- DL manuals

- Eco-ideal

- Stove

- eco 4

- Instructions For Installation, Use And Maintenance Manual

Eco-ideal eco 4 Instructions For Installation, Use And Maintenance Manual

Summary of eco 4

Page 1

1 jineco04 rev i 12/03/15 eco 4 cvsec04fm instructions for: installation/operating/maintenance/servicing approved for use in the united kingdom and the republic of ireland.

Page 2

2 jineco04 rev i 12/03/15 contents index: techincal specification………………………………………………………………………………………………. 3 important information……………………………………………………………………………………………… 4 assembly instructions……………………………………………………………………………………………….. 7 pre installation requirments…………………………………………………………………………………… 8 installati...

Page 3: Eco 4

3 eco 4 technical specification appliance mass 88 kg total efficiency 73.0% nominal heat output 4.9 kw mean co emission (@13% o 2 ) 0.16 % mean flue gas temperature 288 °c flue gas mass flow 6.5 g/s this stove has been designed and assembled so that it may be used to burn wood logs in a smoke contro...

Page 4

4 general guidance this appliance has been certified for use in the countries stated on the cover. Installation in other countries will require translated instructions and may also require modification to comply with local regulations. It is important that your stove is correctly installed and opera...

Page 5: Safety

5 handling adequate facilities must be available for loading, unloading and site handling. Fire cement some types of fire cement are caustic and should not be allowed to come into contact with the skin. In case of contact, wash immediately with plenty of water. Asbestos this stove contains no asbest...

Page 6

6 adverse weather in a small number of installations, occasional local weather conditions (e.G. Wind from a particular direction) may cause downdraught in the flue, causing the stove to emit fumes. In these circumstances the stove should not be used. A professional flue installer can advise on solut...

Page 7: Assembly Instructions

7 assembly instructions f lue c ollar and b lanking p late wind the eight m6 studs supplied into the fixing holes in the flue collar and blanking plate until finger tight. Place a flue outlet gasket in position on the top plate of the stove and lower the flue collar or blanking plate (as required) o...

Page 8: Pre-Installation

8 rear brick pull the top edge of the rear brick forward and lift the brick out of the stove. Baffle / throat plate lift the baffle and slide to the left. When the right side of the baffle clears the baffle support, lower the baffle into the fire box and remove. To assemble the stove, simply reverse...

Page 9: Installation Instructions

9 flue outlet positions (document j): position on roof clearances to flue exit a at or within 600mm of the ridge at least 600mm above the ridge b elsewhere on a roof (pitched or flat) at least 2.3 m horizontally from the nearest point on the weather surface and: a) at least 1.0 m above the highest p...

Page 10

10 w arning ! A faulty installation can cause danger , ill health and even death to the inhabitants and possibly compromise the structure of the building . C ompetent p ersons s cheme members of the following schemes may self-certify the installation of this stove. If the installer is not a member o...

Page 11

11 if the chimney is believed to have previously served an open fire installation, it is possible that the higher flue gas temperature from the stove may loosen deposits that were previously firmly adhered, with the consequent risk of flue blockage. It is therefore recommended that the chimney be sw...

Page 12

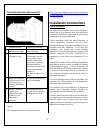

12 the hearth should extend at least 225 mm from the front of the stove. If the stove is to stand in an appliance recess, it should stand wholly above a solid, non-combustible hearth, at least 125 mm thick (this may include the thickness of a solid floor). Fireplace recess plan view: side view : fre...

Page 13: Operating Instructions

13 operating instructions this appliance is not suitable for use in a shared flue operation with the door open can cause excess smoke. This appliance must not be operated with the door open aerosol sprays do not use an aerosol spray on or near the stove when it is alight. Air controls this stove has...

Page 14

14 riddling grate your eco ideal stove is fitted with a locomotive type grate. So that de-ashing can be carried out cleanly and easily, it is riddled from the outside of the stove with the doors closed. The grate is designed to burn both wood and solid mineral fuels. Grate operation & burning wood l...

Page 15

15 the stack to enable it to dry out. Burning wet or unseasoned wood will create tar deposits in the stove and chimney and will not produce a satisfactory heat output. Air controls (solid mineral fuel) solid mineral fuel burns most efficiently with the secondary air control in the closed position. A...

Page 16

16 warning! Petroleum coke fuels or household waste must not be burnt on this appliance. Do not use treated timber. Should any difficulties arise over fuel quality or suitability, consult your local approved coal merchant or: hetas ltd. Telephone 01684 278170 – www.Hetas.Co.Uk solid fuel association...

Page 17: Commissioning and

17 commissioning and handover appliance check please check that all components are correctly assembled and working correctly. Ensure the door catch mechanism is adjusted correctly and the 12mm rope seals around the door are air tight and sealing. Ensure the air controls are working correctly. Eco id...

Page 18: Maintenance &

18 maintenance & servicing warning! No unauthorised modification of this appliance should be carried out. Important! In order to ensure continued compliance with current building regulations and local authority byelaws, this appliance requires regular maintenance by a competent person. N.B. Refer to...

Page 19

19 door catch should the door catch require adjustment, please follow the procedure below: open the door. Slacken the m6 grub screw, on the underside of the handle boss. Turn the inside catch shaft one turn clockwise, this will achieve a tighter lock when the door is closed. Re-tighten the m6 grub s...

Page 20

20 troubleshooting: incorrect flue draught in your chimney/flue system will cause for poor performance of your appliance. Excessive flue draught can cause poor burning control, excessive fuel consumption and even noise from the air controls. Low flue draught can cause difficulty in lighting and runn...

Page 21: Spares Information

21 spares information door spares single door hec07001 glass clip screw fsjm05008ss door slider ch08003 glass gasket eco06007 door handle assembly eco06arrt005 ) glass clip hhr08164 slider knob hce06059 door cover hec07002 door glass eco06008 rope sealing kit scphce09sdsk door hinge eco06003 top hin...

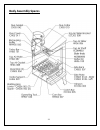

Page 22: Body Assembly Spares

22 body assembly spares.

Page 23

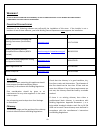

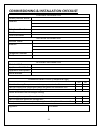

23 commissioning & installation checklist purchase information dealer/retailer name address telephone number email date purchased installer information installer name address telephone number email appliance information date installed appliance stock code appliance description serial number commissi...

Page 24: Service Records

24 service records 1 st service 2 nd service date of service date of service date of next service date of next service servicing company/ engineer service company/ engineer signature signature 3 rd service 4 th service date of service date of service date of next service date of next service servici...