Summary of CN

Page 1

Operating instructions.

Page 2: Index

Page 2 ecom-cn index page important hints 3 1. Instrument design 4 2. Getting started 5 3. Input or selection of a combustion plant 6 4. Gas analysis 4.1. Measurement preparation 8 4.2. Gas analysis 8 4.3. Co measurement (safety check) 10 4.4. Draught / pressure measurement 11 4.5. Soot.. Oil trace ...

Page 3: Important Hints

Ecom-cn page 3 important hints the ecom-cn meets the requirements of din en 50379 part of 2. The ecom-cn may not be used for continuous emission control! Following minimum times must be kept, in order to receive correct measured values: -1 min. To calibrate the sensors at fresh air -2 min. For stabl...

Page 4: 1. Instrument Design

Page 4 ecom-cn 1. Instrument design air tempera- ture connec- tion esc key (quit/ escape menu) gas temperature connection rs232 interface condensate monitoring connection gas connection draft connection charging socket in the input mode the keys are used for numerical input cursor monitoring (up/dow...

Page 5: 2. Getting Started

Ecom-cn page 5 2. Getting started once the instrument is switched on (press key ) the main menu is displayed. 6 sub-menus (non visible menus can be called up while scrolling with the arrow keys) are listed with the following respec- tive function: - gas analysis : perform gas analysis - draft/pressu...

Page 6: Select By:

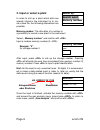

Page 6 ecom-cn 3. Input or select a plant in order to call up a plant which data are already stored in the instrument or to cre- ate a new file, the following alternatives are possible: memory number: the allocation of a number is a possibility to record a new plant in the instrument. Select „ memor...

Page 7: Search Word

Ecom-cn page 7 search word: in case the plant identification is known, so a plant already recorded can be found out using a search machine. Select "search word" and confirm with . Input 4 related digits of the plant identification: input example: "25.11" for plant identification 0000001.25.11.99 aft...

Page 8: 4. Gas Analysis

Page 8 ecom-cn 4. Gas analysis 4.1. Measurement preparation prepare the instrument for operation in that you perform all connec- tions (t-room sensor and t-gas, gas and dra of the 3-chamber hose). Make sure that: - the condensate pad has enough absorption capability (condensate trap with monitoring)...

Page 9

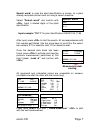

Ecom-cn page 9 the position of the measured and calculated values (gas analysis) on the display pages is free selectable. Proceed as follows to modify the succession: - press to activate the first line on the display - select the measured or calculated value with the cursor keys - press to activate ...

Page 10: Co-Measur.

Page 10 ecom-cn they will be stored there for a later printout and, if need be, a final data record storage (you can view the values in the intermediate memory by pressing - during the inquiry the gas pump switch- es off). The co sensor is protected against overload by the internal pro- gramme. If t...

Page 11

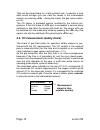

Ecom-cn page 11 4.4. Draft / pressure measurement besides the draught measurement the ecom-cn offers the possibil- ity of a differential pressure measurement (option). The instrument must hereto be fitted with a second connection (pressure) on the front. Draft measurement: the gas analysis mode alre...

Page 12: 4.5. Soot...Oil Trace

Page 12 ecom-cn 4.5. Soot...Oil trace in the sub-menu "soot.Oil deriv." the measurement values for boil- er temperature, soot dot number and oil trace can be inputted. Select the corresponding line on the display and press to acti- vate the input. The input for boiler temperature and soot dots 1-9 c...

Page 13: 5. Adjustments

Ecom-cn page 13 then a data printout can be started ( „print“ and ). The ecom-cn is pre- set for a printout via the infrared printer type hp 82240b . For the case the new ir printer type ecom- p is in use, a corresponding selection must be made under „adjustments“ / „inter- nal“ . Please care for a ...

