- DL manuals

- Echo

- Chainsaw

- CHAIN SAW CS-330T

- Instruction Manual

Echo CHAIN SAW CS-330T Instruction Manual

X7503242504

X750009914

04/12

WARNING

Users of this equipment risk injury to themselves and others if the unit is used improperly

and/or safety precautions are not followed. ECHO provides an operator’s manual and a

safety manual. Both must be read and understood for proper and safe operation. Failure to

do so could result in serious injury.

Chain Saw

Instruction Manual

MODELS : CS-330T

CS-360T

Summary of CHAIN SAW CS-330T

Page 1

X7503242504 x750009914 04/12 warning users of this equipment risk injury to themselves and others if the unit is used improperly and/or safety precautions are not followed. Echo provides an operator’s manual and a safety manual. Both must be read and understood for proper and safe operation. Failure...

Page 2

2 r ules for s afe o peration a. Kickback safety precautions for chain saw users copyright© 2012 by echo, incorporated all rights reserved. B. Other safety precautions 1. Do not operate a chain saw with one hand! Serious injury to the operator, helpers, bystanders, or any com- bination of these pers...

Page 3

3 14. Keep the handles dry, clean, and free of oil or fuel mixture. 15. Operate the chain saw only in well-ventilated areas. 16. Do not operate a chain saw in a tree unless you have been specifically trained to do so. 17. All chain saw service, other than the items listed in the instruction manual m...

Page 4: Symbols And Signs

4 warning the safety alert symbol accompanied by the word “warning” calls attention to an act or condition which can lead to serious personal injury or death if not avoided. Circle and slash symbol this symbol means the specific action shown is prohibited. Ignoring these prohibitions can result in s...

Page 5

5 carburetor adjustment - idle speed carburetor adjustment - high speed mixture carefully read the instruction manual wear eyes, ears and head protection carburetor adjustment - low speed mixture oil and gasoline mixture symbol form/shape symbol description/application symbol form/shape symbol descr...

Page 6

6 d escription the echo product you purchased has been factory pre-assembled for your convenience. Due to packaging restric- tions, guide bar and saw chain installation and other assembly may be necessary. After opening the carton, check for damage. Immediately notify your retailer or echo dealer of...

Page 7

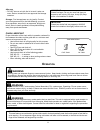

7 1. Hand guard (chain brake actuating lever) 2. Ignition/choke lever 3. Throttle control trigger 4. Throttle control lockout 5. Air cleaner cover 6. Pull starter 7. Front handle 8. Oil tank cap n omenclature of p arts cs-330t, cs-360t 10 11 12 13 14 9. Fuel tank cap 10. Saw chain 11. Guide bar 15 1...

Page 8

8 kick guard® to bar instructions for saws with kick guard ® p/n 2894901 and symmetri- cal or asymmetrical low-kick type guide bars. 1. Install bolt (a) in rear hole (b) of kick guard ® and through front hole (c) in guide bar. 2. Important: dimple in kick guard ® (d) must engage recess in guide bar ...

Page 9

9 p o 7. Turn saw over and check brake band (o) for cor- rect position around clutch drum (p). If brake band is not in place around drum, remove clutch cover, make sure brake is released, and reinstall. Danger never operate saw if chain brake does not function properly, otherwise saw damage and seri...

Page 10

10 notice: use of unmixed, improperly mixed, or fuel older than 90 days, (stale fuel), may cause hard starting, poor performance, or severe engine damage and void the product warranty. Read and follow instructions in the storage section of this manual. Fuel statement warning alternative fuels, such ...

Page 11

11 o peration important this saw features a combination ignition/choke switch that automatically sets the throttle speed to fast idle for quick starting. Do not squeeze trigger during cold starts until after unit has started, or fast idle and choke set- tings will be released, and engine may not sta...

Page 12

12 5. Lay unit on a flat, clear area and keep bar and chain clear of all obstacles. Hold top handle with one hand, and depress throttle trigger lockout (c), but do not depress throttle trigger (d). 6. Pull starter handle (f) several times until engine starts, or first starting sound is heard. (7 pul...

Page 13

13 a a e d d stopping 1. Release throttle trigger (d) and move lever (a) rearward to stop ( o ) position. 2. Move chain brake lever (e) fully forward to lock chain brake. Note if engine does not stop, move ignition/choke lever forward to choke position ( ) to stop engine. Return the unit to your aut...

Page 14

14 warning read the echo “chain saw safety manual” included with your chain saw for additional cutting and safety instruc- tions. Failure to obey all instructions may result in serious or fatal injuries. In all circumstances the operation of the chain saw is a one-man job. It is difficult at times t...

Page 15

15 warning a falling tree can seriously damage anything it may hit - a car, a house, a fence, a power line, or another tree. There are ways to make a tree fall where you want it, so first decide where that is! Before cutting, clear the area around the tree. You will need good footing while working a...

