12288 brawn road, wainfleet, ontario, canada l0s 1v0 phone 905-899-3473 e-mail erw@vaxxine.Com fax 905-899-2262 installation / operating instructions for easy radiant “works” ez-duzzit infrared radiant tube heater model numbers ed-40u ed-40s 40,000 btu liquid propane or natural gas technical data st...

2 f or y our s afety i f y ou s mell g as consignes de securite s i v ous s entez u ne o deur d e g az 1. Open windows 1. Ouvrez les fenetres 2. Do not touch electrical switches, or telephone 2. Ne touchez pas aux interrupteurs electriques 3. Extinguish any open flame 3. Eteignez toute flamme nue 4....

3 clearances to combustibles the clearance to combustible materials represents the minimum distance that must be maintained between the heater and a nearby surface. The stated clearance to combustibles represents a surface temperature of 90 degree fahrenheit (32 degrees celsius) above room temperatu...

4 general installation instructions installation instructions for straight “s” series heater “s” series straight heaters consist of burner, 2-10 ft. (.6 to 3 meters) radiant tubes, 2-10 ft. (.6 to 3 meters) reflectors and four plated hangers. For access to controls, remove screw in center of doors a...

5 installation instructions for u-shaped “u” models “u” shaped models consist of burner, u-shaped 3-1/2” dia. Radiant tube heat exchanger, 2 hanging brackets and reflectors. For access to controls, remove screw in center of doors and swing open. “u” models must be suspended with the chain provided a...

6 venting all venting must be in accordance with all applicable codes 1. The maximum allowable length of vent pipe is 30 ft. (9.14 meters). This length includes the combination of inlet air vent for combustion and exhaust venting. The radiant tube is not included in this measurement. For every 90-de...

7 8. Vents for products of combustion shall not terminate less than 3 ft (.9 meters) from a combustion air inlet of any other appliance, or be less than 3 ft (.9 meters) from a building opening or be directly above a gas utility meter or service regulator. 9. The exhaust vent terminal must be instal...

8 warning this heater must be installed and serviced by a trained gas service technician only. Read and understand these instructions thoroughly before attempting to install, operate or service the easy radiant works heater. Failure to comply with these warnings and instructions, and those on the he...

9 do not use in an atmosphere containing halogenated hydrocarbons or other corrosive chemicals. Some compounds in the environment can cause an accelerated rate of corrosion to the heat exchanger. The heater manufacturer cannot anticipate all types and chemical composition of possible contaminants at...

10 warning start-up smoke condition during start up, the heating of material coatings used in the production process of tubes and reflectors will create smoke during the initial period of operation. This condition is normal and temporary. Ensure that there is sufficient ventilation to adequately cle...

11 installation in commercial aircraft hangars low intensity radiant tube heaters are suitable for use in aircraft hangars when installed in accordance with the latest edition of the standard for aircraft hangars, ansi/nfpa no. 409 in the usa, or the canadian natural gas and propane installation cod...

12 general installation procedure pre-installation survey it is recommended that a full heating design, including a heat loss calculation be conducted. Heater sizing and placement must consider available mounting height, sources of heat loss, and clearances to combustibles with respect to stored mat...

13 suspending the system inadequate or improper suspension of the tube heater can result in collapse of the system, property damage, and personal injury or death. It is the installer’s responsibility to ensure that the hardware and structural supports from which the heater is suspended are sound and...

14 gas piping 1. All gas piping and connections shall be made in accordance with local codes and can/cga b-149 or ansi standard z223.1. 2. Connect the burner to gas supply with flexible gas connector. 3. A drip leg must be installed in the gas line at the heater inlet connection tee followed by a pi...

15 warning never use a match or other flame to test for gas leaks. Use soap and water solution to check for leaks to all connections and joints and if bubbles appear, leaks have been detected and must be corrected. Never operate the heater with leaking connections. The supply system should be checke...

16 warning this heater will expand in length as it heats up. It is a normal condition that during heat-up and cool-down a tube heater will expand and contract. Allowances for heater expansion must be made in the gas connection, venting and combustion air ducting. Improper installation, alteration, o...

17 listed accessories: ac1010 ind. Thermostat 120v ac1020 agricultural thermostat ac1030 remote thermostat ac1050 agricultural thermostat ac1060 24v thermostat ac1070 flexible gas connector ac1080 outside air adapter ac1030 remote thermostat ac1100 outside air wall cap ac1110 combustion air flex duc...

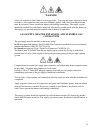

18 easy radiant works accessories easy radiant works accessories.

19 operating sequence the easy radiant gas burner is a very simple device. The normal sequence of events during ignition and operation of the burner is as follows: 1. The heater is energized by means of a thermostat or switch. 2. When 24 volts is applied to the module, the module will energize the b...

20 trouble shooting improper adjustment, alteration, service or maintenance can cause property damage, injury or death. This heater must be installed and serviced only by a trained gas service technician. If at the onset of ignition, no ignition occurs, the following should be checked. Lack of power...

21 recommended maintenance improper adjustment, alteration, service or maintenance can cause property damage, injury or death. This heater must be installed and serviced only by a trained gas service technician. Inspect the entire heater system; venting and gas supply connections, at least annually ...

22 start-up/technical support information this equipment has been factory fired and tested prior to shipment. To ensure that site conditions are compatible with the heater’s performance, the following start up needs to be completed by the qualified gas installer. A technician calling for technical s...

23 qualified installer to complete this start-up report please retain this report for technical supportt type of gas: ng lp does building have a negative condition : yes no if this is a high altitude area what is the altitude above sea level ft. Does application require fresh air to burner yes no is...

24.

25 synetek dh21260k led status indicates check/repair off no power to system control. 1. Line voltage input connectors on module. 2. Low voltage 24v and com connection on module. 3. System wiring harness in good condition and securely connected at both ends. 4. Electrical supply is live and function...

26.

27 honeywell smartvalve led status indicates check/repair off no power to system control. 1. Line voltage input power at l1 and l2 connectors on terminal board. 2. Low voltage (24v) power at 24vac and com terminals on terminal board. 3. System wiring harness in good condition and securely connected ...

28.