- DL manuals

- Farymann Diesel

- Engine

- 15W

- Operator's manual

Farymann Diesel 15W Operator's manual

Summary of 15W

Page 1

Table of contents 2008-12-09 operator´s manual diesel engine series 15w / 18w , doc-id: grea-8247 read the operating instructions before starting work!.

Page 2

2 2008-12-09 © greaves-farymann diesel gmbh industriestraße 19 68623 lampertheim germany tel.: +49 (0) 62 06 / 5 07 - 0 fax: +49 (0) 62 06 / 5 07 - 111 e-mail: info@farymann.De internet: www.Farymann.De release: created by: kothes! Technische kommunikation gmbh & co. Kg www.Kothes.De.

Page 3

Diesel engine series 15w / 18w table of contents 2008-12-09 3 1 general....................................................................................7 1.1 information about this manual .......................................7 1.2 explanation of the symbols.........................................

Page 4

Diesel engine series 15w / 18w table of contents 4 2008-12-09 4 structure and function........................................................ 30 4.1 overview ..................................................................... 30 4.2 electrical system..................................................

Page 5

Diesel engine series 15w / 18w table of contents 2008-12-09 5 7 operation ..............................................................................50 7.1 safety...........................................................................50 7.2 preparing for start ....................................

Page 6

Diesel engine series 15w / 18w table of contents 6 2008-12-09 8.10 cooling water diagram (standard)............................. 101 8.11 cooling water diagram (with water-cooled exhaust manifold) ................................................................... 102 8.12 replacing neoprene impelle...

Page 7: 1 General

Diesel engine series 15w / 18w general 2008-12-09 7 1 general 1.1 information about this manual this manual makes safe and efficient use of the engine possible. The manual is an integral part of the machine and must be kept in the immediate vicinity of the machine and accessible at any time for the ...

Page 8

Diesel engine series 15w / 18w general 8 2008-12-09 1.2 explanation of the symbols safety information safety information in this manual is identified using symbols. The safety information is introduced using signal words which express the scale of the hazard. Always comply with the safety instructio...

Page 9

Diesel engine series 15w / 18w general 2008-12-09 9 1.3 limitation of liability all information and instructions for use in this manual have been compiled taking account of the applicable standards and regulations, the latest state of technology and our many years of expertise and experience. The ma...

Page 10

Diesel engine series 15w / 18w general 10 2008-12-09 1.4 copyright this manual is protected by copyright law and exclusively to be used for internal purposes. Passing this manual on to third parties, duplication of any kind – even in form of excerpts – as well as the use and/or disclosure of the con...

Page 11: 2 Safety

Diesel engine series 15w / 18w safety 2008-12-09 11 2 safety this paragraph provides an overview of all important safety aspects for optimal protection of personnel as well as safe and trouble-free operation. Disregarding this manual and safety regulations specified therein may result in considerabl...

Page 12

Diesel engine series 15w / 18w safety 12 2008-12-09 only fill with fuel when the engine is switched off. Do not fill in the vicinity of naked flames or ignitable sparks, do not smoke and do not spill any fuel. This operator's manual must be kept in the immediate vicinity of the engine and must be ac...

Page 13

Diesel engine series 15w / 18w safety 2008-12-09 13 2.2 personnel requirements 2.2.1 qualifications warning! Danger of injury for unqualified personnel! Improper handling can result in severe personal injury and/or material damage. Therefore: – have all jobs carried out by qualified personnel only. ...

Page 14

Diesel engine series 15w / 18w safety 14 2008-12-09 2.3 appropriate use the system is designed and constructed exclusively for the intended purpose described here. The engine is provided exclusively for the intended purpose which has been specified and tested by the manufacturer of the equipment in ...

Page 15

Diesel engine series 15w / 18w safety 2008-12-09 15 2.4 personal protective equipment wearing of personal protective equipment is required when working to minimize the health hazards. Always wear the protective equipment that is necessary for the respective task when working. Follow the instructions...

Page 16

Diesel engine series 15w / 18w safety 16 2008-12-09 2.5 specific dangers the following section lists the residual risks that have been determined by the risk assessment. Heed the safety instructions listed here, and the warnings in subsequent chapters of this manual, to reduce health hazards and to ...

Page 17

Diesel engine series 15w / 18w safety 2008-12-09 17 substances harmful to health warning! Danger of poisoning and danger of skin rashes and allergies! Fuels, antifreeze and lubricants contain substances harmful to health and can result in severe poisoning and skin rashes or allergies. Therefore: – o...

Page 18

Diesel engine series 15w / 18w safety 18 2008-12-09 highly flammable materials warning! Fire hazard by highly flammable materials! Highly flammable materials, liquids or gases may catch fire causing serious and even fatal injuries. Therefore: – do not smoke within the danger zone and the immediate v...

Page 19

Diesel engine series 15w / 18w safety 2008-12-09 19 antifreeze (for engines with radiators and, e.G. Electric water pump) warning! Danger of poisoning and danger of skin rashes and allergies! Antifreeze contains substances harmful to health and can result in severe poisoning and skin rashes or aller...