Page 16

16 don’t cut with the saw overhead or the bar in a vertical po- sition. If the saw should kick back you may not have good enough control to prevent possible injury. Bucking is the sawing of a log or fallen tree into smaller pieces. There are a few basic rules which apply to all bucking operations. K...

Page 17

17 m aintenance and c are warning moving parts can amputate fingers or cause severe injuries. Keep hands, clothing and loose objects away from all openings. Always stop engine, disconnect spark plug, and make sure all moving parts have come to a com- plete stop before removing obstructions, clearing...

Page 18

18 air filter 1. Close choke (cold start position [ ]). This prevents dirt from entering the carburetor throat when the air filter is removed. Brush accumulated dirt from air cleaner area. 2. Remove air filter cover. Brush dirt from inside cover. 3. Remove air filter and lightly brush debris from fi...

Page 19

19 a b c guide bars and oil holes • follow instructions for “guide bar and saw chain – install/re - move”. • clean after each use -clean the grooves (a) of the guide bar with a small screw- driver. -clean oil holes (b) with a wire. Note: symmetrical shaped guide bars should be inverted each time the...

Page 20

20 d starter side 1. Remove air filter cover and remove spark plug lead. 2. Remove plastic plug in side handle mount (d), and remove side handle mounting screw. 3. Remove four starter cover screws and remove starter cover. 4. Using a stiff bristle cleaning brush (do not use a metal brush), remove de...

Page 21

21 b c d e f g 6. Use a wood or plastic scraping tool to clean deposits from cylinder exhaust ports (g). 5. Remove muffler nuts (b), washer sets (c), eyeplate (d), muffler (e), and muffler gasket (f). Check parts for wear or damage, and replace if necessary. Important if muffler mounting studs loose...

Page 22

22 carburetor adjustment engine break-in new engines must be operated a minimum duration of two tanks of fuel break-in before carburetor adjustments can be made. Dur- ing the break-in period your engine performance will increase and exhaust emissions will stabilize. Idle speed can be adjusted as req...

Page 23

23 high altitude adjustment 1. Start engine and run for several minutes to reach operating temperature. 2. Stop engine. 3. Start engine and turn the hi speed needle (a) lean (cw) until the engine runs between 13,500 and 14,500 rpm. Then turn the lo speed needle lean (b) (cw) until the engine does no...

Page 24

24 for setting saw chains, round file (4 mm ø: 5/32”) and flat file are used. • to keep correct position and correct angle, use the file holder. - round file and flat file are available from your echo dealer. • file cutters as below. Type : 91vg hold file holder level depth gauge one fifth of file d...

Page 25

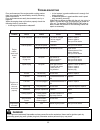

25 t roubleshooting t r a h c g n i t o o h s e l b u o r t m e l b o r p e n i g n e m e l b o r p k c e h c s u t a t s e s u a c y d e m e r e n i g n e - s k n a r c / d r a h s tr a t s t' n s e o d tr a t s r o t e r u b r a c t a l e u f r o t e r u b r a c t a l e u f o n d e g g o l c r e n...

Page 26: Storage After Use

26 the installation of a chain brake may be mandatory by law or as stipulated by insurance regulations in your area of operation. You should inquire through local government offices, your employer or your local dealer to ensure that your chain saw conforms to the required safety standard. Echo chain...

Page 27

27 testing the brake • start the engine on a solid level surface and run at a fast idle until warm. • hold the saw firmly by the handles and accelerate the en - gine to a fast idle. Operation • set the lever in the released position before starting to cut. • if the brake is tripped by kick back reac...

Page 28

28 t echnical d ata * technical data subject to change without notice. Gasoline use 89 octane unleaded. Do not use fuel containing methyl alcohol, more than 10% ethyl alcohol or 15% mtbe. Do not use alternative fuels such as e-15 or e-85. Model cs-330t cs-360t dimension l x w x h mm inch weight powe...

Page 29

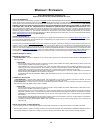

29 echo limited warranty statement for product sold in usa and canada beginning 01/01/2010 echo's responsibility echo incorporated’s limited warranty, provides to the original purchaser that this echo product is free from defects in material and workmanship. Under normal use and maintenance from dat...

Page 30

30 purchased repair parts, short blocks and accessories • 90-day residential, or non-income producing warranty • 30-day commercial, institutional, agricultural, industrial, income producing, or rental application warranty attention two-stroke engine power product owners this echo two-stroke engine p...

Page 31

31 echo incorporated emission control warranty statement for echo and shindaiwa brands the environmental protection agency (epa) and the california air resources board (c.A.R.B.) and echo incorporated (echo inc.) are pleased to explain the emission control system warranty on your 2010 and later equi...

Page 32

Consumer product support 1-800-673-1558 8:30 - 4:30 mon - fri c.S.T. Echo, incorporated 400 o akwood r oad l ake z urich , il 60047-1564 www.Echo-usa.Com dealer? Call 1-800-432-echo 1-800-432-3246 or www.Echo-usa.Com s ervicing i nformation parts / serial number genuine echo parts and echo repower™ ...