Summary of S418

Page 1

Swing gate operator faac international inc. Headquarter & east coast operations 3160 murrell rd rockledge, fl 32955 tel. 800 221 8278 www.Faacusa.Com faac international inc. West coast operations 357 south acacia avenue unit 357 fullerton, ca 92831 s418 ul325 - ul991.

Page 2

2 faac model s418 swing gate operator contents faac model s418 - rev: 03 - oct 2014 read this instruction manual before you begin installing the product. = information regarding personal safety and proper maintanence of the product. Important safety information 3 important safety instructions 3 impo...

Page 3

3 faac model s418 swing gate operator 1. Install the gate operator only when the following conditions have been met: • the operator is appropriate for the type and usage class of the gate. • all openings of a horizontal slide gate have been guarded or screened from the bottom of the gate to a minimu...

Page 4

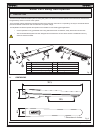

4 faac model s418 swing gate operator gate construction vehicular gates should be constructed and installed in accordance with astm f2200: standard specifica - tion for automated vehicular gate construction. For more information, contact astm at: www.Astm.Org installation • if you have any questions...

Page 5

5 faac model s418 swing gate operator residential vehicular gate operator class i a vehicular gate operator system intended for use in a single family dwelling, garage or associated parking area. Ul325 gate operator classifications commercial / general access vehicular gate operator class ii a vehic...

Page 6

6 faac model s418 swing gate operator the faac model s418 automated system for swing-leaf gates is an electro-mechanical operator which transmits its movement to the gate leaf by means of a worm-screw system. The irreversible system guarantees mechanical locking of the leaf when the motor is not ope...

Page 7

7 faac model s418 swing gate operator 3. Installation technical specifications s418 power supply (vdc) 24 nominal power (w) 35 absorbed current (a) 1.5 maximum thrust force (lbf) 405 stroke (inches) 13 3/4 1 cycles per day at 68 °f (approx) 80 class of operation residential rod speed (inches/sec) 0....

Page 8

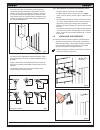

8 faac model s418 swing gate operator if the size of the pillar or the position of the hinge does not permit the proper installation of the operator, a niche will have to be made in the pillar (as indicated in figure 6) in order not to change value a (figure 4). The size of the niche must be such as...

Page 9: 2⅛

9 faac model s418 swing gate operator 2. Secure the rear bracket, as indicated in figure 10, so as to follow the a and b values determined previously. 2⅛ fig. 12 1⅜ fig. 13 fig. 10 fig. 11 fig. 14 4. Check that the front fitting is in the position indicated in figure 12 (with the mechanical stop at ...

Page 10

10 faac model s418 swing gate operator ! Fig. 15 fig. 16 fig. 17 6. Secure the operator to the rear bracket using the appropriate bolt supplied, as indicated in figure 15. 7. Bring the leaf of the gate to the close position. 8. Bring the operator, together with the related bracket, alongside the lea...

Page 11

11 faac model s418 swing gate operator fig. 19 fig. 20 fig. 21 fig. 22 the mechanical stop is coupled to a toothed sector, figure 19 ref. 2. In the case of obstructions during movement, check that the coupling is free. Do not force it. 3.6.2 mechanical stop at closing 1. Prepare the operator for man...

Page 12

12 faac model s418 swing gate operator fig. 24 fig. 23 5.1 restoring normal operation to restore normal operation mode, proceed as follows: 1. Ensure that the system is not powered. 2. Turn the release key clockwise until it stops, figure 24 ref. 1, and remove the key, figure 24 ref. 2. The locking ...

Page 13

13 faac model s418 swing gate operator 8. S418 parts diagram part part number description 01 713002 release key 02 63001555 release cover 03 63001565 release assembly 04 63001575 operator body 05 63001585 rear adjustable bracket 06 63001515 front bracket 07 63001595 lead nut 08 63001525 screw 09 630...

Page 14

Setting + j24 dl19 dl20 dl21 dl22 dl14 dl15 dl16 dl17 dl18 main power supply 115 v~ 60 hz secondary power supply 24 vdc - 16 a max. (min. 20 vdc. - max. 36 vdc.) power consumption stand-by = 4w max. = 400 w max load per motor 7 a accessory power supply 24 vdc - 500 ma battery charge current 150 ma o...

Page 15

A b stp cl op open fsw 24 vdc maglock encoder fig. A2 mot dl1 dl2 1 on on 2 on off pin label function 2 easy 2 easy 2easy bus input for encoders (s800h and s450h only), xib and loop detector boards 1 open a n.O. Contact for total opening command 2 open b / close open b: n.O. Contact for opening of l...

