- DL manuals

- Ecom

- Measuring Instruments

- j2kn pro

- Operation Manual

Ecom j2kn pro Operation Manual

Summary of j2kn pro

Page 1

Ecom america ltd, 1628 oakbrook drive, gainesville, ga 30507 toll free (877) 326-6411 phone (770) 532-3280 fax (770) 532-3620 w ww .Ec o musa .C om operations manual version 3.6.2.

Page 2

Page 2.

Page 3

Page 3 table of contents page(s) j2kn p ro d esign and h ow it w orks 1. Important things to remember …………………………………………4 2. Instrument design 2.1. J2kn pro base unit………………………………………………5 2.2. Remote display unit …………………………………………….6 2.3. Accessories…………………………………………………………7 2.4. Consumables………………………………………...

Page 4

Page 4 1. Important things to remember the j2kn pro meets the requirements of epa ctm-030 and ctm-034 and astm d-6522 test- ing protocols for portable emission analyzers. In order to receive accurate measurements, please allow reading to stabilize for at least 2 minutes. The j2kn pro is not suitable...

Page 5: 2. Instrument Design

Page 5 2. Instrument design 2.1 j2kn pro base unit ambient air temperature sensor thermocouple connection main gas connection draft/pressure connection draft/pressure connection water trap drain hose connection on-board printer filter for ir bench (if applicable) remote display unit (see next page) ...

Page 6

Page 6 2. Instrument design (continued) 2.2 j2kn pro remote display unit escape note: all keypad buttons are used for input of num- bers 0-9 and decimal point ok (press to confirm) up/down/right/left and scroll capture data press to add custom text to printout (press f2 to print normally) on/off dis...

Page 7: 2.3 Accessories

Page 7 2.3 accessories e-comply testing software part no. 9038001h (records mass emissions in g/bhp-hr, lbs/hr, & tons/year) calibration gas kits part no. Available upon request probe shield part no. 3025006g (recommended for high temp applications to protect grip) 15ft/30ft heated sample line part ...

Page 8: 2.4 Consumables

Page 8 2.4 consumables part part # description particulate filter (10/pk) 3015840g 10/pk - particulate filter located on top of water trap assembly in-line smoke filter (1 each) 7118501h 1 each - standard 3/4" in-line filter in clear plastic casing. Nox/sox filter media (1lb) 3014457g 1lb - nox/sox ...

Page 9: 3. Peltier Cooler

Page 9 3. Peltier cooler j2kn pro must be plugged in for the peltier cooler to operate. Exhaust gas with a temperature above dew point is intro- duced into a spiralling gas path with a coated metal surface of good thermal conductivity. The hot gas radiates its heat to this metal coating, which is th...

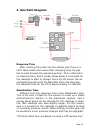

Page 10: 4. Gas Path Diagram

Page 10 4. Gas path diagram response time after inserting the probe into the sample gas, there is a short delay before the values start changing since the gas has to pass through the sampling system. This is referred to as response time, and it usually takes about 4-6 seconds for the readings to sta...

Page 11: 5. Power Supply

Page 11 5. Power supply the j2kn pro base unit has an internal power supply, and it is recommended to always run the unit on ac power. For testing locations where an ac plug-in is not available, the instrument can be operated from 6-8 hours on battery power when fully charged. Connecting the j2kn-pr...

Page 12: 6. Radio Communication

Page 12 6. Radio communication the j2kn pro base unit communi- cates wirelessly to the remote display unit via radio transmisision. To unlock the remote control unit, press on the tab to unlock and release from the cradle on the base unit. The information exchange between the remote control and base...

Page 13: 7. J2Kn Pro Start-Up

Page 13 7. J2kn pro start-up make sure the probe is in fresh air when you turn on the j2kn pro. 1. Switch on the j2kn base unit and the remote control unit. The main menu is displayed with 8 sub-menus: - gas analysis view gas readings & calculations - averaging perform averaging tests - draft/pressu...

Page 14: 8. Emissions Measurement

Page 14 8. Emissions measurement 8.1 gas analysis calibrate the sensors before each emission test for best results. After the 1-minute auto-zeroing phase, the instrument switches to gas analysis mode. The measurement values can be viewed on 3 display pages: a zoomed in 4-line display and 2 full 9-li...