Page 20

Diesel engine series 15w / 18w safety 20 2008-12-09 2.6 safety devices warning! Risk of injury due to non-functional safety devices! Safety is only ensured if the safety devices are intact. Therefore: – check whether the safety devices are functional and correctly installed before starting work. – n...

Page 21

Diesel engine series 15w / 18w safety 2008-12-09 21 2.8 environmental protection caution! Danger to the environment due to mishandling! Significant environmental damage can occur, particularly for incorrect disposal, if environmentally hazardous operating materials are mishandled. Therefore: – alway...

Page 22: 3 Technical

Diesel engine series 15w / 18w technical data 22 2008-12-09 3 technical data 3.1 technical specifications fig. 1 single-cylinder, four-stroke diesel engine, water-cooled, with the following characteristics: direct injection (bosch injection system) power take-off at the flywheel safe manual start wi...

Page 23

Diesel engine series 15w / 18w technical data 2008-12-09 23 3.3 standard configuration the engine is delivered with the following standard configuration: fuel filter dry type air cleaner or oil bath air cleaner fuel feed pump coolant thermostat (opening temperature 50 °c or 70 °c) cooling water pump...

Page 24

Diesel engine series 15w / 18w technical data 24 2008-12-09 3.5 engine type plate fig. 2: example of the engine type plate there is an engine type plate on the engine with the following information: 1 manufacturer 2 series 3 type number 4 version of the speed governor 5 serial number 6 power 7 speed...

Page 25

Diesel engine series 15w / 18w technical data 2008-12-09 25 3.7 engine data description value type vertical single-cylinder diesel engine design vertical cylinders 1 operating method four-stroke combustion method direct injection rotation direction anticlockwise (as seen from output or flywheel side...

Page 26

Diesel engine series 15w / 18w technical data 26 2008-12-09 3.8 performance data description value 15w value 18w max. Power (at 3600 rpm) ifn-iso* 4.3 kw icfn-iso* 3.9 kw ifn-iso* 5.2 kw icfn-iso* 4.7 kw max. Speed 3600 rpm max. Torque 13.0 nm (2500 rpm) 15.3 nm (2500 rpm) bore 82 mm stroke 55 mm di...

Page 27

Diesel engine series 15w / 18w technical data 2008-12-09 27 3.9 dimensions and weight description value overall length 374 mm overall height 422 mm overall width 401 mm dry weight: standard engine with air filter and exhaust silencer 39 kg 3.10 temperatures description value max. Permissible air int...

Page 28

Diesel engine series 15w / 18w technical data 28 2008-12-09 3.11 pressures description value injector setting - nozzle opening pressure 200 bar oil pressure (max.) 5 bar intake vacuum permitted 2 kpa exhaust gas back pressure permitted 5 kpa 3.12 operating materials description value fuel diesel en ...

Page 29

Diesel engine series 15w / 18w technical data 2008-12-09 29 3.13 engine oil specification the engine oil quality has a significant influence on the lifetime, performance and thus also the cost-effectiveness of the engine. The ambient temperature at the installation location or application of the eng...

Page 30: 4 Structure and Function

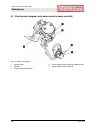

Diesel engine series 15w / 18w structure and function 30 2008-12-09 4 structure and function 4.1 overview note! The engine shown in the pictures 5 and 6 is the d/w crankcase version. Fig. 5: front view left view 1 valve cover 2 dry type air cleaner (oval flange / option) 3 decompression unit 4 engin...

Page 31

Diesel engine series 15w / 18w structure and function 2008-12-09 31 fig. 6: output side right view 12 thermostat housing 13 bell housing (option) 14 stub shaft (option) 15 oil dipstick 16 oil filter (d/w crankcase) 17 injection pump 18 water-cooled exhaust manifold (option) 19 oil filler cap 20 exce...

Page 32

Diesel engine series 15w / 18w structure and function 32 2008-12-09 note! The engine shown in pictures 7 and 8 is the standard engine. Fig. 7: front view left view 1 valve cover 2 oil bath air cleaner 3 decompression unit 4 engine mounting point 5 cooling water pump (neoprene impeller pump) 6 oil dr...

Page 33

Diesel engine series 15w / 18w structure and function 2008-12-09 33 fig. 8: output side right view 12 thermostat housing 13 flywheel 14 water-cooled exhaust manifold (option) 15 oil filler cap 16 injection pump 17 oil dipstick 18 fuel filter 4.2 electrical system 4.2.1 alternator (option) fig. 9: ex...

Page 34

Diesel engine series 15w / 18w structure and function 34 2008-12-09 4.2.2 alternator regulator (option) fig. 10: example: alternator regulator the alternating current is rectified in the alternator regulator (fig. 10) and constantly regulated to approx. 14.2-14.5 v. Z 2 x yellow (alternator coils in...

Page 35

Diesel engine series 15w / 18w structure and function 2008-12-09 35 4.2.4 dangers and cause of failure dangers cause of failure battery terminals incorrectly connected damage to the charging circuit defective battery or complete discharge destruction of the alternator regulator disconnection of the ...

