EASY-BUILD DERBY LIGHTWEIGHT CLASS 108 DMU Assembly Instructions Manual

"EASY-BUILD" DERBY LIGHTWEIGHT CLASS

108 DMU ASSEMBLY INSTRUCTIONS.

SAFETY FIRST! CONSTRUCTING THIS KIT REQUIRES THE USE OF VOLATILE

SOLVENTS, ALWAYS FOLLOW THE MANUFACTURERS INSTRUCTIONS AND

ENSURE ADEQUATE VENTILATION. YOU WILL ALSO REQUIRE SHARP TOOLS

AND THE EDGES OF THE ETCHED PARTS CAN BE VERY SHARP SO TAKE

CARE WHEN HANDLING. WORK STEADILY AND SAFELY AT ALL TIMES.

INTRODUCTION

In order to get the most from your kit we recommend you read these instructions in full prior to

commencing construction making notes as to any assembly options, or changes to the suggested order

you think would suit your method of building better. However, we suggest you do follow to the order

of construction as we know it works! The general idea for assembly is to construct a box with a

removable floor. These are ‘honest’ instructions inasmuch that are based on our actual experience of

building the kit. If we have encountered a problem we will tell you how to get around it and where

practical future examples of this kit will be modified. Photo references will be found throughout these

instructions and consist of images taken of preserved units. Images of our Cravens units are also used

to illustrate a construction idea. To help you find the images they are identified by class and name of

photo. You will also find numerous additional prototype and model images to assist you create an

outstanding model.

GETTING STARTED

The basic steps are the same for both car types, so unless there is an operation specific to a particular

body type the instructions should be applied to both units as required.

PREPARING THE SIDES

1)

Wash all moulded parts to remove molding and machining lubricants. Check each side

molding against the edge of the end moldings. Whilst we take great care to ensure the ends of the

side molding are true and square, take a few moments to check that the ends will make a good joint

with the sides. Also, remove a small amount of the moulded rib on the inside of each side at the non-

cab ends, i.e. the baggage end of the DMBS and the toilet end of the DMCL - about 3mm is ample.

Also check all window openings for cutting burrs and remove as necessary.

2)

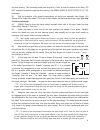

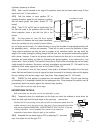

(DMBS) The power car have guard’s doors that, on the prototype, open inward. To help you

identify the sides they are marked inside 1DMBS and 2DMBS in marker-pen. The guard’s

compartment is located in the baggage area, so the guard’s door is

one of the double (baggage) doors with a window on each side. On

the 1DMBS that is the first door with a window at the right hand end;

on 2DMBS the first door with a window at the left hand end (as you

look at the side flat on the table), see right. To depict the guard’s

doors simply scribe a line between the two scribed lines that outline

DOUBLE ‘BAGGAGE’ DOORS

Scribed Line

version 5 Feb 2013