- DL manuals

- Emhart

- Nail Gun

- AutoSet 5

- Operator's Maintenance Manual

Emhart AutoSet 5 Operator's Maintenance Manual - Autoset

Summary of AutoSet 5

Page 1

Autoset ® 5 & 6 operator & maintenance manual.

Page 2: Contents

Contents introduction ___________________________________________________________________________ 2 safety instructions _____________________________________________________________________ 3 ec declaration of conformity_____________________________________________________________ 4 specifications _...

Page 3: Safety Instructions

Safety instructions this manual must be carefully read with particular attention to the safety instructions to insure safe operation, correct functioning, and proper servicing of the autoset ® tool 1. Do not use this tool in a manner other than that recommended by emhart teknologies. 2. Do not use e...

Page 4: Ec Declaration of Conformity

Ec declaration of conformity we, emhart teknologies tucker fasteners limited birmingham b42 1bp england. Declare that: autoset ® conforms to the following standards: en 292 part 1 and part 2 iso pren 15744 iso 3744 en 28662 - 1 iso pren 792 part 1 en 12096 en iso 4871 following the provisions of the...

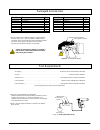

Page 5: Specifications

Specifications overall dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Height: 14.1” [358mm] length: 11.9” [303mm] width: 5.7” [46mm] weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

Packaged accessories part no. Item qty part no. Item qty dp220-155 oil fill bottle (empty) 1 dp220-070 pipe spanner 1 dp220-074 screwdriver 1 dp220-071 t-wrench 1 dp220-165 maintenance tube 1 dp220-623 jaw setting jig (2-pc) 1 dp220-073 14mm flat wrench 1 dp220-154 2.5mm hex key 1 dp220-072 15mm fla...

Page 7: Operation

Operation preparation for operation before operating the tool check the following: • inspect the tool for damage and/or signs of wear and replace or repair parts as required. Do not use the tool if damaged. • if using inline lubrication, check the adjustment on the lubricator and make sure there is ...

Page 8

Tool operation – cont’d loading rivet tape 1. Turn off the air supply to the tool. 2. Open the magazine on the autoset ® tool. 3. Locate the plate spring on the indexing assembly. 4. Insert the leading edge of the rivet tape underneath the plate spring so that the 1 st “rung” of the tape is past the...

Page 9

Tool operation – cont’d reloading the tool once all of the rivets on the rivet tape are used, the rivet tape needs to be removed to load the next coil. 1. With the air supply on, pull the trigger on the tool and hold it so that the nose piston remains in the back position. 2. While holding the trigg...

Page 10: Autoset

Autoset ® 5 & 6 diagram note: item numbers in brackets [ ] are for the autoset ® 6 tool. Autoset 6 indexer assembly page 10 emhart teknologies - 50 shelton technology center, shelton ct 06484 - tel. (203) 924-9341 - fax (800) 225-5614.

Page 11

Emhart teknologies - 50 shelton technology center, shelton ct 06484 - tel. (203) 924-9341 - fax (800) 225-5614 page 11 emhart teknologies - 50 shelton technology center, shelton ct 06484 - tel. (203) 924-9341 - fax (800) 225-5614 page 11.

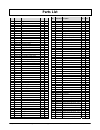

Page 12: Parts List

Page 12 emhart teknologies - 50 shelton technology center, shelton ct 06484 - tel. (203) 924-9341 - fax (800) 225-5614 parts list no. Emhart p/n description as 5 as 6 85 dp220-085 o-ring p18 2 2 88 dp220-088 penta seal, 15mm dia. 1 1 89 dp220-089 penta seal, 24mm dia. 1 1 90 dp220-090 air seal, 41.5...

Page 13

No. Emhart p/n description as 5 as 6 174 dp220-174 torx head cap screw - metric 2 2 176 dp220-176 barb elbow 360, 6 mm 1 1 182 dp220-182 filter holder (upgrade) 1 1 183 dp220-183 filter case (upgrade) 1 1 184 dp220-184 cotton ball (1 pc) 2 2 185 dp220-185 o-ring - filter holder (upgrade) 1 1 201 dp2...

Page 14: Maintenance

Maintenance preventative maintenance schedule item freq action mcs container 1x per rivet strip empty mcs container. Jaw and nose piston front end jaw area cleaning 1x per shift or 5k - 8k cycles remove nosepiece and jaws; clean and lubricate. Clean debris from inside nose piston – step11 (see “jaw ...

Page 15

Tool maintenance – cont’d jaw removal and cleaning – cont’d 8. Turn the tool upside down and remove the slide pipe, jaw pusher spring, jaw pusher and 3-piece jaw set (fig. 13). Note: if the jaws stick to the inside of the jaw case piston, use the t-wrench to push the jaws out from the front of the t...

Page 16

Tool maintenance – cont’d jaw replacement – cont’d 7. Re-insert the jaw pusher, jaw spring and slide pipe using the pipe spanner and screw driver with maintenance tube (fig. 16). 8. Tighten the slide pipe to a torque of 32.7 in-lb (3.7 n-m). 9. Re-connect the air hose and turn on the air supply allo...

Page 17

Tool lubrication – cont’d manual lubrication manual lubrication is a simple method recommended for low volume tool use where there is a qualified technician available to service the tool. The manual lubrication process is as follows: 1. Add one drop of hydraulic oil* inside the air fitting on the to...

Page 18: Safety Data

Safety data moly grease (emhart p/n: dp220-810) manufacturer: t.S. Moly-lubricants, inc., houston, tx emergency: (713)671-2676 msds number: ts-122 lithium ep-2 moly poly grease first aid: skin: prolonged or repeated skin contact with this product tends to remove skin oils, possibly leading to irrita...

Page 19: Troubleshooting

Troubleshooting for any other issues, please contact your distributor. Symptom probable cause remedy mcs chamber full. Empty mcs chamber of spent mandrels. The slide guide and/or the slide pipe have come loose. Examine the parts for damage and reattach per the jaw replacement instructions in the “to...

Page 20

Americas united states connecticut 50 shelton technology center p.O. Box 859 shelton, ct 06484 usa tel. 203-924-9341 fax. 800-225-5614 canada 9870 boul. Du golf anjou, québec h1j 2y7 canada tel. 514-351-0330 fax. 514-351-0458 brazil rua ricardo cavatton, 226 – lapa sao paulo, sp brazil cep 05038-110...