- DL manuals

- Eberspächer

- Heater

- D8LC

- Installation, Operation And Maintenance Instructions

Eberspächer D8LC Installation, Operation And Maintenance Instructions

Summary of D8LC

Page 1

Heater order no. D 8 l c – 12 volt 25 1890 00 00 00 d 8 l c – 24 volt 25 1891 00 00 00 air heater 8 l technical description, installation, operation and maintenance instructions. Engine-independent air heater for diesel fuel 25 1891 90 96 66 04.2009.

Page 2

2 8 7 6 5 4 3 2 1 introduction 1 contents chapter title contents introduction product information installation operation and function • concept of this manual ......................................................................... 3 • special text structure, presentation and picture symbols .........

Page 3

3 1 concept of this manual introduction introduction here you will find important introductory information about installation of the heater and about the structure of the manual. Product information here you will find information about the scope of supply, the technical data and the dimensi- ons of ...

Page 4

4 1 introduction this manual uses special text structures and picture symbols to emphasise different contents. Please refer to the examples below for the correspon- ding meanings and associated actions. Special structure and presentations a dot (•) indicates a list which is started by a hea- ding. I...

Page 5

5 the federal road transport directorate has issued an "ec type approval" and an "emc type approval" for the heater for installation in motor vehicles and with the following official type approval marks, noted on the heater name plate. Air heater 8 l ec- e1 00 0028 emc- e1 021067 statutory regulatio...

Page 6

6 1 introduction • compliance with the statutory regulations, the additional regulations and safety instructions is prerequisite for guarantee and liability claims. Failure to comply with the statutory regulations and safety instructions and incorrect repairs even when using original spare parts mak...

Page 7

7 safety instructions for installation and operation danger! Risk of injury, fire and poisoning! • the heater must only be started up when the maintenance flap is closed and the outlet hood is mounted in position. • the maintenance flap must not be opened during operation. • disconnect the vehicle b...

Page 8

8 product information 2 scope of supply for air heater d 8 l c quantity / designation order number 1 8 l – 12 volt 25 1890 00 00 00 1 8 l – 24 volt 25 1891 00 00 00 scope of supply basic heater, pre-mounted 1 d 8 l c – 12 v 1 d 8 l c – 24 v 1 dosing pump with mounted fuel filter and holder 1 control...

Page 9

9 product information 2 scope of supply.

Page 10

10 caution! Safety instructions for technical data! Failure to comply with the technical data can result in malfunctions. Provided no limit values are given, the technical data listed is subject to the tolerances usually applicable to heaters of ±10% for nominal voltage, ambient tem- perature 20 °c ...

Page 11

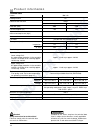

11 2 product information main dimensions 1 minimum installation clearance (space) for intake of heater air. 2 minimum installation space (free space) for opening the lid and removing the glow plug and controller. - + 1 100 103 370 653 42 190 165 260 110 80 145 1m 250 2 1 323 + 1,5 0 - + 1.

Page 12

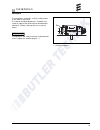

12 location installation position in a coach or bus. The heater is installed in a coach or bus preferably in a separate, splash-proof position outside the passen- ger compartment. If there is no space available outside the passenger compartment, the heater can also be installed in a 3 installation i...

Page 13

13 3 installation installation position in a truck cargo compartment for cargo compartment heating, the heater is fa- stened in a splash-proof position on the vehicle prefe- rably in a box outside the cargo compartment. If no suitable place is available outside the cargo compartment, then the heater...

Page 14

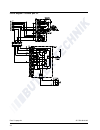

14 mounting and fastening the heater can be fastened to the floor of the vehicle or to a vertical vehicle wall using the anti-vibration pads. Drill the 4 holes for the two fastening brackets and the breakthrough for the exhaust pipe in the floor or wall of the vehicle. 3 installation possible instal...

Page 15

15 3 installation nameplate the nameplate is fastened in a clearly visible position to the jacket of the heater. The second nameplate (duplicate) is included in the scope of supply of the heater and can be adhered as required in a clearly visible position on or near the heater. The regulations and s...

Page 16

16 3 installation heater air system (example) danger! Risk of burning and injuries! • the hoses of the heater air system and the hot air outlet are to be routed and fastened in such a way that they pose no temperature risk to people, animals or materials sensitive to temperature from radiation / con...

Page 17

17 3 installation mounting the exhaust system fasten the flexible exhaust pipe Ø42 mm to the ex- haust fitting of the heater using a pipe clip. If a rigid exhaust pipe is to be used, connect it to the exhaust fitting of the heater with an exhaust pipe bend. Route the flexible or rigid exhaust pipe a...

Page 18

18 3 installation caution! Safety instructions for the combustion air system! • the combustion air opening must be free at all times. • position the combustion air intake to be sure that exhaust fumes cannot be sucked in with the combustion air. • do not arrange the combustion air intake to poin- ti...

Page 19

19 3 installation mounting the dosing pump, routing the fuel pipes and mounting the fuel tank the following safety instructions must be observed when mounting the dosing pump, routing the fuel pipes and mounting the fuel tank. Deviations from the instructions stated here are not allowed. Failure to ...

