- DL manuals

- Ecoflam

- Indoor Fireplace

- BLU TS 5000.1 PRE HT

- Operating Instructions Manual

Ecoflam BLU TS 5000.1 PRE HT Operating Instructions Manual

Summary of BLU TS 5000.1 PRE HT

Page 1

Technical data operating instructions electric diagrams spare parts list gas burners en blu ts 5000.1 pre ht blu ts 6000.1 pre ht gas train manual is separate www.Ecoflamburners.Com blu ts 6000.1 pre md tc ht dn65 ps2 3144761 04-04-2017.

Page 2

Index general warnings - conformity declaration 3 burner designation - modular delivery system 4 burner description 5 gas train - kit - accessories: assembly to the burner 6 technical data 7 gas category by country 7 test boiler - flame dimension 8 overall dimensions air flange 8 overall dimensions ...

Page 3

General warnings - conformity declaration blu burners are designed for the combustion of natural gas or lpg with kit. The design and function of the burners meet the standard en676. They are suitable for use with all heat generators complying with standard within their respective performance range. ...

Page 4

Burner designation modular delivery system gas burners all gas burners are delivered in separate set/box, i.E. Burner body including combustion head and separate gas train with separate additional kit and accessories that shall complete the gas train or the burner according to the applicable standar...

Page 5

Burner description 420010836600 en www.Ecoflam-burners.Com 5.

Page 6

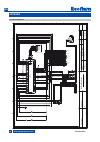

100 p g 144 gas governor 150 throttle valve 151 gas train siemensvgd.... 313 min.Gas pressure switch 314 max.Gas pressure switch (optional) 349 air damper motor 350 gas damper motor m air gas 313 144 142 141 120 150 314 349 m 350 151 143 to be supplied by the installer to be supplied by the installe...

Page 7

7 www.Ecoflam-burners.Com en 420010836600 technical data gas category by country gas category country ii 2r3r be ch cz de dk es fi fr gb gr hu ie it lu nl pt se ee lt lv no pl sk si - ii 2h3b/p at - - - - - - - - - - - - - - - - - - - - - - - - i 3r cy mt - - - - - - - - - - - - - - - - - - - - - - ...

Page 8

8 www.Ecoflam-burners.Com en 420010836600 test boiler - flame dimensions the burner/boiler matching does not pose any problems if the boiler is ce type- approved. If the burner must be combined with a boiler that has not been ce type-approved and/or its combustion chamber dimensions are clearly smal...

Page 9

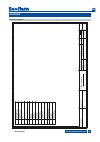

9 www.Ecoflam-burners.Com en 420010836600 overall dimensions how to install the gas train into the burner and calculate the overall dimensions: refer to the dimension page and the gas train manual for all detailed information fixing hole dimensions are “i” and “l” as per dimension table. Boiler hole...

Page 10

Gas operating mode - general safety functions 420010836600 en www.Ecoflam-burners.Com 10 start-up mode as soon as the furnace system is required to supply heat, the burner control circuit will close and the program flow started. When the program has come to its end, the burner will be turned on. An ...

Page 11

420010836600 en www.Ecoflam-burners.Com 11 ! Warning: handling and moving operations must be carried out by specialised personnel. Use the eyebolts to lift the burner in order that it will not overturn and fall down. Installation fitting the burner to the boiler burner lining check before burner ins...

Page 12

M air gas 313 160 142 141 120 150 314 349 151 100 143 to be supplied by the installer to be supplied by the installer 100 burner 120 air damper 141 ball valve 142 gas filter 143 antivibration coupling 144 gas governor 150 throttle valve 151 gas train siemens vgd.... 160 kit tightness control (option...

Page 13

13 www.Ecoflam-burners.Com en 420010836600 installation gas pressure loss diagram: combustion head - platform 380 the diagram provides combustion head pressure loss. To have pressure loss combined with the different type of gas train you must refer to the pressure loss diagrams. Warning: note that t...

Page 14

Installation gas pressure loss diagrams ! Pressure drop includes: “combustion head + gas train + gas governor & filter” as per en676 standard. Back pressure of boiler (or other applications) must be added/included in order to have the total min pressure drop. Legenda pf: back pressure of furnace pb:...

Page 15

Installation gas pressure loss diagrams ! Pressure drop includes: “combustion head + gas train + gas governor & filter” as per en676 standard. Back pressure of boiler (or other applications) must be added/included in order to have the total min pressure drop. Legenda pf: back pressure of furnace pb:...

Page 16

Installation electrical connections ! Warning: electrical wiring must be carried out with electrical supply disconnected and with burner switch in position off. Electrical supply must correspond to the one shown on the burner label. 420010836600 en www.Ecoflam-burners.Com 16 applicable standard the ...