Page 36

Diesel engine series 15w / 18w structure and function 36 2008-12-09 4.2.5 batteries observe the following safety factors: batteries produce explosive gases. Keep away from naked flames and other ignition sources. Do not smoke. Do not lay any tools on the battery. Always disconnect the negative pole ...

Page 37

Diesel engine series 15w / 18w structure and function 2008-12-09 37 4.3 cooling system 4.3.1 open cooling water circuit with direct sea water cooling without thermostat fig. 11 among other things, the engine is designed for direct sea water cooling. The cooling water is circulated using an impeller ...

Page 38

Diesel engine series 15w / 18w structure and function 38 2008-12-09 4.3.3 closed cooling water circuit with radiator and thermostat with this type of cooling, for example, a radiator, an electric water pump and a thermostat with an opening temperature of 70 °c are used. Note! A neoprene impeller pum...

Page 39

Diesel engine series 15w / 18w transport, packing and storage 2008-12-09 39 5 transport, packing and storage 5.1 safety notes for transport improper transport caution! Damage due to improper transport! Significant damage to property and injuries to persons can occur in the case of improper transport...

Page 40

Diesel engine series 15w / 18w transport, packing and storage 40 2008-12-09 5.3 packing concerning packing the individual packages have been packed to match the transport conditions that can be expected. Only environmentally friendly materials were used for packing. The packing has the function of p...

Page 41

Diesel engine series 15w / 18w transport, packing and storage 2008-12-09 41 storage of the engine store new engines under the following conditions: do not store outdoors. Store dry and dust-free. Do not expose to any aggressive media. Protect against direct sunlight. Avoid mechanical vibrations. Sto...

Page 42

Diesel engine series 15w / 18w installation and commissioning 42 2008-12-09 6 installation and commissioning 6.1 safety personnel installation and commissioning may be executed only by specially trained personnel. All work on the electrical system must be performed by a qualified electrician. 6.2 in...

Page 43

Diesel engine series 15w / 18w installation and commissioning 2008-12-09 43 fig. 15 4. Install key (4) into the keyway of the crankshaft and ensure that this sits correctly. Fig. 16 5. Install the flywheel (5) ensuring that it is not twisted during the installation. Note! In the case of improper ins...

Page 44

Diesel engine series 15w / 18w installation and commissioning 44 2008-12-09 fig. 17 fig. 18 7. Screw on the flywheel nut as far as possible by hand. Note! In doing so, ensure that the machined flat side (arrow) of the flywheel nut is facing the crankshaft. 8. Screw two bolts (6) into the thread prov...

Page 45

Diesel engine series 15w / 18w installation and commissioning 2008-12-09 45 6.2.3 attaching speed controller note! Depending on the version and installation position of the engine, the speed controller can be installed differently by the device manufacturer. Depending on the version and installation...

Page 46

Diesel engine series 15w / 18w installation and commissioning 46 2008-12-09 6.3 initial commissioning caution! Engine damage due to missing operating materials! The engine is delivered without operating materials. Operation without all required operating materials can destroy the engine. Therefore: ...

Page 47

Diesel engine series 15w / 18w installation and commissioning 2008-12-09 47 6.4 filling with engine oil caution! Engine damage due to incorrect oil quantity! Too high or too low an engine oil level can result in damage to the engine. Therefore: – never exceed the maximum level. Never drop below the ...

Page 48

Diesel engine series 15w / 18w installation and commissioning 48 2008-12-09 fig. 23 3. Pull out oil dipstick (3) and clean the bottom end with a clean and fluff-free cloth. 4. Replace the oil dipstick (3) and pull it out again. Fig. 24 5. Check the oil level quantity. The oil level should be just un...

Page 49

Diesel engine series 15w / 18w installation and commissioning 2008-12-09 49 6.4.1 venting the fuel system for engines with fuel feed pump (option) note! The engine has a self-venting fuel system. In the case of the fuel tank running empty, faultless operation after refilling is ensured by the self-v...

Page 50: 7 Operation

Diesel engine series 15w / 18w operation 50 2008-12-09 7 operation 7.1 safety improper operation warning! Risk of injury due to improper operation! Improper operation can result in severe personal injuries or material damage. Therefore: – perform all the operating steps in accordance with the inform...

Page 51

Diesel engine series 15w / 18w operation 2008-12-09 51 exhaust gases warning! Danger of poisoning due to exhaust gases! There is a danger of poisoning by odourless carbon monoxide of the exhaust gases are inhaled. Therefore: – never inhale the exhaust gases. – only operate the engine in well-ventila...

Page 52

Diesel engine series 15w / 18w operation 52 2008-12-09 caution! Danger of poisoning due to fuel, antifreeze and engine oil! Contact with engine oil, antifreeze and fuel can result in damage to health. Therefore: – avoid skin contact with engine oil, fuel and antifreeze. – remove oil, fuel and antifr...

