- DL manuals

- ECR International

- Air Conditioner

- R15C

- Installation, Operation & Maintenance Manual

ECR International R15C Installation, Operation & Maintenance Manual

P/N 240010545 Rev. B [10/24/2014

]

Packaged Terminal Air Conditioner (PTAC)

Packaged Terminal Heat Pump (PTHP)

Installation, Operation &

Maintenance Manual

Replacements for:

R15C

- American Air Filter series 25 & Others, American

Standard 41

R50C

- Dunham/Bush Newport Models I, II, III, IV

R60C | R60H

- Remington , Singer, or Mcquay K/EK

R65C

- Reminton, Singer, McQuay J/EJ and others

R15C - R50C

R60C/H - R65C

ECR International, Inc.

2201 Dwyer Avenue • Utica, New York 13501

Ph: 800.325.5279 • Web: retroaire.com

Summary of R15C

Page 2

Table of contents information and specifications outlined in this manual in effect at the time of printing of this manual. Ecr international reserves the right to discontinue, change specifications or system design at any time without notice and without incurring any obligation, whatsoever. Ahri cer...

Page 3

Receiving information shipping damage must be reported to the carrier immediately. Examine exterior. Remove cover and examine compressor and piping for signs of damage. Inspection check shipment against bill of lading. Verify equipment received as ordered. Verify unit: • unit size and type correct p...

Page 4

Important safety information become familiar with symbols identifying potential hazards. All field wiring shall conform to requirements of authority having jurisdiction or in absence of such requirements: • united states - national electrical code, ansi/nfpa 70 • canada - csa c22.1 canadian electric...

Page 5

Figure 1 r15c dimensions - inches (mm) figure 2 r50c dimensions - inches (mm) 15.75 400 34.50in 876mm 3.00 76 22.92in 582mm 34.75in 883mm 18.22in 463mm 17.38 441 11.75 298 19.38 492 12.43in 316mm 13.53in 344mm 3.50in 89mm 13.38 [344 mm] 13.53 in [298mm] 11.75in [441mm] 17.38in [492mm] 19.38in [400mm...

Page 6

Dimensional/physical data figure 3 r60c/r60h chassis figure 4 r65c chassis [349 mm] 13.75 in [155mm] 6.12 in [94 mm] 3.69 in [721 mm] 28.38 in [329 mm] 12.97 in [451 mm] 17.75in [470 mm] 18.50 in the right fit for comfort 6 p/n 240010545, rev. B [10/24/2014 ].

Page 7

Product description • available in straight cooling (ptac) or heat pump systems (pthp). • heat pumps (pthp) reduce energy costs and operate in mechanical heat mode down to outdoor temperature of 40°f (4.4°c). Below 40°f (4.4°c) heating is accomplished by an auxiliary heat option. • use r-410a refrig...

Page 8

Indoor coil freeze protection (standard) prevents indoor coil from freeze up in cooling mode. • indoor coil freeze up can occur due to a dirty air filter, restricted or poor air flow, low refrigerant charge or low room or outdoor temperatures. • this can cause compressor damage. • should freeze cond...

Page 9

Hydronic heating (optional) hydronic heat package may be selected in lieu of electric heat. Heating operation is same as that of units with electric heat. Aquastat connection (optional) all replacement ptac/pthp's with hydronic heat are supplied with standard line volt aquastat connection. Field ins...

Page 10

Installation preparation verify existing wall sleeve/enclosure: 1. Retroaire ptac/pthp's are to be used with metal wall sleeves. 2. Existing front panels must be secured by screws that prevent contact with all parts. 3. Minor dimensions of openings must not exceed ½ inch (12.5mm). 4. Indoor air disc...

Page 11

Installation 1. Verify existing wall thickness . Distance from condenser coil to outdoor louver varies with wall sleeve depth. Units shipped with factory installed baffles. Manufacturer offers alternate air baffle kits for unique applications. Wall sleeve depth is required when ordering to ensure pr...

Page 12: For Best Results

R15c /r15h - installation figure 5 r15c chassis to use this format set your tiff output to print capture, 150dpi, c -landscape, scale to fit for best results to use this format set your tiff output to print capture, 150dpi, c -landscape, scale to fit for best results t41 bracket t25 bracket electric...

Page 13

R15c /r15h - installation figure 6 r15c baffles size 1 size 2 size 3 size 4 top view of baffles baffles figure 7 weather angles reversed to change offset type 25 weather angle type 41 weather angle velcro strips sensing bulb figure 8 direction of baffles and foam installation foam open cell 1/2" x 1...

