- DL manuals

- Ecom

- Measuring Instruments

- EN2

- Operating Instructions Manual

Ecom EN2 Operating Instructions Manual

Summary of EN2

Page 1

Operating instructions creative technology made by rbr.

Page 2: Index

Page 2 ecom-en2 index page important hints 3 1. Instrument design 4 2. Accessories ecom-en2 5 3. Gas cooler (option) / model version ecom-en2-p 6 4. Power supply 7 5. Data memory 7 6. Instrument start 8 7. Input or selection of combustion plants 10 8. Flue gas analysis 8.1. Gas analysis 13 8.2. Co m...

Page 3: Important Hints

Ecom-en2 page 3 important hints the ecom-en2 should not be used for continuous emission control! The ecom-en2 meets the requirements of the din en 50379 part 2. Observe the following minimum times in order to get correct measurement values: - 1 min. For sensors calibration at fresh air - 2 min. For ...

Page 4: 1. Instrument Design

Page 4 ecom-en2 connection sampled gas condensation trap with fine dust filter optical flow control integral printer connection charger 1. Instrument design connection usb connection gas temperature connection air temperature connection draught connection pressure accu and sensors compartment slot f...

Page 5: 2. Accessories Ecom-En2

Ecom-en2 page 5 function keys (function shown on display) print key (access to printing menu) enter key (confirm selection) esc key (quit/ escape menu) cursor keys (up/down/right/ left/scroll) keyboard values recording on / off key info key (access to control menu) in the input mode, the keys are us...

Page 6

Page 6 ecom-en2 gas inlet gas outlet fan peltier element level monitoring condensate evacuation 3. Gas cooler (option) / model version ecom-en2-p exhaust gas with a temperature over the steam dew point (35 - 65 °c) is flown spiral via a long gas path thru a surface coated metal body with good therma...

Page 7: 4. Power Supply

Ecom-en2 page 7 4. Power supply the ecom-en2 comes with an external charger. The analyser can also be powered via the internal accumulator for a while (6 v; 3.8 ah). The accumulator recharge should be started when the instrument requires to (acoustical warning and display indication). The accumulato...

Page 8: 6. Instrument Start

Page 8 ecom-en2 card insert insert the multi-media card as shown. Take care that the card does not stand out and that it well hooks on. 6. Instrument start once the instrument is switched on (key ), the main menu is displayed. 6 sub-menus with the following functions (non-visible sub-menus can be ca...

Page 9

Ecom-en2 page 9 - gas analysis : perform gas analysis - soot...Oil trace : input of soot measurement results - data processing : assign measurements / data transfer (only by inserted mm card) - adjustments : modify instrument adjustements - control : check operation state of instrument - diagnostics...

Page 10

Page 10 ecom-en2 7. Input or selection of combustion plants to call up plant data already recorded or to create a new file, the following possibilities are available: create new (is automatically selected by first use of a mm card): to create a new file, a numerical number should be assigned. Select...

Page 11

Ecom-en2 page 11 - proceed as follows to correct a character: - press to interrupt the character selection - use the cursor keys to select the character requiring correction - activate with the character selection and correct character - return with to character selection and call up next line for p...

Page 12: 17.5

Page 12 ecom-en2 search word: if the plant code is known, it is possible to find the plant data stored with help of a search machine. Select hereto "search word" and confirm with . Using the software keyboard, input at least 3 connected figures of the plant: example: "25.11" for plant code 25.11.200...

Page 13: 8. Flue Gas Analysis

Ecom-en2 page 13 8. Flue gas analysis 8.1. Gas analysis after the 1-minute calibration phase, the instrument switches over to the measurement mode. The gas measurement values can be viewed on 4 display pages. Use the cursor keys to scroll the pages. Pressing enables to switch, from the values displa...

Page 14: Probe Tip

Page 14 ecom-en2 the position of the measured and calculated values (gas analysis sub-menu) on the display pages is free selectable. For alteration of the existing succession, proceed as follows: - press / „display values“ / to activate the function - select line with cursor keys (up/down) - select ...