Page 53

Diesel engine series 15w / 18w operation 2008-12-09 53 personal protective equipment wear the following protective equipment for all operation work: protective clothing safety footwear note! Protective equipment which must be worn for certain work is specially pointed out in the warnings of this cha...

Page 54

Diesel engine series 15w / 18w operation 54 2008-12-09 7.2 preparing for start checks carry out the following checks in order to avoid damage to the engine: check engine oil level, refill with engine oil if necessary. Check fuel level, refill with diesel fuel if necessary. Check cooling water level,...

Page 55

Diesel engine series 15w / 18w operation 2008-12-09 55 setting cold start / warm start caution! Engine damage due to cold start aids! The use of cold starting aid results in engine damage. Therefore: – never use cold starting aids. Fig. 27 the speed can be controlled using the speed adjustment lever...

Page 56

Diesel engine series 15w / 18w operation 56 2008-12-09 fig. 28 1. If the engine is cold, put the speed adjustment lever (3) in the increased idle speed position. If the engine is warm, put the speed adjustment lever into position (2) (depending on the application). Fig. 29: example: automatic decomp...

Page 57

Diesel engine series 15w / 18w operation 2008-12-09 57 fig. 31: example: automatic decompression 1 starting position 2 neutral position 3 operating position fig. 32: example: adjusting the automatic decompression on the starting handle with the adjusting spanner the automatic decompression (fig. 31)...

Page 58

Diesel engine series 15w / 18w operation 58 2008-12-09 excess fuel device note! The excess fuel device (1) must be pulled out for cold starting. Fig. 34: excess fuel device all engines are equipped with an excess fuel device (1) to make starting them easier. A lever limits the injection pump control...

Page 59

Diesel engine series 15w / 18w operation 2008-12-09 59 fig. 36: starting handle (rigid version) note! In the case of engines with cooling water pump (neoprene impeller pump), manual starting with an rd crank handle (limited kickback crank handle) is not possible due to the design. Only the "rigid ve...

Page 60

Diesel engine series 15w / 18w operation 60 2008-12-09 fig. 39 6. Support the air filter with your right hand (3). Caution! Risk of injury due to rotating crank handle! There is a risk of injury when starting the engine by hand. Therefore: – do not encircle the handle with your thumb. 7. Hold crank ...

Page 61

Diesel engine series 15w / 18w operation 2008-12-09 61 7.4 starting with electric starter note! For engines with an electric starter the automatic compression does not need to be activated. The engine is started with e.G. A key switch. Caution! Damage due to starting while the engine is running! Inc...

Page 62

Diesel engine series 15w / 18w operation 62 2008-12-09 starting engine fig. 41 1. If the engine is cold, put the speed adjustment lever in the increased idle speed position (3). If the engine is warm, put the speed adjustment lever in the position (2) (depending on the application of the engine). 2....

Page 63

Diesel engine series 15w / 18w operation 2008-12-09 63 first use warning! Risk of injury due to leaking fuel! Fuel escaping from the injection system can penetrate the skin and eyes due to the high pressure and cause severe injuries. Therefore: – wear safety goggles during first use and check the fu...

Page 64

Diesel engine series 15w / 18w operation 64 2008-12-09 7.6 switching off caution! Risk of injury due to engine run-on! After switching off, the engine runs on for approx. 10 to 20 seconds. Therefore: – wait until the engine is at a standstill before starting all work. Caution! Engine damage due to p...

Page 65

Diesel engine series 15w / 18w operation 2008-12-09 65 7.6.1 engine without electric starter fig. 42 put the speed adjustment lever (1) in the stop position and hold it there until the engine comes to a complete standstill after approx. 10 to 20 seconds. Note! Never turn off the engine with the auto...

Page 66

Diesel engine series 15w / 18w operation 66 2008-12-09 7.7 decommissioning decommissioning and preservation the following preservation protects the engine during decommissioning (e.G. Winter break) for 3 months. 1. Perform thorough external cleaning of the engine. 2. Drain engine oil and fill engine...

Page 67

Diesel engine series 15w / 18w operation 2008-12-09 67 restarting perform the following work for restarting the engine: 1. Perform thorough external cleaning of the engine. 2. Remove textile adhesive tape from the inlet and exhaust openings. 3. Drain corrosion protection oil from the engine into a s...

Page 68: 8 Maintenance

Diesel engine series 15w / 18w maintenance 68 2008-12-09 8 maintenance 8.1 safety maintenance work not carried out correctly warning! Risk of injury due to incorrectly carried out maintenance work! Improper maintenance can result in severe personal injuries or material damage. Therefore: – always un...

Page 69

Diesel engine series 15w / 18w maintenance 2008-12-09 69 caution! Danger of poisoning due to fuel, antifreeze and engine oil! Contact with engine oil, antifreeze and fuel can result in damage to health. Therefore: – avoid skin contact with engine oil, fuel and antifreeze. – remove oil and fuel splas...

Page 70

Diesel engine series 15w / 18w maintenance 70 2008-12-09 note! Independent repair and adjustment work on the engine beyond a very limited scope is forbidden for safety reasons. Improper work on components relevant for safety endangers you and others. This particularly applies to work on the valve ad...