Page 14: Keyboard Beep

Page 14 ecom-cn unit (adjustment via - ): - calculation of gas concentrations in: - ppm = volume concentration (parts per million) - mg/m 3 = mass concentration per volume unit - mg/kwh = mass concentration per performance unit undiluted (adjustment via ): - conversion of gas concentration on entere...

Page 15: 6. Control

Ecom-cn page 15 ecom-p (adjustment for yes / for no): - adjusted of selected printer: „yes“ = ecom-p „no“ = hp 82240b eta(c) ( for yes / for no): - efficiency calculation with or without condensation gain 6. Control the electrochemical sensors used for the gas analysis are submitted to a wearing pro...

Page 16: 7. Data Processing

Page 16 ecom-cn 7. Data processing 7.1. Menu data processing the menu „data processing“ allows the selection of the following functions: select: this sub-menu enables to search for or create a plant file for the allocation of measurement values (see chapter 3.). Look at: the recorded values of the s...

Page 17

Ecom-cn page 17 7.2. Data processing via irda the following possibilities are available for data processing via irda: 1.Using the measurement data management programme minidv (gratis software from ecom gmbh). Hereto the following adjustments must be made at the ecom-cn : adjustments-internal-baud ra...

Page 18

Page 18 ecom-cn once the ecom-cn is identified, the message „connection build-up ...“ and then „start trans- fer at ecom-cn“ are displayed. Press the „print“ key to start transferring the data stored in the ecom-cn . Once the transfer is completed, the measurement values are displayed in a table on ...

Page 19

Ecom-cn page 19 3. Using the pda solution the bluetooth interface (option) of the pda can be used to transfer current measurement data from the ecom-cn into the pda. The communication via a virtual bluetooth com port is used as transfer principle. Ecom gmbh offers a programme called cnre- mote which...

Page 20: 8. Maintenance Tips

Page 20 ecom-cn the desired function can be selected in the rider „measurement da- ta“. The following functions are available for the remote operation of the ecom-cn : gas analysis starts gas analysis procedure until the key „stop“ is pressed o2 check starts o2 check until the key „stop“ is pressed ...

Page 21

Ecom-cn page 21 the following advices will be of help for the daily check and mainte- nance of single parts and assemblies: change fine dust filter (condensate trap profi version): screw off the cover. Release the filter and check the soiling state of the filter. Change it once it has a grey colour ...

Page 22

Page 22 ecom-cn change fine dust filter (condensate trap basis version): release the upper cap. Release the fine dust filter and check its state. It should be replaced once the soiling degree in the gas flow area shows a grey colour (ca. Number 3 on soot comparison scale). The safety filter should a...

Page 23

Ecom-cn page 23 sensors: the sensors get calibrated with the reference gas fresh air by each switch-on procedure. The state of the sensors is permanently con- trolled by the instrument. New sensors age along the operation peri- od because of the wearing of the reagents (oxygen sensor) and due to soi...

Page 24: 9. Technical Data

Page 24 ecom-cn 9. Technical data parameters range principle o 2 0 ... 21 vol.% electrochemistry co 0 ... 4000 ppm electrochemistry no (option) 0 ... 5000 ppm electrochemistry co 2 0 ... Co 2max calculation t-g 0 ... 500 °c nicr-ni t-r 0 ... 99 °c semiconductor differential pressure 0 ... +/- 20 hpa...

Page 25: 10. Faq

Ecom-cn page 25 10. Faq where do i find important instru- ment information? How long is the life span of the sensors? Which sensors can i exchange? The instrument shows the error message „o2 sensor 0 mv“! The instrument shows the mes- sage „check required“! The instrument shows the error message „t-...

Page 26

Page 26 ecom-cn hint: if you have several instruments of the same type, you can locate an error by exchanging the accessories (probe, hose, temperature sensor etc.). If further questions or problems should arise, please contact the next authorised ser- vice centre. My instrument cannot be switched o...