- DL manuals

- Eastwood

- Welding System

- TIG 200

- Instructions Manual

Eastwood TIG 200 Instructions Manual

Summary of TIG 200

Page 1

Tig200 ac/dc welder instructions item #20565.

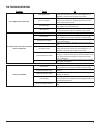

Page 2: Specs

2 tig welding is the most controllable, efficient and most versatile method of welding many metals including steel, stainless steel, aluminum and more. Your eastwood tig 200 welder with high-frequency inverter technology is capable of welding thin or heavy gauge steel and aluminum with precision and...

Page 3: Safety Information

Safety information danger indicates a hazardous situation which, if not avoided, will result in death or serious injury. Warning indicates a hazardous situation which, if not avoided, could result in death or serious injury. Caution used with the safety alert symbol, indicates a hazardous situation ...

Page 4: Safety Information

4 fumes & welding gases can be a health hazard! • fumes and gasses released during welding are hazardous. Do not breathe fumes that are produced by the welding operation. Wear an osha-approved respirator when welding. • always work in a properly ventilated area. • never weld coated materials includi...

Page 5: Required Items

5 required items before you begin using the eastwood tig welding system, make sure you have the following: • our tig 200 is supplied with the popular nema 6-50p plug, requiring a nema 6-50r receptacle. • the tig 200 will also operate on a 110-120 vac 20 amp circuit. To operate on this voltage it is ...

Page 6: Components And Controls

6 components and controls 1. Power switch – the power switch also serves as the overload circuit breaker and is located at the right of the rear panel (fig. C). 2. Amperage (front panel) – set the output amperage knob marked “a” (fig. A), located at up- per left of the top panel, to an appropriate s...

Page 7: Setup

7 setup shielding gas connection a shielding gas bottle is not included with your eastwood tig 200 but is necessary while tig welding. A shielding gas bottle can be bought at most local welding supply stores. Eastwood recommends the use of 100% argon shielding gas when tig welding steel, aluminum, a...

Page 8: Preparing To Tig Weld

8 preparing to tig weld torch disassembly 1. Make sure the welder is turned off and unplugged. 2. Remove the back cap from the torch. 3. If there is a tungsten installed in the torch pull it out of the front of the torch 4. Slide the collet out of the torch. 5. Unscrew and remove the gas nozzle. 6. ...

Page 9: Settings Selection

9 settings selection with the materials selected of which you will be welding you can begin to set up the welder for the specific material. 1. Ac/dc – the type of current will need to be selected depending on the type of material being welded. For the most part when welding steels the switch will be...

Page 10: Tig Welding

10 tig welding important note: these instructions are intended only to provide the user with some familiarity of the eastwood tig 200. Tig welding is a highly complex proce- dure with many variables. If you have no experience with tig welding; it is extremely important to seek the advice of someone ...

Page 11

11 fig. J fig. K fig. L 75° 90° 1. Turn the power switch/circuit breaker to the on position. 2. Slowly open the gas cylinder valve. Note: always open valve fully to avoid shielding gas leakage. 3. Depress gun trigger switch or foot pedal and adjust the flow regulator. (refer to data chart for actual...

Page 12: Welder Care & Maintenance

12 welder care & maintenance • constantly inspect the torch tip for excessive erosion, molten metal accumulation burning. If damaged, it must be replaced. • before each use, inspect all electrical connections, cables, supply line, torch, air supply, housing and controls for damage. If any damage or ...

Page 13: Tig Troubleshooting

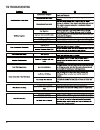

3 tig troubleshooting problem cause fix incomplete circuit check ground connection. Make sure that the ground is on a freshly cleaned surface and close to the welding area. It is suggested to weld towards the ground connection. Incorrect tungsten consult chart for proper tungsten for the base metal ...

Page 14: Tig Troubleshooting

14 tig troubleshooting.

Page 15: Stick Welding

15 stick welding 1. Plug the power cord into a properly grounded, 110-120 volt ac, 50/60hz, 20 amp or a 220-240 volt ac 50/60hz. 30 amp circuit. 2. Move the tig/stick switch to the “stick” position. 3. Make sure the electrode or “stick” is not making contact with the grounded workpiece. 4. Switch th...

Page 16: Accessories

Accessories tig wire & tungsten: #12253 er70s-2 steel tig wire 1/16-36” #12254 er70s-2 steel tig wire 3/32-36” #12375 4043 aluminum tig wire 1/16-36” #12376 4043 aluminum tig wire 3/32-36” #12463 308l stainless tig wire 1/16-36” #12464 308l stainless tig wire 3/32-36” #20176 e3 purple tungsten 1/16-...