Summary of C-Major

Page 1

O pe ra tin g m an ua l c-major turntable european audio team version 2.0

Page 2

2 dear music lover, important: your turntable was shipped partially disassembled in order to avoid damage to sensitive parts. Please check immediately to make sure that neither the packaging nor the device was damaged in transit. If you are missing parts or if the unit is damaged, please do not oper...

Page 3

5-6 setup 1. Transport screws 7 2. Sub-platter and drive belt installation 7-8 3. Platter installation 8 4. Tonearm assembly 4.1 cartridge assembly 9 4.2 counterweight assembly 9 4.3 vertical tracking force setting (vtf) 10 4.4 tonearm output connection 10 4.5 vertical tracking angle setting (vta) 1...

Page 4

Packaging layout 4 please do your part to help protect the environment: disposal of packaging material e.A.T. Packaging is carefully designed to protect your component from damage in transit and you are strongly urged to keep the original packaging in order to safely ship or otherwise transport your...

Page 5

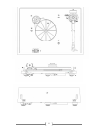

Key: controls, features and connections 1. On/off switch 2. Platter with bonded vinyl mat 3. Record clamp 4. Tonearm counterweight 5. Tonearm lift lever 6. Tonearm rest 7. Headshell with finger lift 8. Anti-skating mechanism 9. Floating sub-chassis 10. Rca output with earth connection 11. Power supp...

Page 6

6.

Page 7

Setup 1. Transport screws remove the three transport screws (15) from the carbon part of the chassis before installing the sub-platter (14), the drive belt (13) and the platter (2). The transport screws are used to ensure safe shipping and transport, and should be reinstalled prior to any future shi...

Page 8

3. Platter installation install the platter (2) on the sub-platter (14). 3a. Adjusting the pulley height in rare instances, you may have to adjust the pulley height if it taps against the platter: 4. Tonearm assembly the tonearm includes a combination of cardan and unipivot bearings, immersed in spe...

Page 9

9 4.1 cartridge installation* install the cartridge into the aluminum headshell, using the appropriate hardware included with your cartridge. Connect the cartridge as indicated below: • white • red • green • blue left channel l+ right channel r+ right channel r- left channel l- for correct cartridge...

Page 10

4.3 vertical tracking force setting (vtf) before setting the vertical tracking force, confirm the exact weight of your cartridge. Depending on your cartridge weight, determine whether to use the counterweight with or without the additional insert, in accordance with the specifications above. Pushing...

Page 11

11 4.5 vertical tracking angle setting (vta) to set the vertical tracking angle, first put a record on the platter. When the needle is lowered into the record groove, the tube of the tonearm should be parallel to the surface of the record. If it is not, loosen both hexagonal screws in the tonearm ba...

Page 12

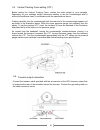

12 4.7 anti-skating assembly and adjustment the anti-skating mechanism is shipped partially disassembled to avoid damage during transport. For correct installation, please follow the steps below. Step 1: prepare all parts supplied from the accessories bag: • anti-skating sliding mechanism with anti-...

Page 13

13 put the anti-skating sliding mechanism on the end of the anti-skating support rod. The anti-skating thread should fit into the groove in the tonearm. Be careful when handing the anti-skating thread in order to avoid damaging it. ! Step 4: step 5: anti-skating force adjustment: adjust the anti-ska...

Page 14

5. Leveling the turntable three precision adjustable damped feet are mounted under the turntable for leveling the turntable. Once the turntable is in final position, put the supplied spirit level on the carbon fiber sub-chassis, and then level the turntable by screwing or unscrewing the feet as need...

Page 15

15 technical specifications e.A.T. C-major model c-major nominal speed 33/45 rpm, manual speed change speed variance 33rpm: ± wow and flutter 33rpm: ± signal to noise s/n ratio (mechanical noise): - 40 db s/n ratio (electrical noise): -68 db downforce range 0 - 30 mn 0 - 3.0 grams supplied counterwe...

Page 16

Troubleshooting the platter doesn’t turn although the unit is switched on: • the unit is not connected to the mains power supply (the building’s electrical system). • no mains power is being delivered at the socket. • the drive belt is not fitted properly or has slipped off. No signal through one or...