Page 71

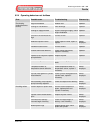

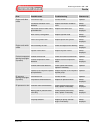

Diesel engine series 15w / 18w maintenance 2008-12-09 71 maintenance table components component group work to be performed daily before every start-up after 25 operating hours every 250 operating hours every 500 operating hours engine oil check oil level, refill with engine oil if necessary x engine...

Page 72

Diesel engine series 15w / 18w maintenance 72 2008-12-09 components component group work to be performed daily before every start-up after 25 operating hours every 250 operating hours every 500 operating hours exhaust system check for leaks, arrange repair by a greaves farymann diesel service partne...

Page 73

Diesel engine series 15w / 18w maintenance 2008-12-09 73 maintenance for special conditions caution! Reduced maintenance intervals in the case of special conditions! Additional maintenance is necessary in the case of special operating conditions in order to maintain the lifetime of the engine. There...

Page 74

Diesel engine series 15w / 18w maintenance 74 2008-12-09 8.4 checking threaded connections caution! Damage due to too high tightening torque! Bolts tightened too much can break off and the thread can be damaged. Therefore: – only check and tighten threaded connections with appropriate commercially a...

Page 75

Diesel engine series 15w / 18w maintenance 2008-12-09 75 tightening torques threaded connection relevant for safety tightening torque nm high pressure line of the injection nozzle holder 25 mounting of the fuel filter 10 wing nut of sealing cap of the air filter case after cleaning or replacing the ...

Page 76

Diesel engine series 15w / 18w maintenance 76 2008-12-09 fig. 46 6. Check oil drain plug (1) for damage and replace if necessary. 7. Always replace the copper seal (2). 8. Screw in oil drain plug by hand and tighten with e.G. Ring spanner sw 13. Tightening torque: 12 nm fig. 47 9. Release oil filler...

Page 77

Diesel engine series 15w / 18w maintenance 2008-12-09 77 fig. 49 3. Screw special oil drain hose (2) onto the oil drain valve (3). This opens the quick-release coupling. 4. Collect old oil in a suitable container and dispose of in accordance with the environmental regulations. 5. Unscrew and remove ...

Page 78

Diesel engine series 15w / 18w maintenance 78 2008-12-09 8.5.3 removing and installing oil strainer fig. 52 1. Place a suitable container underneath. 2. Drain engine oil (see chapter 8.5.1). 3. Unscrew both bolts (1). 4. Remove oil strainer housing (2). 5. Collect old oil in a suitable container and...

Page 79

Diesel engine series 15w / 18w maintenance 2008-12-09 79 8.6 changing oil filter (for d/w crankcase version) note! Always replace engine oil and oil filter together. Changing engine oil (see chapter 8.5.) fig. 55 1. Slacken oil filter (3) with an oil filter wrench (1) and e.G. A ring spanner 27 (2) ...

Page 80

Diesel engine series 15w / 18w maintenance 80 2008-12-09 fig. 57 3. Clean the sealing surface on the oil filter case. 4. Use new oil filter (7) and wet seal (6) with clean engine oil. Fig. 58 5. Tighten the oil filter (7) only by hand. 6. Fill with engine oil. 7. Start engine and check for leaks..

Page 81

Diesel engine series 15w / 18w maintenance 2008-12-09 81 8.7 fuel system fig. 59: fuel system 1 fuel pressure line 2 connection for fuel line to the fuel tank (return) 3 injection nozzle holder 4 fuel feed pump 5 connection for fuel line to the fuel tank (feed) 6 fuel filter (standard) 7 injection p...

Page 82

Diesel engine series 15w / 18w maintenance 82 2008-12-09 fig. 61: fuel filter (standard) fuel filter (2) version (standard): with this version, the fuel lines are fixed using hose clamps. 8.7.2 replacing fuel filter (with thread) fig. 62 1. Switch off the engine 2. Disconnect fuel line (1) using spe...

Page 83

Diesel engine series 15w / 18w maintenance 2008-12-09 83 fig. 64 5. Detach fuel line (6) from the fuel filter (4). Fig. 65 5. Undo hose clamp (7) and remove fuel filter (4). Fig. 66 6. Collect the fuel from the fuel line (6) in a suitable container (5) and dispose of in accordance with the environme...

Page 84

Diesel engine series 15w / 18w maintenance 84 2008-12-09 fig. 67: fuel filter with thread fuel filter with thread (option) 6. Install new fuel filter (4) and pay attention to the flow direction. The arrow (8) must point in the direction of the injection pump. Fig. 68 7. Check banjo bolts (9) for dam...

Page 85

Diesel engine series 15w / 18w maintenance 2008-12-09 85 fig. 70 3. Disconnect fuel line (2) using special fuel line disconnecting tool (3). Fig. 71 4. Undo hose clamp (4) and pull off the fuel line (2) from the fuel filter (5). Fig. 72 5. Collect the fuel from the fuel line (2) and from the fuel fi...

