- DL manuals

- ECR International

- Boiler

- CCB-150

- Installation, operation & maintenance manual

ECR International CCB-150 Installation, operation & maintenance manual

Summary of CCB-150

Page 1

Combi wall mounted gas boiler installation, operation & maintenance manual p/n# 240010632, rev. B [07/17/2014] model ccb-150 manufactured for: ecr international, inc. 2201 dwyer avenue, utica ny 13501 web site: www.Ecrinternational.Com cod. 3541f060

Page 2

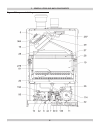

Figure 1 - overall dimensions rear view bottom view 1 = 1“ mpt supply water to heating system (out) 2 = 3/4” mpt tap water outlet 3 = 3/4” fpt gas inlet 4 = 3/4” mpt tap water inlet 5 = 1” mpt return water from heating system (in) 2 dimensions top view side view front view.

Page 3

Table of contents 3 1 - introduction ................................................................................................................... 4 2 - important safety information ........................................................................................... 5 3 - general view a...

Page 4

1 - introduction 1.1 designated use • hot water heating boiler. • indoor installation. • closet or alcove installation. • catagory i or iii venting. • direct vent boiler. • for use with natural gas or lique fi ed petroleum gases (lp/propane). • directly heat potable water. Indirect heating is accept...

Page 5

2 - important safety information notice used to address practices not related to personal injury. Caution indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. ! ! Warning indicates a hazardous situation which, if not avoided, could result in death or serio...

Page 6

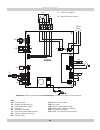

Figure 2 component listing 6 3 - general view and main components.

Page 7

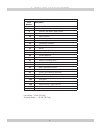

Item number description 5 sealed chamber 7 gas inlet 8 domestic hot water (dhw) outlet 9 domestic cold water (dhw) inlet 10 supply system 11 system return 16 modulating fan 19 combustion chamber 20 burner assembly 22 burner 26 combustion chamber insulation 27 copper heat exchanger 28 exhaust manifol...

Page 8

Remove boiler jacket 1. Unscrew screws (a). 2. Pivot jacket upwards. See fi gure 3. 3. Raise jacket up and off boiler. See fi gure 4. 1 3 2 a a figure 3 - jacket removal - screw locations figure 4 - pivot jacket and raise to remove warning fire, explosion, asphyxiation and electrical shock hazard. D...

Page 9

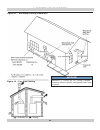

Figure 5 - boiler clearances 9 4 - locating boiler 4.1 boiler location considerations • ambient room temperature always above 32°f (0°c) to prevent freezing. • approved for installation in closets. • protect gas ignition system components from water (dripping, spraying, rain, etc.) during operation ...

Page 10

Figure 6 - wall mounting bracket 10 4 - locating boiler 4.2 pre-pipe supply and return water connections with factory fi ttings before wall mounting. 4.3 wall mounting mount boiler on wall using wall mounting bracket included with unit. • structure must be capable of supporting boiler weight plus 60...

Page 11

11 5 - hydronic piping 5.1 general • install piping in accordance with authority having jurisdiction. Notice use two (2) wrenches when tightening and fi tting pipe to boiler's threaded fi ttings. Boiler's internal piping can be damaged if subjected to excessive torque. • support system piping and sa...

Page 12

12 warning burn and scald hazard. Safety relief vlave could discharge steam or hot water during operation. Install discharge piping per these instructions. Failure to do so could result in death or serious injury. ! 5.4 safety relief valve notice boiler rated at 43.5 psig (.30mpa) maximum allowable ...

Page 13

13 5 - hydronic piping check local codes for maximum distance to floor safety relief valve gas shutoff valve in open position figure 8 - safety relief valve discharge piping.

Page 14

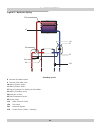

14 5 - hydronic piping figure 9 - hydronic piping 27 32 136 11 10 8 9 278 95 241 42 114 36 - plumbing circuit 8 domestic hot water outlet 9 domestic cold water inlet 10 heating system supply 11 heating system return 27 copper exchanger for heating and hot water 32 heating circulating pump 36 automat...

