Art. Ng 160 istruzioni per luso e manutenzione instructions for use and maintenance gebrauchsanleitungen und wartung mode demploi et entretien instrucciones para el uso y manutencion instruÇÕes de utilizaÇÃo gebruik- en onderhoudsaanwijzingen segatrice a nastro band-saw machine bandsÄgemaschine sc...

Italiano (it) .............................................................................................................. 3 ÷ 8 english (en) ........................................................................................................... 9 ÷ 14 deutsch (de) ...............................

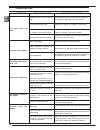

01 07 02 08 03 09 04 10 05 11 06 12 2006 2009 2007 2010 2008 2011 dichiarazione di conformitÁ ce del costruttore femi s.P.A. Via del lavoro, 4 - 40023 castel guelfo (bo) - italia tel. +39-0542-670160 - fax +39-0542-670185 - http://www.Femi.It dichiara che la: segatrice a nastro ng160 è conforme alle...

9 en 1 introduction to use ...................................... 9 2 installation ....................................................... 10 3 adjustment ........................................................ 11 4 use ........................................................................ 11 5 a...

10 en 1.4 standard safety procedurs - do not use the machine in very damp places or in the presence of inflammable liquids or gases. - do not use it in the open air when general weather and environmental conditions are unfavourable (eg. Explosive atmospheres, during a storm or rain). - wear suitable...

11 en 2.4 position/work station (fig.3) place the machine on a sufficiently flat workbench so that the machine has the better possible stability. In respect of ergonomic criteria during cutting operations, the workbench must be positioned at such a height that the clamp level is between 90 and 95 cm...

12 en after running-in, the same piece may easily be cut in about 2 minutes. If the running-in process is done correctly, the finish and precision of the cut will be of better quality and the blade will last longer. 4.2 working (fig. 7) turn the main switch d to position 1 : in doing the switch come...

13 en 4.6 correct positioning of the piece in the clamp (fig. 11) the pieces to be cut should be fitted directly between the jaws without adding other objects. Attention: never hold the pieces to be cut in your hand. (fig. 11) when the pieces to be cut are profiled sections, flat pieces or special s...

14 en defective motor, power cable or plug. Blown electric panel fuses. No voltage in the mains system. The overload cutout has tripped. Motor overheating. Motor overload caused by excessive cutting pressure. Motor breakdown. The setting of the h and k retainers (point 3.3) is inaccurate. Excessive ...