Page 15

Ecom-en2 page 15 co 2 , efficiency, losses, excess air and dew point are calculated values. They can only be calculated if realistic values for the basic parameters like o 2 and the temperatures are available. It must be ascertained that: o 2 and t.Gas - t.Air > + 5 °c are given. The dew point can o...

Page 16: 17.5

Page 16 ecom-en2 the co sensor is protected against exceedings thanks to an internal programme. If the 4000 ppm limit value is exceeded, so a purging pump is activated which provides the sensor with fresh air. After sufficient purging time (x behinds co disappears) the sensor can be reintegrated int...

Page 17: 8.3. O

Ecom-en2 page 17 8.3. O 2 check this measurement is performed by room-independant plants like gross calorific value plants. It is determined if exhaust gas flows into the combustion air (o 2 content drops down / co content can be present) and herewith influence on the combustion quality. For this an...

Page 18: 0.12

Page 18 ecom-en2 re-connect the draught tubing. The display shows the exact measurement value which can be stored while pressing and added to those results previous stored in the intermediate memory. The stored value is shown on the display. Press to exit the draught measurement menu. 8.5. Flow meas...

Page 19: 8.6. Soot...Oil Trace

Ecom-en2 page 19 8.6. Soot...Oil trace the sub-menu "soot...Oil trace" enables the input of measured results for boiler temperature, soot dots and oil trace. Select the desired line on the display and activate the input with . The input for boiler temperature and soot measurements 1-3 can be made on...

Page 20

Page 20 ecom-en2 8.7. Measurement record and printout inportant: once the gas analysis is completed, transfer the values recorded in the intermediate memory on the mm card, otherwise they would get lost by switch-off of the instrument! Press (printer symbol) to enter the printing menu. The sampled d...

Page 21

Ecom-en2 page 21 9. Mean value measurement (option) by mean value measurement function, measurements can be sampled within an adjustable time frame and mean values can be calculated. Should the single measurement values be stored, then a storage place must be defined as described in chapter 7. Based...

Page 22

Page 22 ecom-en2 the setting for „record“ can be changed as follows: - select menu point and confirm with - activate memory function with or - deactivate it with activate „start measurement“ / to start the sampling of the data. On the display the current measurement values (constantly updated with n...

Page 23: 10. Adjustments

Ecom-en2 page 23 10. Adjustments additionally to those ecom-en2 functions described previously, various adjustments can be made in the instrument. From the main menu, select the sub-menu "adjustments" and confirm with . A selection of modifiable parameters, adjustable according to the application, i...

Page 24

Page 24 ecom-en2 fuel type (press to access selection list): - modification of adjusted fuel type (e.G. By measurements at combi-plants) air pressure (press to access menu): - input of barometric air pressure for dew point calculation clock set (press to access setting menu): - correction of interna...

Page 25

Ecom-en2 page 25 internal (press to open menu): - further instrument settings: printout contraste (0..9) (press to access input menu): - printer contraste adjustment display contraste (press to access input menu): - display contraste adjustment with cursor keys key beep ( for yes / for no): - acoust...

Page 26

Page 26 ecom-en2 printout (selection after pressing ): - text input for printout on measurement protocol (8 x 24 characters) - input the text of line 1 as follows: 1. Activate character selection list with . 2. Select keyboard type with (4 different keyboards available). 3. Use the cursor keys to se...

Page 27: 11. Control

Ecom-en2 page 27 11. Control the electrochemical sensors for gas analysis are submitted to a wearing process and do age. They alter their output values along the time depending on the gas concentration, the exposure time and the soiling grade of the sampled gas. The programme monitors the sensors an...

Page 28: 12. Data Processing

Page 28 ecom-en2 12. Data processing if a mm card is inserted in the slot, so it will be used as record medium. The menu „data processing“ offers the following functions: select: for search or creation of plant files in the scope of assigning measurement values (see § 7.). View: recorded values of t...

Page 29

Ecom-en2 page 29 rdt pc !: load data: enables the data import from e.G. Rbr software (available on our website „www.Rbr.De“). See chapter „technical data“ for data format information (please observe the transfer options of your software!). Proceed as follows: -connect ecom-j2kn and pc via usb cable....

