- DL manuals

- FAAC

- Door Opening System

- 950 BM

- User Manual

FAAC 950 BM User Manual

Summary of 950 BM

Page 1

950bm 950bm para la naturaleza 100% papel reciclado ist umweltfreundlich 100% altpapier pour la nature papier recyclé 100% for nature recycled paper 100% carta riciclata 100% per la natura.

Page 2

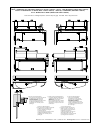

Fig. 2a fig. 2b fig. 3 1 1 2 2 3 3 1 2 4 5 fig. 4 fig. 4b fig. 4a 6.

Page 3

Fig.5 fig.6.

Page 4

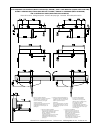

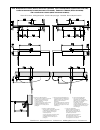

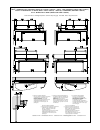

Quota con albero standard. Nel caso fosse necessario aumentare la distanza tra l’operatore ed il braccio, utilizzare le prolunghe modulari opzionali. Ciacuna prolunga aumenta il valore di altezza standard di 30 mm. E’ suggeribile non montare più di 2 prolunghe . (*) distance with standard extension....

Page 5

Quota con albero standard. Nel caso fosse necessario aumentare la distanza tra l’operatore ed il braccio, utilizzare le prolunghe modulari opzionali. Ciacuna prolunga aumenta il valore di altezza standard di 30 mm. E’ suggeribile non montare più di 2 prolunghe . (*) distance with standard extension....

Page 6

Quota con albero standard. Nel caso fosse necessario aumentare la distanza tra l’operatore ed il braccio, utilizzare le prolunghe modulari opzionali. Ciacuna prolunga aumenta il valore di altezza standard di 30 mm. E’ suggeribile non montare più di 2 prolunghe . (*) distance with standard extension....

Page 7

Quota con albero standard. Nel caso fosse necessario aumentare la distanza tra l’operatore ed il braccio, utilizzare le prolunghe modulari opzionali. Ciacuna prolunga aumenta il valore di altezza standard di 30 mm. E’ suggeribile non montare più di 2 prolunghe . (*) distance with standard extension....

Page 8

22 english english ce declaration of conformity for machines (directive 98/37/ec) manufacturer: faac s.P.A. Address: via benini, 1 40069 - zola predosa bologna-italy declares that: 950 bm automated system, • is built to be integrated into a machine or to be assembled with other machinery to create a...

Page 9: Faac 950 Bm

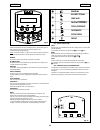

23 english english faac 950 bm fig. 1 1 cable hole 2 support profile 3 950 i/o electronic control unit 4 adjustment of internal mechanical stops. 5 transmission shaft coupling 6 protection for drive system and re-closure spring. 7 dc motor 8 950 mps programming unit 9 toroidal transformer 10 mains p...

Page 10

24 english english 1.2 door max opening angle according to the type of mounting and respecting the installation dimensions shown in tables a,b,c, or d, different door max. Opening angles can be obtained according to the lintel thickness. Table 5 and 6 shows the maximum values of the opening angles t...

Page 11

25 english english 3.3.2. Mounting the sliding arm (fig.6) 1) mount arm (1) on the operator transmission shaft by means of the standard shaft (5) and the screw (2) provided (fig.6). The arm must be fitted pointing 45° outwards as shown in fig. 6(a). Note: if a larger distance is required between the...

Page 12

26 english english 5.2. Setting the adjusting trimmers the programming unit features trimmers (fig.8) which regulate the following parameters: trimmer tr1 to set the opening speed. Setting from 4 to 10 seconds. Trimmer tr2 to set the closing speed. Setting from 4 to 10 seconds. Trimmer tr3 to set th...

Page 13

27 english english warning: always disconnect the electric power supply before carrying out any work on the control unit (connection, maintenance). Ds1 no.2: lock activation delay off = disabled on = enabled if this dip-switch is enabled, the door movement is delayed by 500msec with respect to the e...

Page 14

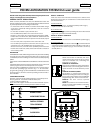

28 english english 15 key command - n.O. Contact any pulse generator (pushbutton, sensor, etc.) which, by closing a contact, commands door opening. To install several pulse generators as internal command, connect the n.O. Contacts in parallel. 16 fire-alarm command - n.O. Contact any device (fire-al...

