- DL manuals

- Ferroli

- Portable Generator

- ECONCEPT 100

- Instructions for use, installation and maintenance

Ferroli ECONCEPT 100 Instructions for use, installation and maintenance

Summary of ECONCEPT 100

Page 1

Econcept 100 premixed gas-fired heat generator with condensation instructions for use, installation and maintenance.

Page 2

Econcept 100 2 important your "benchmark" installation, commissioning and service record log book is enclosed in the last pages of this manual. “this record must be completed and left with the end user ”. Ferroli is a member of the benchmark initiative and fully supports the aims of the programme. B...

Page 3

Econcept 100 3 1. Operating instructions .............................................................. 4 1.1 introduction ................................................................................................. 4 1.2 control panel ..............................................................

Page 4

4 econcept 100 1. Operating instructions 1.1 introduction dear customer, thank you for choosing econcept 100, a ferroli heat generator of the latest generation featuring ad- vanced design and cutting-edge technology. Econcept 100 is a high-efficiency modular heat generator for condensation premixed ...

Page 5

5 econcept 100 off on off on display d1 boiler 1 display d2/d3 boiler 1 boiler 1 ignition button (switches the top boiler shell on) display d1 boiler 2 display d2/d3 boiler 2 boiler 2 ignition button (switches the bottom boiler shell on) 1.2 control panel from the control panel it is possible to dis...

Page 6

6 econcept 100 operating mode standby heating standby after heating op. Display d1 display d2/d3 system delivery temperature system delivery temperature system delivery temperature summer/winter selection (00 = summer 11 = winter) do not change this parameter* system delivery temperature displ...

Page 7

7 econcept 100 20 30 40 50 60 70 80 90 20 10 0 -10 -20 outside temperature °c system delivery temperature c° 1 2 3 4 5 6 7 8 9 10 adjustments setting the system temperature to set the system delivery temperature on the single boiler shell, access the operational menu and press the key to display par...

Page 8

8 econcept 100 6 1 2 3 4 5 6 hg/sq-2 honeywell a b s 7 8 9 10 11 12 13 14 15 16 17 18 l n l l l n 1 2 3 4 5 6 -- common -- jp7 043002x0 1.3 external control units cascade control unit (code 1kwmh18a) a cascade control unit enabling advanced management of the two internal boiler shells is available o...

Page 9

9 econcept 100 1.4 switching on and off ignition check that any external system shut-off valves are open. Open the gas cock ahead of the generators, turn the main switch on and press the ignition keys on the control panel. The boiler will run a self-test cycle of approx. One minute, after which it i...

Page 10

10 econcept 100 safety elements gas delivery return generators connected in this way can be considered a single “equivalent” heat generator with a total power of n x 90.4 kw. All the requirements of current standards and regulations applicable to this “equivalent” generator with total heating power ...

Page 11

11 econcept 100 2.3 place of installation the generator can be installed directly outside or in a special room with ventilation openings to the outside as prescribed by current regulations. If there are several burners or exhauster units that can work together in the same room, the ventilation openi...

Page 12

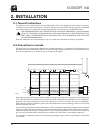

12 econcept 100 connection side 1 2 3 1 2 3 4 1 2 3 1 2 3 4 seals flanges with joining section blind flanges blind flanges flanges with joining section connection side fig. 5 fig. 6a plumbing connection using one generator with a water trap plumbing connection using two or more generators with a wat...

Page 13

13 econcept 100 2 b 1 a 1 2 2 b a fig. 7 fig. 8 condensate outlet connection using one generator condensate outlet connection using two or more generators a - place the pipe 1 Ø40 (not supplied) on the side of the generator. B - slide the pipe 2 towards the side of the arrow for at least 2-3 cm to i...

Page 14

14 econcept 100 off on off on generator 1 generator 2 123456789 10 11 12 operation enabling signal external sensor sequence adj. Connection (opentherm) operation enabling signal external sensor sequence adj. Connection (opentherm) l n 230v 50hz 12-pole connector 6-pole connector s3 t2 t1 fig. 9 2.5 ...

Page 15

15 econcept 100 h 1/2h 1/2h h n n w fig. 10 positioning the external sensor the external sensor should preferably be installed on the north, north-west wall or on the wall that most of the main living room faces. The sensor must never be exposed to early morning sun, and in general, it should not be...

