- DL manuals

- Ecotec

- Indoor Fireplace

- Amalfi

- Owners & Installation Manual

Ecotec Amalfi Owners & Installation Manual

Amalfi Wood Pellet Burning Heater

Owner’s & Installation Manual

PLEASE READ THIS ENTIRE MANUAL BEFORE INSTALLATION AND USE OF THIS PELLET BURNING ROOM

HEATER. FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE, BODILY

INJURY, OR EVEN DEATH.

Contact your local building or fire official about restrictions and installation inspection requirements in your area.

economical

user

friendly

leading

design

healthy

home

visible

flame

clean air

approved

Summary of Amalfi

Page 1

Amalfi wood pellet burning heater owner’s & installation manual please read this entire manual before installation and use of this pellet burning room heater. Failure to follow these instructions could result in property damage, bodily injury, or even death. Contact your local building or fire offic...

Page 2: Owner’S Section

2 owner’s section table of contents 1. Introduction ..................................................................................... 4 1.1 specifications ....................................................................................................4 1.1.1 rating label location ..............

Page 3

3 3.12 modification of the boiler water temperature setting .................................. 15 3.13 stove status menu ..........................................................................................15 3.14 working hours menu .................................................................

Page 4: 1. Introduction

4 1. Introduction this manual is designed for both the technician and the home owner. Please read this entire manual before installing or operating your ecoteck amalfi freestanding wood pellet burning heater. Failure to follow these instructions may result in property damage, bodily injury or even d...

Page 5

5 1.2 measurements 590 34 575 1079 1046 34 554 16 figure 1..

Page 6

6 2. Safety warnings & recommendations pellet quality is important, please read the following: your pellet heater has been designed to burn ¼” (6mm) diameter wood pellets, manufactured to the as/nzs 4014.6 only. Do not use this appliance as an incinerator. Do not use unsuitable and non recommended f...

Page 7

7 2.5 flammable liquids never use gasoline, gasoline – type lantern fuel, kerosene, charcoal lighter fluid or similar liquids to start or “freshen up” a fire in the heater. Keep all such liquids well away from the heater while it is in use. 2.6 installation the stove must be installed and tested by ...

Page 8

8 the switching off phase, guaranteeing safe functioning. The burn pot used for combustion allows most of the ashes produced by the combustion of the pellets to fall into the collection drawer. However, it is recommended that you check the burn pot every day, as not all pellets have high standards o...

Page 9

9 3. Operating your pellet fire 3.1 description of the controls 3.2 switching on the stove 1. Before switching the stove on, proceed as follows: 2. Plug in the power lead. 3. Put the switch at the back of the stove in position 1. 4. Check that the plant is connected to the flue. 5. Make sure that th...

Page 10

10 3.4 priming of the screw (auger) to prime the screw/auger (when the stove is new or has been completely run out of fuel, the loading screw/auger is empty), proceed as follows: 1. Turn the stove off completely, using the general switch on the back 2. The display will show final cleaning and then o...

Page 11

11 3.6 setting the clock (clock set menu) proceed as follows to set the current time: 1. Switch the power supply to the thermostove on and off using the main switch at the back of the stove. 2. The display will display final cleaning and then off. 3. Keep key p4 pressed for 2 seconds. The message cl...

Page 12

12 the strings that appear on the display go from ut05 to pr40. A setting from a program corresponds to each string. 3.7.1 description of the strings ut05: this parameter shows the switch on time of programme 1. Ut06: this parameter shows the switch off time of programme 1 (this must be at least 60 ...

Page 13

13 example let us suppose we want to turn the stove on at 06:00 and switch it off at 08:30 ( program 1 ) and that we want to switch it on again at 16:00 and switch it off at 22:00 (program 2). Programming will be as follows: at this point you must decide on which days you want the programming carrie...

Page 14

14 3.8 setting the language (language menu) to set the language, proceed as follows: 4. Remove and reset the electricity supply of the stove using the general switch on the back. 5. The display will show final cleaning and then off. 6. Keep button p4 pressed for 2 seconds, clock setting menu will ap...

Page 15

15 external thermostat procedure if an external thermostat is used, correctly connected to the mother board as shown in the electrical circuit diagram, the message t on will be shown on the display instead of room temperature. Room temperature will be adjusted directly by the thermostat mounted on t...

Page 16

16 3.15.2 symbols 3.16 description of alarms warning reason solution smoke probe alarm • fault in the sensor recording flue temperature • contact your local service technician. • sensor is faulty or disconnected hot smoke alarm • smoke sensor detects a temperature over 280ºc • press the off button a...

Page 17

17 3.17 amalfi electrical circuit diagram f n fumi scamb. Coc. Acc. Al2 al1 n -tc1+ term. N.Amb. N.H2o n.Pel. Enc +5v gnd blu red blue azzurro blu/nero yellow / green blue encoder red black white brown flat cable red trasducer water circulator cod. 55130 cod. 38000-51-001 room probe w ater probe smo...

Page 18

18 4. Maintenance and cleaning before carrying out any maintenance take the following precautions: • make sure that the fire has been turned off, and that the general power supply has been disconnected (ensure that the plug is disconnected from the socket, thus avoiding accidental electric shocks). ...

Page 19

19 4.3 description of inner parts of the ecoteck amalfi 4.4 routine cleaning (every two - three days) fire pot cover grill fire pot drawer cover guard fire pot holder ash drawer ash drawer compartment remove the fire pot cover grill so that the drum is clearly visible remove the fire pot to check ho...