Page 15

29 english english 3 electric lock - n.C. Contact (max. Capacity 0.5 a/24 v) (fig.14). The output is suitable for commanding a magnetic closure system. If no power is supplied, the electric lock is not active. In the night function the electric lock is powered and hence active. In the event of an op...

Page 16

30 english english 9. Adjusting the spring 9.1. Spring preloading if door movement is not uniform (e.G.: door not closing completely or closing with too much force) proceed as follows to adjust the spring preloading: 1) cut power to the automated system and release from the door the arm secured dire...

Page 17

31 english english 10. Kp-controller programming unit kp-controller is used for selecting operational functions, as well as adjusting and programming the 950 series automatic doors. It is divided into two parts: a fixed part used for signalling of operational functions by means of pushbuttons and re...

Page 18

32 english english 10.4 . Operational functions selection is performed by pressing the keys on the fixed part of the programmer - the function is indicated by the corresponding led lighting up. Note: when the “night” or “manual” modes have been set, the relevant selection keys must be pressed to exi...

Page 19

33 english english 10.7. Programming to access programming while the standard view is shown on the display, press any of keys , or ok. Programming is subdivided into main menus (see chart 1) split into subjects. After selecting the menu with keys or , to access it press ok. Each menu is, in turn, su...

Page 20

34 english english diagram 3: setup diagram 4: lock setup 80% 7 sec. * * 2 sec. * closing: standard no standard * obstacle detection night pause time partial opening pause time exit lock off on * * always one way+night night kit lock exit.

Page 21

35 english english diagram 5: diagnostics diagram 6: operation parameters reset 950 v. Diagnostics nr. Cycle xxxx alarm n. (alarm description) password 0000 password 0000 password 0000 password 0000 keep settings off on 8 8 exit * * * advanced menu operation parameters closing speed opening speed co...

Page 22

36 english english diagram 7: in/out setup password 0000 password 0000 password 0000 password 0000 in/out setup emerg open close out op/cl no out alarm no nc uscita * * nc no nc * * advanced menu operation parameters various exit change password correct code incorrect code.

Page 23

37 english english codice errato codice corretto diagram 8: various - change passwod - test prog password 0000 password 0000 password 0000 password 0000 in/out setup stand setup standard no standard interlock master slave no memory with memory exit new password 0000 new password 0000 new password 00...

Page 24

38 english english diagramma 9: clock diagram 10: timer diagram 11: timer programming sun 00:00 00/00/00 clock sun 00:00 00/00/00 sun 00:00 00/00/00 sun 00:00 00/00/00 sun 00:00 00/00/00 sun 00:00 00/00/00 sun 00:00 00/00/00 sun 00:00 00/00/00 sun 00:00 00/00/00 sun 00:00 00/00/00 sun 00:00 00/00/00...

Page 25

39 english english 1 language (diagram 2) select the language for showing the messages on the display 2 setup (diagram 3) 2.1 partial opening partial opening percentage select the opening percentage (referred to total opening) performed in the “partial opening” operational function. Standard value: ...

Page 26

40 english english master the master door (usually the internal one). Slave the slave door. No memory with interlock operation, you must wait for one door to close before commanding the other to open: any opening pulses sent during the operating cycle of the first door, have not effect. With memory ...

Page 27

41 english english 11. Special applications 11.1. Interlock the interlock function makes it possible to control two doors (master and slave) so that opening of one depends on closing of the other and vice versa. 11.1.1. Interlock with internal sensors this application is recommended when the distanc...

Page 28

42 english english 11.2. 2 leaves the “2 leaves” function makes it possible to manage two opposing doors with a synchronised movement and preset delay angles (these cannot be modified). The leaf controlled by the master automated system (see fig. 30) is the first to start the opening movement and, w...

Page 29

43 english english 950 bm automation system end-user guide manual operation if the door has to be activated manually due to failure of the electrical power supply or a malfunction of the automatic unit, proceed as follows: function selector - turn the selector to the “2” manual/night position (fig.1...

Page 30

Le descrizioni e le illustrazioni del presente manuale non sono impegnative. La faac si riserva il diritto, lasciando inalterate le caratteristiche essenziali dell’apparecchiatura, di apportare in qualunque momento e senza impegnarsi ad aggiornare la presente pubblicazione, le modifiche che essa rit...