- DL manuals

- Easymount

- Laminator

- Cold EM-1400

- Instruction Manual

Easymount Cold EM-1400 Instruction Manual

Summary of Cold EM-1400

Page 1

Product instruction manual easymount wide format laminators the easymount has been designed to be user friendly, however we strongly recommend you take a few minutes to read through this manual to ensure correct operation. Keep this manual safe for future reference..

Page 2

Contents page 3 - introduction page 4 - safety instruction & environmental requirements page 5 - specifications page 6 - the control panel page 7 - components of the laminator page 8 - unpackaging your laminator page 9 - should be included... Page 10 - features page 11-12 - set-up page 13-15 - insta...

Page 3

Introduction thank you for purchasing the easymount laminator. Easymount is a high performance wide format mounting and laminating system with a solid construction built to last. The easymount is great for mounting prints to boards and applying pressure sensitive laminates as well as applying applic...

Page 4

Safety instructions • please ensure that the voltages of power supply you are using match with rated working voltages before operating the machine • the power supply should be close to the machine for convenient use • the power supply should provide reliable protective earthing connection • this mac...

Page 5

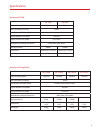

Specifications em-1400 em-1600 max laminating width 1400mm 1600mm max laminating thickness 25mm temperature of rubber roller ambient temperature approx highest line speed 6m/min approx lowest line speed 0.7m/min rated working voltage/frequency 220v, 50hz (100v, 60hz) rate input power 1000w 1300w dim...

Page 6

The control panel easymount cold easymount single hot stop reverse footswitch speed forward drive footswitch forward drive temperature adjustment down temperature adjustment up heat on / off 6.

Page 7

Components of the laminator 1. Roller lift wheel 2. Patented rollers setting 3. Lift up feed table 4. 2x emergency stop buttons 5. 3x media support brackets 6. Film mandrel 7. Laminate film mandrel 8. Take-up mandrel 7 8 3 6 5 4 2 1 6 7.

Page 8

Unpacking your easymount unpacking the laminator unpacking the laminator... Stand assembly... Position the laminator on the stand... Stand assembly laminator on stand 8.

Page 9

Should be included... 2 boxes... Box with media support brackets easymount box to include • manual • video • mandrel allen key 5mm • maintenance allen keys • safety cutter • dust cover • foot pedal • spirit level • mandrel adaptors • spare fuses 8 9.

Page 10

Features the safety guard lock can be removed to assist easy set up and re-fitted for running jobs. Remove the media bar if required, when mounting boards. The media bar helps keep prints flat going into the rollers, whilst keeping your hands away. 10

Page 11

Set-up ensure the system is positioned in a safe and convenient place, please read all safety requirements before operating your easymount. Connect the foot pedal into the relevant socket at the rear of the system. If you are operating the easymount cold system please skip the next 2 steps... The si...

Page 12

Set-up to drive the machine press either the forward drive button (left hand arrow) for continuous drive or step button (middle arrow) for the foot switch. The foot switch over rides the magic eye, it is advisable to start the machine with the foot pedal & then press the continuous button when runni...

Page 13

Installation of laminating films remove the top mandrel from the mandrel support brackets loosen the two fastening screws on one of the mandrel core grips, slide off one side. Slide on the laminating film positioning it centrally on the mandrel. Refit the core adaptor and tighten. 12 13.

Page 14

Installation of laminating films to aid lining up films the mandrels are marked with both metric & imperial mesurements. This is especially useful when lining up laminating film and vinyl. Sit the mandrel with laminate film back onto the mandrel brackets. Lock core adaptors using 5mm allen key ‘t’ w...

Page 15

Installation of laminating films the release liner take up mandrel is held in place with a spring loaded bracket: to remove push towards the spring and lift upwards slide an empty cardboard core onto the take up mandrel and replace, this helps when removing waste release liner as the whole core and ...

Page 16

Load the film as shown. Film loading feed the film with release paper attached between the rollers. Lower roller to hold in position. Using the safety cutter provided carefully slide the pointed edge between the release liner and film. Draw across, cutting the release liner only. 16.

Page 17

Film loading feed some scrap vinyl through the rollers under the film and drive forwards slowly, lifting the split release paper. Remove release liner on take up and stick the film release liner to the take up. To adjust the rollers to the correct laminating pressure wind handle in an anti clockwise...

Page 18

Alternative loading of film using the pressure handle raise the upper roller. Attach the film including release liner to the core on the take up unit. Lift feed tray. Pull the film off the take up and drape over so it goes over top & bottom roller. 18.

Page 19

Alternative loading of film remove bottom rear mandrel and fit vinyl onto the mandrel. Centralise on mandrel using the same measurements as the top roll to ensure bottom film & vinyl line up correctly. Pull vinyl forward over the front roller and stick to laminate. Both laminate and vinyl should cov...

Page 20

Alternative loading of film using a feeder board to push the film & vinyl through the rollers. The easymount is now ready to run. Add required tension to both the laminate & vinyl to make sure they run smoothly over the rollers. Showing lamination with the feed table lifted. 20

Page 21

3 media brackets space evenly on cross member for small roll of vinyl the media brackets allow rolls of media to run without being on the floor keeping everything tidy. Place your roll of media on the brackets and bring leading edge over the front of the feed tray either tape leading edge to feeder ...

Page 22

...With rollers lifted feed through the machine and attach to the take up unit (optional extra) lower the rollers until neutral position and tighten until you feel resistance, you are now ready to run the media from reel to reel. Please note: when the easymount is not in use lift the rollers to prev...

Page 23

Optional extras to fit remove blanking plates from rear of the machine one either side. 5mm allen key required. Fit motorized bracket in place of the blanking bracket - left hand side looking from the rear of the machine fit the other bracket in place of the right hand blanking plate take-up unit 22...

Page 24

Optional extras plug in the take up unit put a spare core onto the take up mandrel fit the take up mandrel (note the bracket is sprung loaded on the unmotorised unit). Then using double sided tape attach media/laminate to the core, the easymount laminator is now ready to run prints reel to reel. 24.

Page 25

Laminating adjustments temperature most pressure sensitive films benefit from around 40°c / 104°f of heat being applied to help elliminate ‘silvering’. If you dont get the desired result with 40°c / 104°f continue adding 5°c / 41°f of heat until you get the finish required. Speed adjust the speed un...

Page 26

Trouble shooting problem media lifting and wrinkling going through the rollers. This is caused by adding too much roller pressure. Solution take pressure off rollers and drop down loosely into the neutral position. The media will then correct itself and run through smoothly. 26.

Page 27

Trouble shooting problem film running loose and climbing up onto the take up core. This occurs when there is no tension added to the film. Solution firstly, ensure the core collars are tight to the shaft by tightening all 4 screws. Add tension to the film by turning the core collar in the directions...

Page 28

Trouble shooting problem media running too tight over the feed tray. This happens when the media is loaded onto the system and fed over the feed tray. Solution load media on holders supplied with the machine. Or run media loosely through the machine. Or run media from the top mandrel at the back of ...

Page 29

Trouble shooting problem creasing on laminate. This can occur when the laminate is loaded incorrectly. Solution lift rollers. Pull media tightly from the back of the system. This will enable the laminating film and media to ‘coat’ the rollers evenly. Before running, ensure that the film is smooth an...

Page 30

Warranty & incorrect use important information your laminator should reach you in perfect condition, however please retain all original packaging once you have unpacked your laminator in case you need to return it to us. If your laminator arrives damaged or faulty in anyway, this must be reported to...