1 d s gb f documentation for installation* eberspächer ® subject to change b 4 w sc and b 5 w sc technical description mounting instructions j. Eberspächer gmbh & co. Kg eberspächerstr. 24 d - 73730 esslingen telefon (zentral) (0711) 939 - 00 telefax (0711) 939 - 0500 www.Eberspaecher.Com contents p...

2 d s gb f control elements, optional quantity / designation order no. 1 mini-clock – 12 / 24 volt 22 1000 31 31 00 the mini-clock can be combined with the tp41i radio remote control. 1 module clock – 12 / 24 volt 22 1000 30 34 00 the module clock can be combined with the tp4i radio remote control. ...

3 d s gb f scope of the delivery 햲 hydronic b 4 w sc / b 5 w sc 햳 dosing pump parts without drawing number are included in the universal mounting kit. Cable harness “control elements” cable harness “fan control” positive cable negative cable a b c d.

4 d s gb f attention ! ! § safety instructions concerning the installation and repair of the hydronic danger of burns and injury! Before commencing any work on the hydronic, disconnect the vehicle battery. Always switch off the hydronic prior to any repair work and allow hot components to cool down....

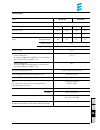

5 d s gb f technical data heater b 4 w sc b 5 w sc heating medium water, coolant heat flow settings large small large small heat flow (watt) 4300 1500 5000 1500 fuel consumption (l/h) 0.6 0.2 0.69 0.2 average electrical power consumption (watt) during operation 48 22 50 22 when starting 120 during a...

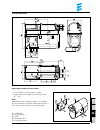

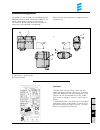

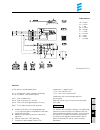

6 d s gb f sectional drawing (shown here is the hydronic b 5 w sc) 1 1 electric motor 1 2 controller 1 3 combustion air blower 1 4 intersection / 8-channel connector 1 5 fan relay 1 6 fuse carrier 1 7 mini-clock 1 8 fuel connection 1 9 vent screw 10 water pump 11 overheating sensor 12 heat exchanger...

7 d s gb f principal dimensions mounting the heater onto the holder • insert heater in retaining lugs on holder. • screw heater onto holder with fastening screw (6 +0.5 nm). Note: depending on the installation space, it is possible to move the heater inside the holder and to secure it with screws in...

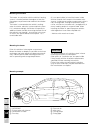

8 d s gb f mounting instructions the heater, in conjunction with the vehicle’s heating system, is used to preheat the engine, to heat the passenger compartment and to defrost the window panes. The heater is connected to the vehicle’s cooling- water circulation, electrical system and fuel system. If ...

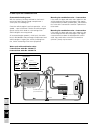

9 d s gb f permissible mounting positions or type plate the type plate must be clearly visible after the heater has been installed. If necessary, a second type plate (duplicate) with the same details as the original one can be mounted at a clearly visible point on the air heater or a cover in front ...

10 d s gb f connection to the cooling water circuit a careful deaeration of the water cycle (including heater) after installation of the heater is necessary for the perfect functioning of the device: 1. Fill heater and water hoses with coolant after instal- lation, but before connection to the cooli...

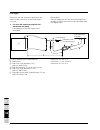

11 d s gb f please note! Execute connections 1, 2 and 3 as described in the drawing. 2. As “1”, but check valve parallel to the heater in the pipe from the engine to the vehicle’s heat exchanger characteristic heating curve as for water cycle “1” advantage: no loss of efficacy of engine heating with...

12 d s gb f 4. Water cycle with combination valve characteristic heating curve: with the stationary heating switched on, the heat is exclusively fed to the passenger compartment = small cycle, fast heating up. Once the vehicle engine is put into operation – at low speed – a part of the heat is fed t...

13 d s gb f bis 2 m bis 1,5 m 2 3 4 5 1 conducting the combustion air / exhaust gas conducting the combustion air the combustion air must be drawn in from the out- side (not from the passenger compartment or boot). As described in these mounting instructions, the heater is installed inside the engin...

14 d s gb f fuel supply deviations from the instructions given here are impermissible, otherwise functional disorders can arise. 1. For cars with carburetor engines with mechanical fuel pump fuel tapping from the fuel supply line to the engine. Precondition: the fuel supply line from the tank to the...

15 d s gb f 2. For cars with fuel injected engines the fuel tapping from the fuel supply line of cars after the conveying pump is generally prohibited as pressures up to 10 bar do occur. The following possibilities exist: 2.1 fuel tapping from the tank with separate rising pipe. For cars the rising ...

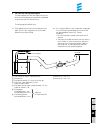

16 d s gb f mounting position of the dosing pump permissible suction and pressure level of the dosing pump 햲 dosing pump 햳 maximum fuel level 햴 minimum fuel level 햵 connection on the heater mounting position of the dosing pump mount the dosing pump in the vehicle with the pres- sure side rising by a...

17 d s gb f • always fasten the fuel pipes at intervals of approx. 50 cm. • always use a rubber hose to connect the fuel branching piece – never use a plastic pipe. • the fuel pipe must always be butt-jointed where there is a connection between fuel pipes and a fuel hose (see drawing a). • when inco...

18 d s gb f circuit diagram hydronic b 4 w sc / b 5 w sc 25 1920 00 96 01 d.

19 d s gb f parts list 1.1 burner motor 1.2 glow plug 1.5 overheating and flame sensor 1.12 flame sensor 1.13 temperature probe 2.1 controller 2.2 dosing pump 2.5.7 relay, vehicle fan 2.7 main fuse 20 a 2.7.1 fuse, actuation 5 a 2.7.5 fuse, vehicle fan 25 a 2.12 water pump 5.1 batterie 5.1.2 fuse st...

20 d s gb f circuit diagram control elements – part 1 25 1920 00 97 01 c.

21 d s gb f 25 1920 00 97 01 c parts list 2.15.9 sensor, outside temperature 3.1.9 change-over switch ‘heating / ventilating’ 3.1.16 key button, radio remote control 3.2.9 timer, module clock 3.2.12 timer, mini-clock 12 / 24 volts 3.2.14 timer, mini-clock lightning (only 12 volts) 3.3.6 tp 41i radio...

22 d s gb f 25 1920 00 97 02 a circuit diagram control elements – part 2.

23 d s gb f 25 1920 00 97 02 a cable colours sw = black ws = white rt = red ge = yellow gn = green vi = violet br = brown gr = grey bl = blew li = purple parts list 2.15.9 sensor, outside temperature 3.1.16 key button, radio remote control 3.1.18 calltronic push-button 3.2.12 timer, mini-clock 12 / ...

24 d s gb f function depending on the wiring, the heater can be operated as purely stationary heater or as combined stationary and auxiliary heater to compensate for an insufficient output of heat by the vehicle engine. Stationary heating operation switching on the pilot lamp in the control unit lig...

25 d s gb f controls and safety devices • if the heater does not ignite within 90 seconds after fuel pumping has started, then the start procedure must be repeated in the described manner. A fault shut-down is effected if the air heater once again fails to ignite after 90 seconds of fuel pumping. Af...