Page 30: 13. Diagnostics

Page 30 ecom-en2 13. Diagnostics 13.1. Fault diagnostic the ecom-en2 is able to receive and to process information provided via cable transfer by the ecom-ak (read-out head for digital firing automates). Out of the main menu, select the sub-menu "fault diagnostic" and confirm with . The ecom-en2 tri...

Page 31

Ecom-en2 page 31 use the cursor keys (up/down) to call up further data of the firing automate. On the 2 nd display page the current error and the number of burner starts are displayed. Ther 3rd display lists information about error history (type and volume of information dependind on firing automat)...

Page 32: 13.2. Delta-T Measurement

Page 32 ecom-en2 13.2. Delta-t measurement with the ecom-en2 a difference temperature measurement is possible. For measurements at pipings (e.G water-in and water-out of heating systems), special temperature sensors are needed, available from your authorised rbr agency. Out of the main menu point "d...

Page 33

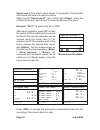

Ecom-en2 page 33 the gas losses measurement is to be performed with the instrument´s sampling probe in the gas core stream after menu call up (see chapter 8.1.). Once the measurement is recorded with (disk symbol) the conversion of the measurement results in negative points is available under the me...

Page 34

Page 34 ecom-en2 press (start + ->) to start the real measurement. Proceed as follows: - select surface (boiler side) to be measured with or - position surface sensor - record temperature difference with - up to 10 values can be recorded per surface out of which a mean value will be calculated autom...

Page 35

Ecom-en2 page 35 quit with: esc heating check gas losses 2.9 % points 2.6 surface loss 2.29 % points 3.4 ventil. Loss 3.11 % points 3.0 press (start) prior to going thru the following steps to start the measurement: - release tubing of the flow probe - wait for zeroing of pressure sensor - re-connec...

Page 36

Page 36 ecom-en2 13.2. 4 pa measurement (option) the simultaneous operation of room-dependent firing place and air evacuation system can lead to dangerous low pressure conditions. With the ecom-en2 it is possible to check the low pressure limit value of 4 pa and to document in a diagramme the time c...

Page 37: 14. Maintenance Tips

Ecom-en2 page 37 14. Maintenance tips we recommend to send your instrument for maintenance one time a year, however after max. 250 operation hours, to the next authorised service centre. The following advices will be of help for the daily check and maintenance of single parts or assemblies: fine dus...

Page 38

Page 38 ecom-en2 prefilter the prefilter made of high-grade steel is within the condensate container. It should be cleaned when contamination (with warm water and dry). Unscrew condensate container and prefilter. Assemble after cleaning again in reverse order. Sensors the sensors get calibrated with...

Page 39

Ecom-en2 page 39 probe and tubing depending on the frequency of use, probe and tubing should be regularly cleaned in order to release particle deposits and to prevent early wearing due to corrosion. - release the connections at the instrument and at the probe grip to free the tubing. - clean it (flo...

Page 40: 15. Technical Data

Page 40 ecom-en2 15. Technical data parameter range principle o 2 0 ... 21 vol-% electrochemistry co 0 ... 4000 ppm electrochemistry no (option) 0 ... 5000 ppm electrochemistry no 2 (option) 0 ... 1000 ppm electrochemistry so 2 (option) 0 ... 5000 ppm electrochemistry co% (option) 4000 ... 63000 ppm...

Page 41

Ecom-en2 page 41 description of data record ecom-en with multi media card format data logger recordings: j2kdl-xx.Csv (separation mark between values = comma) format punctual measurements: j2kdv.Txt (separation mark between values = comma) column description remark/example a datum dd.Mm.Yyyy (also b...

Page 42

En2 manual addendum i. Data logging onto memory card setup data processing shortcut to f1 hotkey 1. Turn on analyzer 2. Go to adjustments -> internal -> f1 hotkey 3. Press right arrow to select data processing and press enter 4. The f1 hotkey is now set to data processing -> press esc twice to retur...

Page 43

Print with text (i.E. Site and equipment) 1. While in gas analysis mode, press enter to display options 2. Select insert text and press enter, then press enter again to select first line of text 3. If one of the letters in the grid is not already highlighted, press f4 to toggle down to the alphanume...