Page 14

Installation - b15c figure 9 b15c blower deck wire ties installation instructions - b15c 1. Remove existing wire ties holding wires shown on blower deck. See figure 9. 2. Guide the wire harness and 4 position molex from b15 to r15 chassis plenum. See figure 11. Figure 10 wire harness and 4 position ...

Page 15

Installation - r50c installation 1. Verify existing wall thickness . Distance from condenser coil to outdoor louver varies with wall sleeve depth. Two sets of air baffles are included with each unit to accommodate most installation requirements. Manufacturer offers alternate air baffle kits for uniq...

Page 16

Figure 13 r50c chassis and install kit installation kit contents: • installation manual • size 1 - left & right baffles • size 2 - left & right baffles • 1∕2” x 1∕2” open-cell foam tape • 1” x 1” open-cell foam tape • screws 4 optional hydronic heat controls • (1) 2-position connector • (2) pin mate...

Page 17: For Best Results

Installation - r50c/r50h figure 15 r50c chassis to use this format set your tiff output to print capture, 150dpi, c -landscape, scale to fit for best results removeable control box cover manual fresh air fan cycle switch hydronic no/nc switch valve orientation switch (vos) high pressure switch (hps)...

Page 18

Installation - r60c/r60h installation 1. Verify existing wall thickness . Distance from condenser coil to outdoor louver varies with wall sleeve depth. Several sets of air baffles are included with each unit to accomodate most installations. Manufacturer offers alternate air baffle kits for unique a...

Page 21

Installation - r65c/r65h installation 1. Verify existing wall thickness . Distance from condenser coil to outdoor louver varies with wall sleeve depth. Each chassis includes standard air baffles to accommodate most common condenser coil to outdoor louver requirements. Optional condenser-side air baf...

Page 24

R65c - field installation of sensor wires 1. Route sensor wires from chassis to control board. 2. Connect wires to control board. Chassis blower section control box to ensure proper operation connect wires to control board indoor. Label indoor indoor outdoor label outdoor to ensure proper operation ...

Page 25

Sequence of operation • r_ _c units are straight cool, single stage air conditioners available with electric or hydronic heat. • r_ _h units are limited range, single stage heat pump. Mechanical compression heating (heat pump mode) is locked out at outdoor temperatures of approximately 35º f (1.7º c...

Page 26

• if equipped with motorized fresh air damper, and is active with fresh air switch [fas], damper will open with call for the indoor fan. • if room temperature is below thermostat setting fan operation continues as noted. • if room temperature is above thermostat setting, reversing valve is energized...

Page 27

B. If fan cycle switch [fcs] is set to “off” (cycling fan operation), indoor fan motor starts with call for heating from internal thermostat [t’stat]. C. If unit is equipped with motorized fresh air damper, and is activated with fresh air switch [fas], damper opens with call for indoor fan. D. If ro...

Page 28

Final inspection & start-up before operating the unit 1. Install unit per the instructions outlined in this manual and all applicable local and national codes. 2. Verify electrical supply matches electrical requirements of the unit, and unit is properly grounded. 3. Examine control box. Verify all w...

Page 29

Electrical connections installation and wiring shall be in accordance with requirements of authority having jurisdiction in absence of such requirements refer to: • usa- national electrical code, ansi/nfpa 70. • canada - canadian electrical code, part i, csa c22.1: safety standard for electrical ins...

Page 30

Final inspection & start-up test jumper heat pump jumper figure 31 - test jumper (selects normal or test mode) the right fit for comfort 30 p/n 240010545, rev. B [10/24/2014 ].

Page 31

Figure 32 typical representation - unit mount control thermostat knob do not rotate thermostat knob back and forth from heating to cooling. This causes compressor to cycle on and off rapidly and will cause damage to the compressor. Allow compressor to remain off for at least three minutes prior to r...

Page 32

Heating cycle — electric option 1. Outdoor fan does not run during heating cycle. 2. Place thermostat or system switch in heat position. 3. Adjust thermostat for warmer temperature until indoor fan starts running and electric heater coil starts emitting heat. 4. After unit starts running and space g...

Page 33

Final inspection & start-up heat pump pthp's unit is equipped with reversing valve, energized for cooling and de-energized in heating mode. Cooling cycle — heat pump units 1. Place thermostat or system switch in cool position. 2. Adjust thermostat to cooler temperature until indoor fan starts runnin...

Page 34

Auxiliary heating operation — heat pump units — outdoor temperature below 40°f (4°c) — hydronic option room temperature must be below 85°f (29°c) for hydronic heater to operate on pthp's with unit-mounted controllers. Hydronic valve is 24vac normally open valve. Should power be lost to the unit, the...