Page 16

Fsw stp cl op how to connect normally open contacts. (connect them in parallel) how to connect normally close contacts. (connect them in series) the photocells must be connected depending on which area they must protect. (see fig. A5) closing safety d : these photocells protect the area covered by t...

Page 17

Fsw stp cl op fsw stp cl op connection of two pairs of closing photocells connection of a pair of closing photocells, a pair of opening photcells and a pair of opening/closing photocells other optional safety devices to connect in series fig. A7 fig. A8 to use the fail-safe mode connect the nega- ti...

Page 18

8 8 fsw stp cl op fsw stp cl op fsw stp cl op fsw stp cl op to use the fail-safe mode connect the negative power supply of the transmitters to out (pin 9), and set dip- switch 11 and 12 to on on ds1 connection of a pair of closing photocells and a pair of opening photocells fig. A9 connection of no ...

Page 19

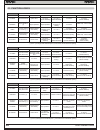

Operating logic ds 1: sw 1 - sw 2 - sw 3 logic sw 1 sw 2 sw 3 pause time description e (default) semiautomatic off off off no one command opens, the next one closes. A command du- ring opening stops the gate a automatic on on on 0 - 4 min one command opens, waits for the pause time an then closes au...

Page 20

6 tr 3 – speed adjustment for motor1 and motor 2 turn clockwise to increase the opening and closing speed tr 4 – sensitivity adjustement for obstacle detection for motor 1 and motor 2 turn clockwise to increase the sensitivity for obstacle detection. See par. 6.3 for more details about the obstacle ...

Page 21

Board setup ds 1: sw 4 to sw 12 opening delay sw 4 the opening of leaf 2 is delayed after the opening of leaf 1. This is to avoid that the gate’s leafs interfere with each other during the initial part of the movement. In case there is only one leaf is has no effect. 0 sec (default) off 2 sec on rev...

Page 22: 9 10

Ds2 setting + j24 1 2 3 4 5 6 7 8 9 10 dl19 dl20 dl21 dl22 dl14 dl15 dl16 dl17 dl18 ds 2 operator selection operator type sw 1 sw 2 sw 3 s450h, s800h off off off s418 off off on 415, 390, 770 on off off ds 2 lock output mode output mode sw 4 active only for 3 sec. After an open impulse (from gate cl...

Page 23

A11 l e d description led status in bold the normal state with gate closed and working on steady off blinking 1 led battery board working on ac power board working on battery power or ext supply battery charging 2 led +24 main power present main power off 3 led set-up normal operation slow blink (1 ...

Page 24

Warning: if the time learning setup is done automatically then the slow down points are set by the board on his own move the leafs to the mid position very important for a good result 1. Press and hold the setup button until the setup led lights up, wait about 3 sec. Until it turns off and then rele...

Page 25

The obstacle detection function is achieved by controlling the current absorption and / or through the encoder connected to the motors. If the gate encounters an obstacle during the movement of opening or closing, the obstacle detection function is activated and the operator reverses the direction o...

Page 26

Ac power connection to connect ac power to the controller: 1. Turn the circuit breaker for the ac gate operator power off before connecting the ac input wires. 2. Turn off the power switch located on the left side of enclo- sure before connecting the ac input wires. 3. Connect the ac input wires to ...

Page 27

Setting + dl 1 dl 2 dl 3 dl 4 dl 5 j24 setting + dl 1 dl 2 dl 3 dl 4 dl 5 j24 to disable the battery charger unplug jumper j24 j24 present = battery charging active j24 not present = battery charging not active 9.1 disable the battery charger setting + dl 1 dl 2 dl 3 dl 4 dl 5 j24 1. Disconnect the ...

Page 28

Logic “s” pulses system status open a open b stop fsw op fsw cl fsw cl/op closed opens and closes after pause time opens released leaf and closes after pause time no effect (open disa- bled) no effect (open disabled) no effect no effect (open disabled) opening no effect (1) no effect stops operation...

Page 29

Logic “ep” pulses system status open a open b stop fsw op fsw cl fsw cl/op closed opens the leaves opens leaf 1 no effect (open disabled) no effect (open disabled) no effect no effect (open disabled) opening stops operation (1) stops operation stops operation immediately reverses at closure no effec...

Page 30

Logic “b” pulses system status open a open b stop fsw op fsw cl fsw cl/op closed opens the leaves no effect no effect (open disabled) no effect (open disabled) no effect no effect (open disabled) opening no effect closes leaves stops operation reverses at closure no effect stops and, at release, clo...

Page 31

A19 e024u control board to the original purchaser only: faac international, inc., warrants, for twenty- four (24) months from the date of invoice, the gate operator systems and other related systems and equipment manufactured by faac s.P.A. And distributed by faac international, inc., to be free fro...