Page 86

Diesel engine series 15w / 18w maintenance 86 2008-12-09 fig. 73 7. Install new fuel filter (5) and pay attention to the flow direction. The arrow (7) must point in the direction of the injection pump. Assembly is in the reverse order to the dismantling. Fig. 74 8. Tighten screw (1) of the hose clam...

Page 87

Diesel engine series 15w / 18w maintenance 2008-12-09 87 8.8.1 dry type air cleaner (standard engine) fig. 75 1. Switch off the engine 2. Unscrew and remove the wing nut (1). 3. Release sealing clips (2) and remove air filter case (3). Fig. 76 4. Remove air filter element (4). Fig. 77 5. Remove air ...

Page 88

Diesel engine series 15w / 18w maintenance 88 2008-12-09 fig. 78 6. Thoroughly clean intake area (fig. 78/8), air filter cover (fig. 77/5) and air filter pot (fig. 77/6) as well as centring ring (fig. 77/7). Note! When removing the air filter and when cleaning the air filter case, always ensure that...

Page 89

Diesel engine series 15w / 18w maintenance 2008-12-09 89 8.8.2 dry type air cleaner (oval flange) fig. 81 1. Switch off the engine. 2. Unscrew and remove the wing nut (1). 3. Remove air filter cover (2). Fig. 82 4. Remove air filter element (3). Fig. 83 5. Clean suction area (fig. 83/4) and air filt...

Page 90

Diesel engine series 15w / 18w maintenance 90 2008-12-09 fig. 84 6. Install new air filter element (3); in doing so, ensure that the spacer sleeve (4) is also installed. Fig. 85 7. Position air filter case (2) straight, in the process pay attention to correct seating, and fasten with the wing nut (1...

Page 91

Diesel engine series 15w / 18w maintenance 2008-12-09 91 fig. 87 4. Check filter material (3) depending on occurrence of dust. In the case of severe contamination, remove filter and wash out in diesel fuel or replace complete oil bath air cleaner. Note! Before assembly of the filter, let the diesel ...

Page 92

Diesel engine series 15w / 18w maintenance 92 2008-12-09 8.9 adjusting valve clearance safety warning! Risk of injury due to starting the engine! The engine can be accidentally started when adjusting the valve clearance and thereby cause severe injuries. Therefore: – disconnect the high pressure lin...

Page 93

Diesel engine series 15w / 18w maintenance 2008-12-09 93 8.9.1 engines with visible flywheel and o.T. Marking preparations fig. 89 1. Switch off engine and let it cool down to the ambient temperature. 2. Unscrew the nuts (1) on the valve cover (2) and remove bracket (3) for fuel line and plastic sea...

Page 94

Diesel engine series 15w / 18w maintenance 94 2008-12-09 adjusting inlet valve - exhaust valve fig. 92 5. Insert crank handle (6) in the starting handle support bearing and slowly turn the crankshaft in the engine rotation direction (anticlockwise) until the end of the compression stroke or fig. 93 ...

Page 95

Diesel engine series 15w / 18w maintenance 2008-12-09 95 fig. 95 7. If the clearance is too large or too small, undo the lock nut (12) and adjust the clearance with the adjusting screw (11). The feeler gauge must be able to be pulled through without noticeable resistance (drag). 8. Hold the adjustin...

Page 96

Diesel engine series 15w / 18w maintenance 96 2008-12-09 fig. 98 12. Replace valve cover gasket (13). Fig. 99 13. Install valve cover (2) using two new plastic seals (14). 14. Mounting bracket (3) of the fuel line. 15. Tighten both nuts (1) of the valve cover (2). Tightening torque 8–12 nm note! Alw...

Page 97

Diesel engine series 15w / 18w maintenance 2008-12-09 97 8.9.2 engines with covered flywheel (without visible o.T. Marking) preparations fig. 100 1. Switch off engine and let it cool down to the ambient temperature. 2. Unscrew both nuts (1) on the valve cover (2) and remove bracket (3) for fuel line...

Page 98

Diesel engine series 15w / 18w maintenance 98 2008-12-09 adjusting exhaust valve fig. 103 5. Insert crank handle (6) into the starting handle support bearing and slowly turn the crankshaft in the engine rotation direction (anticlockwise) until the inlet valve's spring is pushed down completely (inle...

Page 99

Diesel engine series 15w / 18w maintenance 2008-12-09 99 adjusting intake valve fig. 106 10. Insert crank handle (6) into the starting handle support bearing and slowly turn the crankshaft in the engine rotation direction (anticlockwise) until the exhaust valve's spring is pushed down completely (ex...

Page 100

Diesel engine series 15w / 18w maintenance 100 2008-12-09 fig. 109 15. Tighten the high pressure line (4) on the injection nozzle holder. Tightening torque 25 nm fig. 110 16. Replace valve cover gasket (13). Fig. 111 17. Install valve cover (2) using two new plastic seals (14). 18. Mounting bracket ...

Page 101

Diesel engine series 15w / 18w maintenance 2008-12-09 101 8.10 cooling water diagram (standard) fig. 112: cooling water diagram (standard) 1 cylinder head 2 cylinder 3 cooling water flow direction 4 cooling water pump (neoprene impeller pump).