Page 35

Maintenance figure 33 - manual reset limit switch reset button *note: button will pop out when limit switch opens. Push in to reset. Seasonal start-up and maintenance beginning of cooling and heating seasons, complete mechanical check should be performed and maintenance/ inspections performed as des...

Page 36

Maintenance 11. Air leaks may make the conditioned area uncomfortably drafty or produce noises. Visually inspect foam gasket between wall and unit, taking note of separation between air inlet for condenser and condenser coil discharge. These two areas must be sealed off from each other. If you exper...

Page 37

Troubleshooting warning electrical shock hazard. Disconnect power to unit before servicing or accessing control compartment. Failure to follow these instructions could result in death or serious injury. ! Notice have qualified technician conduct troubleshooting procedures. Symptom suggestion no heat...

Page 38

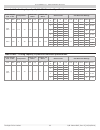

Table 3 r15 c performance data model r15 cooling sensible heat ratio eer indoor air flow fresh air inlet flow shipping weight btuh (kw) cfm (l/s) cfm (l/s) lbs (kg) r_ _c 09 9,000 (2.6) 0.75 8.98 400 (189) 35 (17) 140 (64) r_ _c 12 11,500 (3.7) 0.70 8.45 400 (189) 35 (17) 140 (64) r_ _c 15 14,000 (4...

Page 39

Power supply volt 1–60 compressor indoor fan motor outdoor fan motor electric heat unit electrical ratings volt min rla lra fla hp fla hp htr # volt w ha tca tha mca mocp plug 115v 104 8 45.6 1.4 0.09 1.6 0.125 n/a n/a n/a n/a 11 n/a 13.0 20 5-20p 208/ 230v 197 4 22.2 0.6 0.08 0.71 0.09 0 n/a n/a n/...

Page 40

Electrical specifications power supply volt 1–60 compressor indoor fan motor outdoor fan motor electric heat unit electrical ratings volt min rla lra fla hp fla hp htr # volt w ha tca tha mca mocp plug 208/ 230v 197 7.4 33 0.6 0.08 1.0 0.25 0 n/a n/a n/a 9.0 n/a 10.9 15 6-15p 3 208 2454 11.8 12.4 15...

Page 41

Power supply volt 1–60 compressor indoor fan motor outdoor fan motor electric heat unit electrical ratings volt min rla lra fla hp fla hp htr # volt w ha tca tha mca mocp plug 115v 104 8 45.6 1.4 0.09 1.6 0.125 n/a n/a n/a n/a 11.0 n/a 13.0 20 5-15p 208/ 230v 197 4 22.2 0.6 0.08 0.71 0.09 0 n/a n/a ...

Page 42

Power supply volt 1–60 compressor indoor fan motor outdoor fan motor electric heat unit electrical ratings volt min rla lra fla hp fla hp htr # volt w ha tca tha mca mocp plug 115v 104 8 45.6 1.4 0.09 2.5 0.17 n/a n/a n/a n/a 11.0 n/a 13.0 20 hard wire 208/ 230v 197 4 22.2 0.6 0.08 1.1 0.15 0 n/a n/...

Page 43

Electrical specifications power supply volt 1–60 compressor indoor fan motor outdoor fan motor electric heat unit electrical ratings volt min rla lra fla hp fla hp htr # volt w ha tca tha mca mocp plug 115v 104 8 45.6 1.4 0.09 1.6 0.125 n/a n/a n/a n/a 11.0 n/a 13.0 20 hard wire 208/ 230v 197 4 22.2...

Page 44

Electrical specifications power supply volt 1–60 compressor indoor fan motor outdoor fan motor electric heat unit electrical ratings volt min rla lra fla hp fla hp htr # volt w ha tca tha mca mocp plug 208/ 230v 197 7.4 33 0.6 0.08 1.0 0.25 0 n/a n/a n/a 9.0 n/a 10.9 15 hard wire 3 208 2454 11.8 12....

Page 45

Legend rla rated load amps fla full load amps hp horse power w watts ha heater amps tca total cooling amps tha total heating amps mca minimum circuit amps mocp maximum over current protection electrical specifications 45 made in usa p/n 240010545, rev. B [10/24/2014 ].

Page 46

Notes the right fit for comfort 46 p/n 240010545, rev. B [10/24/2014 ].

Page 47

P/n 240009782 rev b (9/2013) limited product warranty retroaire offers to the original purchaser/owner that under normal use and maintenance for comfort cooling and conditioning applications, all retroaire equipment will be free from defects in material and workmanship for a period of 12 months from...

Page 48

Ecr international, inc. 2201 dwyer avenue • utica, new york 13501 phone: 1.800.325.5279 • web: retroaire.Com.