Page 15

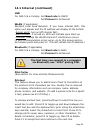

Page 15 8.1 gas analysis (continued) heated probe if you are testing in a cold temperature environment, you may require a heated probe so that condensation does not form (or freeze) in the probe or probe grip. To turn on the heated probe, go to adjustments>internal>probe heat- ing>f1. Remember to tu...

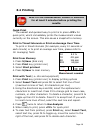

Page 16: 8.2 Printing

Page 16 8.2 printing quick print the easiest and quickest way to print is to press for quick print, which immediately prints the measurement values currently on the screen. This also saves a snapshot to memory. Print in timed intervals or print an average over time to print in timed intervals (for e...

Page 17: 8.3 Soot Test

Page 17 8.3 soot test the soot test is a measure of soot or smoke density in the exhaust sample. The soot test must be performed with the heated probe turned on in order to prevent the filter paper from becoming wet due to condensation. To turn probe heating on, go to adjustments > internal > probe ...

Page 18: (2Gb Max)

Page 18 9. Capturing data on memory card (2gb max) data logging in timed intervals 1. Go to automatic meas. > save to mm card. This is the time interval that each data point is recorded to the memory card (min. 1sec, max 255sec). Input desired amount in seconds and press ok. 2. Select datalogger > “...

Page 19: 10. Averaging Tests

Page 19 10. Averaging tests the averaging function allows you to take a sample of emissions data and compute an average over time. 1. Go to averaging -> select meas. Time 2. Input total measuring time in minutes or seconds (for seconds, press decimal 1st) 3. Select scanning and input interval time i...

Page 20: 11. Software Communication

Page 20 11. Software communication if you need help with installation or operation of your das or e-comply software, please consult the user manual for your software product. If you are having trouble communicating from the analyzer to a computer, please check the following: adjustments > internal >...

Page 21

Page 21 12. Frequently asked questions where do i find important in- strument information? How long is the life span of the sensors? Which sensors can i exchange? The instrument shows the error message “ o2 sensor 0 mv“ the instrument shows the error message “t - gas“ or “t - air“ the instrument sho...

Page 22

Page 22 12. Frequently asked questions (continued) if you have any further questions, do not hesitate to contact the ecom america service department at 770-532-3280 j2kn-pro cannot be switched on j2kn- pro doesn’t print all of the values i want pump flow seems too low the water is not pumping out of...

Page 23: 13. Draft/pressure

Page 23 13. Draft/pressure a trend indication for the draft conditions in the exhaust channel is displayed in the gas analysis screen. Note that the pressure sensor tends to drift because of its sensitivity, and it is necessary to calibrate the sensor immediately before sam- pling to get an accurate...

Page 24

Page 24 14. Adjustments (continued) mass emissions the j2kn-pro calculates mass emissions in units of lbs/hour, tons/year, or gr/bhp. First, under adjustments, set the unit to ppm and choose the correct fuel type. Then select mass emission and press . Press up/down to select the correct unit. For lb...

Page 25: 14.1 Internal

Page 25 14.1 internal (go to adjustments > internal) print contrast choose print contrast from 0-9 reload function choose remote unit battery recharging settings (see 5. Power supply) key beep press f1/f4 to turn key beep on/off graphic menu press f1/f4 to turn graphic menu on/off probe heating pres...

Page 26: 14.1 Internal (Continued)

Page 26 14.1 internal (continued) usb for das 5 & e-comply: set baud rate to 38400 set protocol to enhanced wlan (if applicable) wireless local area network. If you have internal wifi, this option will appear and the ip address will display at the bottom -access point: turn on/off internal wifi -aut...

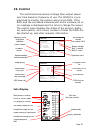

Page 27: 15. Control

Page 27 15. Control the electrochemical sensors change their output values over time based on frequency of use. The j2kn-pro is pro- grammed to monitor the sensors and correct drifts. If the drifts and the correlated measurement errors increase, an er- ror message is displayed and it is time to chan...