Page 102

Diesel engine series 15w / 18w maintenance 102 2008-12-09 8.11 cooling water diagram (with water-cooled exhaust manifold) fig. 113: cooling water diagram 1 cylinder head 2 cylinder 3 cooling water flow direction 4 cooling water pump (neoprene impeller pump) 5 water-cooled exhaust manifold.

Page 103

Diesel engine series 15w / 18w maintenance 2008-12-09 103 8.12 replacing neoprene impeller of the cooling water pump note! The neoprene impeller of the cooling water pump must be considered as a wearing part. The service life of the neoprene impeller can be extremely different and depends solely on ...

Page 104

Diesel engine series 15w / 18w maintenance 104 2008-12-09 fig. 116 7. Mark neoprene impeller for the case (see arrow). Note! It is ensured by the marking that the neoprene impeller is inserted in the correct position in the event of reinstallation. Fig. 117 8. Carefully remove the neoprene impeller ...

Page 105

Diesel engine series 15w / 18w maintenance 2008-12-09 105 fig. 119 10. Check cooling water pump case (5) and neoprene impeller (3) for damage; replace if necessary. Note! Coat the neoprene impeller with some vaseline ® before installing in the water pump case. Fig. 120 11. Insert neoprene impeller (...

Page 106

Diesel engine series 15w / 18w maintenance 106 2008-12-09 fig. 121 12. Clean the sealing surface of the cooling water pump cover (6). 13. Use new gasket (7). Fig. 122 14. Replace cooling water pump cover (2), screw in all screws (1) and tighten with a screwdriver. 15. Fill with water. 16. Start engi...

Page 107

Diesel engine series 15w / 18w maintenance 2008-12-09 107 8.13 removing, installing and checking thermostat fig. 123 1. Switch off engine and let it cool down to the ambient temperature. 2. Drain coolant and collect in a suitable container. 3. Unscrew both bolts (1). 4. Remove thermostat housing (2)...

Page 108

Diesel engine series 15w / 18w maintenance 108 2008-12-09 fig. 126 9. Measure the water temperature with a suitable temperature measuring instrument. 10. The thermostat must be completely open at 50 °c water temperature (for the salt water version) or at 70 °c water temperature (for the fresh water ...

Page 109

Diesel engine series 15w / 18w maintenance 2008-12-09 109 fig. 129 11. Remove deposits and gasket residues on the cylinder head (5) and on the thermostat housing (2); in doing so, ensure that no dirt gets into the water channel in the cylinder head. Fig. 130 12. Install thermostat (3). Note! Ensure ...

Page 110

Diesel engine series 15w / 18w maintenance 110 2008-12-09 8.14 checking the cooling system for leaks 8.14.1 engines with radiator (and e.G. Electric water pump) hot operating materials warning! Risk of burns due to hot operating materials! Operating materials can reach high temperatures during opera...

Page 111

Diesel engine series 15w / 18w maintenance 2008-12-09 111 8.14.3 checking the cooling water hoses and hose clamps check the cooling water hoses daily. If a cooling water hose is damaged or sea water / coolant discharges, this can result in overheating of the engine. This can also result in severe sk...

Page 112

Diesel engine series 15w / 18w maintenance 112 2008-12-09 8.15 checking level of the coolant (for engines with radiator) hot operating materials warning! Risk of burns due to hot operating materials! Operating materials can reach high temperatures during operation and cause burns / scalding in the c...

Page 113

Diesel engine series 15w / 18w maintenance 2008-12-09 113 determine coolant level by visual inspection and coolant if necessary (the coolant level should be up to the bottom edge of the radiator filler neck (see also the operating manual of the device manufacturer). Do not start work on the cooling ...

Page 114: 9 Faults

Diesel engine series 15w / 18w faults 114 2008-12-09 9 faults possible causes of faults and the work for rectifying them are described in the following chapter. In the case of increasingly occurring faults, reduce the maintenance intervals in accordance with the actual load. In the case of faults wh...

Page 115

Diesel engine series 15w / 18w faults 2008-12-09 115 improper fault clearance warning! Risk of injury due to improper fault clearance! Improper fault clearance can result in severe personal injuries or material damage. Therefore: – ensure there is sufficient installation clearance before starting wo...

Page 116

Diesel engine series 15w / 18w faults 116 2008-12-09 antifreeze (for engines with radiator and, e.G. Electric water pump) warning! Danger of poisoning and danger of skin rashes and allergies! Antifreeze contains substances harmful to health and can result in severe poisoning and skin rashes or aller...

Page 117

Diesel engine series 15w / 18w faults 2008-12-09 117 9.2 troubleshooting chart 9.2.1 engine does not start error possible cause troubleshooting clearance by no fuel in the tank filling with fuel operator speed adjusting lever is in the stop position put speed adjusting lever in the "full load" posit...

Page 118

Diesel engine series 15w / 18w faults 118 2008-12-09 error possible cause troubleshooting clearance by decompression unit defective check decompression unit, replace if necessary skilled employee leaky valves check valves, repair or replace skilled employee leaky cylinder head / cylinder head gasket...

