- DL manuals

- Eberspächer

- Heater

- Hydronic B5 S

- Installation Instructions Manual

Eberspächer Hydronic B5 S Installation Instructions Manual

Summary of Hydronic B5 S

Page 1

Part number: 13438560 13 439 373 12/12.

Page 2

3 new vehicle-specifi c installation kit + heater installation recommendations eberspächer 24 8756 90 20 00 12.2012 we reserve the right to make changes printed in germany © j. Eberspächer gmbh & co. Kg page 5 water circuit 19 6 fuel supply 27 7 after installation 33 8 parts overview 36 contents page...

Page 3

4 1 introduction important! Safety instructions for installation and repair! Improper installation or repair of eberspächer heaters can cause a fi re or result in poisonous exhaust fumes entering the vehicle interior. This can pose a serious risk to life and limb. The heater may only be installed ac...

Page 4

5 1 introduction tightening torques if no tightening torques are specifi ed, tighten the screw con- nections (hexagon screw and hexagon nut) according to the following table. Screwed connections tightening torques m6 10 nm m8 20 nm m10 45 nm other tightening torques: • wiper arms on linkage 35 nm • ...

Page 5

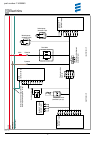

6 2 electrics position of the components (see photo 1) cable laying (cable loom 1) (see photos 2 to 9 and 19) water pump cable connection, cable loom 2 metering pump cable with connector connection, heater earth cable positive cable fuses figure 1 heater fuse holder cable grommet cable laying positi...

Page 6

7 2 electrics photo 5 10-pin connector from cable loom 1 lay the connection to cable loom 2 through the cable pen- etration made in the engine partition and into the interior of the vehicle. Use body sealing compound to seal the cable grommet inserted in the engine partition. Route the 10-pin connec...

Page 7

8 photo 7 fuse block install the fuse block beneath the wiper tray along the engine partition to the left side of the vehicle as shown. Fasten the fuse block to the fuse holder using two m4 x 10 fi llister head screws as shown. Route the 4 mm² rt positive cable from cable loom 1 to the battery fuse ...

Page 8

9 2 electrics fasten the holder for the svm module and the r + receiver to the right retaining strut of the centre console using two m6 x 12 screws as shown. Photo 11 right retaining strut of the centre console holder of the svm module and r + receiver fasten the svm module and the easystart r + rec...

Page 9

10 2 electrics mount the premounted right retaining strut of the centre con- sole using the vehicle's m8 screws. Photo 14 right retaining strut mounted connect the black 6-pin connector and the black 4-pin con- nector. Slot the 1 mm 2 ws cable in pin 1 of the grey 2-pin connector and the 1 mm 2 br /...

Page 10

11 2 electrics mount the temperature sensor in the passenger footwell to the a-pillar panelling using an m2.9 x 25 screw as shown. Photo 17 temperature sensor mounted photo 18 button mounted drill a 16 mm Ø hole on the right side of the glove compart- ment for the button as shown and insert the butt...

Page 11

12 2 electrics photo 19 plug-in connection 6-pin, sw svm (connector 26-pin) button easystart r (connector 4-pin) + easystart r (connector 12-pin) + plug-in connection diagnosis (connector 1-pin) (lead harness 1) (lead harness 2) parking heater hydronic ii (connector 10-pin) metering pump (connector ...

Page 12

13 3 installation - heater photo 20 drill a 9 mm Ø hole existing m6 stud bolt prepare the installation position (see photos 20 and 21) on the outside of the front right chassis beam, drill a 9 mm Ø hole in the middle of each of the ribbed points as shown and insert an m6 blind rivet nut in each case...

Page 13

14 3 installation - heater premount heater and affi x duplicate nameplate (see photos 24 to 28) insert four rubber buffers and two spacer sleeves (note instal- lation direction) as shown. Remove the duplicate nameplate from the heater. Photo 24 unit holder rubber buffers inserted spacer sleeve insert...

Page 14

15 3 installation - heater connect the combustion air pipe to the heater with a 16-25 mm Ø hose clip and fasten to the heater using a 28 mm Ø clamp and an m6 x 16 screw as shown. Push the end sleeve onto the inlet side of the combustion air pipe. Connect the 4 x 1.25 mm Ø fuel pipe with 3.5 x 3 x 10...

Page 15

16 3 installation - heater photo 29 unit holder mounted mount the prepared unit bracket, route the combustion air pipe and route the 1 x 1.25 mm Ø fuel pipe (see photos 29 to 34) mount the prepared unit bracket to the two prepared upper fi xing points using two m6 x 20 screws and two b6 body washers...

Page 16

17 3 installation - heater photo 33 fuel pipe, Ø 1 x 1.25 mm, routed route the 1 x 1.25 mm Ø fuel pipe to the middle of the engine partition and on to the vehicle underbody as shown. Please note! When laying fuel lines, always ensure they are at an adequate distance from hot vehicle and heater parts...

Page 17

18 4 exhaust system photo 36 exhaust silencer installed premount exhaust silencer (see photo 35) mount the bracket for the exhaust silencer to the exhaust silencer using an m6 x 12 screw. Push a piece of exhaust insulation onto the exhaust pipe and shape as shown. Connect the exhaust pipe to the inl...

Page 18

19 5 water circuit photo 37 5 6 1 - heizgerät 2 - wasserpumpe 3 - Übergangsrohr 5 - fahrzeugwärmetauscher 6 - motor - schlauchschelle - Ø 15 mm 4 schnellkupplung Ø 20 - 32 mm oder - wasserschlauch 1 - wasserschlauch 2 - wasserschlauch 3 Ø 16 - 25 mm 2 3 4 1 heater water pump adapter pipe, 15 mm Ø qu...

