until the fan/brush stops completely or dust and debris may be ejected. Warning: electrocution could occur if you handle the plug or appliance with wet hands. Do not handle plug or ap...

Page 5

Page 3.

Page 6

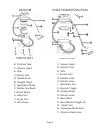

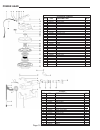

Parts list b. Purifying tank c. Vacuum head e. Tank f. Suction inlet g. Flexible hose m. Straight wand p. Upper bent wand s. Double use brush t. Round brush u. Hand tool v. Crevis tool Ω idro device vacuum injection/extraction parts list c. Vacuum head d. Solution tank e. Tank f. Suction inlet g. Fl...

Page 7

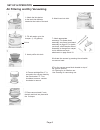

Set up & operation air filtering and dry vacuuming 1. Attach the idro device to the tank inlet deflector located at the inside of the tank. 2. Fill with water up to the bumper (1-1/2 gallons). 3. Insert purifier into tank. 4. Ensure cartridge filter “l” is secured to the vacuum head by the filter br...

Page 8: Wet Pick-Up

Wet pick-up 1. Remove idro device (if attached) from tank. 2. Insert purifier into the tank. 3. Attach hose to the inlet. 4. Attach extraction wand (see extension wand assembly, page 9. 5. Activate the vacuum by pressing the red switch on vacuum head. 6. Turn the vacuum speed control knob located on...

Page 9

Injection - extraction washing 1. Remove cartridge filter l and retainer z from vacuum head. 2. Remove air purifier and idro unit from the tank. 3. Pour cleaning solution and water into the solution tank. 4. Insert the solution tank into the recovery tank. 5. Attach the vacuum head onto the tank by ...

Page 10

Page 8 power head and wand assembly 1. Locate power head wands and locking collars. The power head wands do not have the solution hose guides. The wand pieces with the solution hose guides are for the extraction wand (see picture 1 under extraction wand assembly to identify extraction wand). Slide o...

Page 11

Page 9 extraction wand assembly 2. Firmly press the lower bent wand piece into the straight wand piece. Make sure the solution hose guides are aligned with each other. 1. Locate the lower bent wand piece and the straight wand piece. The solution hose guides molded on one side easily identify these p...

Page 12

Page 10 to change from carpet tool to double use brush attachment 1. Unclip the injection nozzle from carpet tool. 2. Remove carpet tool from lower bent wand piece. 3. Firmly press the double use brush attachment into the lower bent wand piece. 4. The injection nozzle and hose serves no function for...

Page 13

Daily maintenance caution: some detergents produce foam which will damage the vac motors. The vac shut-off may not be sensitive to all foams. Be sure to check that the tank is not filling with foam. Use a defoaming agent to avoid pulling foam through the vac motor. Should vac motor become wet, remov...

Page 14

Pos p/n description qty 1 s80117 power cord 1 2 s80138 strain relief 1 3 s80139 clamp 1 4 s81006 screw, 5 x 20 2 5 s80450 terminal, block 1 6 s82589 cover, hook 1 7 s81026 screw, 5 x 30 4 8 s82588 handle 1 9 s81050 screw, 5 x 35 2 10 s81050 screw, 5 x 35 2 11 s8231idro cover, top 1 12 s80484 switch ...

Page 15

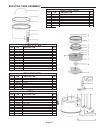

Solution tank assembly pos p/n description qty 1 s83214 handle 1 2 s82622 screw, 4.2 x 16 4 3 s82598 extension, tank 1 4 s82597 tank 1 5 s82580 sleeve 1 6 s82622 screw, 4.2 x 16 1 7 s82592 filter 1 s82638 complete solution tank solution tank pos p/n description qty 1 s83706 spacer 4 2 s83724 screw, ...

Page 16

Pos p/n description qty 1 s86167 button 1 2 s86158a curved plastic 1 3 s86188 cuff 1 4 s86160ott trigger 1 6 s86240idro wand,straight 1 7 s86261idro wand, curved 1 s86175 complete trigger wand/trigger assembly pos p/n description qty 1 s82732 spray tip housing 1 2 s83171 plastic sleeve 2 3 s82747 hy...

Page 17

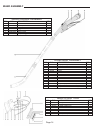

Pos p/n description qty 1 s80652/b cuff 1 2 s82824 housing 1 3 s83257 screw, 4.2 x 13 4 4 s82713 retainer, nozzle 1 5 s82759 nozzle 1 6 s82711 filter 1 7 s83060 ring 1 8 s81005 screw, 5 x 14 2 9 s82826 base, nozzle 1 10 s83171 clamp 2 11 s82658a tube, l= 75 mm 1 12 s86077 connector, male 1 s86174 co...

Page 18

Warranty policy limited warranty eagle power products (epp) warrants new cleaning equipment against defects in material and workmanship under normal use and service to the original purchaser as detailed below. 10 years subject to the conditions stated below, epp warrants polyethylene tanks and housi...