Page 15

15 6 - combustion air and vent piping - category i (chimney vent) 6.1 check your chimney chimney must be clean, right size, properly constructed and in good condition. 1. Installation must conform to requirements of the authority having jurisdiction or, in absence of such requirements, to the nation...

Page 16

16 6 - combustion air and vent piping- category i (chimney vent) 6.2 minimum vent pipe clearance • use type b vent pipe through crawl space. Where vent pipe passes through combustible wall or partition, use ventilated metal thimble. Thimble should be 4 inches larger in diameter than vent pipe. • boi...

Page 17

17 6 - combustion air and vent piping of direct vent and category iii induced draft boilers horizontal (category iii) venting systems installation shall conform to the requirements of the authority having jurisdiction or, in the absence of such requirements, to the national fuel gas code, ansi z223....

Page 18

18 warning vent extending through exterior wall shall not terminate adjacent to wall or below building extensions such as eaves, balconies, parapets or decks. Failure to comply could result in death or serious injury. ! Table 3 - combustion air and vent pipe fittings 6 - combustion air and vent pipi...

Page 19

19 6 - combustion air and ventilation provide combustion air and ventilation air in accordance with the section “air for combustion and ventilation,” of the national fuel gas code, ansi z223.1/nfpa 54, or sections 8.2, 8.3 or 8.4 of natural gas and propane installation code, can/csa b149.1, or appli...

Page 20

20 6 - combustion air and vent piping ( = combustion air / = venting) figure 11 - horizontal venting clearances figure 12 - two pipe venting notice maintain 12” (30cm) us, 18” (46cm) canada clearance above highest anticipated snow level or grade..

Page 21

21 6 - combustion air and vent piping figure 13 - chimney venting with room air single wall ( = combustion air / = venting) ( = combustion air / = venting) figure 14 - chimney venting with outside air single wall notice refer to section 6.1, numbers 3 through 12, page 15 of this manual for proper in...

Page 22

22 7 - gas supply piping caution what to do if you smell gas • do not try to light any appliance. • do not touch any electrical switch; do not use any phone in your building. • immediately call your gas supplier from a neighbor’s phone. Follow gas supplier’s instructions. • if you cannot reach your ...

Page 23

23 8 - electrical connections 8.1 general electrically bond boiler to ground in accordance with requirements of authority having jurisdiction. Refer to: • usa- national electrical code, ansi/nfpa 70. • canada - canadian electrical code, part i, csa c22.1: safety standard for electrical installations...

Page 24

Warning asphyxiation hazard. Carbon monoxide is odorless, tasteless, clear colorless gas, which is highly toxic. Carbon monoxide production shall not exceed 400ppm. Failure to follow these instructions could result in death or serious injury. Warning asphyxiation hazard. Verify cap is fi rmly placed...

Page 25

9.6 check combustion natural gas 1. Measure input. English unitsturn off gas to all other appliances. • activate some heating zones to dissipate heat. • set boiler on high fi re. • use ½, 1 or 2 cu ft dial on gas meter. Measure time required for one or more complete revolutions. Measure time for 1-2...

Page 26

26 caution what to do if you smell gas • do not try to light any appliance. • do not touch any electrical switch; do not use any phone in your building. • immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions. • if you cannot reach your gas supplier, call...

Page 27

10.5 indicator during operation heating call for heat (generated by room thermostat) is indicated by hot air fl ashing above radiator symbol on the control. Hot water call for hot water (generated by drawing off hot tap water) is indicated by hot water fl ashing under the tap on the control. 10.6 tu...

Page 28

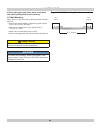

Boiler ignition supply unit with electricity. Boiler ignition for 120 seconds display will show fh which identi fi es the air venting cycle for the heating system. During the fi rst 5 seconds the display will show the software release of the card also. Open the gas valve before the boiler. When fh v...

Page 29

Eco/comfort selection the unit has a function that ensures a high domestic hot water delivery speed and maximum comfort for the user. When the device is activated (comfort mode), the water contained in the boiler remains hot, ensuring faster availability of domestic hot water. The device can be deac...