Page 17

Start-up: checking procedure checks before commissioning: • that the burner is assembled in accordance with the instructions given here. • that the burner is pre-set in accordance with the values in the adjustment table. • setting the combustion components. • all electrical connections must be corre...

Page 18

18 www.Ecoflam-burners.Com en 420010836600 exhaust gas test q f = q n = 1000 = 1136 kw volumetric gas flow rate at stp: v bn = q n = 1000 = 125 m 3 /h volumetric gas flow rate in operating condition: v bb = v bn t = p n = = 125 273+15 1013,25 = 123,9 m 3 /h to ensure an economically efficient and tr...

Page 19

19 www.Ecoflam-burners.Com en 420010836600 start-up select the gas operation in order to proceed with start up on the gas side. On the selector put the operation on minimum capacity. Firing head setting the ring head is pre-adjusted at the 50% from the factory. The setting fully open enables to reac...

Page 20

20 www.Ecoflam-burners.Com en 420010836600 start-up adjusting the intermediate burner capacity gas adjustment is accomplished through lamtec parameters setting. Refer to lamtec manual attacched. Warning: the variable profile of the cam shall have a normal proportional curvature in order to have good...

Page 21

21 www.Ecoflam-burners.Com en 420010836600 maintenance program ! Burner and boiler servicing must only be carried out by authorised and qualified personnel at least once a year. Depending on the type of installation, shorter maintenance intervals may be necessary. The system operator is advised to t...

Page 22

Maintenance program position of electrodes gas filter cleaning removing the blast tube removing the firing head 420010836600 en www.Ecoflam-burners.Com 22 attention: check the position of the electrodes after any intervention as wrong position could cause ignition troubles. Elettrodo di accensione a...

Page 23

420010836600 en www.Ecoflam-burners.Com 23 troubleshooting instructions for setting and error lists refer to lamtec manual attacched. Operating trouble in case of operating trouble it should be checked whether the system is in proper working order. Make a check for the following: 1. Availability of ...

Page 24

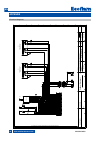

Appendix electrical diagrams t p st c t p st s f 1 e d 2 3 4 c b a 1 2 3 4 5 6 7 8 f e d 5 6 7 c b 8 a to t. Shee t shee t designer description d ate fist crea tion code signa ture r&d dep ar tment controller ec oflam bruciat o ri ser vomo to r flame sensor s.P .A ecn first crea tion by term laws we...

Page 25

Appendix electrical diagrams f 1 e d 2 3 4 c b a 1 2 3 4 5 6 7 8 f e d 5 6 7 c b 8 a to t. Shee t shee t designer description d ate fist crea tion code signa ture r&d dep ar tment controller ec oflam bruciat o ri ser vomo to r flame sensor s.P .A ecn first crea tion by term laws we reserved the prop...

Page 26

26 www.Ecoflam-burners.Com en 420010836600 appendix electrical diagrams f 1 e d 2 3 4 c b a 1 2 3 4 5 6 7 8 f e d 5 6 7 c b 8 a 1 2 2 to t. Shee t shee t designer description d ate first crea tion code signa ture r&d dep ar tment controller ec oflam bruciat o ri ser vomo to r flame sensor s.P .A ecn...

Page 27

27 www.Ecoflam-burners.Com en 420010836600 appendix electrical diagrams to t. Shee t shee t designer description d ate first crea tion code signa ture r&d dep ar tment controller ec oflam bruciat o ri ser vomo to r flame sensor s.P .A ecn first crea tion by term laws we reserved the property of this...

Page 28

Appendix spare parts 420010836600 en www.Ecoflam-burners.Com 28 1 9 2 b lu t s 5-6000 .1 pre ht 1 20 3 4 1 8 7 9 16 11 1 3 14 1 5 1 7 1 2 2 1 5 6 22 2 6 25 2 7 2 4 23 1 9.

Page 29

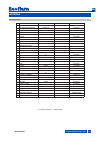

Appendix spare parts list 420010836600 en www.Ecoflam-burners.Com 29 tc = short head tl = long head blu ts 5000.1 pre blu ts 6000.1 pre n° description code code 1 air pressure switch lgw10a2p 65323047 65323047 2 wieland plug 6 pin 65322072 65322072 3 down cover 65325217 65325217 4 up cover 65325218 ...

Page 30

30 www.Ecoflam-burners.Com en 420010836600

Page 31

31 www.Ecoflam-burners.Com en 420010836600

Page 32

Ecoflam bruciatori s.P.A. Via roma, 64 - 31023 resana (tv) - italy tel. +39 0423 719500 fax +39 0423 719580 http://www.Ecoflam-burners.Com e-mail: export@ecoflam-burners.Com società soggetta alla direzione e al coordinamento di ariston thermo s.P.A. Via a. Merloni, 45 - 60044 fabriano (an) - cf 0102...