Earlex SPRAY SYSTEM HV 1900 Operating Manual - 1. Work Area Safety

EN

2

HV1900

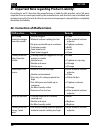

1. Explanation of symbols used

This symbol indicates a potential danger to you or for the tool.

Under this symbol you can find important information on how to

avoid injuries and damage to the power tool.

Danger of electrical shock

i

Indicates tips for use and other particularly useful information.

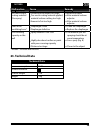

2. General Safety Instructions

CAUTION! Read all the instructions. Non-observance of the instructions below can cause

electric shock, fire and or serious personal injuries. The term "power tool" used

below covers both mains-operated power tools (with supply cord) and battery-

operated power tools (without supply cord).

1. Work area safety

a) Keep your workplace clean and well lit. Disorderly or unlit workplaces may result

in accidents.

b) Never use the tool in hazardous areas that contain flammable liquids, gases

or dusts. Power tools generate sparks that can ignite the dust or vapours.

c) Keep children and other persons away when using the power tool. You can

lose control of the tool if you are distracted.

2. Electrical safety

a) The tool plug must fit into the socket-outlet. The plug may not be modified in

any form. Do not use adaptor plugs together with protective-earthed tools.

Unmodified plugs and suitable sockets reduce the risk of an electric shock.

b) Avoid physical contact with earthed surfaces such as pipes, heating

elements, stoves and refrigerators. The risk through electric shock increases if

your body is earthed.

c) Keep the equipment away from rain and moisture. The risk of an electric shock

increases if water penetrates electrical equipment.