- DL manuals

- ECOPURE

- Water Dispenser

- EPWHCW

- Installation and operation manual

ECOPURE EPWHCW Installation and operation manual

S

ystems tested and certified by NSF International

against NSF/ANSI Standard 42.

See performance data sheet for details.

How to install, operate

and maintain your Central

Water Filtration System

Model EPWHCW

Central Water

Filtration System

Installation and Operation Manual

Manufactured and warranted by

Ecodyne Water Systems LLC

1890 Woodlane Drive

Woodbury, MN 55125

7306774 (Rev. F 1/18/10)

Printed on recycled paper

If you have any questions or concerns when

installing, operating or maintaining your Central

Water Filtration System, call our toll free number:

1-800-693-1138

Monday- Friday, 7 AM - 6 PM CST

or visit

www.ecopurewaterproducts.com

When you call, please be prepared to provide the

model, date code and serial number of your product,

located on the rating decal on back of the cover.

Summary of EPWHCW

Page 1

S ystems tested and certified by nsf international against nsf/ansi standard 42. See performance data sheet for details. How to install, operate and maintain your central water filtration system model epwhcw central water filtration system installation and operation manual manufactured and warranted...

Page 2

2 table of contents central water filtration system safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 before you start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 3

3 central water filtration system safety before you start your safety and the safety of others are very important. We have provided many safety messages in this manual and on your appliance. Always read and obey all safety messages. This is the safety alert symbol. This symbol alerts you to potentia...

Page 4

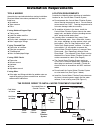

4 packing list inspect shipment ground clamp kit bypass valve 10 ft. Drain hose clips adaptor elbow installation adaptors the parts required to assemble and install the central water filtration system are included with the unit. Thoroughly check the central water filtration system for possible shipp...

Page 5

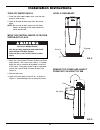

5 central water filtration system dimensions for future reference, enter the following information. Model no. _____________________________ code ________________________ serial no. _____________________________ installation date _______________ model no. And serial no. Are on the shipping carton and...

Page 6

6 how a central water filtration system works normal operation during normal operation water enters the central water filtration system and flows through several fil- tration processes where tastes, odors and sediment are reduced. Clean rinse cycle a clean rinse cycle will automatically be initiated...

Page 7

7 installation requirements tools needed assemble the required tools before starting installation. Read and follow instructions provided with any tools listed here. = screwdriver = tape measure = pliers if using soldered copper pipe = tubing cutter = lead-free solder and flux = propane torch = emery...

Page 8

8 installation requirements plumbing codes all plumbing must be completed in accordance with national, state and local plumbing codes. Valve drain requirements using the flexible drain hose (included), measure and cut to the length needed. Flexible drain hose is not allowed in all localities (check ...

Page 9

9 plan the installation inlet - outlet plumbing options install a single bypass valve (provided) to the contrac- tor/plumber-supplied plumbing, as shown in fig. 7 or if desired, a 3 valve bypass system (parts not includ- ed) can be installed, as shown in figure 6. Bypass valves allow you to turn off...

Page 10

10 installation instructions turn off water supply 1. Close the main water supply valve, near the well pump or water meter. 2. Open all faucets to drain water from the house pipes. Note: be sure not to drain water from the water heater, as damage to the water heater ele- ments could result. Move the...

Page 11

11 1. Install metal grounding clamp to metal house water supply pipes before beginning installation. 2. Securely tighten connection in center of metal ground clamp (see figure 10). 3. Loosely assemble any pipe and fittings needed from the main water supply to the inlet and outlet ports of the centra...

Page 12

12 installation instructions fig. 11 single bypass valve pull handle out for normal operation push handle in for bypass install valve drain hose 1. Measure, cut to needed length and connect the 3/8" drain line (provided) to the central water filtration system valve drain fitting (see figure 11). Use...

Page 13

13 start up procedure important: run the start up cycle immediately after completing installation, before using any water in the home. The filtration media in this central water filtration system contains a small number of harmless activated carbon particles generated during shipping that are small ...

Page 14

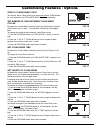

14 programming the central water filtration system if you have questions about installation, programming, operating and routine maintenance... Call 1-800-693-1138, monday - friday, 7 am to 6 pm, cst. When the transformer is plugged into the electrical outlet, a model code and a test number (example:...

Page 15

15 customizing features / options start a clean rinse cycle to manually start a clean rinse cycle, press and hold the clean button for a few seconds, until “recharge now” flashes in the display. Set number of days between clean rinse cycles by default the central water filtration system will automat...

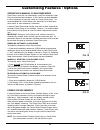

Page 16

16 customizing features / options operating in manual clean rinse mode clean rinse cycles will run automatically, unless the automatic clean rinse function has been disabled. If this function has been disabled, it will be necessary to manually initiate any clean rinse cycles. It is recommended that ...

Page 17

17 care of your central water filtration system vacations and extended periods of no water use if your central water filtration system will not be used for an extended period of time (several months), please follow one of these recommendations: = if the water supply to the unit is not turned off, an...

Page 18

18 warranty central water filtration system warranty warrantor: ecodyne water systems llc, 1890 woodlane drive, woodbury, mn 55125 warrantor guarantees, to the original owner, that: one year full warranty: for a period of one (1) year after installation, all parts will be free from defects in materi...

Page 19

19 troubleshooting problem cause correction water has black or gray color (new system) start up procedure has not been completed run start up procedure (see page 13) or run consecutive clean rinse cycles (see page 15) until water color returns to nor- mal. (not a new system) normal abra- sion of fil...

Page 20

20 troubleshooting fig. 23 removing drain fitting to clean flow control clip hose clamp drain hose flow control drain fitting cleaning the drain flow control this procedure is not required if the central water filtration system is operating normally. It should be performed only if a problem with lac...

Page 21

21 troubleshooting cleaning the sediment filter screen this procedure is not required if the central water filtration system is operating normally. It should be performed only if a problem with low water pressure at household faucets is encountered, as detailed in the troubleshooting table on page 1...

Page 22

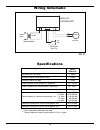

22 wiring schematic position switch nc no transformer 24vac motor 24vdc back of controller fig. 27 120vac 60hz specifications model epwhcw rated service flow rate 6.0 gpm pressure drop at rated service flow 10 psig * pressure drop at 9.6 gpm 15 psig * water pressure limits (minimum / maximum) 30 - 1...

Page 23

23 notes.

Page 24

24 central water filtration system exploded view 1 3 2 4 5 6 8 7 11 10 9 12 13 19 16 17 18 22 25 24 valve assembly see pages 26 & 27 for parts 23 20 21 14 15.

Page 25

25 questions? Visit www.Ecopurewaterproducts.Com or call toll free 1-800-693-1138 central water filtration system parts list key no. Part no. Description ¢ 7290876 assembly, replacement mineral tank, w/media & asso- ciated components (includes key nos. 1 through 12) 1 7170296 o-ring, 2-7/8” x 3-1/4”...

Page 26

26 valve assembly exploded view 51 50 53 54 55 56 57 60 59 58 52 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 wear-strip seal cross-section view.

Page 27

27 valve parts list key no. Part no. Description 50 7224087 screw, #8-32 x 1” (2 req.) 51 7286039 motor (incl. 2 ea. Of key no. 50) 52 0900857 screw, #6-20 x 3/8” (2 req.) 53 7231385 motor plate 54 0503288 bearing 55 7284964 cam & gear 56 7142942 clip, drain 57 0900431 tubing clamp (2 provided) 58 7...