- DL manuals

- Ferroli

- Fan

- ECONCEPT 50 A

- Installation And Operating Instructions Manual

Ferroli ECONCEPT 50 A Installation And Operating Instructions Manual

Summary of ECONCEPT 50 A

Page 1

Econcept 50 a appr. Nr. B99.15 a - ce 0063 bl 3475 cod. 3544205/1 ediz. 04/2004 w all - hung , p re - mix g as - fired c ondensing b oiler installation and operating instructions.

Page 2

Econcept 50 a 2 important your “benchmark” installation, commissioning and service record log book will be enclosed in your customer information pack. “this record must be completed and left with the end user”. Ferroli is a member of the benchmark initiative and fully supports the aims of the progra...

Page 3

Econcept 50 a 3 • read the warnings given in this manual thoroughly. They provide important in- formation for safe installation, use and maintenance • keep the manual safe for future consul- tation. • the instruction manual is an integral and essential part of the product and must be kept by the use...

Page 4

Econcept 50 a 4 1. Characteristics and technical data .................................. 5 1.1 introduction ................................................................................................. 5 1.2 boiler control panel ......................................................................

Page 5

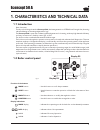

Econcept 50 a 5 1. Characteristics and technical data 1.1 introduction dear customer, thank you for having chosen the econcept 50 a, the latest generation of ferroli wall-hung boiler, featuring advanced design and cutting-edge technology. The econcept 50 a is a pre-mix condensing thermal generator f...

Page 6

Econcept 50 a 6 1.3 ignition and shut-down ignition check that any shut-off valves in the heating system and domestic hot water circuit outside of the boiler are open. Open the gas control upstream from boiler and press the main switch. The boiler will perform a self- test cycle lasting approximatel...

Page 7

Econcept 50 a 7 1.4 regulations setting the heating system temperature set, using the room thermostat or remote control, the desired temperature inside the rooms. When acting on the room thermostat, the boiler is turned on and the heating system water is brought to the central heating outlet set tem...

Page 8

Econcept 50 a 8 20 30 40 50 60 70 80 90 20 10 0 -10 -20 external temperature °c ch supply temperatur e - c ° 1 2 3 4 5 6 7 8 9 10 1.5 maintenance this appliance must be serviced anually by an approved corgi engineer. The casing, the control panel and the aesthetic parts of the boiler can be cleaned ...

Page 9

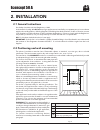

Econcept 50 a 9 2. Installation 2.1 general instructions gas safety (installation & use) regulations: 1996 in the interest of safety, it is the law that all gas appliances are installed by a competent person in accordance with the above regulations, building regulations/building standards scotland, ...

Page 10

Econcept 50 a 10 fig. 3 50 120 145 145 120 50 1 2 3 4 5 6 1 ch flow 2 dhw flow 3 gas inlet 4 dhw return 5 ch return 6 safety valve 2.3 connection to the hydraulic system make the connections to the corresponding couplings, according to the positions indicated in fig. 3. The discharge of the safety v...

Page 11

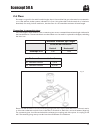

Econcept 50 a 11 a aaa aaa kit 1kwmh17a cylinder not supplied fig. 4 dhw calorifier connection(optional kit 1kwmh17a) the optional kit 1kwmh17a is available for connection with an external cylinder. The kit, which includes circulator, cylinder feeler and hydraulic pipe fittings, has to be mounted in...

Page 12

Econcept 50 a 12 2.5 electrical connections connection to the electrical grid the boiler must be connected to a single-phase, 230 volt-50 hz electric line. The unit’s electrical safety is only guaranteed when correctly connected to an efficient earthing system executed according to current safety st...

Page 13

Econcept 50 a 13 into the boiler jacket, there is a terminal block as showed on the pictures (fig. 6a): • external temperature probe (5-6) with the probe (optional) connected, the boiler works in outside compensation temperature mode, depend- ing on the compensation curve settled (ref. 1.4). If no p...

Page 14

Econcept 50 a 14 2 3 4 5 6 7 8 9 10 11 12 econcept 50 a connection block e f l h e 230/50 vac supply fused @ 3amp. X y room thermostat cyl thermostat x - ch circuit -- must be volt free e - cascade unit option r - resistors y - dhw circuit -- must be volt free f - dhw storage sensor they must not be...

Page 15

Econcept 50 a 15 2.6 flues econcept is a type-c boiler with forced draught, the air inlet and the flue gas outlet must be connected to one of the exhaust–intake systems indicated as follows. Using the tables and the methods of calculation described, first verify, before installation, that the flues ...

Page 16

Econcept 50 a 16 two pipe flue system the separate Ø80 pipes for air intake and flue gas exhaust can be connected directly to the boiler, as shown in fig. 10. Upon request, a wide range of pipes, bends and accessories can be supplied. For the various components, refer to tables 1-2 or to the flue ac...

Page 17

Econcept 50 a 17 table of losses for piping and accessories kwma86a kwma85a kwma84u air flue v e rtical horizontal v e rtical horizontal kwma82a kwma38a • 0,50 m kwma83a • 1,00 m description tubo Ø 80 male-female male-female bend 90 ° Ø 80 mm description airwall terminal products of combustion Ø80 m...

Page 18

Econcept 50 a 18 fig. 11 ref. 1 2 3 n ° pieces 12 12 1 vertical air pipe vertical flue pipe flue terminal description length o loss 19,2 m 12,0 m 12,0 m 43,2 m total 12 m 1 2 3 example of how to calculate the connection of two separate pipes, max flue length: 45 metres the flue and air pipes must be...