Page 30

Compensation curve and curve offset press the button (see item 6 on the control panel display) for 5 seconds once to display the actual compensation curve, which can be modi fi ed with the dhw buttons (see items 1 and 2 on the control panel display). Adjust the required curve from 1 to 10 according ...

Page 31

Press the button (see item 6 on control panel display) for 5 seconds again to exit parallel curve adjustment mode. If the room temperature is lower lower than the required value, it is advisable to set a higher order curve and vice versa. Proceed by increasing or decreasing in steps of one and check...

Page 32

Water system pressure adjustment the fi lling pressure with system cold, read on the boiler water gauge, must be approximately 11 psi. If the system pressure falls to values below minimum, the boiler control will activate fault f37. Low system pressure fault once the system pressure is restored, the...

Page 33

33 11 - general maintenance and cleaning 11.1 beginning of each heating season • check boiler area is free from combustible materials, gasoline, and other fl ammable vapors and liquids. • visually inspect combustion air and vent piping for proper operation. Check for and remove any obstruction to fl...

Page 34

34 12 - ratings and capacities.

Page 35

35 12.1 ratings and capacities • constructed and hydrostatically tested for maximum allowable working pressure of 43.5 psig (pounds per square inch gauge) 43.5 psig (.30mpa) in accordance with asme boiler and pressure vessel code, section iv, rules for construction of heating boilers. • usa - input ...

Page 36

36 12 - ratings and capacities diagrams pressure - power diagrams 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 44 45 kw 6 5 4 3 2 1 0 wc ccb 150 a lpg b natural gas losses of load / head of circulators a boiler losses of head 1 - 2 - 3 circulator speed 0...

Page 37

37 13 - trouble shooting diagnostics the boiler is equipped with an advanced self-diagnosis system. In case of a boiler fault, the display will fl ash indicating the fault code. There are faults that cause permanent shutdown (marked with the letter “ a ”): to restore operation just press the reset b...

Page 38

Gnd out +5v 47 42 72 114 136 297 95 ° t ° t 278 32 16 44 dbm34 l 120vac 60hz gnd + 15v out n 1k 81 5 6 4 1 2 138 1 4 aux l n x2 x7 1 m 370 3 key 16 modulating fan 32 heating circulating pump 42 dhw temperature sensor 44 gas valve 47 modulation regulator 72 room thermostat ( fi eld sourced) 81 igniti...

Page 39

39.

Page 40

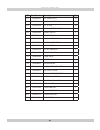

Key part number description qty a01 fe3980b990 casing "ctr" 1 40 repair parts list.

Page 41

Key part number description qty b01 fe3980c200 kit control box 1 b02 fe3980b850 kit control board dbm34 2 b03 fe3980c210 kit front cover "ctr" 1 b04 fe3980b840 kit press.Temp. Gauge 1 b05 fe3980c330 kit wiring 1 b06 fe3980c220 kit mono cable el. 1 41 repair parts list.

Page 42

42 repair parts list.

Page 43

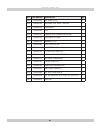

Key part number description qty c01 fe3980c000 kit gaskets set 10 c02 fe3980c010 kit 20 gasket oring 1 c03 fe3980c020 kit 10 clip 10 c04 fe3980c030 mono heat exchanger 2 c05 fe3980c040 senor temp dp 1 c06 fe3980c340 senfor temp 14 1 c07 fe3980c350 5 flow controller 1 c08 fe3980c360 kit flowmeter elt...

Page 44

44 repair parts list.

Page 45

Key part number description qty d01 fe3980b930 kit gaskets set 1 d02 fe3980c090 pressure test point "venturi" 1 d03 fe3980c100 fan gasket 1 d04 fe3980b940 fan 2 d05 fe3980c110 combustion chamber insulation 1 d06 fe3980c120 ignition electrode 1 d07 fe3980c130 burner 17 r.M. 1 d08 fe3980b960 gas valve...

Page 46

46 notes.

Page 47

47 notes.

Page 48

Ecr international, inc 2201 dwyer avenue, utica ny 13501 web site: www.Ecrinternational.Com.