Page 119

Diesel engine series 15w / 18w faults 2008-12-09 119 9.2.2 engine starts, however runs irregularly or stops error possible cause troubleshooting clearance by fuel filter blocked replace fuel filter operator fuel line interrupted check fuel line operator leaky fuel line check fuel line, tighten conne...

Page 120

Diesel engine series 15w / 18w faults 120 2008-12-09 9.2.3 bad engine performance error possible cause troubleshooting clearance by engine overloaded reduce load; troubleshooting at machine operator operating conditions performance reduction due to increased intake temperature improve operating cond...

Page 121

Diesel engine series 15w / 18w faults 2008-12-09 121 9.2.4 operating behaviour not faultless error possible cause troubleshooting clearance by engine overloaded reduce load operator cooling air inlet blocked clear blockage operator cooling air supply blocked improve cooling air supply, check engine ...

Page 122

Diesel engine series 15w / 18w faults 122 2008-12-09 error possible cause troubleshooting clearance by piston and cylinder worn overhaul engine (change piston and cylinder) skilled employee main bearing, connecting road bearing worn overhaul engine skilled employee loose flywheel check flywheel and ...

Page 123

Diesel engine series 15w / 18w faults 2008-12-09 123 error possible cause troubleshooting clearance by oil level too high correct oil level operator crankcase ventilation valve defective replace crankcase ventilation valve skilled employee valve stem seal on intake valve guide defective replace valv...

Page 124

Diesel engine series 15w / 18w faults 124 2008-12-09 error possible cause troubleshooting clearance by speed adjusting lever is not at the maximum position set speed adjusting lever to the maximum position (increased speed) operator engine oil too viscous change engine oil, use correct viscosity ope...

Page 125: 10 Replacement Parts List

Diesel engine series 15w / 18w replacement parts list 2008-12-09 125 10 replacement parts list 10.1 spare parts warning! Risk to safety due to use of non-original spare parts! Defective and non-original spare parts can adversely affect the safety and result in damage and malfunctions or total failur...

Page 126

Diesel engine series 15w / 18w replacement parts list 126 2008-12-09 wearing parts for maintenance work order number description quantity 541.052.2 air filter element (dry type air cleaner) 1 555.129.1 sealing clip 2 514.093.2 wing nut 1 541.059.2 air filter cover 1 541.058.2 air filter pot 1 541.05...

Page 127

Diesel engine series 15w / 18w replacement parts list 2008-12-09 127 order number description quantity 555.003.2 cooling water thermostat 50 °c (salt water) 1 555.006.2 cooling water thermostat 70 (fresh water) 1 890.07.03 split pin for thermostat 1 770.108.4 thermostat housing gasket 1 538.219.2 ne...

Page 128

Diesel engine series 15w / 18w replacement parts list 128 2008-12-09 special tools order number description 748.115.6 fuel line disconnecting tool 748.173.2 (for engines with d/w crankcase) oil filter wrench (dismantling the oil filter) special tools can be ordered from the nearest greaves farymann ...

Page 129: 11 Service History

Diesel engine series 15w / 18w service history 2008-12-09 129 11 service history 11.1 proof of purchase fig. 133 using the type plate, copy the following information on to the proof of purchase and arrange confirmation. There is a type plate on the engine with the following information: 1 model 2 ty...

Page 130

Diesel engine series 15w / 18w service history 130 2008-12-09 11.2 handover and servicing history arrange maintenance work during the warranty period and afterwards to be carried out by one of our authorised greaves farymann diesel sales and service partners. Comply with the maintenance intervals an...

Page 131

Diesel engine series 15w / 18w service history 2008-12-09 131 after 2000 operating hours / 48 months dealer stamp: after 2250 operating hours / 54 months dealer stamp: after 2500 operating hours / 60 months dealer stamp: hours ........................... Date ............................. Hours .......

Page 132

Diesel engine series 15w / 18w service history 132 2008-12-09 after 4250 operating hours / 102 months dealer stamp: after 4500 operating hours / 108 months dealer stamp: after 4750 operating hours / 114 months dealer stamp: hours ........................... Date ............................. Hours ....

Page 133

Diesel engine series 15w / 18w service history 2008-12-09 133 after 6500 operating hours / 156 months dealer stamp: after 6750 operating hours / 162 months dealer stamp: after 7000 operating hours / 168 months dealer stamp: hours ........................... Date ............................. Hours ....

Page 134: 12 Index

Diesel engine series 15w / 18w index 134 2008-12-09 12 index a accident ............................................................. 20 adjusting valve clearance .................................. 92 applications........................................................ 22 appropriate use...............

Page 135

Diesel engine series 15w / 18w index 2008-12-09 135 commissioning ................................................42 faults ............................................................114 installation .......................................................42 maintenance ................................

Page 136: Notes

Diesel engine series 15w / 18w notes 136 2008-12-09 notes.

Page 137

Diesel engine series 15w / 18w notes 2008-12-09 137 art. 903.01.44 08.08.