Page 19

20 5 water circuit lay and connect water hoses (see photos 38 to 45 and 37) connect water hose 1 "engine - heater" to the water inlet con- nection of the heater using a 16-25 mm Ø hose clip. Connect water hose 3 "water pump - heat exchanger" to the discharge end of the water pump using a 16-25 mm Ø ...

Page 20

21 5 water circuit fasten water hose 1 with a rubberised 26 mm Ø clip and an m6 nut to the premounted m6 x 25 screw as shown. Photo 41 water hose 1 water hose 3 clip, rubberised, 26 mm Ø, mounted route water hoses 1 and 3 along the front right-hand chassis beam to the water cutting point. Fasten wat...

Page 21

22 5 water circuit photo 44 water hose 1 routed cable ties water hose 3 routed take water hose 3 below the vehicle's air-con line as shown and route it on to the left along the engine partition to the cut- ting point. Take water hose 1 to the left along the vehicle's air-con line to the cutting poin...

Page 22

23 5 water circuit use the quick-release hose coupling to connect water hose 3 to the top connection of the heat exchanger. Use cable ties to secure the water hoses at suitable points as shown. Photo 48 water hose 3 connected cable ties secure all hose connections with hose clips. Protect the water ...

Page 23

24 for vehicles with 1.7 cdti engine disconnect the water fl ow hose and integrate water hoses 1 and 3 (see photos 50 to 52) cut the water fl ow hose from the engine to the heat exchang- er (the top water hose at the heat exchanger) according to the dimensions shown in the photo. Pull off the couplin...

Page 24

25 5 water circuit for vehicles with 1.3 cdti engine disconnect the water fl ow hose and integrate water hoses 1 and 3 (see photos 53 to 55) cut the water fl ow hose from the engine to the heat exchang- er (the top water hose at the heat exchanger) according to the dimensions shown in the photo. Pull...

Page 25

26 5 water circuit prepare wiper tray cover (see photo 56) after mounting the water hoses, prepare the dismantled water hose as shown and mount again. Drill two 5 mm Ø holes on the left side of the wiper tray cover in the dimensions shown. Photo 56 wiper tray cover prepared 13 14 60 30 photo 57 prep...

Page 26

27 6 fuel supply please note! Photo 59 for vehicles with 1.4 ecotec engine install fuel tank extractor (see photos 59 to 62) prepare the riser pipe of the fuel tank extractor as shown in the photo. When drilling, ensure that no dirt gets into the tank or supply lines. Remove the tank according to th...

Page 27

28 6 fuel supply the tank fi tting should not be removed for longer than 10 minutes because of expansion of the tank! Please note! Guide the prepared tank extractor through the drilled hole, screw tight with the m8 nut and align as shown. Figure 61 fuel tank extractor mounted figure 62 fuel tank ext...

Page 28

29 6 fuel supply please note! The tank fi tting should not be removed for longer than 10 minutes because of expansion of the tank! When drilling, ensure that no dirt gets into the tank or supply lines. Figure 63 for vehicles with 1.3 and 1.7 cdti engine install fuel tank extractor (see photos 63 to ...

Page 29

30 6 fuel supply the tank fi tting should not be removed for longer than 10 minutes because of expansion of the tank! Please note! Take the prepared tank extractor through the drilled hole, screw tight with the m8 nut and align as shown. Figure 65 fuel tank extractor mounted figure 66 fuel tank extr...

Page 30

31 6 fuel supply install and connect the metering pump (see photos 67 to 69) the installation position for the metering pump is located to the left of the tank at the rear opening of the left chassis beam. Insert the metering pump in the rubber holder and screw the rubber holder to the holder stud b...

Page 31

32 6 fuel supply figure 70 "refuel" label adhered adhere the "fuel tank" sticker (see photo 70) stick the "refuel" information sticker on the inside of the fuel tank fl ap as shown. Part number: 13438560

Page 32

33 7 after installation fill the cooling system only with the coolant liquid specifi ed by the vehicle manufacturer. Please note! Starting up the heater • switch on the heater at the control. See operating instructions - control. Complete the vehicle • comply with the manufacturers' guidelines/instr...

Page 33

34 10 the submenu c1 has been selected: after the individual menu items have been set to of or on using or or selected using or and confirmed with , they are displayed step by step. If the menu item c1 / 07 has been confirmed with the data is trans- ferred. Then the time is displayed. The system con...

Page 34

35 11 teach additional mobile unit • press the pushbutton installed in the vehicle until the pushbutton‘s led begins to flash. • activate mobile unit. • select symbol using or and confirm with . The additional mobile unit has been taught. Activate mobile unit confirm symbol with . Heater is switched...

Page 35

36 8 parts overview no. Designation quantity order number 1 vehicle-specifi c additional parts 13438560 hose holder, rotatable, 22-24 hose holder, rotatable, 4.3-5 holder 4.3-10 hex screw m6 x 20 hex screw m6x12 hex screw m6x30 din933 hex screw m6x25 hex screw m6x50 din931 washer Ø6.4x18 iso7093 col...

Page 36

37 8 parts overview no. Designation quantity order number 1 vehicle-specifi c additional parts 13438560 relay 20a n/o contact mini emergency button insulation collar screw st5x20 clamp nut, pale blue ejot heater holder fuse holder exhaust holder control box ffb holder hose heater inlet spacer horn, ...