Page 19

Econcept 50 a 19 terminal position fig. 12 p d, e q q l b c a g f l j h h k n n m m q directly below an opening, air brick, (0-7 kw) opening windows, etc. (>7-14 kw) (>14-32 kw) (>32-70 kw) above an opening, air brick, (0-7 kw) opening windows, etc. (>7-14 kw) (>14-32 kw) (>32-70 kw) horizontally to...

Page 20

Econcept 50 a 20 2.7 condensation discharge connection boiler is provided with an internal watertrap for the condensation discharge. Fit the inspection bowl "a" and the flexible tube "b". Fill the siphon with 0,5 l. Of water and connect the flexible tube to the draining system. If this is not possib...

Page 21

Econcept 50 a 21 2.8 modular installation can be used as a single unit or for modular installation. If the output required from the system exceeds 44,9 kw, two or more econcept 50 boilers can be connected in a modular system (or cascade), as shown as an example in figure. It is necessary to meet all...

Page 22

Econcept 50 a 22 2 3 4 5 6 7 8 9 10 150 180 200 250 250 300 300 350 350 n ° econcept 50 a Ø collector/chimney • air intake can take place in the boiler room, on condition that the room is properly ventilated according to the standards in force. Be careful to remove air blanking plus from every singl...

Page 23

Econcept 50 a 23 a 3. Service and maintenance 3.1 settings the adjustment of the software operations must only be performed by qualified personnel. Ferroli s.P.A. Declines all liability for damage to persons and/or things deriving from tampering with the appliance by non-authorised persons. Gas conv...

Page 24

Econcept 50 a 24 temperatures regulation pressing " - mode" button it is possible to enter the user menu (see par. 1 for a complete description) where it is possible to modify: par. “1” • ch temperature par. “2” • dhw temperature regulations over described can be made only if remote control is not c...

Page 25

Econcept 50 a 25 igniting the boiler: • open the gas control valve upstream from the boiler. • purge the gas supply. • ensure electrical controls are calling for heat. • place the main switch in the on position. • the boiler will switch on and perform a complete self-test cycle lasting around one mi...

Page 26

Econcept 50 a 26 3.3 maintenance the following operations must only be performed by qualified personnel, such as personnel from ferroli limited uk. Seasonal checks on the boiler and the flue the following checks should be made on the appliance at least once a year: • the control and safety devices (...

Page 27

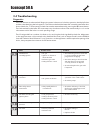

Econcept 50 a 27 3.4 troubleshooting diagnostics the boiler features an advanced self-diagnostic system. In the case of an fault in operation, the display flashes and the code identifying the fault appears. The faults marked with the letter “a” cause the permanent shut- down of the boiler. To reset ...

Page 28

Econcept 50 a 28 domestic hot water sensor faulty • sensor damaged or wiring cut • check wiring or replace the sensor flue gas sensor faulty • sensor damaged or wiring cut • check wiring or replace the sensor external probe faulty (if installed) • sensor damaged or wiring short-circuited • check wir...

Page 29

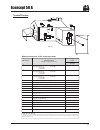

Econcept 50 a 29 4. Technical characteristics and data 4.1 dimensions and connections key 1 gas inlet 2 c. H. Flow 3 c. H. Return fig. 17.

Page 30

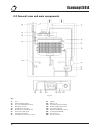

30 econcept 50 a 4.2 general view and main components key 16 fan 32 central heating pump 34 c.H. Flow temperature sensor 36 automatic air vent 44 combination gas valve 49 overheat cut-off thermostat 68 control box with p.C.B. 82 ionisation electrode 83 full sequence automatic control 98 switch 101 m...

Page 31

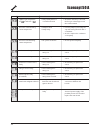

Econcept 50 a 31 4.3 technical data table 46,0 13,8 45,2 13,6 48,4 14,4 6,70 20,0 4,86 1,46 4,75 37,0 3,6 1,8 23,5 6 2,7 720 630 280 51 3/4” 1” 1” 190 230/50 x4d pmax pmin output heat rate hi (input) useful heat output 80 °c - 60°c useful heat output 50 °c - 30°c gas supply gas injector g20 supply p...

Page 32

32 econcept 50 a 4.4 diagrams 0 0,5 1 1,5 2 2,5 3 3,5 4 0 1 2 3 4 5 6 mc/h mt.Ca 1 2 3 p fig. 19.

Page 33

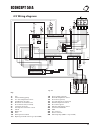

Econcept 50 a 33 4.5 wiring diagrams 1 2 3 4 5 6 7 8 10 11 12 14 15 x6 1 2 5 6 7 8 9 10 12 11 10 9 8 7 6 5 4 3 2 3 4 11 12 1 2 3 4 5 6 7 8 10 11 12 9 83 82 188 186 p 114 34 130 15 14 13 12 11 10 8 7 6 5 4 2 1 x5 x7 104 4,0 a t x3 n l 2 3 x2 n l n l 2 3 1 1 x1 dmf04 101 104 2 a t x4 207 1 2 3 4 5 6 7...

Page 36

Lichfield road, branston industrial estate, burton upon trent, staffordshire de14 3hd tel. 08707 282 885 - fax 08707 282 886 all specifications subject to change phone numbers: installer service engineer because of our constant endeavour for improvement details may vary slightly from those quoted in...