Page 20

20 vacuum the ash deposited in the compartment under the drawer with a vacuum cleaner. Unscrew the side ceramic brick to reach the smoke duct cleaning plates. Unscrew and vacuum the deposited ash. Before carrying out the operation described above, clean the tube bundle with the cleaning rods, as sho...

Page 21

21 4.5 cleaning the glass the glass is self-cleaning, therefore while the stove is in operation, a flow of air runs along the surface of the glass keeping ash and dirt away. However, a greyish patina will form after a few hours and this must be cleaned once the stove has been turned off. The glass m...

Page 22: 5. Guarantee

22 5. Guarantee 5.1 certificate of guarantee ecoteck thanks you for the confidence you have placed in it with the purchase of one of our pellet stoves and invites the purchaser to: - examine the instructions for the installation, use and maintenance of the stove. - examine the conditions of guarante...

Page 23: 6. What Are Wood Pellets?

23 6. What are wood pellets? Wood pellets are made from sawdust and wood shavings. The material used cannot contain any foreign substance such as glue, varnish or synthetic substances. Subjecting it to high pressure, the wood is pressed through a plate with holes and due to the high pressure the saw...

Page 24: Installation Section

24 installation section table of contents 1. Dimensions (ecoteck amalfi) 25 1.1 deciding where to locate your wood pellet burning heater: 26 1.2 clearances to combustibles – ecoteck amalfi freestanding 26 1.3 exhaust and fresh air intake locations 27 1.4 safety devices for closed expansion tank syst...

Page 25

25 1. Dimensions (ecoteck amalfi) the data shown above are indicative and not binding. Ecoteck reserves the right to make any modifications for the purpose of improving the performances of the product. Unit of measurement height mm 1079 width mm 575 depth mm 604 weight kg 130 diameter of smoke exhau...

Page 26

26 1.1 deciding where to locate your wood pellet burning heater: 1. Do not install the pellet heater in a bedroom or room where people sleep. 2. Locate the pellet heater in a large and open room that is centrally located in the house. This will optimize heat circulation. 3. Check clearances to combu...

Page 27

27 1.3 exhaust and fresh air intake locations exhaust hearth to centre of flue 305 mm left side of unit to centre of flue 139 mm centre of unit to centre of flue 148 mm fresh air intake hearth to centre of intake 346 mm left side of unit to centre of intake 370 mm centre of unit to centre of intake ...

Page 28

28 after positioning the thermal stove and installing all the smoke discharge pipes, the hydraulic plant can be connected. First of all make sure that the bleeder valve ( 1 ), on the top right-hand side of the boiler (see images below) is closed when the water is filling as shown in the figure below...

Page 29: 2. Installation

29 2. Installation 2.1 dimensions – amalfi freestanding refer to safety test 09/1910 for all clearances to combustible. 2.2 clearances & specifications minimum clearances shown are in millimetres. All ecoteck fires are tested to as/nzs2918:2001. Specifications were correct at time of printing but ma...

Page 30

30 2.3 minimum clearance to combustibles 2.4 location of the pellet fire installation of the ecoteck amalfi freestanding wood pellet burning heater should be undertaken by an experienced installer. Please read the amalfi owners’ and installation manual thoroughly before commencing installation as fa...

Page 31: Pellet Fire Flue Kits

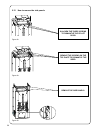

31 2.6.1 flue the thermostove functions irrespective of the flue’s draught since it is the smoke engine that conveys the smoke from the combustion chamber to the flue. Installation examples 2.7 internal standard flue kit (50) each 51 external standard flue kit contains:- y ti t n a u q n o i t p i r...

Page 32: Pellet Fire Flue Kits

32 2.8 external standard flue kit (51) internal standard flue kit each 50 internal standard flue kit contains:- y ti t n a u q n o i t p i r c s e d o n t r a p 1 galvanised outer liner ø100mm x 900mm long 2 stainless steel inner liner ø75mm x 900mm long 4a black p/coat outer liner ø100mm x 900mm lo...

Page 33

33 2.9 hydraulic installation 2.9.1 open vase plant safety devices according to standard uni 10412-2 (2006) in force in italy, systems with open expansion vases must be fitted with: • open expansion vase • safety pipe • loading pipe • circulator control thermostat (except for natural circulation sys...

Page 34

34 first of all check that the relief valve ( 1 ), situated on the upper right hand side of the boiler (see figure 24 and figure 25) is open once the water has been filled as shown in the figure below. Connect the boiler connectors correctly (see figure 26) to the hydraulic plant, bringing the plant...

Page 35

35 2.9.4 hydraulic plant thermostove for heating this diagram is given as an indication only. Installation must be carried out by a plumber. 2.10 seismic restraint all installation scenarios for amalfi require the use of hold-down anchors (one on each side). Fixing to concrete floor: • minimum m8 ex...

Page 36

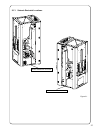

36 2.12 how to remove the side panels slacken the three screws to dismantle the pellet door. Remove the screws on the top plate to dismantle the sides. Remove the side panels. Figure 28. Figure 29. Figure 30..

Page 37

37 2.13 seismic restraint locations seismic restraint location seismic restraint location figure 31..

Page 38

38 3. Installation data sheet name of owner: ________________________________ address: ________________________________ ________________________________ ________________________________ ________________________________ phone: ________________________________ name of dealer: _________________________...

Page 39: 4. Maintenance Record

39 4. Maintenance record date work carried out signature.