Page 28: 16. Maintenance Tips

Page 28 16. Maintenance tips only use sensors, filters, and filter media provided by ecom. Do not use desiccant! 16.1 filters particulate filter (water trap filter) unscrew the cover of the water trap and check the particu- late filter for grayness. Change the filter when it is dark gray. Tip: use t...

Page 29: 16.1 Filters (Continued)

Page 29 16.1 filters (continued) ventilation filter the ventilation filter should be changed if the filter has a darkness of 2-3 on the soot chart scale. Use a screwdriver to pry open the filter holder from the slots on each side. Change the filter cartridge and refasten the filter holder. Ventilati...

Page 30: 16.3 Sensors (Continued)

Page 30 16.3 sensors (continued) the co sensor is protected from exposure to high con- centrations by the automatic co bypass pump. If the limit value of 4000 ppm is exceeded, a second pump switches on and purges the sensor with fresh air. 14.4 printer paper to change the printer paper, please follo...

Page 31: 17. How To Change Sensors

Page 31 17. How to change sensors 17.1 how to change o2 sensor step 1: use a t-10 torx wrench to remove screws from o2/co cover plate step 2: the o2 sensor is attached to 2 wires, located below the co sensor step 3: disconnect the lead wires and unscrew counter clockwise until loose, then pull direc...

Page 32

Page 32 17.2 how to change a5f co sensor step 1: use t-10 torx wrench to remove screws from o2/co cover plate step 2: the a5f co sensor is in gray housing attached to a ribbon cable step 3: disconnect ribbon cable from co sensor step 4: remove co sensor using coin or fingers turn 45 degrees counter ...

Page 33

Page 33 17.2 how to change a5f co sensor (continued) step 5: pop open the gray cap using a small screwdriver use the side of the hous- ing as a leverage point step 6: after the cap is removed, slide the sensor out of the housing as shown here step 7: remove the board from the sensor using a small sc...

Page 34

Page 34 18. How to calibrate sensors for best results, the calibration gas concentration should be as close to the expected levels of emissions as possible. However, because each sensor is linear through a nominal range, one calibration gas concentration can be used for a reasonably wide range of em...

Page 35

Page 35 18. How to calibrate sensors (continued) on-demand regulator: (recommended) use an on-demand regulator which uses the analyzer pump draw to establish flow. Connect the on-demand regulator to the sample train and open the cylinder valve. The analyzer pump controls the flow as to not over or u...

Page 36

Page 36 19. Flow velocity measurement (option) stack flow or exhaust gas flow can be measured by the j2kn-pro using a special flow probe. If you are using a standard ecom probe, set this to 0.93. First, the pitot factor must be entered in the adjustments menu to get the correct flow rate calculation...

Page 37: 20. Technical Data

Page 37 20. Technical data parameter range principle o2 0 ... 21.0 vol-% electrochemical co 0 ... 4000 ppm electrochemical co% (option) 4000 ... 63000 ppm electrochemical no 0 ... 5000 ppm electrochemical no 2 0 ... 500 ppm electrochemical so 2 (option) 0 ... 5000 ppm electrochemical c x h y (option...

Page 38: 21.

Page 38 21. Description of data fields using j2kn-pro data logging onto memory card file format: j2kdl-xx.Csv (comma-separated-values) column description remark / example a date dd.Mm.Yyyy b time hh:mm:ss c o2 in vol.% 0.0 – 21.0 d co in ppm 0 – 4000 e no in ppm 0 – 4000 f no2 in ppm 0 – 500 g so2 i...

Page 39: 22. Calculations

Page 39 22. Calculations note: a1, b, co 2 max & eta max are constants based on fuel type. Excess air (lambda) range=1-infinity excess air = 21 21 – o 2 measured combustion efficiency (eta) range=0-99.9% efficiency = eta max - ( a1 + b) x (t gas – t air ) co2 carbon dioxide (co2) range=0-co2max co 2...

Page 40: Ugged

Page 40 r ugged . R eliable . A ccurate . Ecom a merica l td 1628 o akbrook d rive g ainesville , ga 30507 t oll free (877) 326-6411 p hone (770) 532-3280 f ax (770) 532-3620 ecom.Info@ecomusa.Com w w w . E co m us a . Co m.