Page 20

20 fuel feed point with t-piece from the fuel supply line from the tank fitting to the vehicle engine 1 fuel feed pipe from tank connection 2 fuel return pipe to the tank connection 3 dosing pump 4 t-piece 5 fuel filter – only necessary for contaminated fuel. 6 fuel hose, 5 x 3 (di = Ø 5 mm) 7 fuel ...

Page 21

21 fuel feed point with tank connection – ascending pipe, integrated in the vehicle tank or in the tank fitting 1 tank connection for metal tank, di = Ø 4 mm 2 dosing pump 3 fuel filter – only necessary for contaminated fuel. 4 fuel hose, 5 x 3 (di = Ø 5 mm) 5 fuel pipe, 6 x 1 (di = Ø 4 mm) 6 fuel h...

Page 22

22 possible suction and pressure height of the dosing pump pressure height from vehicle tank to dosing pump: a = max. 1000 mm intake height in pressure-less vehicle tank: b = max. 750 mm intake height in vehicle tanks with withdrawal by negative pressure (valve with 0.03 bar in tank cap): b = max. 4...

Page 23

23 • mixtures with used oil are not allowed! • after refuelling with winter or cold diesel or the listed blends, the fuel pipes and the dosing pump must be filled with the new fuel by letting the heater run for 15 mins.! Operation with biodiesel (pme) the heater is not certified for operation with b...

Page 24

24 the heater is controlled by the operating device (heating / ventilation). The control element is included in the scope of supp- ly. It is necessary to operate the heater. A heater timer can also be installed in addition to the operating device. The heating timer can be used to switch the heater o...

Page 25

25 switching on. When the heater is switched on, the control lamp in the control element lights up. The glow plug is switched on and the fan starts at maximum speed. Starting the heater after approx. 25 seconds, the dosing pump starts to supply fuel for the control stage “large”. Once a sta- ble fla...

Page 26

26 * the controller can be enabled again and the faults read off: • using the module timer • using the radio remote control tp5. For other controls: • by connecting up a diagnosis unit • using the customer service program kd2000. For operation and fault list, please refer to the enclosed operating i...

Page 27

27 caution! Safety instructions for wiring the heater! The heater is to be connected up electrically accor- ding to the emc directives. Emc can be affected if the heater is not connected up correctly. For this reason, comply with the follo- wing instructions: • ensure that the insulation of electric...

Page 28

28 2.5.9 ventilation relay 2.15.1 temperature sensor (room temperature) 2.15.9 temperature sensor (outside temperature) 3.1.11 controll device circular 3.1.12 fault code query, optional 3.1.16 button, radio remote control 3.1.18 button, calltronic 3.2.8 timer (adr – potentiometer) 3.2.9 timer, adr 3...

Page 29

29 electrical system 5 parts list for the circuit diagrams easystart r+ / r / t the circuit diagrams are printed at the end of this manual. 2.5.9 ventilation relay 2.15.1 temperature sensor (room temperature) (included in the easystart r+ scope of supply, optional for easystart r / t) 2.15.9 externa...

Page 30

30 • if the heater does not start after being switched on: – switch the heater off and on again. • if the heater still does not start, check whether: – there is fuel in the tank? – the fuses are ok? – the electrical cables, connections etc. Are ok? – anything is clogging the combustion air supply or...

Page 31

31 with regard to the following products air heater type 8 l we herewith confirm that it conforms with the prime safety requirements stipulated in the directives of the eu council for harmonisation of the legal regulations of the member states with regard to electromagnetic compatibility (89 / 336 /...

Page 32

32 a accident prevention ................................................... 7 adr / adr99 .................................................... 12, 26 ambient temperature ................................................ 10 c certificates .................................................................

Page 33

33 t technical data .......................................................... 10 temperature selection .............................................. 25 test symbol ................................................................. 5 text structure ......................................................

Page 34

34 circuit diagram air heater 8 l parts list page 28 25 1766 00 96 01 f.

Page 35

35 parts list page 28 circuit diagram – controls part 1 25 1766 00 96 01 f.

Page 36

36 parts list page 28 25 1766 00 96 03 circuit diagram – controls part 2.

Page 37

37 parts list page 28 25 1766 00 96 02 circuit diagram – controls part 3.1.

Page 38

38 circuit diagram – controls part 3.2 parts list page 28 25 1766 00 96 02.

Page 39

39 circuit diagram – controls part 4 parts list page 28 25 1766 00 96 04.

Page 40

40 25 1890 00 97 01 c parts list page 29 circuit diagram – control unit easystart r+.

Page 41

41 25 1890 00 97 01 c parts list page 29 circuit diagram – control unit easystart r+.

Page 42

42 parts list page 29 25 1890 00 97 02 b circuit diagram – control unit easystart r.

Page 43

43 parts list page 29 25 1890 00 97 02 b circuit diagram – control unit easystart r.

Page 44

44 parts list page 29 25 1890 00 97 03 a circuit diagram – control unit easystart t.

Page 45

45 parts list page 29 25 1890 00 97 03 a circuit diagram – control unit easystart t.

Page 48: Www.Eberspaecher.Com

Www.Eberspaecher.Com j. Eberspächer gmbh & co. Kg eberspächerstr. 24 d - 73730 esslingen telefon 0711 939 - 00 telefax 0711 939 - 0643 info@eberspaecher.Com 25 1891 90 96 66 en 04.2009 subject to changes printed in germany © j. Eberspächer gmbh & co. Kg.