Page 16

16 econcept 100 2.6 flue connection • manifold, ducts and flue must be suitably sized, designed and constructed in compliance with current regulations. They must be made of suitable materials, i.E. Resistant to heat and corrosion, smooth on the inside and airtight. In particular, joints must be cond...

Page 17

17 econcept 100 fig. 13 3. Service and maintenance 3.1 adjustments all adjustment and conversion operations must be carried out by qualified personnel such as local technical assistance service personnel. Ferroli declines any liability for damage or injury caused by unqualified and unauthorized pers...

Page 18

18 econcept 100 setting 70°c adjustable from: 30 to 90°c boiler parameter adjustment press the “mode” and keys at the same time for more than 3 seconds to access the boiler parameter menu. Then press to scroll through the parameters, whereas the set values can be modified with the and keys. For the ...

Page 19

19 econcept 100 before lighting the generator: • open any shut-off valves between the generator and the systems • check the tightness of the gas system, proceeding with caution and using a soap and water solution to detect any leaks in connections. • fill the system as indicated above and make sure ...

Page 20

20 econcept 100 3.3 maintenance the following operations are strictly reserved for qualified personnel, such as those of our sales organiza- tion or the local customer technical assistance service. Seasonal inspection of the generator and flue have the following checks carried out at least once a ye...

Page 21

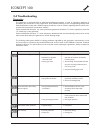

21 econcept 100 3.4 troubleshooting diagnostics the generator is equipped with an advanced self-diagnosis system. In case of operation problems or anomalies, the control unit of the single boiler shell activates flashing of the corresponding display (with fault identification code) and a 230vac outp...

Page 22

22 econcept 100 resistance at terminals 7-8 of connector x5 not connected check value and connection of resistance resistance at terminals 11-12 of connector x7 not connected check value and connection of resistance external sensor fault sensor damaged or wiring short circuit check wiring or...

Page 23

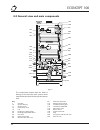

23 econcept 100 4 technical characteristics and data 4.1 dimensions and connections keys 1 gas inlet 2 system delivery 3 system return 4 condensate drain fig. 14 700 Øi150 400 290 110 145 4 35 575 390 225 115 250 275 1650

Page 24

24 econcept 100 4.2 general view and main components fig. 15 44a 44b 188a 82a 188b 82b 186a 186b 193 32a 32b 154 253b 253b 16a 16b 34a 49a 34b 49b 114b 114a 7 10 11 252a 252b 175a 175b 179a 179b 14 a 14 b the components marked with the letter a belong to the top boiler shell system; those marked wit...

Page 25

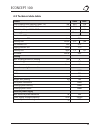

25 econcept 100 4.3 technical data table powers pmax pmin heat output (lower heating power - hi) kw 92,0 13,8 useful heat output 80°c - 60°c kw 90,4 13,6 useful heat output 50°c - 30°c kw 96,8 14,4 gas supply pmax pmin gas nozzles g20 mm 6,70 supply pressure g20 mbar 20,0 delivery g20 nm3/h 9,72 1,4...

Page 26

26 econcept 100 4.4 diagram of circulating pump losses of pressure / head 0 1 2 3 4 5 6 7 0 500 1.000 1.500 2.000 q [l/h] h [m h 2 o] 3 1 2 a fig. 16 the figure shows the diagram of the local circulating pump and pressure losses of the single exchanger bodies. Key 1 - 2 - 3 = circulating pump speed ...

Page 27

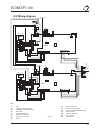

27 econcept 100 4.5 wiring diagram key 16 fan 32 heating circulating pump 34 heating temperature sensor 44 gas valve 49 safety thermostat 82 detection electrode 83 electronic controller 98 switch 101 electronic board 114 water pressure switch 175 transformer 220-240/300-330v 186 return sensor 188 ig...

Page 28

Benchmark controls to comply with the building regulations, each section must have a tick in one or other of the boxes time & temperature control to heating room t/stat & programmer/timer programmable roomstat time & temperature control to hot water cylinder t/stat & programmer/timer combi boiler he...

Page 29: Service Interval Record

Service interval record it is recommended that your heating system is serviced regularly and that you complete the appropriate service interval record below. Service provider. Before completing the appropriate service interval record below, please ensure you have carried out the service as described...

Page 32

Phone numbers: installer service engineer because of our constant endeavour for improvement details may vary slightly from those quoted in these instructions. Lichfield road, branston industrial estate, burton upon trent, staffordshire de14 3hd tel. 08707 282 885 - fax 08707 282 886 all specificatio...